Oil-water separation filtering structure and production method thereof

A technology of oil-water separation and filtration structure, which is applied in the direction of separation methods, liquid separation, chemical instruments and methods, etc. It can solve the problems affecting the efficiency of micro-nano emulsified oil-water separation, the combination of different wettability surfaces, and the preparation method requires high-temperature baking and other problems, to achieve the effect of easy operation, excellent pressure resistance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for preparing an oil-water separation filter structure, comprising the steps of:

[0037] 1) Add silica particles and hexamethyldisilazane into a round-bottomed flask, and after stirring at 80°C for 2 hours, it will be modified into superhydrophobic silica particles; the hydrophobicity in all embodiments of the present invention Particle modification is prepared according to this method.

[0038]2) Take the hydrophilic silica particles with a particle size of 25-50 μm, and take the hydrophobic silicon dioxide particles with a particle size of 25-50 μm modified by hexamethyldisilazane, and mix them in a mass ratio of 8:1 The hydrophilic silica particles and the hydrophobic silica particles are mixed, and after adding ethanol, stir in a stirrer for 5 minutes.

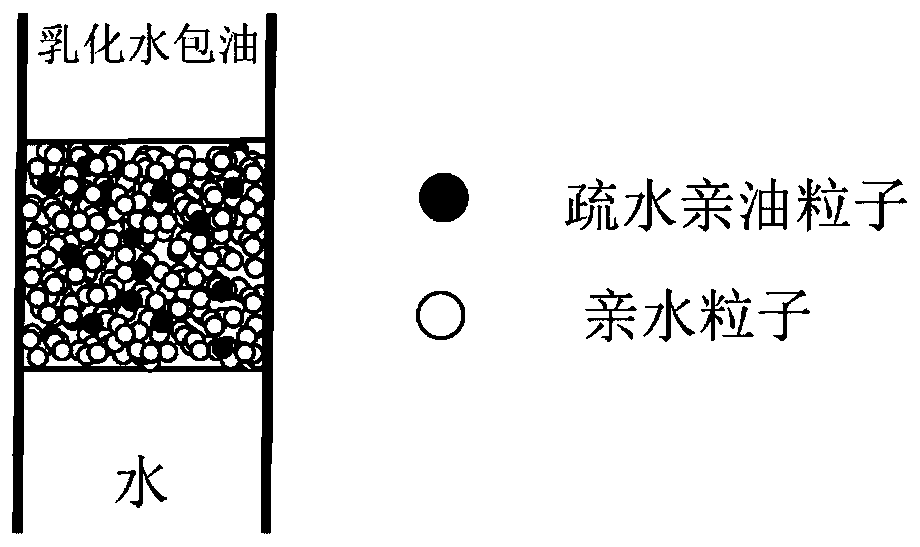

[0039] 3) Fix a sand-type glass column with a pore diameter of 25 μm on an iron stand. Pour the mixed particles prepared in step 1) together with ethanol into the column; let stand to make the hydrophili...

Embodiment 2

[0049] A method for preparing an oil-water separation filter structure, comprising the steps of:

[0050] 1) Mix the hydrophilic sand with a particle size of 200-250 μm and the hydrophobic sand with a particle size of 200-250 μm modified with octadecyldimethylchlorosilane at a mass ratio of 1:99, and add ethanol to the mixer Stir for 5 minutes;

[0051] 2) Install a stainless steel support plate with a hole diameter of 200 μm in the channel of the ceramic tube and fix the ceramic tube on the iron stand. Pour the mixed particles prepared in step 1 together with ethanol into the tube, and let it stand to make the hydrophilic sand and hydrophobic sand settle into an oil-water separation medium layer;

[0052] 3) Hydrophilic sand and hydrophobic sand are deposited on the support plate in the ceramic tube by gravity, that is, the filling of the separation medium is completed, and the height of the separation medium is 10cm.

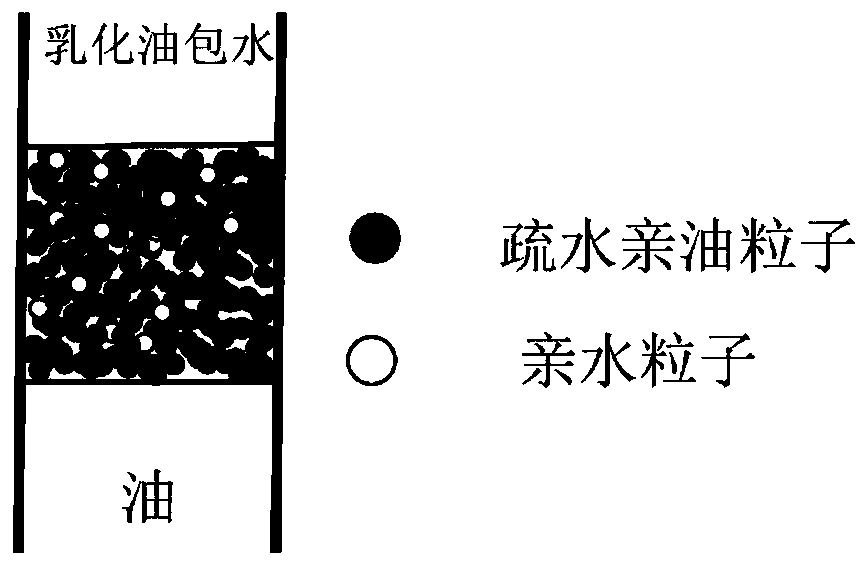

[0053] figure 2 It is a schematic diagram of the str...

