A kind of oil cleaning cotton and preparation method thereof

A technology for cleaning cotton and oil stains, applied in the field of cleaning cotton, can solve problems such as poor mechanical properties, and achieve the effects of low cost, improved mechanical properties, and a wide range of sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

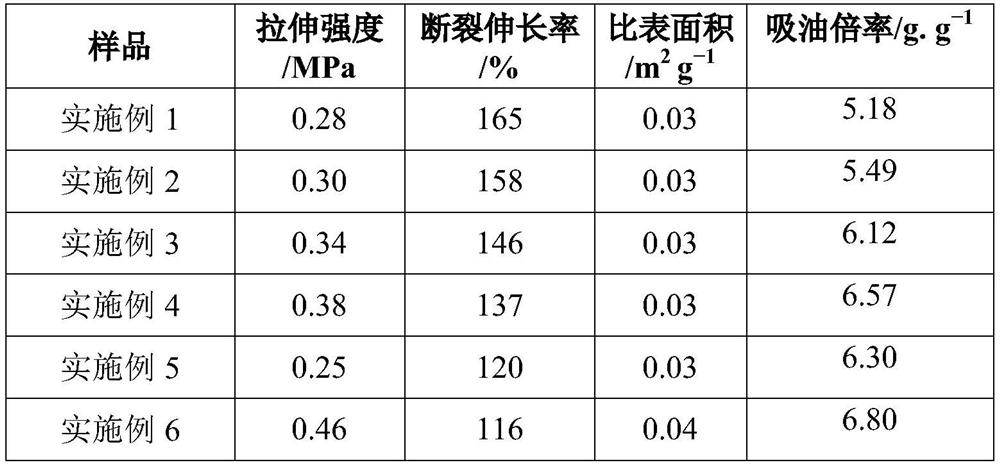

Examples

Embodiment 1

[0025] Add 1kg of peanut oil into the stirred reactor and heat it to 170°C, then add 200g of polybutadiene rubber, stir and mix evenly. Add 900g of sulfur and 10g of zinc oxide whisker composite antibacterial agent within 10 minutes, stir and mix evenly. The reaction temperature was raised to 180° C., and 6 kg of ground sodium chloride powder was added. Stirring was continued for 15 minutes. Pour the mixture hot into stainless steel molds and cool to room temperature. The material cured in the mold is removed and immersed in tap water. After 2 hours, the soaked material was taken out and dried under hot air (<45° C.) to obtain Example 1.

Embodiment 2

[0027] Add 1 kg of rapeseed oil into the stirred reactor and heat it to 170° C., then add 200 g of polybutadiene rubber, stir and mix evenly. Add 900g of sulfur and 10g of zinc oxide whisker composite antibacterial agent within 10 minutes, stir and mix evenly. The reaction temperature was raised to 180° C., and 6 kg of ground sodium chloride powder was added. Stirring was continued for 15 minutes. Pour the mixture hot into stainless steel molds and cool to room temperature. The material cured in the mold is removed and immersed in tap water. After 2 hours, the soaked material was taken out and dried under hot air (<45° C.) conditions to obtain Example 2.

Embodiment 3

[0029] Add 1kg of soybean oil into the stirred reactor and heat it to 170°C, then add 200g of polybutadiene rubber, stir and mix evenly. Add 900g of sulfur and 10g of zinc oxide whisker composite antibacterial agent within 10 minutes, stir and mix evenly. The reaction temperature was raised to 180° C., and 6 kg of ground sodium chloride powder was added. Stirring was continued for 15 minutes. Pour the mixture hot into stainless steel molds and cool to room temperature. The material cured in the mold is removed and immersed in tap water. After 2 hours, the soaked material was taken out and dried under hot air (<45° C.) conditions to obtain Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com