A kind of intrinsically hydrophobic polyimide airgel, its preparation method and application

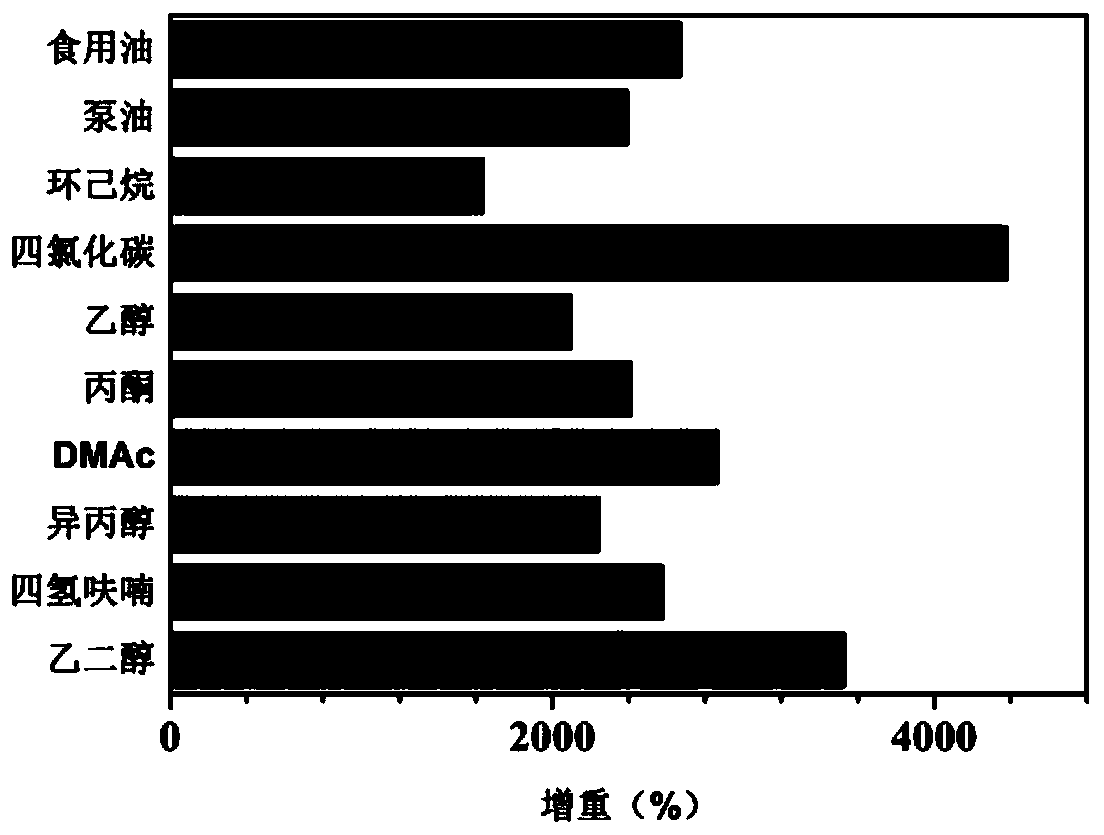

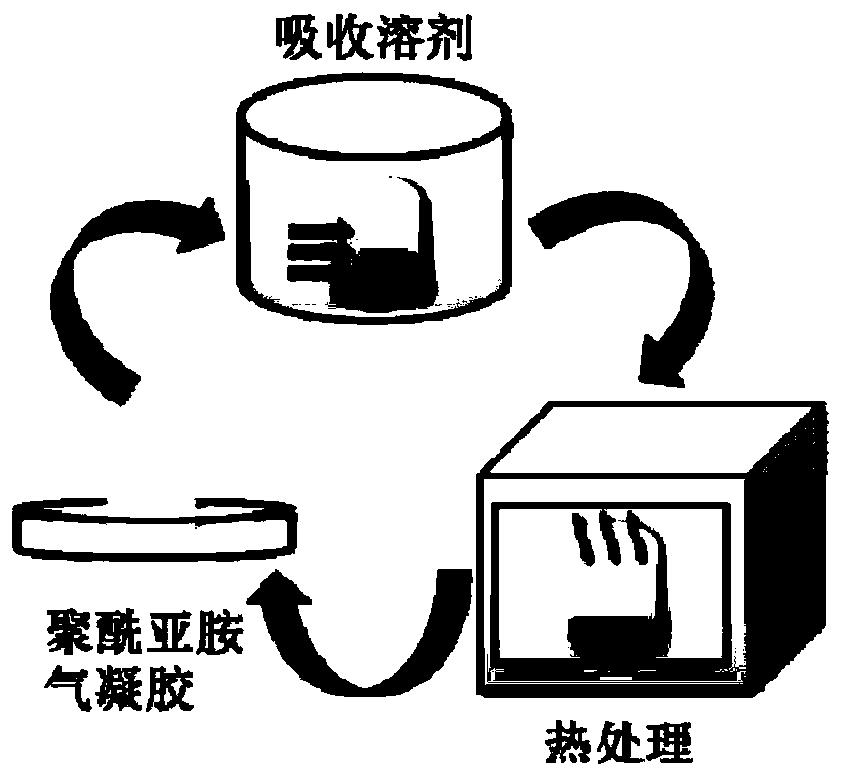

A water polyimide and polyimide technology, applied in the field of intrinsically hydrophobic polyimide airgel, can solve the problems of decreased hydrophobic performance, complicated preparation process and high cost, and unsuitability for large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

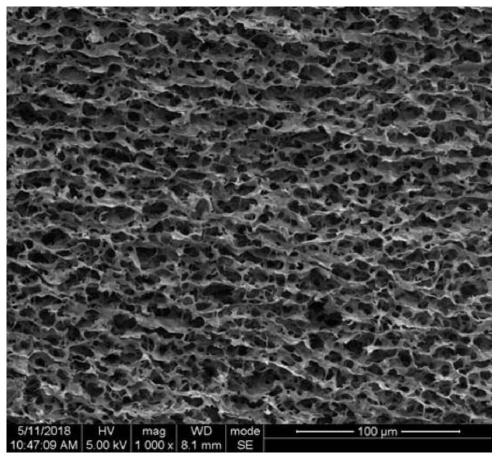

[0059] A preparation method of intrinsically hydrophobic polyimide airgel, comprising the following steps:

[0060] The preparation steps of polyamic acid salt solution:

[0061] Under an inert atmosphere (nitrogen), mix 39.16 g of dimethylacetamide with 2.24 g of 2-(4-aminophenyl)-5-aminobenzimidazole, then add 2.94 g of 3,3',4,4' - Biphenyltetracarboxylic dianhydride, stirred and reacted at 0°C for 8 hours to obtain a brown polyamic acid solution;

[0062] Mix the brown polyamic acid solution with 2.02g triethylamine and stir for 1 hour to obtain a white polyamic acid salt suspension, then add 1.67g deionized water to the suspension to obtain a brown viscous polyamic acid salt suspension .

[0063] It should be noted that, since the suspension of polyamic acid salt will be obtained after adding triethylamine, the polyamic acid salt can be dissolved after adding deionized water to obtain a uniform glue, which is beneficial to the polyamic acid salt in acetone. Precipitated...

Embodiment 2

[0074] This embodiment provides a preparation method of intrinsically hydrophobic polyimide airgel, which is roughly the same as the preparation method provided in Example 1, except that the parameters are different, and it includes the following steps:

