Preparation method of palladium-wood film capable of synchronously carrying out oil-water separation and dye degradation

A technology for oil-water separation and wood, applied in separation methods, chemical instruments and methods, water pollutants, etc., can solve the problems of decreased membrane flux, easy blockage of hydrophilic membrane pores by oil pollution, and inability to degrade dyes, etc. The effect of improving, abundant reserves, and efficient degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

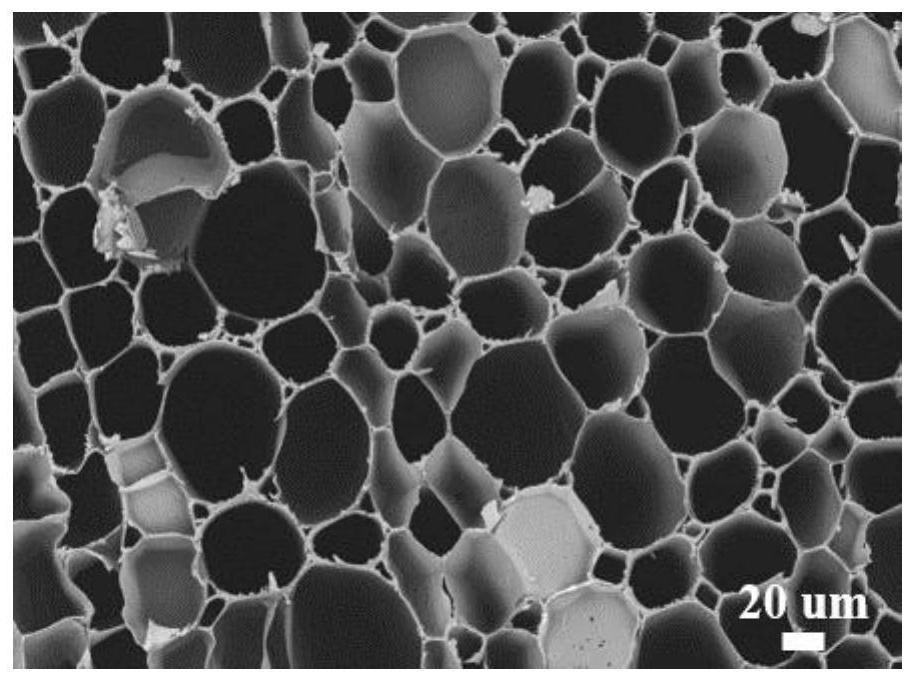

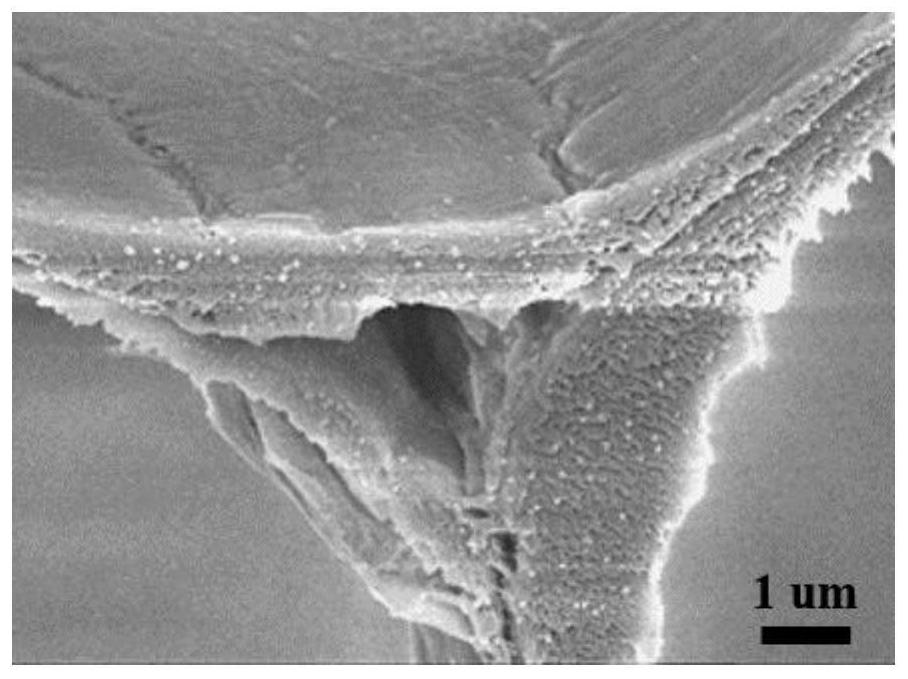

[0028] Specific embodiment one: a kind of preparation method of the palladium-wood film that can synchronize oil-water separation and dyestuff degradation in this embodiment, it is carried out according to the following steps:

[0029] 1. Preparation of pretreated raw materials:

[0030] Immerse the wood chips into the mixed solution, and heat them for 4h-8h at a temperature of 40°C-80°C to obtain the pretreated raw material;

