Patents

Literature

40results about How to "Strong thermal insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

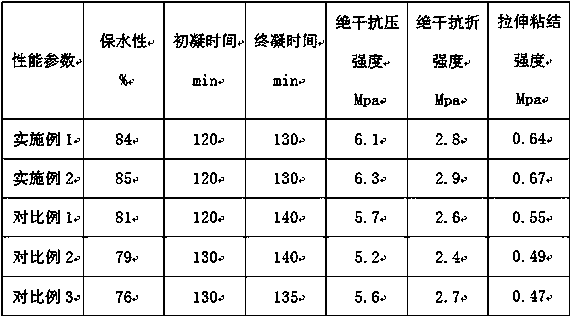

Anti-cracking plastering gypsum mortar

The invention discloses anti-cracking plastering gypsum mortar. The anti-cracking plastering gypsum mortar is prepared from the following raw materials: high-temperature calcined gypsum, ash calcium powder, composite portland cement, expanded perlite, fly ash, hydroxypropyl methyl cellulose ether, a retarder, a water reducing agent, starch ether, redispersible latex powder, polypropylene fibers and a waterproof agent. The invention provides the environment-friendly type lightweight bottom-layer plastering gypsum mortar which has good anti-cracking performance, has good heat insulation performance and can automatically adjusting temperature and humidity. By adopting the anti-cracking plastering gypsum mortar, the density of the mortar and the self weight of buildings can be effectively reduced; the anti-cracking plastering gypsum mortar has good sound insulation and noise reduction effects and has the advantages of uniformity in material preparation, convenience for construction, capability of being firmly stuck with a base layer, no hollowing, no falling, no cracks, fireproof and heat-resisting performance, heat insulation and sound insulation, greenness and environment protection,low cost and the like.

Owner:安徽省万帮新型建材科技有限公司

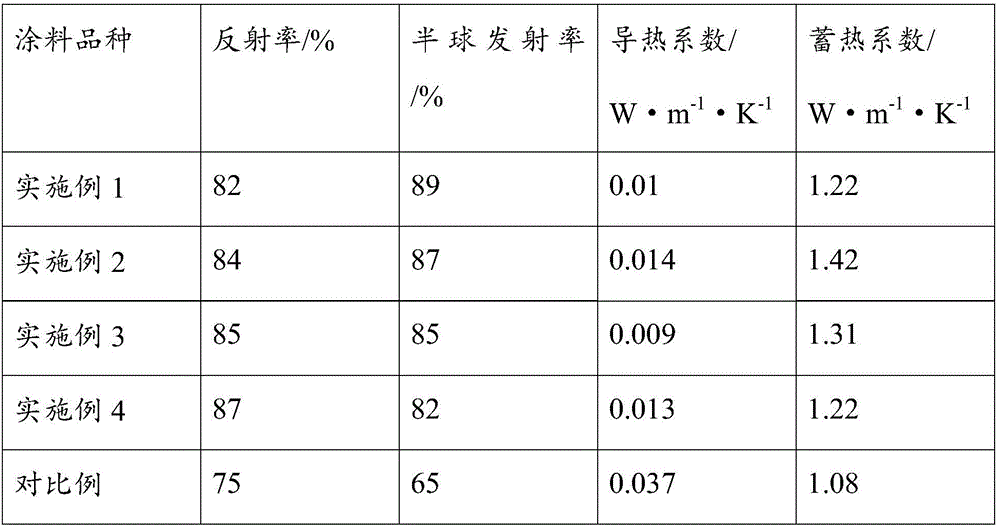

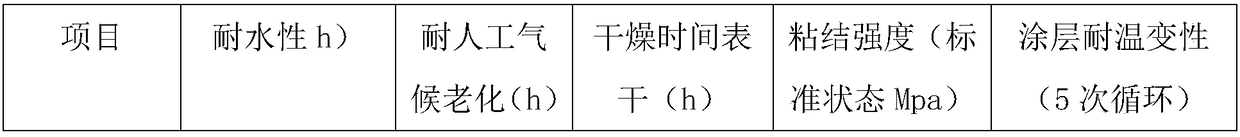

Thin coating type water-based heat insulation and thermal isolation paint and preparation method thereof

InactiveCN106752431AReduce thicknessStrong thermal insulationFireproof paintsAnti-corrosive paintsWater basedThermal isolation

The invention provides thin coating type water-based heat insulation and thermal isolation paint and a preparation method thereof. The thin coating type water-based heat insulation and thermal isolation paint is prepared from the following ingredients in parts by mass: 5 to 20 parts of hydrophobic modified expanded vermiculite, 5 to 20 parts of hollow glass micro beads, 20 to 45 parts of emulsion, 5 to 15 parts of filling materials, 0.1 to 1 part of wetting agents, 0.1 to 1.0 part of dispersing agents, 0.8 to 1.5 parts of thickening agents, 0.1 to 0.5 part of pH regulators, 0.01 to 0.2 part of antifoaming agents, 0.01 to 0.2 part of sterilizing agents and 10 to 30 parts of water. The thin coating type water-based heat insulation and thermal isolation paint provided by the invention has the advantages that hydrophobic modified expanded vermiculite and the hollow glass micro beads are used and are uniformly dispersed into the elastic acrylic ester type emulsion with excellent heat-resistant weather-resistant anti-corrosion alkali-resistant and water-proof performance to form the paint; good heat insulation and thermal isolation performance is realized; the coating thickness can be reduced to 850 to 1500 micrometers.

Owner:YANGTZE UNIVERSITY

Putty powder for exterior wall and preparation method thereof

ActiveCN110724404AImprove flatnessStrong thermal insulationFilling pastesCelluloseMagnesium silicate

The invention discloses putty powder for an exterior wall and a preparation method thereof, belonging to the field of building coatings. The putty powder for the exterior wall is prepared from the following raw materials in parts by weight: 300-400 parts of ground calcium carbonate, 250-350 parts of white cement, 350-500 parts of quartz sand, 12-30 parts of latex powder, 4-5 parts of cellulose ether, 0.1-2 parts of starch ether and 1-3 parts of magnesium aluminum silicate. The thickness of the exterior wall putty powder can be finely adjusted; tiles pasted by using the exterior wall putty powder are high in flatness; and the putty powder is strong in heat preservation perfromance, good in constructability and high in viscosity.

Owner:浙江壁灵宝建材科技有限公司

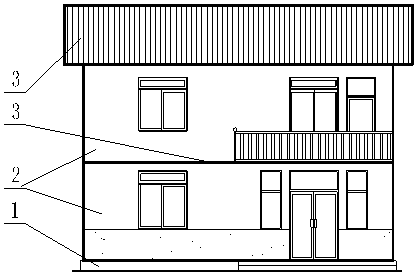

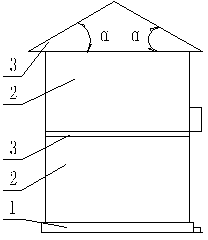

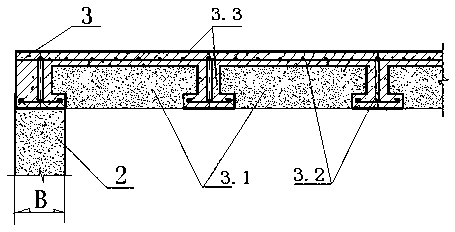

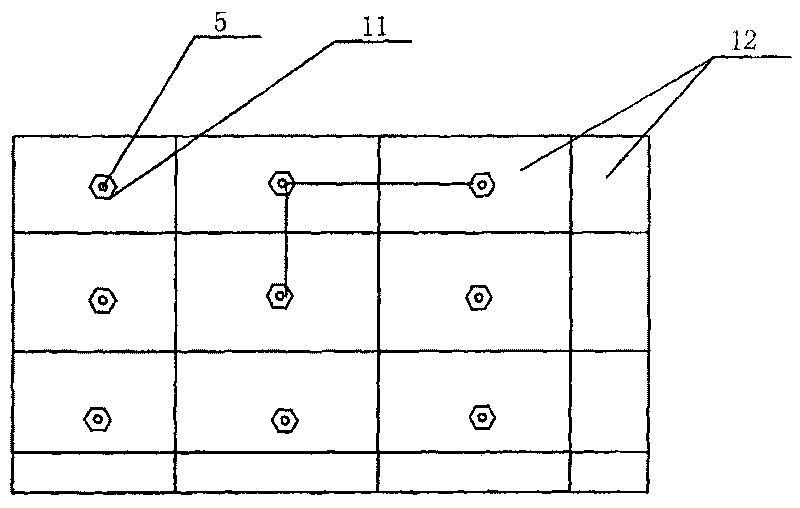

Energy-saving domestic architecture with cast-in-place industrial gypsum bearing wall and manufacturing method thereof

ActiveCN103306501AAvoid steamIncrease loading capacityWallsBuilding material handlingReinforced concreteThermal insulation

The invention discloses an energy-saving domestic architecture with a cast-in-place industrial gypsum bearing wall and a manufacturing method thereof. The method comprises the following steps: pouring industrial gypsum slurry into a wall body template in the field to manufacture the gypsum bearing wall of the domestic architecture; afterwards, performing pouring for gypsum / concrete compound building floor or house cover on the gypsum bearing wall, after the completion of the pouring, erecting a bottom template of the building floor or the house cover in advance; and arranging prefabricated industrial gypsum molded cases onto the bottom template at equal intervals, and performing concrete pouring after bars are arranged among the industrial gypsum molded cases and at the upper parts thereof, so as to manufacture the gypsum / concrete compound building floor or house cover on the gypsum bearing wall body. Due to the adoption of the method, the construction cost is low, no reinforced concrete structure is required for the wall body support, the structure is reliable, the construction is easy, the thermal insulation performance is good and the energy saving effect is obvious. The domestic architecture is particularly suitable for low-storey and small-bay domestic architectures in rural.

