A kind of hydrophobic and oleophobic self-cleaning material and its preparation method and application

A hydrophobic and oleophobic, self-cleaning technology, applied in the field of coatings, can solve the problems of short duration of hydrophobic and oleophobic properties, oily substance pollution, loss of hydrophobicity and oleophobicity, etc., achieving good thermal stability, good water resistance, oil resistance, heat resistance, excellent The effect of toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

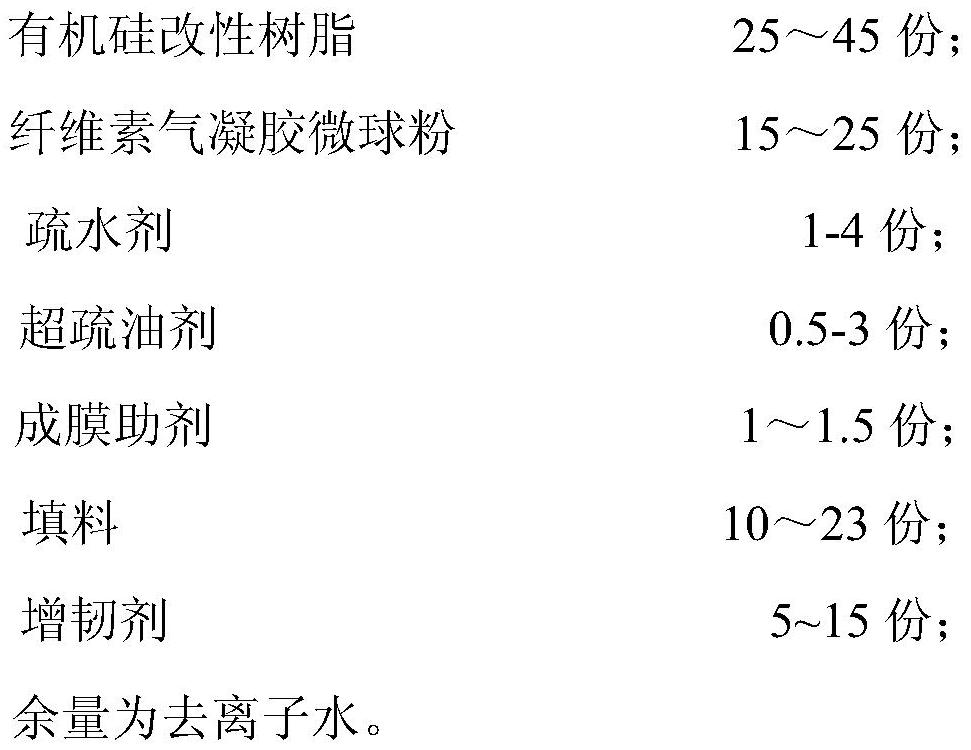

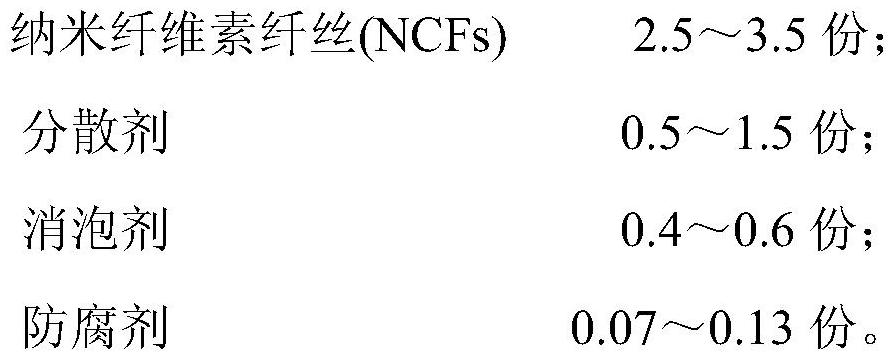

Method used

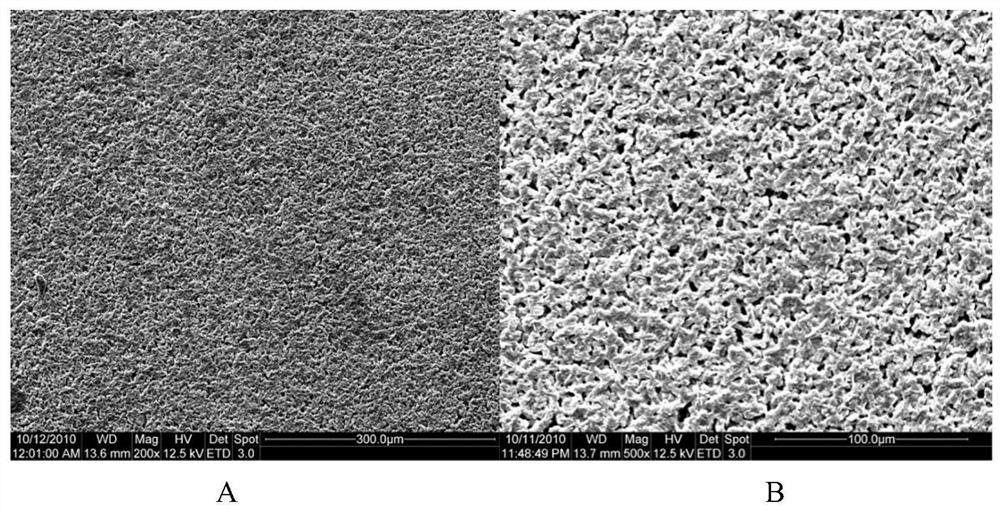

Image

Examples

Embodiment 1

[0049] The hydrophobic and oleophobic self-cleaning material prepared in this example can be used as an internal coating for food packaging paper or packaging film.

[0050] 1. Preparation of silicone modified resin:

[0051]1.1. Add polysiloxane monomer into the four-neck flask, stir and heat up to 80°C, add dropwise 30% hydrochloric acid solution to adjust the pH to 5, reflux for 6 hours, distill under reduced pressure, and remove the ethanol generated by the reaction , down to normal temperature, and filtered to obtain ethoxy-containing organosilicon oligomers;

[0052] 1.2. Add ethoxy-containing silicone oligomer and epoxy resin to the cyclohexanone solution in a mass ratio of 1:3. After completely dissolving, add the total mass of silicone oligomer and epoxy resin to 0.5 % of triphenylphosphine / butyl titanate composite catalyst with a mass ratio of 1:2, stirred and heated to 160°C, refluxed, the ethanol generated by the reaction was removed through an oil-water separator...

Embodiment 2

[0064] Using the silicone modified resin and cellulose airgel microsphere powder prepared in Example 1 as raw materials, the hydrophobic and oleophobic self-cleaning material prepared in this example can be used as an inner coating material for food trays or lunch boxes.

[0065] Based on 100 parts of the total weight of raw materials, the composition of raw materials includes: 30 parts of silicone modified resin, 25 parts of cellulose airgel microsphere powder, 3 parts of lotus leaf hydrophobic agent, 3 parts of fluorine-containing polyurethane oleophobic agent, propylene glycol butyl ether 0.7 parts, 12.0 parts of talcum powder, 5 parts of polyamide thermoplastic elastomer, and the balance is water.

[0066] 1. Add silicone modified resin to deionized water, stir at 500rpm, add sodium hydroxide solution to adjust pH to 7, add 1 / 3 of cellulose airgel microsphere powder, titanium dioxide and stir to obtain S1 premix ;

[0067] 2. Put lotus leaf hydrophobic agent, fluorine-con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com