Mussel bionic functional hydrophilic polymer and hydrophilic polymer network modified super-hydrophilic net membrane, as well as preparation methods and application of mussel bionic functional hydrophilic polymer and hydrophilic polymer network modified super-hydrophilic net membrane

A technology of hydrophilic polymers and bionic functions, applied in chemical instruments and methods, separation methods, liquid separation, etc., can solve problems such as short use time, poor separation effect of oil-water mixture/emulsion, and complicated modification methods, and achieve Effects of high separation efficiency, simple and versatile method, excellent contamination resistance and reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

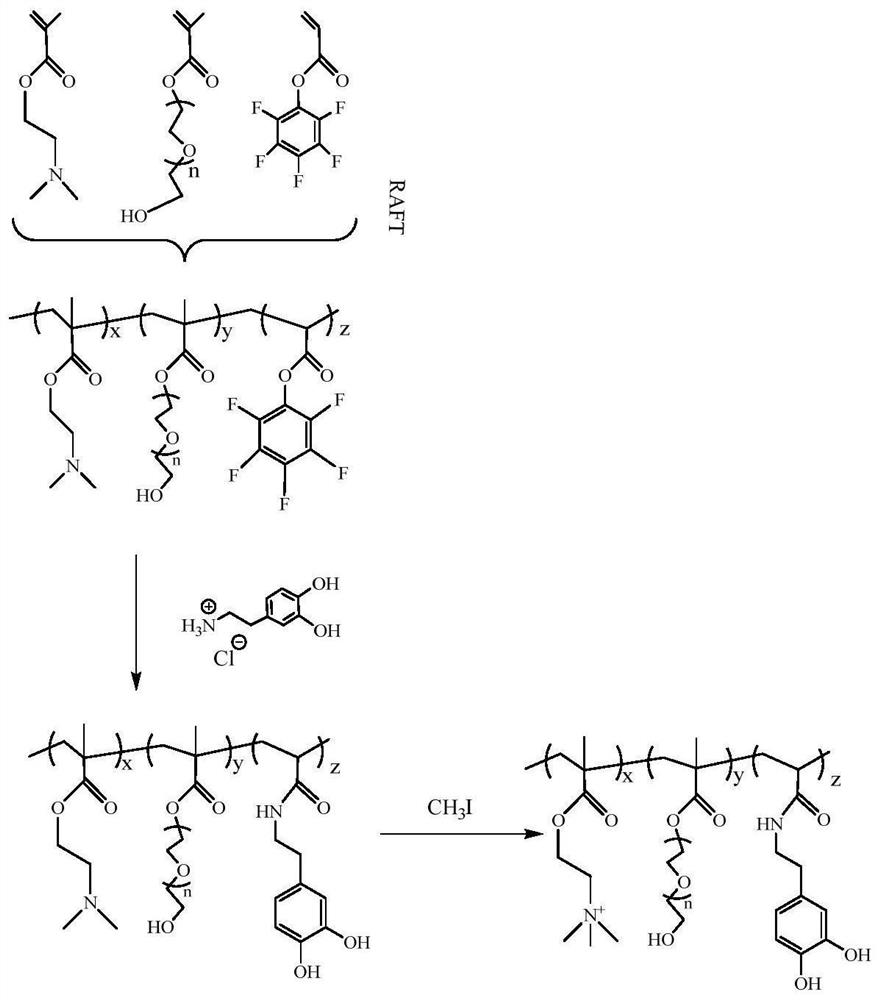

[0043] In order to achieve the purpose of the present invention, the first aspect of the present invention provides a method for preparing a mussel biomimetic functionalized hydrophilic polymer, wherein the preparation method comprises:

[0044] (1) In the presence of an initiator, 2-(dimethylamino)ethyl methacrylate, polyethanol methacrylate, pentafluorophenol acrylate, 4-cyano-4(dodecyl sulfide Alkylthiocarbonyl)sulfanylvaleric acid and 1,4-dioxane are contacted for heating and concentration treatment to obtain the product I;

[0045] (2) Under oil bath conditions, the product I, dichloromethane, dopamine hydrochloride and triethylamine are contacted and centrifuged to obtain the product II;

[0046] (3) Under nitrogen protection, the product II, dichloromethane and methyl iodide were contacted to obtain a hydrophilic polymer.

[0047] The inventors of the present invention unexpectedly found that: 4-cyano-4 (dodecylsulfanylthiocarbonyl) sulfanylvaleric acid is used as RAFT...

Embodiment approach

[0058] According to a preferred embodiment of the present invention, the preparation method of the hydrophilic polymer comprises:

[0059] (1') Take -2-(dimethylamino)ethyl methacrylate, polyethanol methacrylate, pentafluorophenol acrylate, 4-cyano-4 (dodecylsulfanylthiocarbonyl) Dissolve sulfanyl valeric acid in 1,4-dioxane in a round-bottomed flask; blow nitrogen gas and stir for 20-40 minutes; add initiator azobisisobutyronitrile, nitrogen gas and stir for 10-20 minutes to obtain the first reaction system , relative to 10-30mL of 1,4-dioxane, the 2-(dimethylamino)ethyl methacrylate, polyethanol methacrylate, pentafluorophenol acrylate, 4-cyano The millimolar (unit, mmol) ratio of the consumption of -4 (dodecylsulfanylthiocarbonyl) sulfanylvaleric acid and azobisisobutyronitrile is (8-15): (10-16) :(9-18):(0.75-1.7):(0.1875-0.425);

[0060] (2') Transfer the first reaction system to an oil bath for heating, and stir at 72° C. for 3-4 hours to obtain a second reaction syste...

preparation example 1

[0095] This preparation example is to illustrate the hydrophilic polymer prepared by the preparation method of the present invention.

[0096] according to figure 1 The synthetic route of the shown hydrophilic polymer:

[0097] In the first step, take 2-(dimethylamino)ethyl methacrylate (10mmol, 1.57g), polyethanol methacrylate (10mmol, 4.75g), pentafluorophenol acrylate (10mmol, 2.38g), 4-cyano-4 (dodecylsulfanylthiocarbonyl) sulfanylvaleric acid (1mmol, 0.403g) was dissolved in 17mL 1,4-dioxane in a 50mL round bottom flask; nitrogen gas was stirred for 20min Add the initiator azobisisobutyronitrile (0.25mmol, 0.041g), and stir for 10min with nitrogen gas to obtain the first reaction system; transfer the first reaction system to an oil bath for heating, and stir for 4h at 72°C to obtain the second Reaction system: The obtained second reaction system was concentrated by rotary evaporation at 60°C, and then slowly dropped into petroleum ether (or n-hexane), and the product I ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com