Owner:GUIZHOU UNIV +4

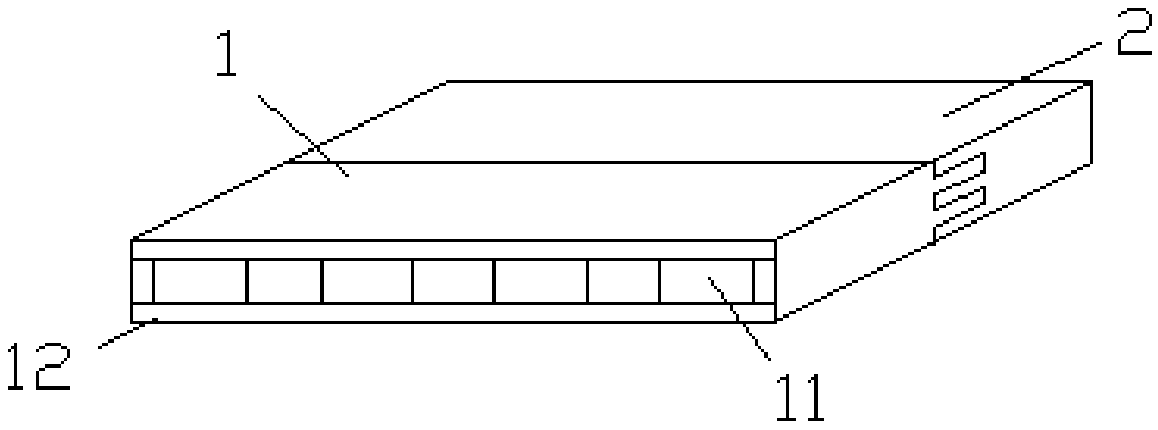

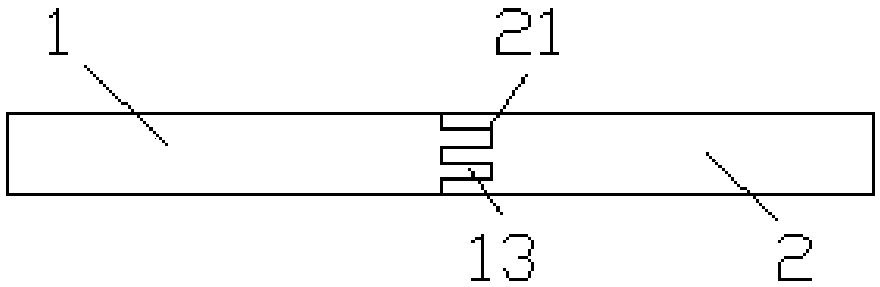

Prefabricated building with good heat insulation performance

The invention discloses a prefabricated building with the good heat insulation performance. The prefabricated building comprises a base plate. A top plate is arranged on the top of the base plate. Theinner ends of heat insulation plates are fixedly connected with decorative plates. The inner ends of side plates are provided with clamping assemblies. Through rotatable connection between the base plate and the side plates, between the side plates and between the side plates and the top plate and arrangement of the heat insulation plates, the prefabricated building with the good heat insulationperformance has the high heat insulation performance. Through clearance fit between clamping rods and transverse grooves and clearance fit between the clamping rods and through holes, the side platescan be vertically tightened, the prefabricated building can be folded and pressed down. Through clearance fit between sliding blocks and sliding grooves and clamping connection between slots and grooves, fulcrum bars can be inserted into the slots by rotating cranked levers and can be tightened by reversely rotating the cranked levers. Through threaded connection of screw rods and cylindrical tubes, cams abut against the cranked levers, and then the top plate below and the base plate above can be in fastened connection. Therefore, the assembly efficiency is greatly improved, and the assembly difficulty is reduced.

Owner:定州市筑业装配式建筑科技有限公司

Building waterproof thermal-insulation mortar and preparation method thereof

InactiveCN103664082AStrong thermal insulationGood heat insulationSolid waste managementHydroxypropylmethyl celluloseAluminium salts

A building waterproof thermal-insulation mortar is characterized by being prepared from the following raw materials in parts by weight: 300-400 parts of cement, 40-50 parts of waste building brick powder, 20-24 parts of wood fiber, 4-6 parts of calcium formate, 7-9 parts of hydroxypropyl methyl cellulose, 40-45 parts of silicon carbide micro powder, 10-20 parts of calcium oxide powder, 10-12 parts of brown fused alumina powder, 30-35 parts of dry city sludge powder, 40-45 parts of Datong earth, 4-6 parts of aluminum sulfate, 20-24 parts of carboxymethyl starch, 4-6 parts of modified nano carbon powder and 600-650 parts of water. The building waterproof thermal-insulation mortar has a good thermal-insulation property, can be cemented to a wall firmly, and has excellent compressive and tensile properties, as well as good weather-resistant, environmental-friendly, waterproof, anti-cracking and anti-flaking properties.

Owner:BENGBU TIANWANG FISHING NEED SUPPLIES

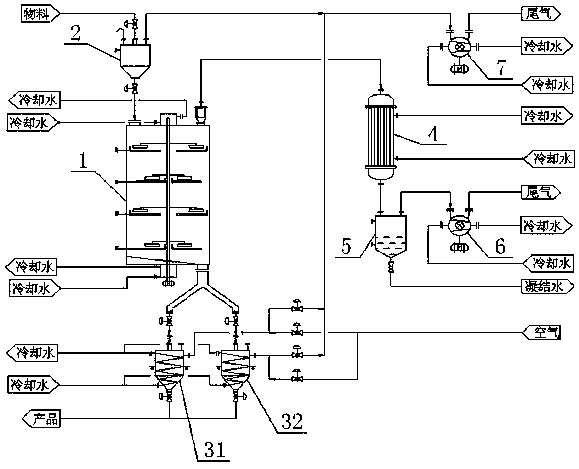

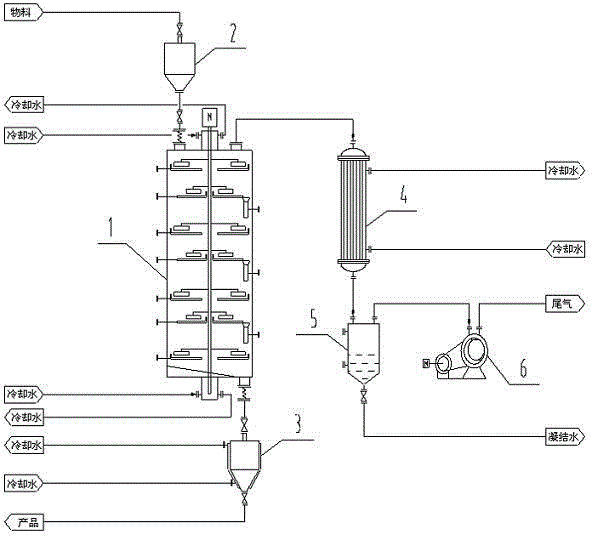

Continuous vacuum drying roasting method for small crystal grain 5A molecular sieve

ActiveCN111059894AHigh degree of automationAccurate temperature controlOther chemical processesMuffle furnacesMolecular sieveTemperature control

The invention relates to a continuous vacuum drying roasting method for small crystal grain 5A molecular sieve. The method includes the following steps: (1) filling a feed tank with the 5A molecular sieve material; (2) performing vacuumizing on the feed tank; (3) performing vacuumizing on a vertical disc rotary vacuum roasting furnace; and sucking the 5A molecular sieve into the vertical disc rotary vacuum roasting furnace, and performing heating in sections to obtain a dried roasted and activated 5A molecular sieve; (4) performing vacuumizing on a product bin; (5) opening an automatic controlvalve V of a material inlet II of the product bin, and automatically closing the automatic control valve V after a weighing system of the product bin shows full tank; (6) performing cooling to 50 DEGC in the product bin through a jacket to obtain a product; and (7) discharging the product from the product bin; and at the same time, performing switching to start a spare product bin. The method has precise temperature control, safety and environmental protection, and can realize continuous operation under a high vacuum degree.

Owner:CHINA PETROLEUM & CHEM CORP +3

Heat insulation coating for building and preparation method of heat insulation coating

InactiveCN107141902AImprove insulation effectStrong adhesionFireproof paintsAntifouling/underwater paintsThermoplasticFiber

The invention discloses a heat insulation coating for a building and a preparation method of the heat insulation coating, and relates to the field of building materials. The heat insulation coating is prepared from the following raw materials in parts: 90 to 100 parts of styrene-acrylic emulsion, 55 to 65 parts of glass wool, 45 to 55 parts of short fiber, 40 to 45 parts of thermoplastic expanded hollow microspheres, 25 to 30 parts of nano aluminium silicate, 20 to 25 parts of nano calcium carbonate, 10 to 20 parts of nano titanium dioxide, 10 to 20 parts of a filler, 10 to 15 parts of an auxiliary and 150 to 180 parts of water. A coating film formed by the coating is good in heat insulation and preservation effect, high in bonding strength, difficult to crack and high in abrasion resistance; furthermore, the preparation method is scientific and simple; the energy consumption is greatly reduced; meanwhile, the heat insulation coating is free of pollution to the environment.

