Conductive polymer composite nanofiber resistive-type humidity sensor and preparation method thereof

A technology of composite nanofibers and humidity sensors, applied in the direction of material resistance, etc., to achieve the effects of enhanced adhesion, good sensitivity, and good processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

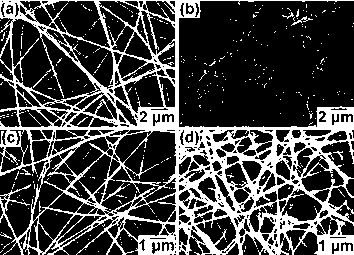

Embodiment 1

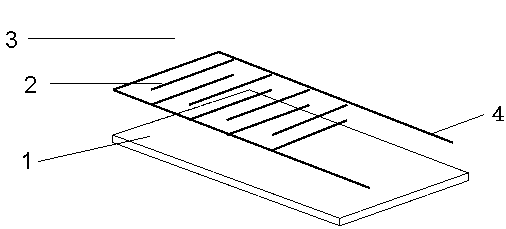

[0031] A method for manufacturing a conductive polymer composite nanofiber resistance type humidity sensor, comprising the following steps:

[0032] 1) Clean the surface photolithography and evaporate the ceramic substrate with interdigitated gold electrodes, and dry it for later use;

[0033] 2) Prepare the N,N-dimethylformamide solution of polyaniline, polyethylene oxide, and polyvinyl butyral doped with polystyrenesulfonic acid, in which the concentration of polyaniline is 10 mg / mL, polyethylene oxide The concentration is 20 mg / mL, the concentration of polyvinyl butyral is 50 mg / mL, and the molar ratio of styrene sulfonic acid to aniline in polystyrene sulfonic acid-doped polyaniline is 1: 1;

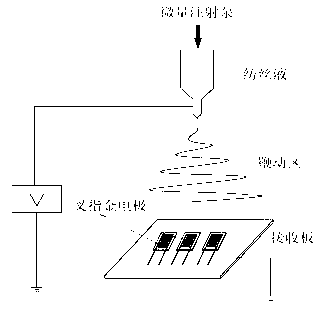

[0034] 3) Put the solution prepared in step 2) into a syringe with a needle, the injection needle is connected to the anode of the high voltage power supply, the cathode of the high voltage power supply is connected to the copper plate, and the copper plate is placed on the ceramic s...

Embodiment 2

[0037] A method for manufacturing a conductive polymer composite nanofiber resistance type humidity sensor, comprising the following steps:

[0038] 1) Clean the surface photolithography and evaporate the ceramic substrate with interdigitated gold electrodes, and dry it for later use;

[0039] 2) Prepare N,N-dimethylformamide solution of polyaniline, polyethylene oxide and polyvinyl butyral doped with polystyrene sulfonic acid, wherein the concentration of polyaniline is 20 mg / mL, polyethylene oxide The concentration is 3 mg / mL, the concentration of polyvinyl butyral is 20 mg / mL, and the molar ratio of styrene sulfonic acid to aniline in polystyrene sulfonic acid-doped polyaniline is 3: 1;

[0040] 3) Put the solution prepared in step 2) into a syringe with a needle, the injection needle is connected to the anode of the high voltage power supply, the cathode of the high voltage power supply is connected to the copper plate, and the copper plate is placed on the ceramic substra...

Embodiment 3

[0043] A method for manufacturing a conductive polymer composite nanofiber resistance type humidity sensor, comprising the following steps:

[0044] 1) Clean the surface photolithography and evaporate the ceramic substrate with interdigitated gold electrodes, and dry it for later use;

[0045] 2) Prepare a N,N-dimethylformamide solution of polystyrenesulfonic acid-doped polyaniline (polyethylene oxide and polyvinyl butyral, in which the concentration of polyaniline is 40 mg / mL, polyoxy The concentration of ethylene is 10 mg / mL, the concentration of polyvinyl butyral is 30 mg / mL, and the molar ratio of styrene sulfonic acid to aniline in polystyrene sulfonic acid-doped polyaniline is 6: 1;

[0046] 3) Put the solution prepared in step 2) into a syringe with a needle, the injection needle is connected to the anode of the high voltage power supply, the cathode of the high voltage power supply is connected to the copper plate, and the copper plate is placed on the ceramic substrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com