Separation membrane, preparation method, aviation kerosene dehydration and purification method and application

A technology of aviation kerosene and separation membrane, applied in the direction of mechanical dehydration/demulsification, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of emulsified water adhesion, pollution, attenuation, membrane pore clogging, separation performance, etc. , to achieve enhanced separation performance, efficient separation and purification, and high separation throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The present invention provides a kind of preparation method of oil-water separation membrane, and this method comprises the following steps:

[0048] Step one, any one or Other polymer film-forming materials and fluorine-containing water repellents with the same main chain and different side chains, such as heptadecafluorodecyltrimethoxysilane, heptadecafluorodecyltrichlorosilane, tridecafluorooctyltriethoxysilane, Any one of perfluorooctyltrichlorosilane and perfluorododecylmercaptan, dissolved in N,N-dimethylformamide, N,N-dimethylacetamide, N-methylpyrrolidone, tris In organic solvents of any one of methyl chloride, dioxane, m-cresol, diphenyl sulfone, diphenyl ether, tetrahydrofuran and dimethyl sulfoxide, stir at 70-100°C for 36-60 hours to form a uniform high Molecular solution; the concentration of polymer film-forming material is 0.01-1g / mL; the concentration of fluorine-containing water repellent is 0.0001-1g / mL;

[0049]In order to obtain a uniform separatio...

Embodiment 1

[0068] Weigh a certain amount of polyvinylidene fluoride and heptadecafluorodecyltrimethoxysilane, dissolve in N,N-dimethylformamide organic solvent, wherein the concentration of polyvinylidene fluoride is 0.1g / mL, seventeen The concentration of fluorodecyltrimethoxysilane was 0.005g / mL, stirred at 85°C for 48h, and prepared into a homogeneous polymer solution. The above solution was spun into a film by electrospinning at room temperature, the relative air humidity was 70% during spinning, the spinning voltage difference was 12kV, the spinning distance was 10cm, and the spinner was spun at a spinning injector speed of 1.5mL / h. Silk time is 1h. After spinning, the porous membrane was dried at 60° C. for 24 h to obtain the desired separation membrane.