Owner:HEFEI YAKELI NEW BUILDING MATERIAL CO LTD

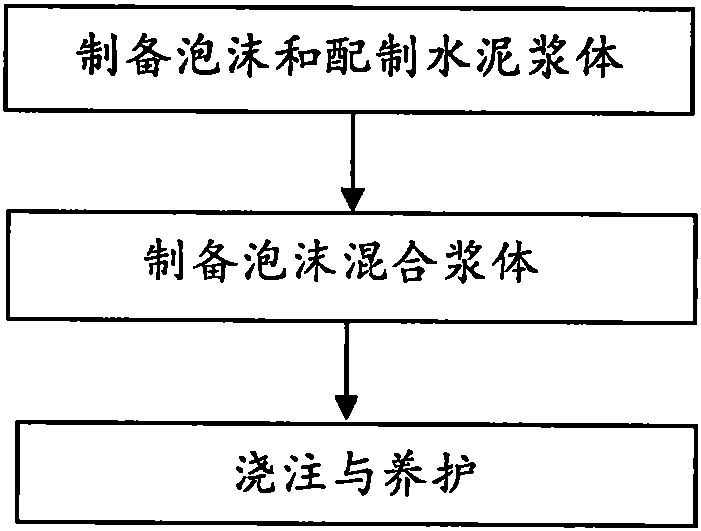

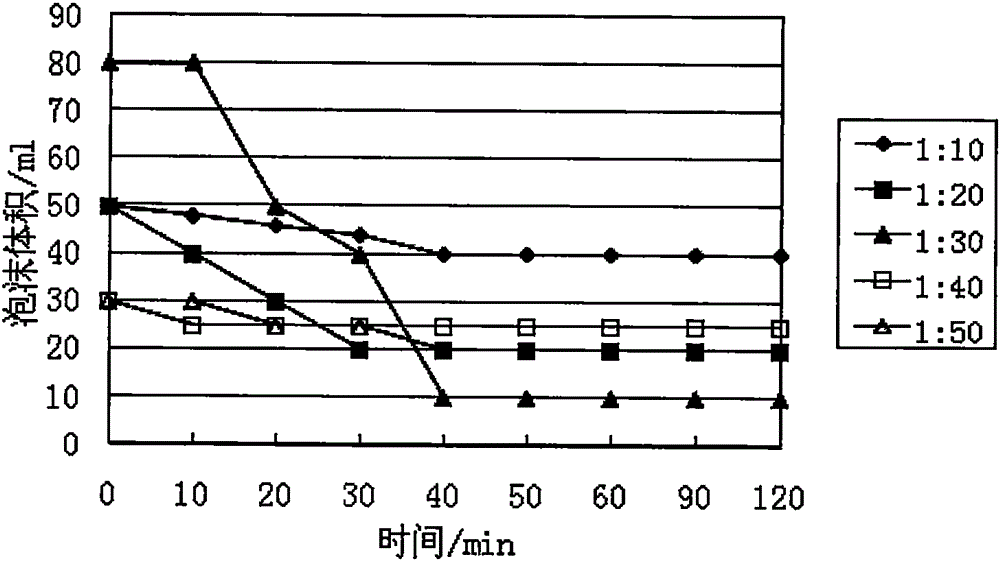

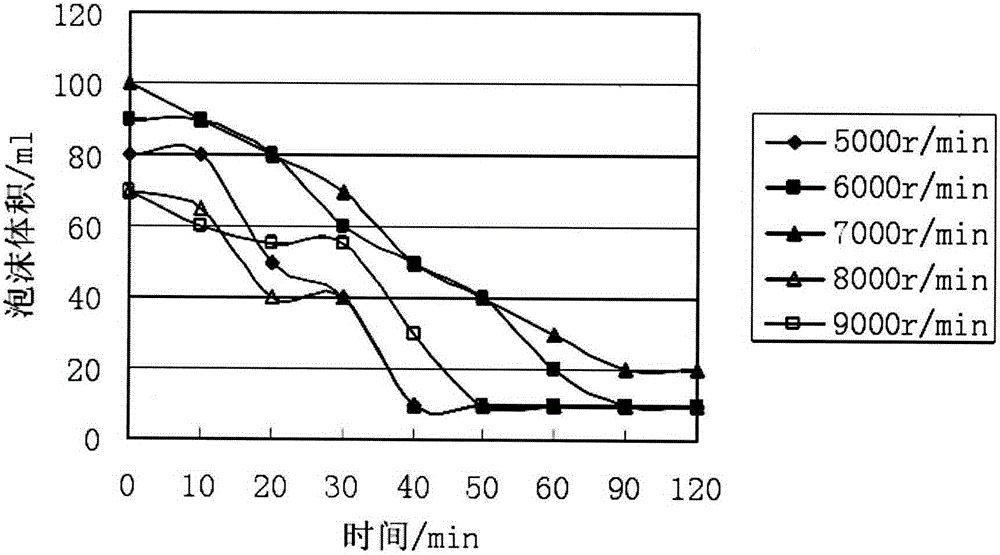

Composite self-insulation concrete block and production method thereof

InactiveCN105347842ASolve the problem of poor thermal insulation performanceImprove thermal insulation performanceCeramicwareFoam concreteCold winter

The invention discloses a composite self-insulation concrete block. The composite self-insulation concrete block is composed of a concrete hollow block and an inner core material in a cavity of the concrete hollow block, wherein the inner core material is a low density foam concrete, the raw materials comprise a cement mortar and foamed foams with a volume ratio being 1:4-8, and the composite self-insulation concrete block is prepared by mixing the foamed foams and the cement mortar, casting a mixture in the cavity in the concrete hollow block, and performing natural maintenance. A production method comprises the following steps: 1) preparing the foams and preparing the cement mortar; 2) preparing a foam mixing slurry; and 3) casting and maintaining the material. The composite self-insulation concrete block can reach the requirements of heat transfer coefficients prescribed by a national standard and can satisfy the heat insulation requirements in hot summer and cold winter areas, the heat insulation performance of the composite self-insulation concrete block is stronger than that of the concrete hollow block, the heat transfer coefficients account for 80% of that of the hollow building block unfilled with the foam concrete, and thermal resistance of the composite self-insulation concrete block can reach as high as 1.25 times of that of the hollow building block.

Owner:HUANGHUAI UNIV

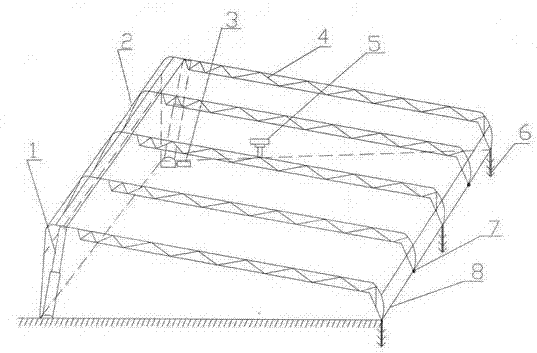

Self control adjustable steel frame greenhouse

InactiveCN102783382AGood lightingStrong thermal insulationClimate change adaptationGreenhouse cultivationAgricultural engineeringSunlight

The invention relates to a self control adjustable steel frame greenhouse, which comprises a telescopic support frame, a steel frame, a hydraulic jack, a greenhouse, a sunlight tracking device, a covering film and a ground shaft and is characterized in that steel frame is arranged on the telescopic support frame, the covering film is arranged at the outer side of the telescopic support frame and above the steel frame, the sunlight tracking device is fixedly arranged on the steel frame and at the outer side of the covering film, the bottom of the telescopic support frame is provided with the ground shaft, the ground shaft is inserted under the ground through a ground spear, the telescopic support frame is fixedly arranged on the ground, and the hydraulic jack is arranged in the telescopic support frame. The self control adjustable steel frame greenhouse has the advantages that the lighting performance is good, the heat insulation performance is high, and the greenhouse is favorable for the greenhouse vegetable growth. Meanwhile, the work intensity of people is reduced, the work efficiency of people is improved, and good foundation is laid for the large-scale planting.

Owner:孟现芳

Casting powder for casting magnesium aluminum alloy

The invention relates to a casting powder for casting magnesium aluminum alloy. The casting powder comprises the following components at weight percentage: 55-69% of a deflocculant and 31-45% of a fire retardant. The casting powder can be added with a binder accounting for 5-6% of the casting powder by weight, and the binder can be chosen from silicasol or aluminum phosphate. The deflocculant can be chosen from micanite, bentonite, diatomite, palygorskite clay and the like. The fire retardant can be chosen from alkyl sodium sulfonate, boric acid and the like. The casting powder has better temperature retention, fire retardancy and paintability, excellent floatability, and is uneasy for deposition in use. The casting powder reduces hot crack trend of magnesium aluminum alloy castings. The casting powder forms a layer of reducing protective atmosphere on a riser magnesium aluminum interface in casting, which prevents the magnesium aluminum alloy from oxidation, prevents the magnesium aluminum alloy from burning in a cast mould in casting, and ensures sequential cooling of the magnesium aluminum alloy so as to improve feeding effect during solidification of the magnesium aluminum alloy, thus producing the magnesium aluminum alloy casting with small surface but without internal crystallographic direction defect and oxide scale.