[0075] The preparation steps of polyamic acid salt solution:

[0076] Under an inert atmosphere (nitrogen), mix 39.16g of N,N-dimethylformamide with 2.24g of 2-(4-aminophenyl)-5-aminobenzimidazole, then add 2.94g of 3,3', 4,4'-Biphenyltetracarboxylic dianhydride was stirred and reacted at 0°C for 8 hours to obtain a brown polyamic acid solution;

[0077] Mix the brown polyamic acid solution with 2.02g triethylamine and stir for 1 hour to obtain a white polyamic acid salt suspension, then add 1.70g deionized water to the suspension to obtain a brown viscous polyamic acid salt suspension .

[0078] Preparation steps of polyamic acid salt powder:

[0079] The polyamic acid salt solution obtained in the above steps was mixed w...

Embodiment 3

[0085] This embodiment provides a preparation method of intrinsically hydrophobic polyimide airgel, which is roughly the same as the preparation method provided in Examples 1-2, the difference lies in the different parameters, which includes the following steps:

[0086] The preparation steps of polyamic acid salt solution:

[0087] Under an inert atmosphere (nitrogen), mix 39.16g of N-methylpyrrolidone with 1.12g of 2-(4-aminophenyl)-5-aminobenzimidazole, 1.00g of 4,4'-diaminodiphenyl ether, Then 2.94g of 3,3',4,4'-biphenyltetracarboxylic dianhydride was added, stirred and reacted at 0°C for 8h to obtain a brown polyamic acid solution;

[0088] Mix the brown polyamic acid solution with 2.02g triethylamine and stir for 1 hour to obtain a white polyamic acid salt suspension, then add 1.52g deionized water to the suspension to obtain a brown viscous polyamic acid salt suspension .

[0089] Preparation steps of polyamic acid salt powder:

[0090] The polyamic acid salt solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com