Photosensitive modified chitosan, preparation method and application thereof

A technology of photosensitivity and chitosan, applied in the field of composite materials, can solve the problems of the decrease of the apparent quality of the gel, the high requirements of the hardware of the forming equipment and the control precision, etc., to achieve the effect of enhancing the mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

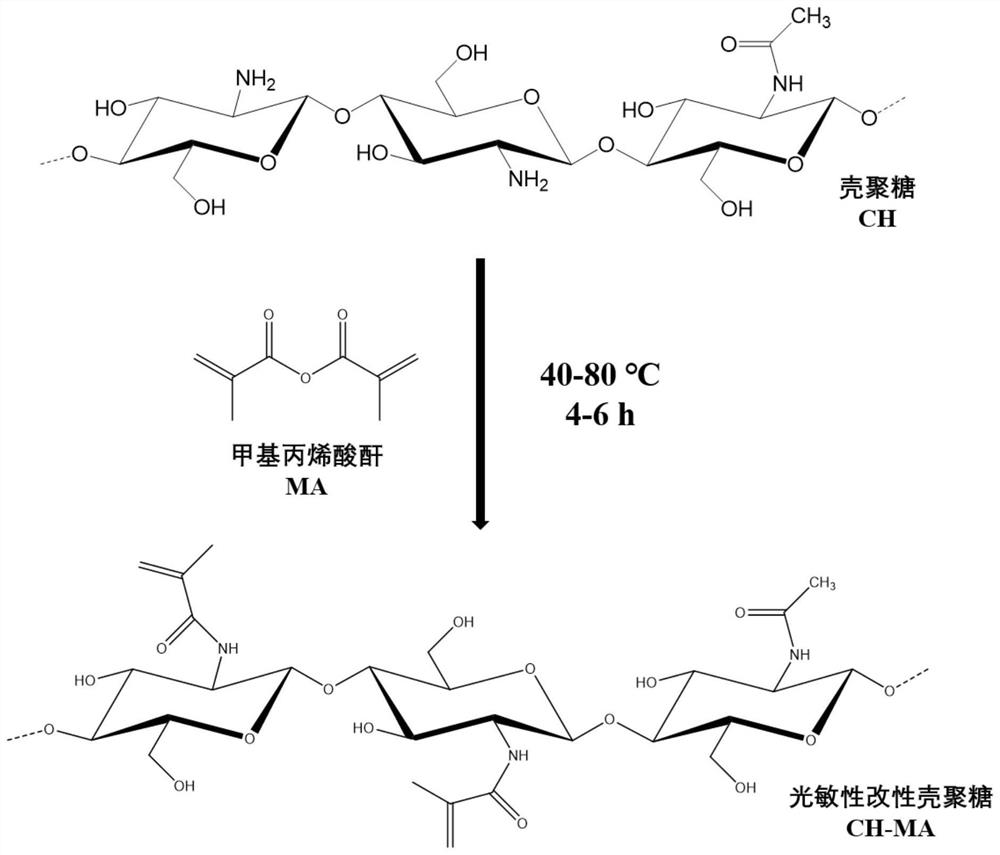

[0047] Embodiment 1 prepares photosensitive modified chitosan (CH-MA)

[0048] Add methacrylic anhydride (MA) in the chitosan (CH) solution of 1.5% (w / v), react 4h, reaction process is as follows figure 1 shown. The resulting product was added dropwise to sodium bicarbonate solution to neutralize and remove excess anhydride. Then dialyzed to obtain methacrylic acid modified chitosan (CH-MA). Change the ratio of methacrylic anhydride to amino groups in chitosan (1:1, 2:1, 4:1, 5:1, 7:1, 8:1, 10:1, 15:1, 16:1) , to explore the effect of grafting ratio on the water solubility of modified chitosan, the prepared modified chitosan were named as CH-MA 1, CH-MA 2, CH-MA 4, CH-MA 5, CH-MA 7, CH-MA 10, CH-MA 15, CH-MA16. Specific steps are as follows:

[0049] Add 0.5±0.025mg chitosan and 0.5±0.08ml acetic acid to 30±0.5ml deionized water and mix well. Add a certain proportion of methacrylic anhydride at 40±20°C, the volume fraction of methacrylic anhydride added is 1% (v / v) to 15...