Owner:大连核心铸造技术工程研究所

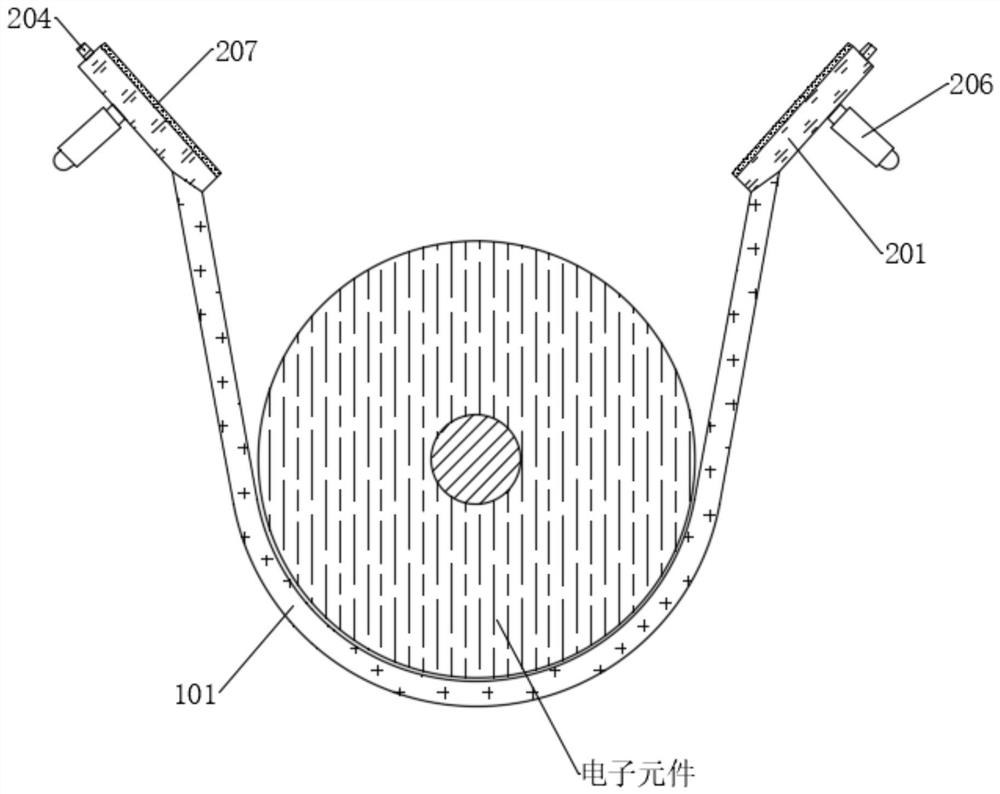

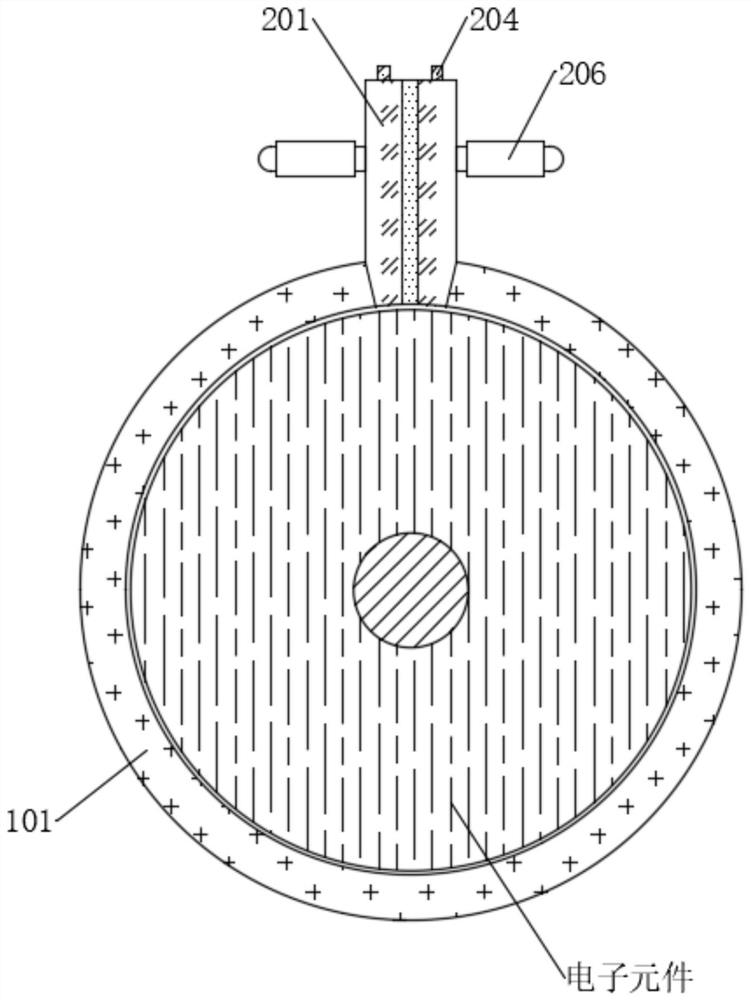

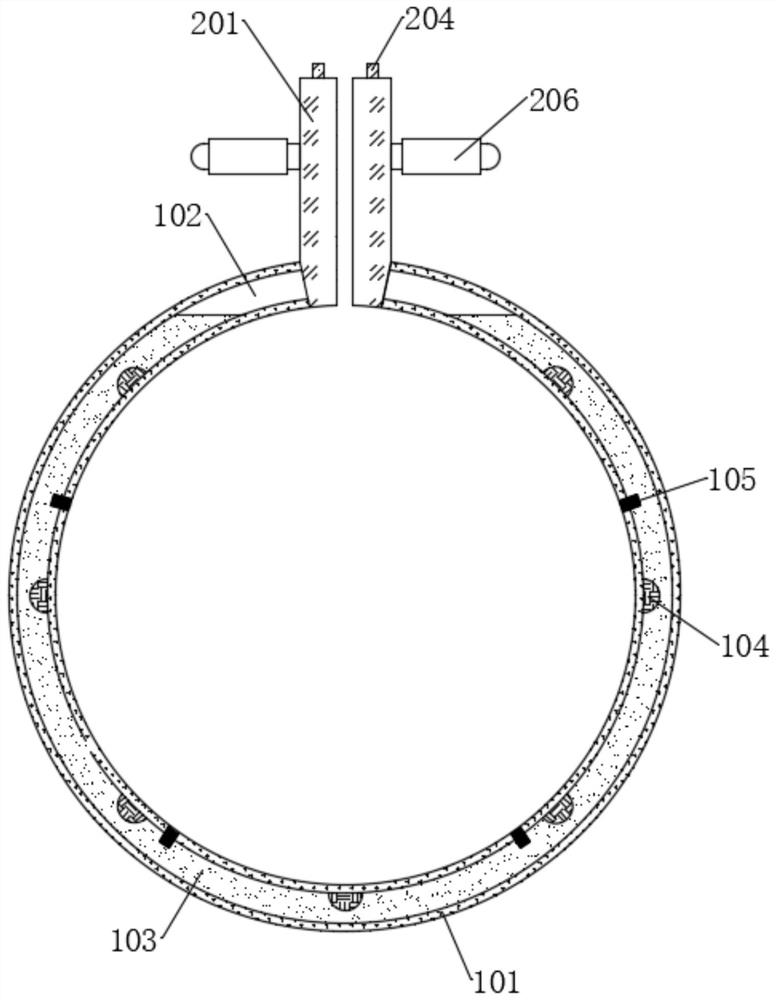

Double-phase temperature control type protective sleeve for electronic element

ActiveCN113260222AHeat dissipation fastAvoid damageModifications by conduction heat transferTemperature controlLiquid state

The invention discloses a double-phase temperature control type protective sleeve for an electronic element, which belongs to the technical field of electronic elements. By the arrangement of specially-made floating heat conductors, floating heat preservation balls, a phase change temperature control body and the like, when the electronic element generates large heat due to work, the phase change temperature control body can absorb the heat and gradually converts from a solid state to a liquid state, the change of the physical state of the phase change temperature control body enables the heat conduction plate to float upwards to abut against the heat dissipation strip and establish heat conduction connection with the outside, and therefore heat absorbed by the phase change temperature control body is dissipated to the outside, and then rapid heat dissipation is conducted on an electronic element. Compared with the prior art, theprotective sleeve not only has heat preservation and heat insulation performance, the electronic element can be prevented from being invaded and disturbed by external high and low temperatures, meanwhile, the electronic element can be cooled spontaneously and quickly, so that the electronic element can be effectively prevented from being damaged by high temperature generated by the electronic element on the premise that the heat preservation and heat insulation performance is guaranteed, and the practicability is improved.

Owner:宜宾综合保税区供应链管理有限公司

Prefabricated wallboard of multifunctional green building

InactiveCN104631697AImprove sound insulationExcellent sound fieldBuilding componentsCalcium silicateFiber

The invention relates to a prefabricated wallboard of a multifunctional green building. The prefabricated wallboard comprises a reinforced concrete layer positioned at the indoor side, a calcium silicate board layer positioned at the outdoor side, and a polyphenyl granule layer positioned between the reinforced concrete layer and the calcium silicate board layer; reinforcing steel bars are arranged in the reinforced concrete layer; FRP (Fiber Reinforce Plastic) ribs are arranged in the reinforced concrete layer and the polyphenyl granule layer. Compared with the prior art, the prefabricated wallboard has the advantages of being good in heat and sound insulation performances, high in strength, convenient to construct, and recyclable in materials.

Owner:TONGJI UNIV

Preparation method of environment-friendly blue brick

InactiveCN106747334AHigh strengthLow costCeramic materials productionClaywaresEnvironmental resistanceBrick

The invention relates to a preparation method of an environment-friendly blue brick and belongs to the field of building wall materials. The preparation method comprises the following steps: (1) raw material pretreatment; (2) batching and stirring: weighing shale, clay, sludge, waste ceramics, vermiculite, volcanic ash, bean curd swilling, pine barks, bamboo residues and carbon according to the proportion occupied by all the raw materials, adding a proper amount of water, stirring the raw materials and uniformly mixing to obtain a mixture; (3) digesting; (4) pressing and molding: pressing and molding the digested mixture to obtain a brick blank, and naturally airing the brick blank till the moisture content is 16-20 percent to obtain the air-dried brick blank; (5) brick blank sintering: enabling the air-dried brick blank to enter a kiln for firing and sintering for 8-10 hours at a temperature of 1050-1250 DEG C; (6) sealing the kiln and cooling. According to the preparation method of the environment-friendly blue brick, the cost can be reduced, and safety and environmental protection are realized.

Owner:柳州市圣垒贸易有限公司

Novel thermal insulation building inner wall board

InactiveCN108442633AImprove insulation performanceStrong insulationCovering/liningsFlooringThermal insulationPolystyrene

The invention discloses a novel thermal insulation building inner wall board. The novel thermal insulation building inner wall board structurally comprises a first building inner wall board and a second building inner wall board. Through holes, a decorative board, a convex block, a first thermal insulation layer, a first reinforcement layer, a first heat preservation layer, a second heat preservation layer, a second reinforcement layer and a second thermal insulation layer are arranged on the first building inner wall board. A groove is formed in the first building inner wall board. The firstbuilding inner wall board is arranged on the left side of the second building inner wall board, and is connected with the groove in a matched mode through the convex block. The novel thermal insulation building inner wall board has the advantages of good thermal insulation, good heat preservation, low cost and non-polluting material. The first thermal insulation layers are made from rock wool materials to prevent the temperature infiltrated from the outside world, and a good thermal insulation effect is achieved; the heat preservation layers are made from polystyrene foam materials, so that indoor temperature is not easy to lost, and the heat preservation effect is excellent; and the convex block and the groove are formed, so that the installation and disassembly of the building interior wall board is facilitated, the structure is simple, and the operation is simple.

Owner:FOSHAN TIANLI TONGSE DECORATION MATERIAL CO LTD

Potassium feldspar tailing environmentally-friendly brick and preparation method thereof

InactiveCN108840709AReduce processing timeReduced processing performanceCeramic materials productionCeramicwareBrickSludge

The invention discloses a potassium feldspar tailing environmentally-friendly brick and a preparation method thereof, and relates to the technical field of preparation of an environmentally-friendly brick. The preparation method comprises the following steps: (1) taking the following components in parts by weight: potassium feldspar tailing, oyster shells, sludge, ceramic powder, vermiculite powder, cinerite, bean curd swill, pine bark scraps, bamboo scraps, carbon powder, modified coal ash, quick lime, an anti-cracking agent and a foaming agent; (2) pulverizing the potassium feldspar tailing,the oyster shells, the ceramic and the vermiculite into powder; (3) mixing the feldspar tailing powder and the oyster shell powder, adding water and grinding to obtain a first mixed material; (4) adding water into all the raw materials and stirring to obtain a second mixed material; (5) digesting; (6) pressing and forming; (7) sintering a green brick; and (8) sealing a kiln and cooling. Accordingto the potassium feldspar tailing environmentally-friendly brick and the preparation method thereof, waste serves as the raw material, so that the production cost is reduced while environmental pollution is reduced.

Owner:贺州市骏鑫矿产品有限责任公司

Vertical vacuum-tight "dry-calcination" method for px spherical adsorbents

ActiveCN104841370BHigh degree of automationAccurate temperature controlOther chemical processesFurnace typesExhaust gasFilling materials

The invention relates to an upright vacuum sealed type "drying-firing" method for a PX spherical adsorbent. The method comprises the steps of: 1, filling materials in a charging stock tank at room temperature, closing the inlet valve and outlet valve, and vacuumizing an upright disc rotation vacuum roaster; and inhaling a PX spherical adsorbent to be dried and fired into the upright disc rotation vacuum roaster under vacuum conditions; 2, sending the PX spherical adsorbent into a first heating section under vacuum conditions; 3, sending the PX spherical sorbent into a first constant temperature section under vacuum conditions; 4, sending the PX spherical adsorbent into a secondary heating section under vacuum conditions; 5, sending the PX spherical adsorbent into a secondary constant temperature section under vacuum conditions; 6, sending the PX spherical adsorbent into a product hopper and cooling under vacuum conditions, so as to obtain a product and non-condensable gas respectively; and discharging the product from the product hopper; and 7, cooling the non-condensable gas, and sending into a collection tank to obtain condensate and exhaust respectively; discharging the condensate through a condensate discharge pipe; and discharging the exhaust through a vacuum pump. The invention is safe and environment-friendly and can realize continuous operation.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

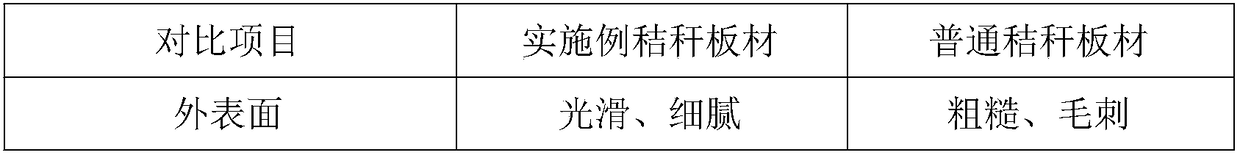

Mildewproof, mothproof and bacteriostatic straw plate and preparation method thereof

InactiveCN109291204AHigh densityHigh bonding strengthWood working apparatusDomestic articlesSurface layerUltimate tensile strength

The invention discloses a preparation method of a mildewproof, mothproof and bacteriostatic straw plate. The preparation method comprises the following steps: smashing crop straws into particles, soaking the particles in sodium hydroxide solution and sulfuric acid solution to obtain straw fibers, mixing the straw fibers with rosemary powder, bamboo charcoal fiber, expanded vermiculite and kieselguhr separately to obtain a surface layer mixture, mixing the straw fibers with coconut carbon fiber and green bean starch to obtain a core layer mixture, paving the surface layer mixture into a die according to the odd number layer principle, paving the core layer mixture into the die according to the even number principle, and carrying out drying, thermo-compression formation, cooling, demoulding,maintaining, edge cutting and packaging to obtain a finished product. The mildewproof, mothproof and bacteriostatic straw plate is non-toxic, tasteless, formaldehyde-free, and environmental-friendly,has higher strength, is high in fireproof performance and humidity resistance, is light in weight, facilitates transportation and construction installation and can enhance memory and refresh throughrosemary. Various performance of the mildewproof, mothproof and bacteriostatic straw plate meets corresponding requirements. Furniture made of the mildewproof, mothproof and bacteriostatic straw platecan effectively prevent mildew, acarid, resist bacteria and can automatically adjust the indoor humidity.

