Polyimide microporous film and preparation method thereof, and application of polyimide microporous film in oil-water separation

A technology of microporous film and polyimide, applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of insufficient purity of emulsion separation, complicated preparation process, poor designability, etc., and achieve excellent oil-water separation Ability to solve the effect of high preparation cost and high applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The present invention provides a kind of preparation method of polyimide microporous film in the first aspect, described preparation method comprises the steps:

[0057] (1) polyamic acid solution is provided;

[0058] (2) adding a hydrophobic modifier to the polyamic acid solution;

[0059] (3) forming the mixed solution obtained in step (2) into a membrane material, and coagulating the obtained membrane material by a coagulation bath to obtain a polyamic acid microporous film;

[0060] (4) adopt low surface tension solvent to carry out solvent replacement to polyamic acid microporous film; With

[0061] (5) imidizing the polyamic acid microporous film treated in step (4) to obtain a polyimide microporous film.

[0062] Step (1): Step (1) is a step of providing a polyamic acid solution. The polyamic acid solution is a solution in which the solvent is polyamic acid. In the technical solution provided by the present invention, the polyamic acid solution can be prepar...

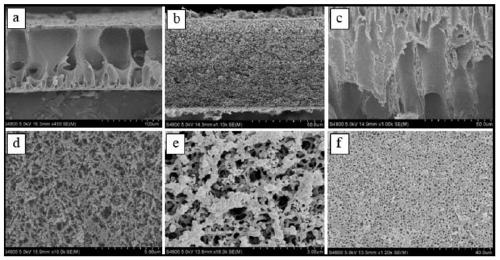

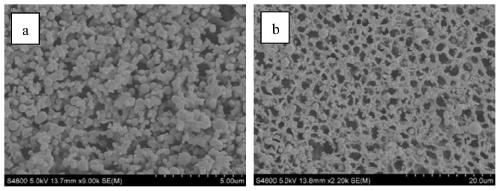

Embodiment 1

[0092] Step 1: dissolving diaminodiphenyl ether and pyromellitic dianhydride in methylpyrrolidone, and reacting to obtain a 10wt% polyamic acid solution;

[0093] Step 2: Add a fluorosilane surface modifier (trimethoxy (1H, 1H, 2H, 2H-perfluorodecyl) silane) to the polyamic acid solution obtained from the reaction. The fluorosilane surface modifier is added to the polyamide The concentration in the acid solution is 2.5wt%, stirring to obtain a mixed solution;

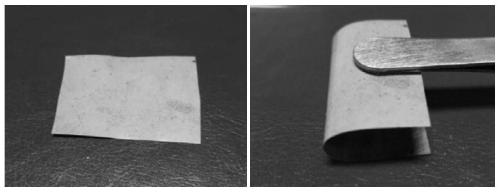

[0094] Step 3: Scrape-coat the mixed solution on the substrate, then place it in ethanol at a temperature of 20°C, let it stand for 10 minutes, peel it off after solidification, and obtain a polyamic acid microporous film;

[0095] Step 4: Place the obtained polyamic acid microporous film into n-hexane for solvent replacement, the number of replacements is 4 times, and then dry it under normal pressure at 50°C to obtain the dried polyamic acid microporous film;

[0096] Step 5: imidizing the polyamic acid microporous f...

Embodiment 2

[0100] Step 1: dissolving diaminodiphenyl ether and pyromellitic dianhydride in methylpyrrolidone, and reacting to obtain a 25wt% polyamic acid solution;

[0101] Step 2: Add a fluorosilane surface modifier (trimethoxy (1H, 1H, 2H, 2H-perfluorodecyl) silane) to the polyamic acid solution obtained from the reaction. The fluorosilane surface modifier is added to the polyamide The concentration in the acid solution is 2.5wt%, stirring to obtain a mixed solution;

[0102] Step 3: Scrape-coat the mixed solution on the substrate, then place it in ethanol at a temperature of 20°C, let it stand for 10 minutes, peel it off after solidification, and obtain a polyamic acid microporous film;

[0103] Step 4: Place the obtained polyamic acid microporous film into n-hexane for solvent replacement, the number of replacements is 4 times, and then dry it under normal pressure at 50°C to obtain the dried polyamic acid microporous film;

[0104] Step 5: imidizing the polyamic acid microporous f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com