[0031] The thickness of the wood chip is 1mm~10mm;

[0032] The mixed solution is obtained by mixing choline chloride and oxalic acid and heating and melting at a temperature of 40°C to 80°C; the mass ratio of the choline chloride to oxalic acid is 1:(1~5) ;

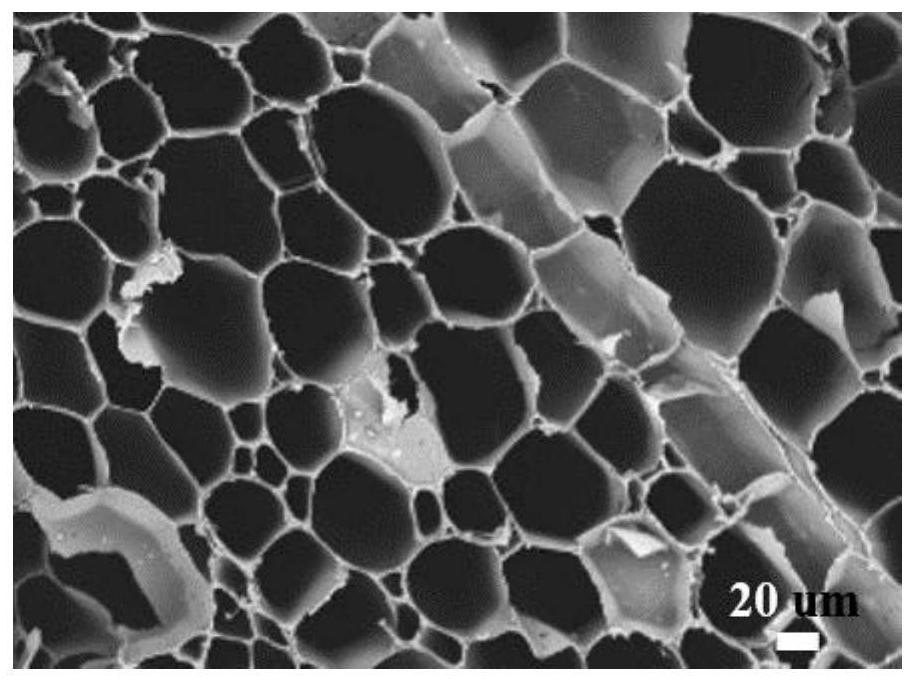

[0033] 2. Loaded palladium particles:

[0034] cleaning the pretreated raw material, then immersing the cleaned raw material in an aqueous palladium source solution, and heating at a temperature of 40°C to 80°C for 4h to 8h to obtain a wood film loaded with palladium particles;

[0035] The ma...

specific Embodiment approach 2

[0046] Embodiment 2: This embodiment differs from Embodiment 1 in that the palladium source aqueous solution described in step 2 is an aqueous palladium chloride solution. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0047] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the drying described in Step 3 is standing and drying at room temperature. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com