Owner:安徽科纳家居饰材有限公司

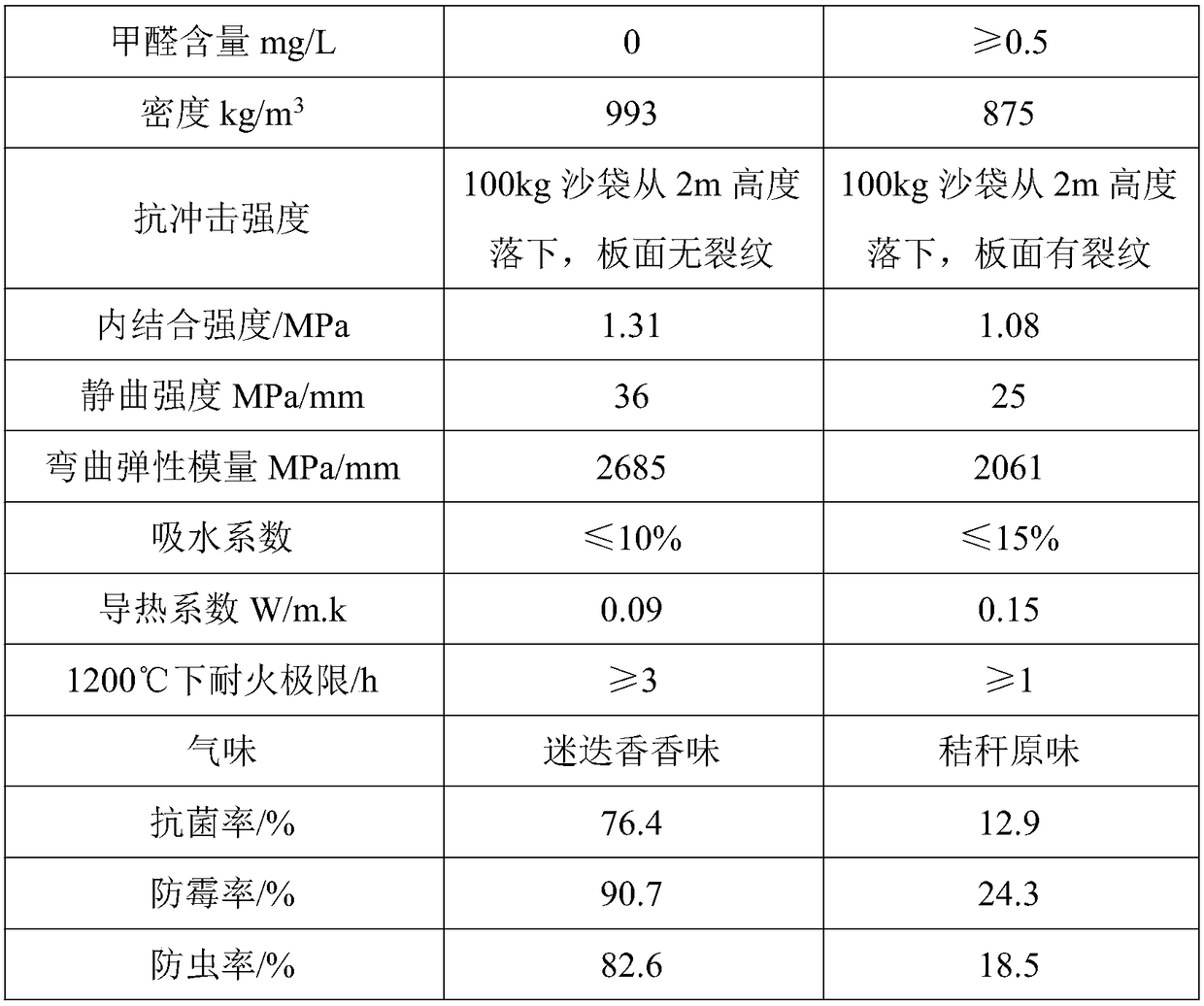

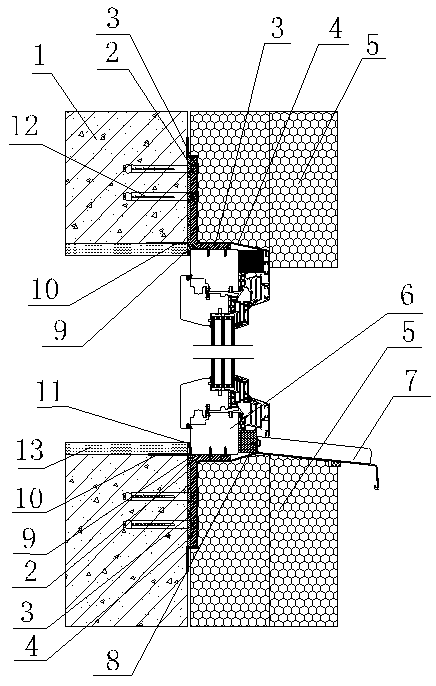

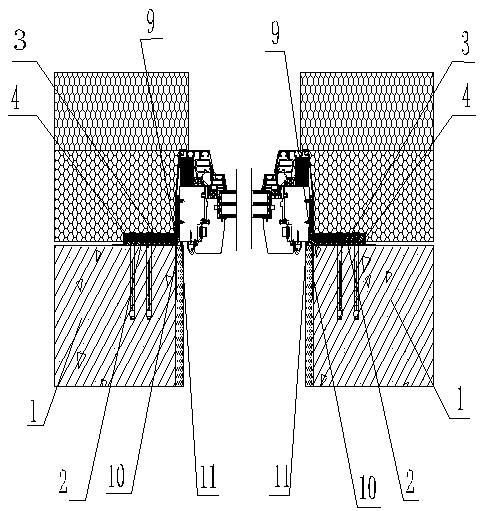

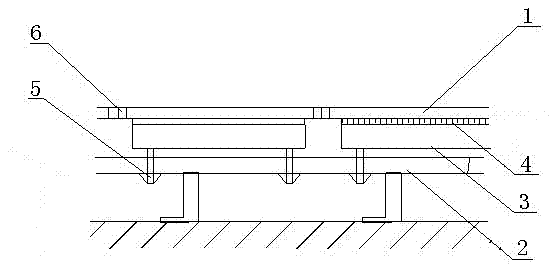

Installing method of passive externally hanging window of house

InactiveCN109707276ANot prone to cracksAvoid crackingFrame fasteningWindow/door framesThermal isolationPolystyrene

The invention discloses an installing method of a passive externally hanging window of a house. The method comprises the following steps of uniformly fixing long-wall ends of a plurality of L-shaped metal fixing plates onto a wall body at the left, right, upper and lower sides of a hole opening; bonding and fixing a circle of waterproof airtight film with most parts extending out of the indoor endonto the outer side of the indoor end of a window frame; fixing the short wall end of the L-shaped metal plate to the window frame; totally covering the outdoor end of the window frame by a waterproof ventilation film in a way of exceeding the edge; bonding the waterproof ventilation film totally covering the L-shaped metal fixing plate into the position of the L-shaped metal fixing plate; fixinga window sill onto the lower end of the outdoor end surface of the window frame at the lower end of the window; totally covering and fixing one layer or multiple layers of graphite polystyrene boardsonto the wall in the position of the waterproof ventilation film; unfolding the waterproof airtight film; pasting the waterproof airtight film onto the wall of the hole opening; and pasting and fixing a wall plate. Installed doors and windows cannot easily generate cracks; the airtightness and water tightness performance is good; seepage cannot easily occur; the heat insulation and thermal isolation performance is good; the heat transfer coefficient is low; and the installation requirements of the passive doors and windows of the house can be met.