Embodiment 3

[0056] A method for preparing an oil-water separation filter structure, comprising the steps of:

[0057] 1) Mix the hydrophilic ore with a particle size of 30-60 μm and the hydrophobic ore with a particle size of 50-100 μm modified with dodecyltrichlorosilane at a mass ratio of 9:1, add ethanol and stir in a stirrer for 5 minutes ;

[0058] 2) Install a perforated stainless steel support plate with a hole diameter of 60 μm in the copper tube channel and fix it on the iron stand. Pour the mixed ore prepared in step 1 together with ethanol into the tube; let stand to make the mixed ore precipitate into an oil-water separation medium layer;

[0059] 3) Hydrophilic ore and hydrophobic ore are deposited on the support plate of the plastic pipe by gravity, that is, the filling of the separation medium is completed, and the height of the separation medium is 4cm.

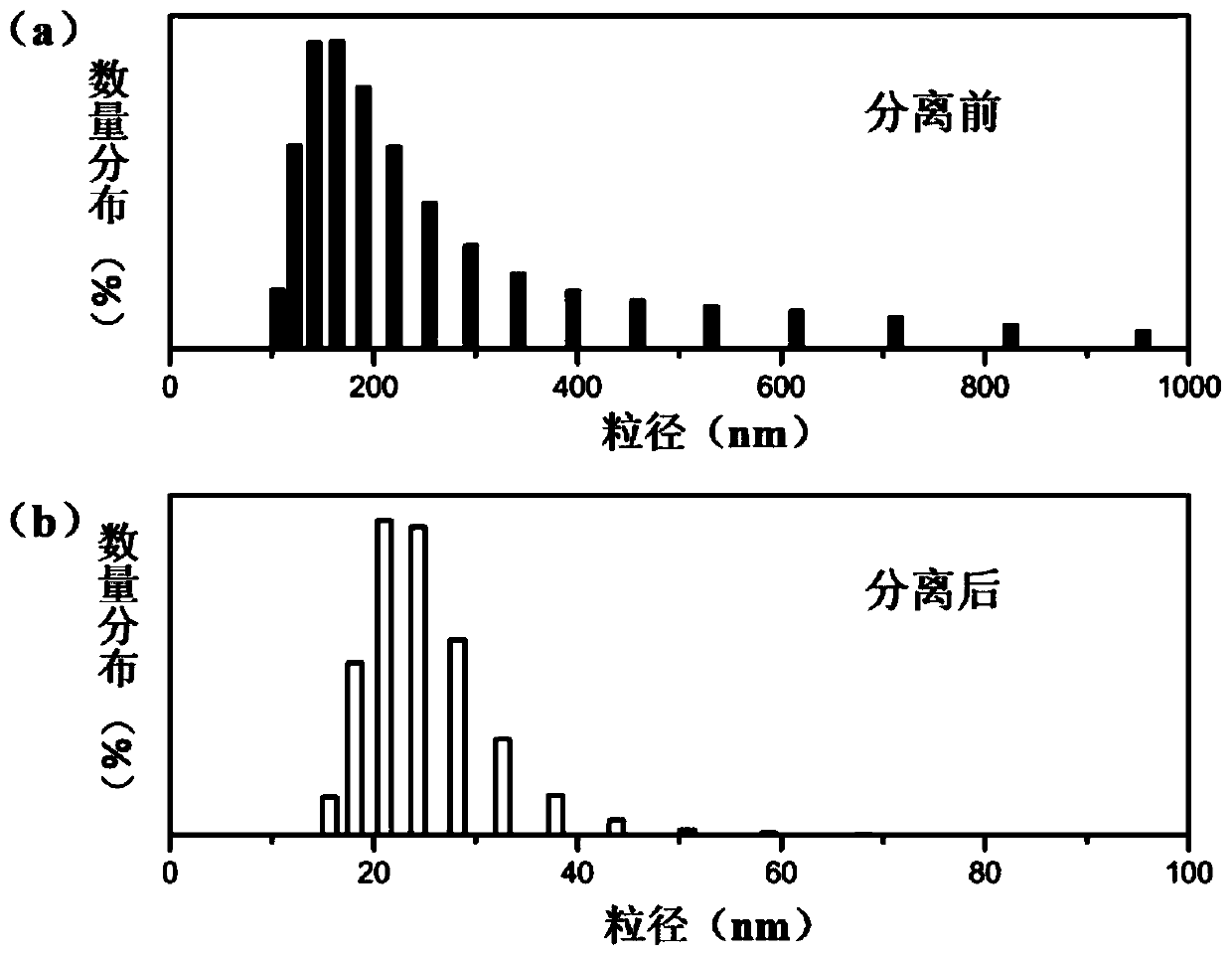

[0060] Take 3g of Tween 80 and place it in a beaker, add 500mL of deionized water and 10mL of chloroform, add a magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com