Embodiment 2

[0050] Example 2 Preparation of photosensitive 3D printing ink (CH-MA / GE)

[0051] Weigh a certain amount of CH-MA, add 0.05-0.4wt% I2959 photoinitiator and gelatin solution, stir evenly, and put the solution into a 3D printing barrel to obtain 3D printing ink.

[0052]S1 adds 200±10mg of photosensitive chitosan fiber and 5-40mg (0.05wt%-0.4wt%) photoinitiator I2959 (2-hydroxyl-2-methyl-1-[4- (2-hydroxyethoxy) phenyl]-1-propanone), after stirring evenly, the mixed solution was obtained for subsequent use.

[0053] Preparation of S2 gelatin solution: Prepare a 5w / v%-12w / v% gelatin solution at 40±5°C for later use.

[0054] Preparation of S3 ink: At room temperature, mix the mixed solution obtained in S1 with the gelatin solution in equal volumes to obtain 3D printing ink.

Embodiment 3

[0055] Embodiment 3 Ink characterization:

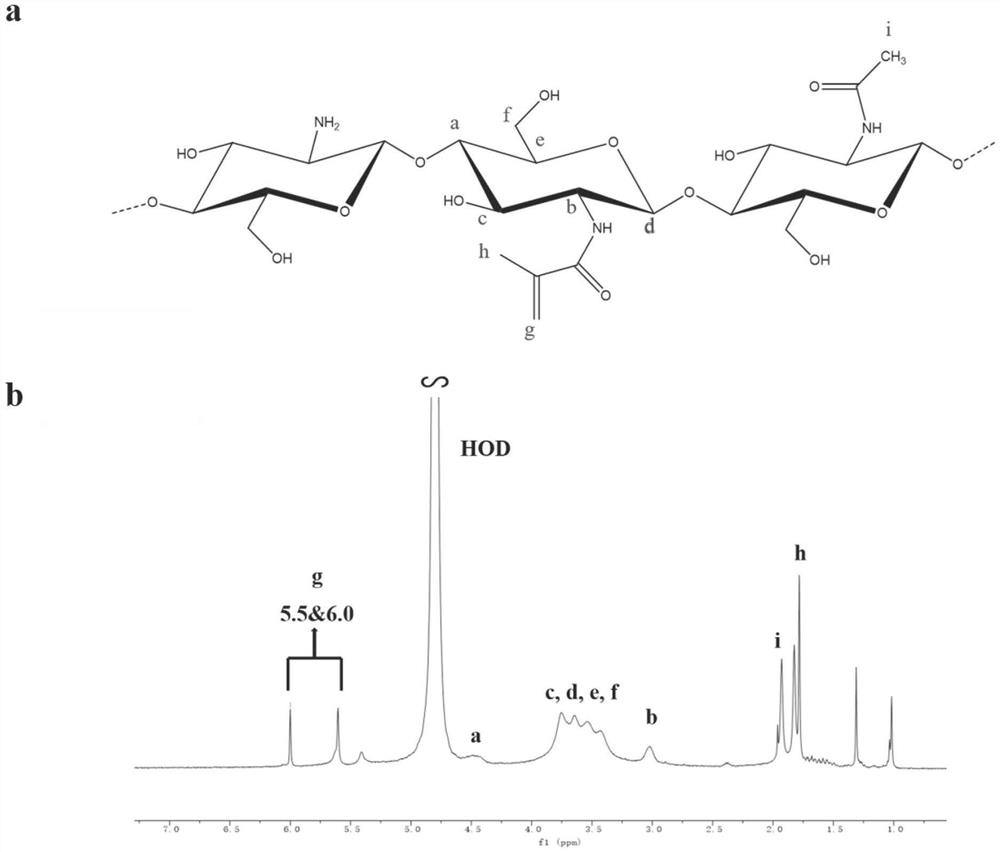

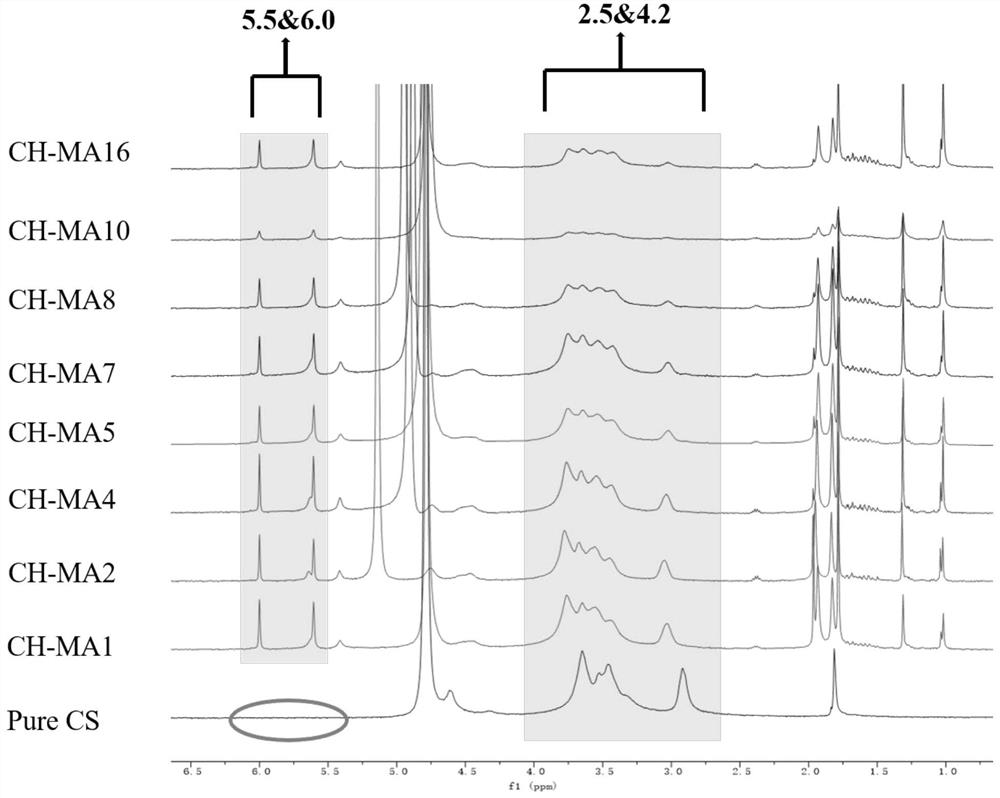

[0056] The successful grafting of methacrylic anhydride to chitosan was verified by infrared spectroscopy (FTIR) and hydrogen nuclear magnetic spectroscopy (1H NMR). Nicolet Impact410 infrared spectrometer was used for measurement, and the test resolution was 4

[0057]

[0058] cm -1 , the number of scans is 32 times, and the test range is 400-4000cm -1 . Utilizing the selective absorption characteristics of different substances for different wavelengths of infrared rays, high-resolution infrared spectroscopy is used to detect CH-MA, and the main components in the sample can be qualitatively analyzed according to the characteristic peaks that are characterized. at the same time through 1 Quantitative analysis of modified chitosan by H NMR can determine the grafting rate of MA on CH. The formula for calculating the grafting ratio (DS) of CH-MA is as follows:

[0059] where A H(5.5&6.0) Corresponding to the vinyl proton peak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

| oil-water separation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com