Owner:HEBEI ORIENT SUNDAR WINDOW

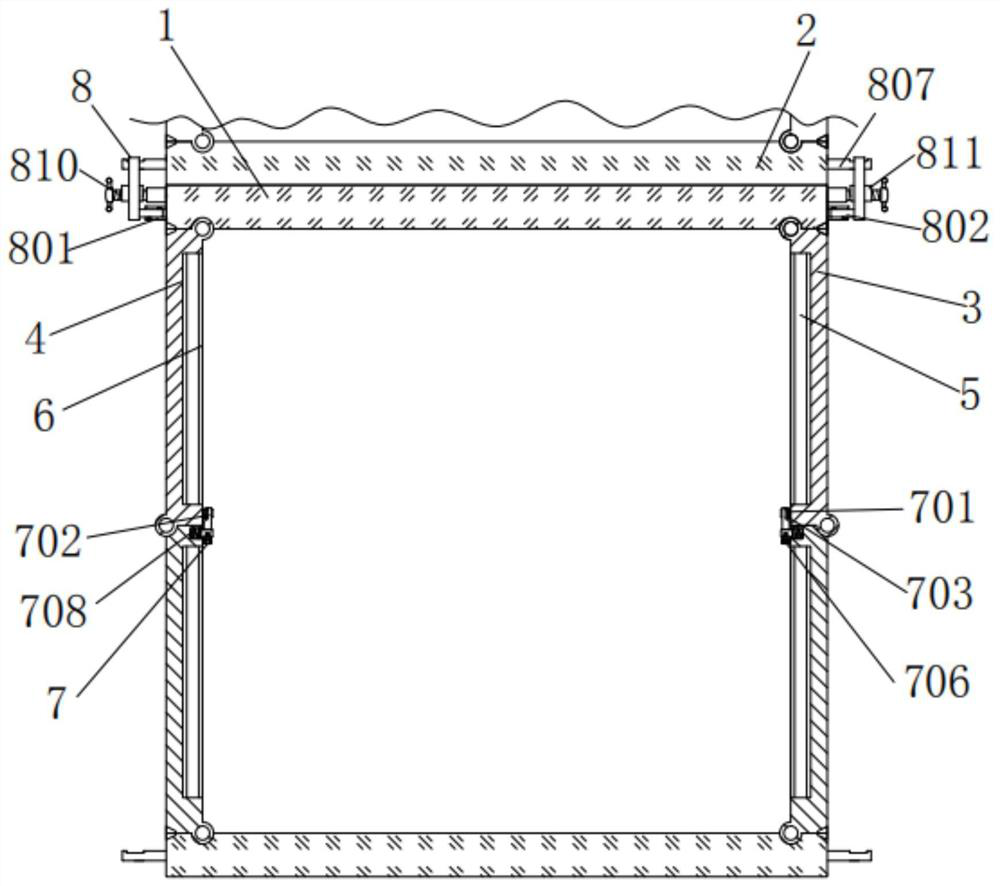

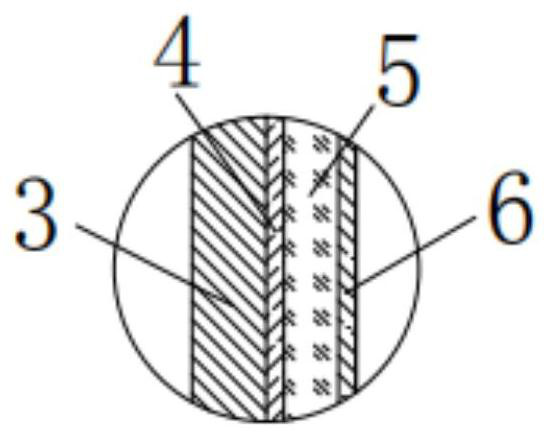

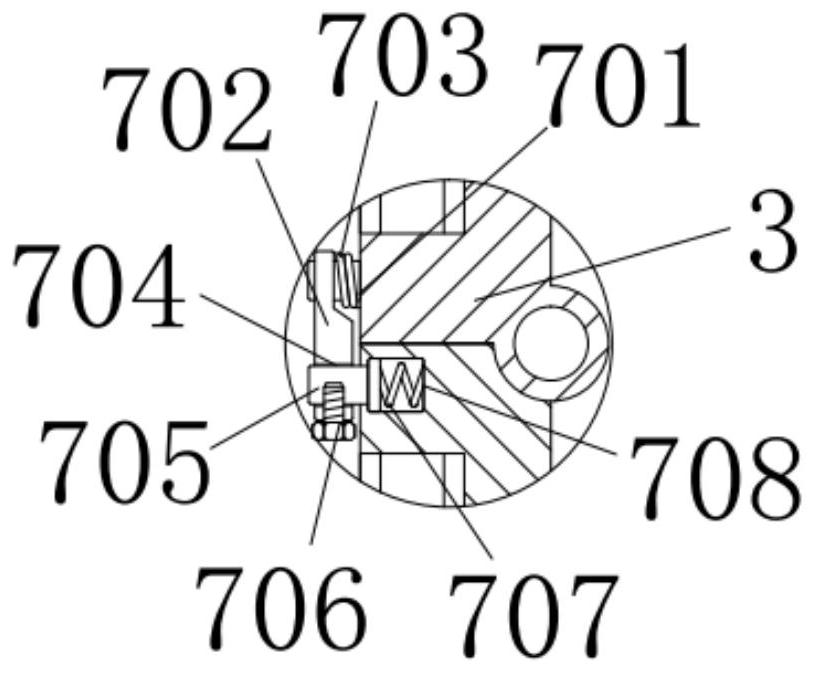

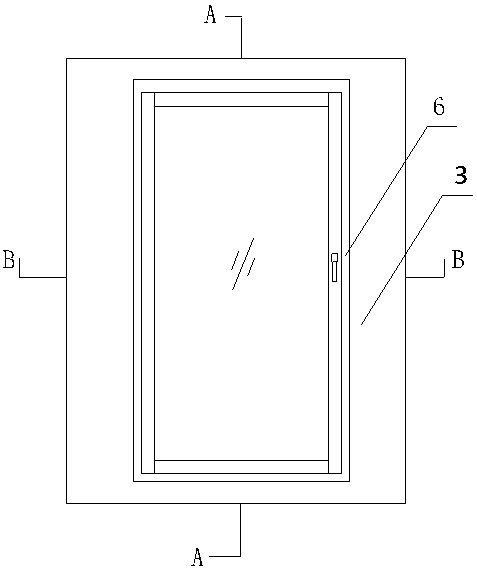

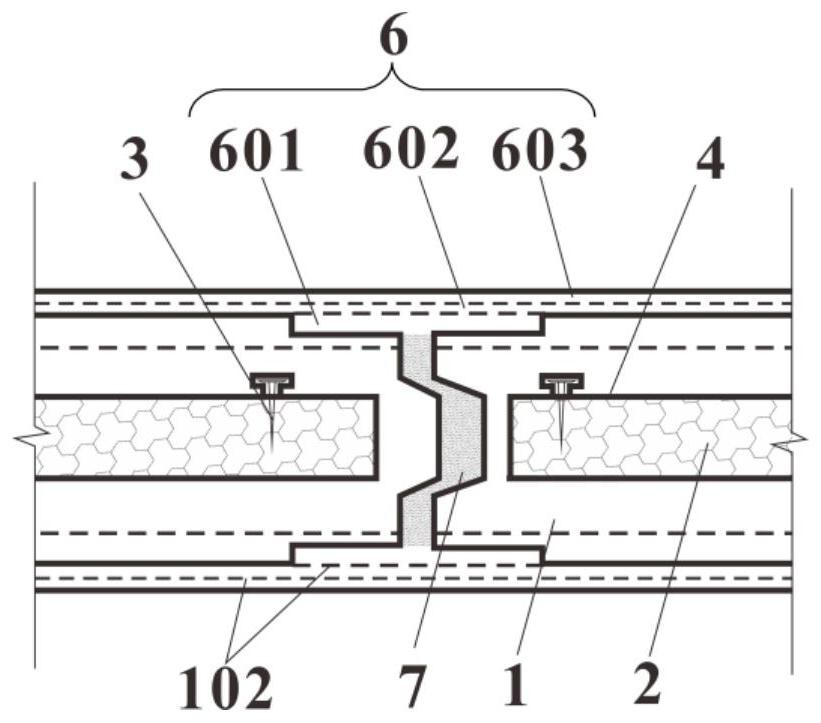

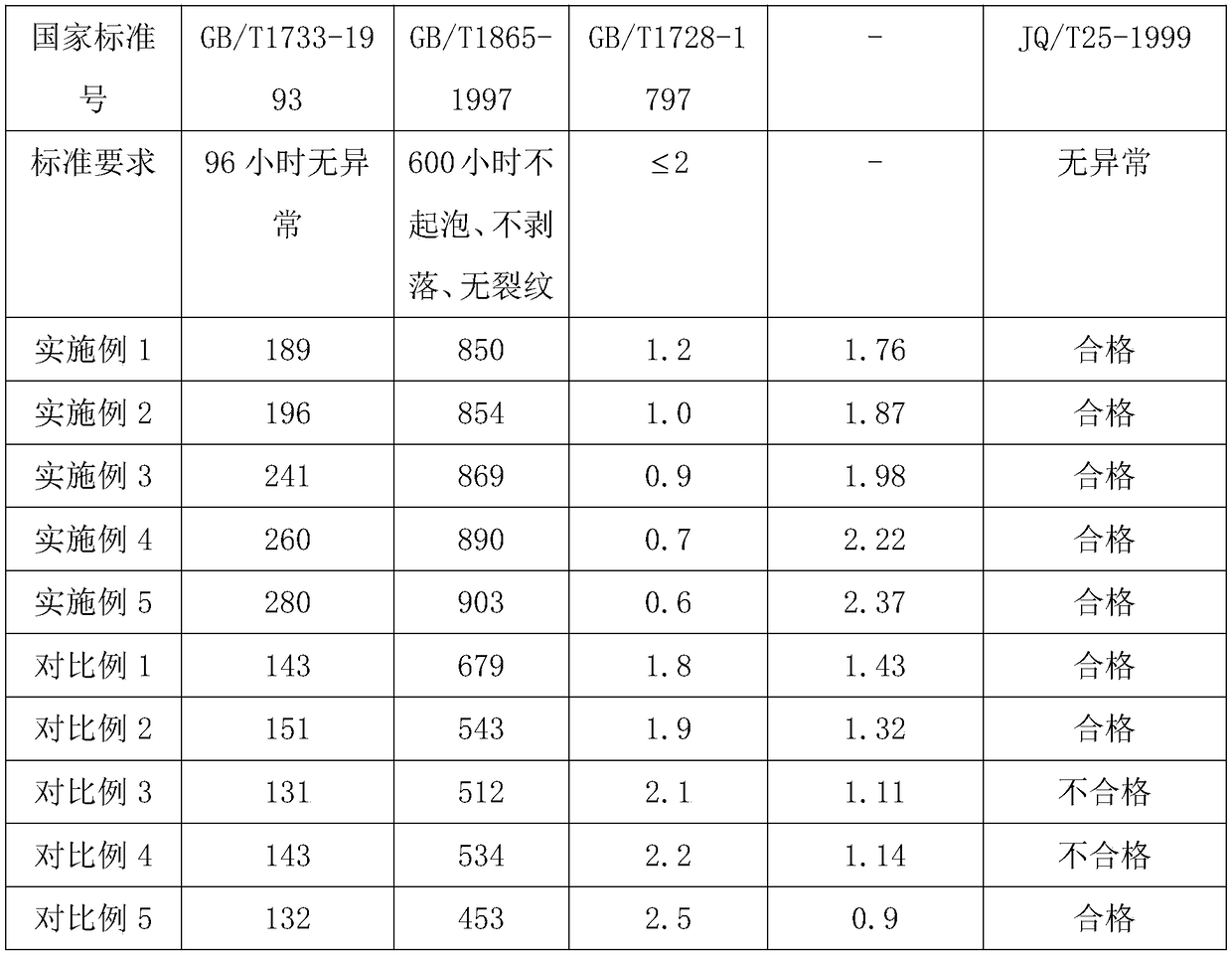

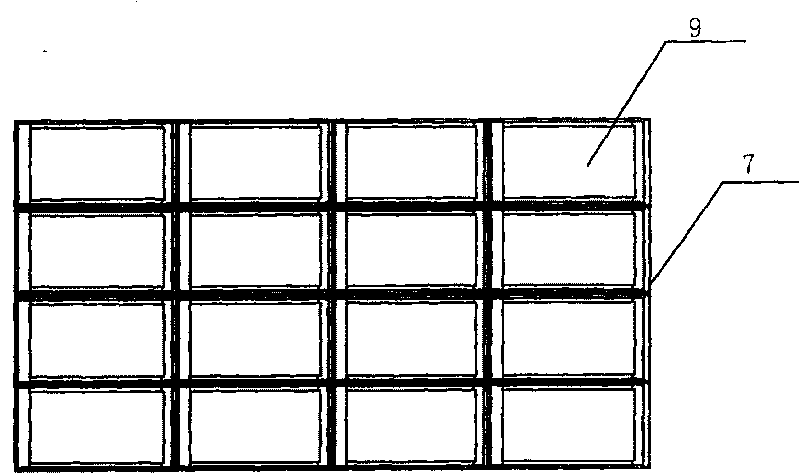

Aluminum alloy thermal insulation curtain wall and manufacturing process thereof

ActiveCN103206036AReduce heat transferLower heat transfer coefficientWallsBuilding material handlingAdhesiveThermal insulation

The invention discloses an aluminum alloy thermal insulation curtain wall and a manufacturing process thereof. The aluminum alloy thermal insulation curtain wall comprises glass (1) and an aluminum alloy frame system (2). The aluminum alloy frame system (2) is fixed on the surface of a building outer wall. The glass (1) is adhered to the surface of a glass frame (3) through structural adhesives. The glass frame (3) is fixedly mounted on the aluminum alloy frame system (2) through bolts (5). Rubber strips (6) for sealing and damping are mounted on the periphery of the glass (1). The manufacturing process includes: manufacturing thermal insulation section bars; manufacturing the glass frame; adhering the glass; and mounting the frame system and the glass frame. The glass is double-layer hollow coated glass, so that solar radiation, far-infrared radiation, and heat transfer inside and outside a building are reduced effectively. The glass frame is made of honeycomb aluminum alloy thermal insulation section bars which are lightweight, high in hardness and capable of forming a continuous thermal insulation area inside and outside the building, and accordingly thermal insulation effect of the glass curtain wall is enhanced greatly.