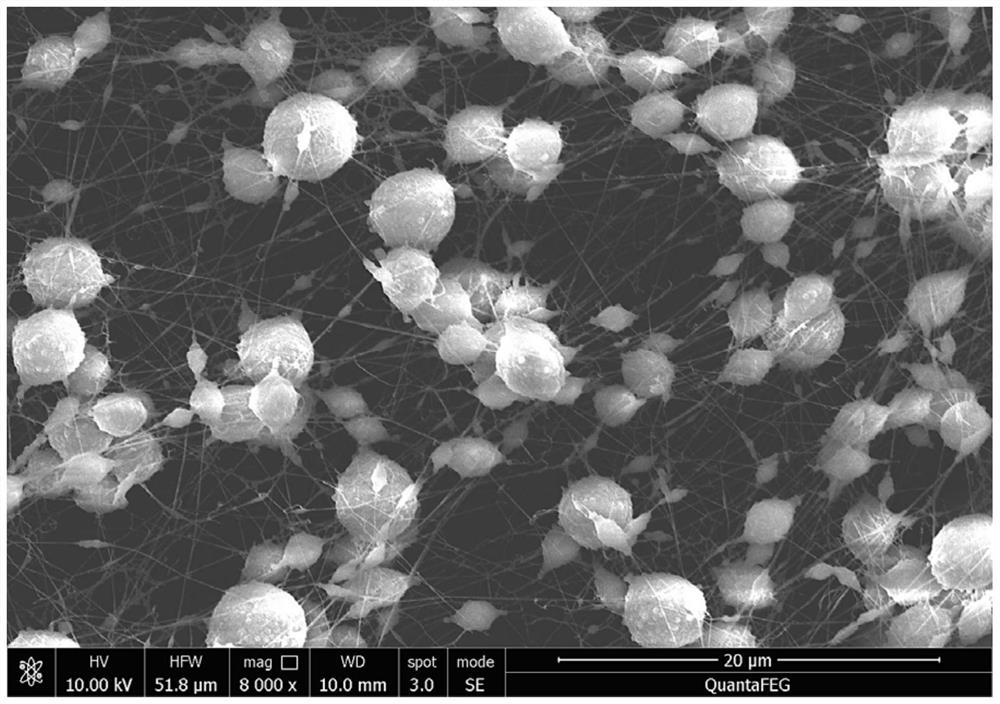

[0069] Scanning electron microscope image of the separation membrane see figure 1 , it can be seen that the separation membrane has a porous structure connected by ball filaments, which is composed of micro-nano balls and micro...

Embodiment 2

[0071] Different from Example 1, the spinning time of this example is 10h.

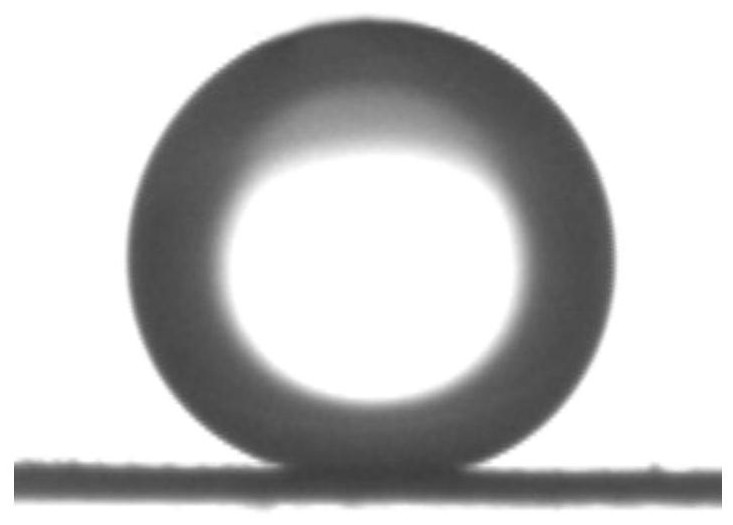

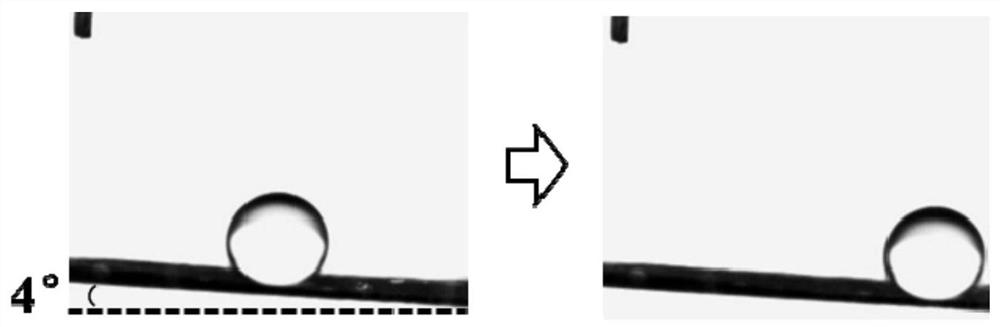

[0072] Scanning electron microscope image of the separation membrane see Figure 5 , it can be seen that the separation membrane also has a porous structure connected by filaments, and the diameter of the micro-nano balls and micro-nano fibers does not change much when the spinning time increases, but due to the increase in the density of the micro-nano balls and micro-nano fibers, The pore diameter of the separation membrane is reduced to 0.9-1.0 μm. After testing, the water contact angle of the separation membrane is 161°, the rolling angle is 3°, and the aviation kerosene contact angle is 0°, indicating that the separation membrane has superhydrophobic and superoleophilic properties.

[0073] The separation membrane is used for the water removal and purification test of emulsified aviation kerosene with a water content of 30000ppm. The photos of the emulsified aviation kerosene before and after th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com