Owner:四川阳光坚端铝业有限公司

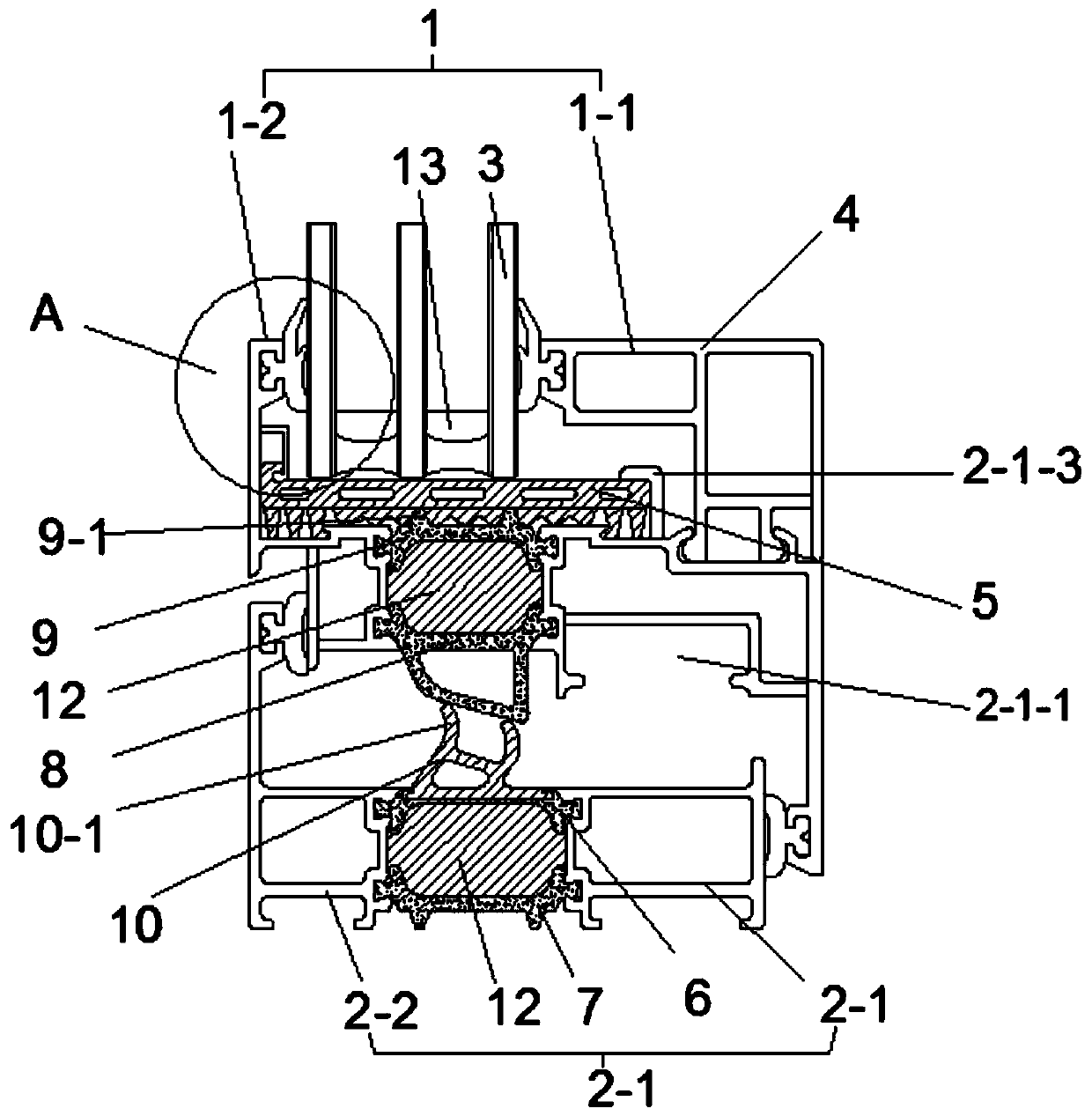

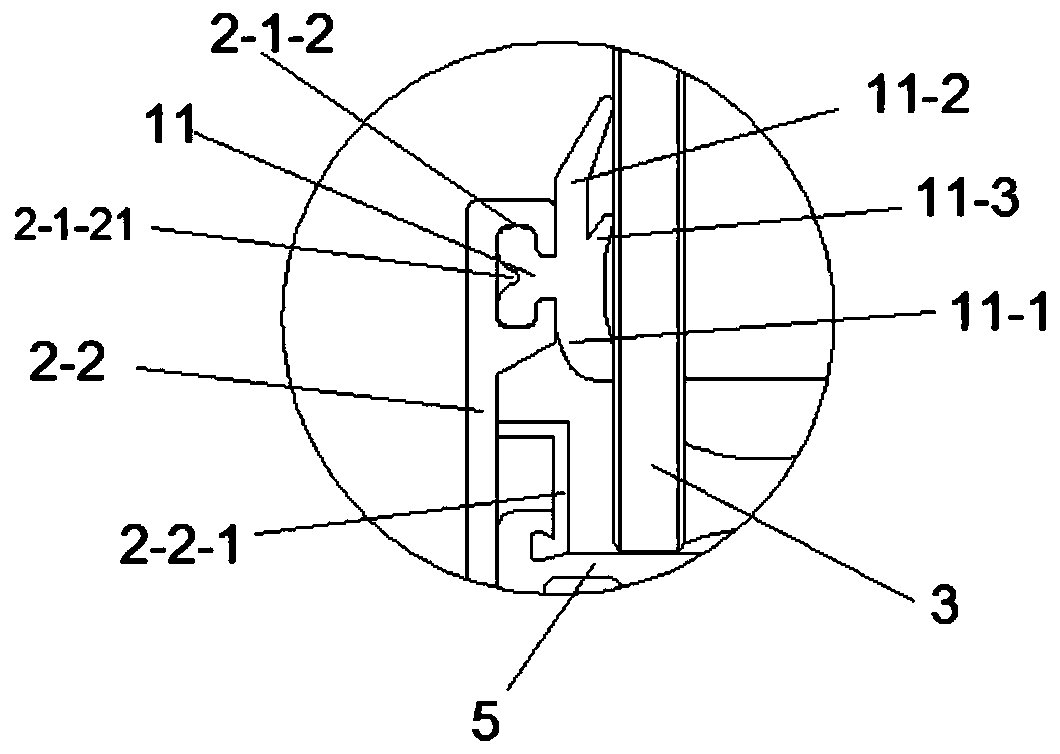

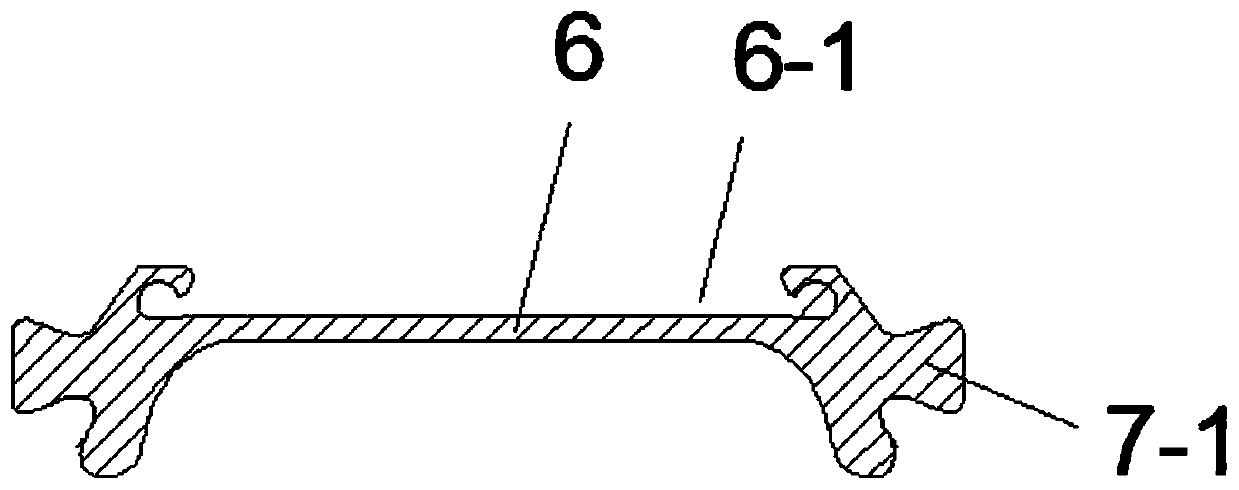

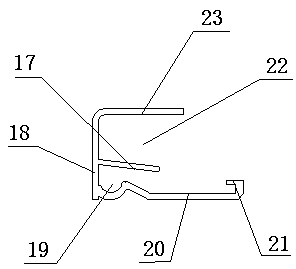

Energy-saving type efficient insulating aluminum alloy door-window unit

InactiveCN111472648AGuaranteed airtightGuaranteed compactWindow/door framesSealing arrangementsSash windowEngineering

The invention provides an energy-saving type efficient insulating aluminum alloy door-window unit. The energy-saving type efficient insulating aluminum alloy door-window unit comprises a window frameprofile, a window sash profile, glass, a trim strip and a glass insulating strip; an inner frame profile and an outer frame profile are connected through a window frame inner insulating strip and a window frame outer insulating strip; an inner sash profile and an outer sash profile are connected through a window sash inner insulating strip and a window sash outer insulating strip; a clearance sealing strip is arranged on the top side of the window frame profile; the bottom end of the trim strip and the outer sash profile clamp and fix the glass, adhesive tape fixing grooves are formed in one side of the top end of the inner sash profile and one side of the top end of the trim strip, adhesive tapes are embedded and fixed into the adhesive tape fixing grooves, and the glass is sealed with the outer sash profile and the trim strip through the adhesive tapes; and the glass insulating strip is arranged at the top end of the outer sash profile and located on the bottom side of the glass, andthe glass insulating strip is fixed with the outer sash profile. The aluminum alloy door-window unit has high insulating performance, good insulating effect and excellent energy-saving effect.

Owner:扬州市新亚铝业科技有限公司

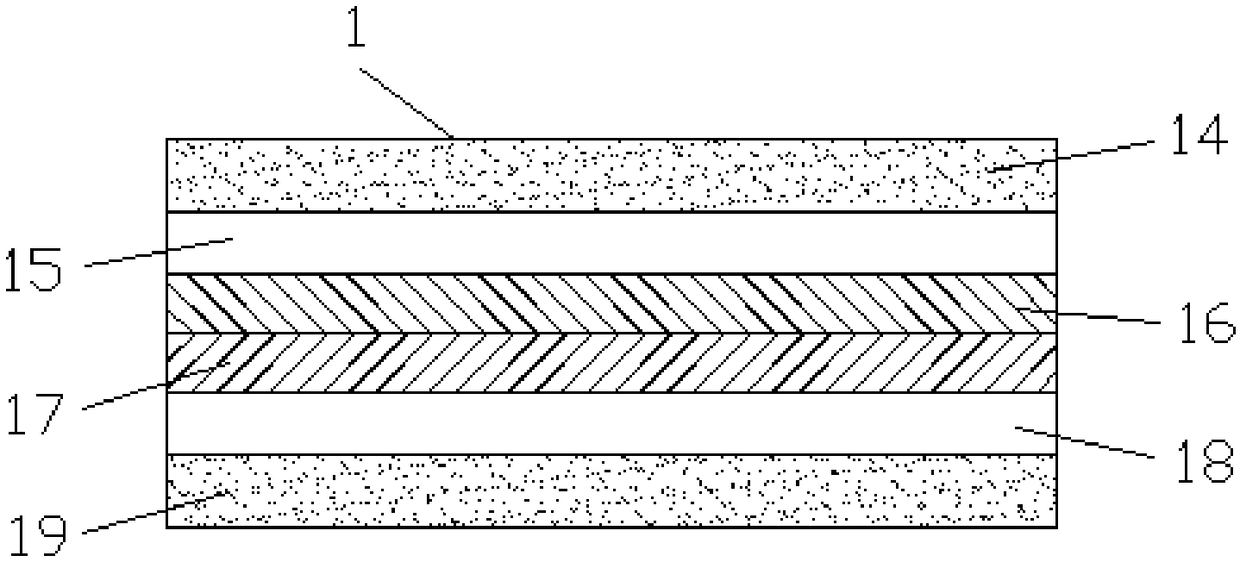

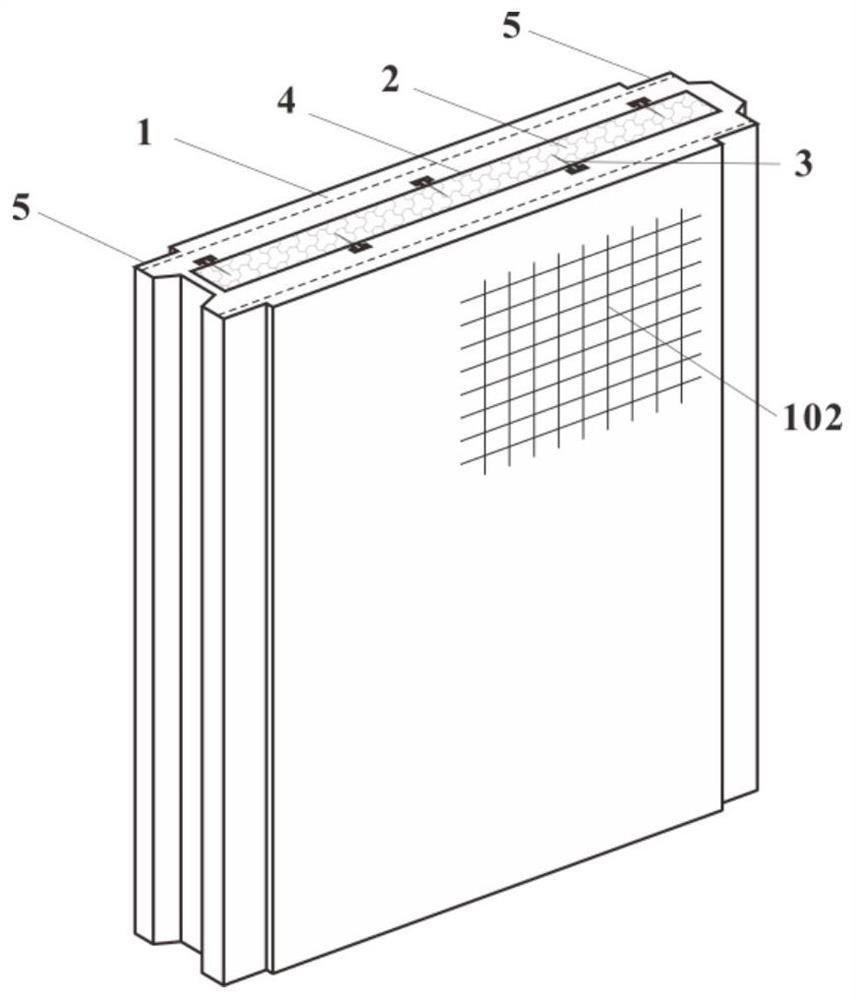

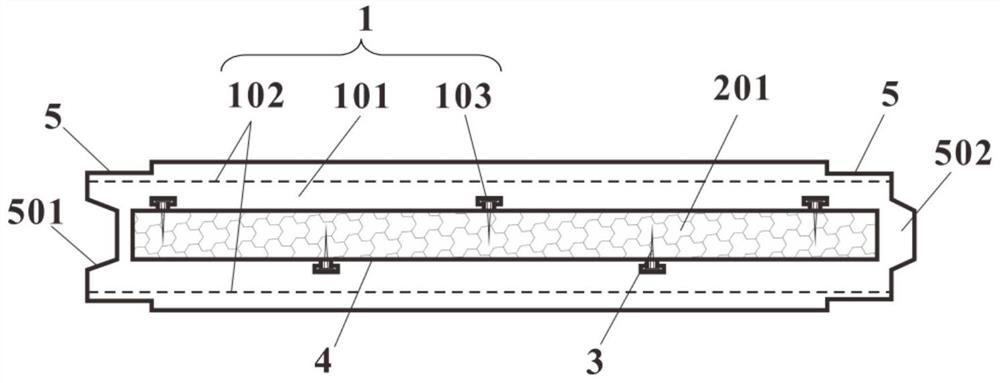

Prefabricated fireproof thermal insulation partition board and assembling method thereof

InactiveCN113356467AImprove thermal insulation performanceHigh tensile strengthWallsHeat proofingFiberglass meshGlass fiber

The invention discloses a prefabricated fireproof thermal insulation partition board and an assembling method thereof. The prefabricated fireproof thermal insulation partition board comprises an outer side fireproof wall board and an inner side heat-preservation heat-insulation wall board, the outer side fireproof wall board is mainly made of high-strength foaming special cement and alkali-resistant glass fiber gridding cloth, and the inner side heat-preservation heat-insulation wall board is made of graphite molding polystyrene foam plastic boards. The outer side fireproof wall board and the inner side heat-preservation heat-insulation wall board are connected through self-tapping screws and a special binding agent. Through factory prefabrication production, the prefabricated fireproof thermal insulation partition board can achieve the purpose of integration of thermal insulation, fire prevention and decoration, overall strength is high, assembly method is simple, disassembly is convenient, fireproof thermal insulation performance is good, and the thermal resistance meets the national standard; through the on-site mechanical assembly construction process, assembly method is easy and convenient to operate, labor intensity can be reduced, operation cost is reduced, construction efficiency is improved, and construction quality is guaranteed.

Owner:青海平兴建设集团有限公司 +2

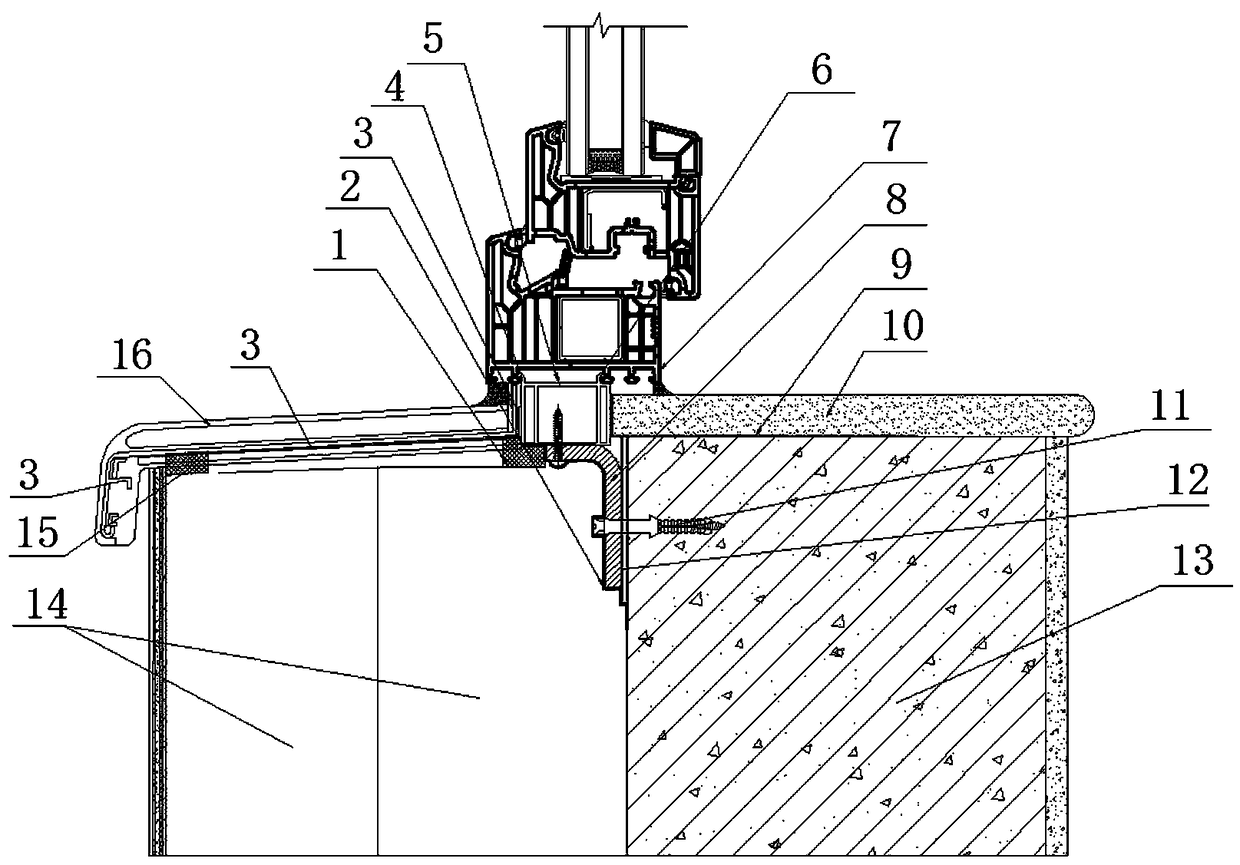

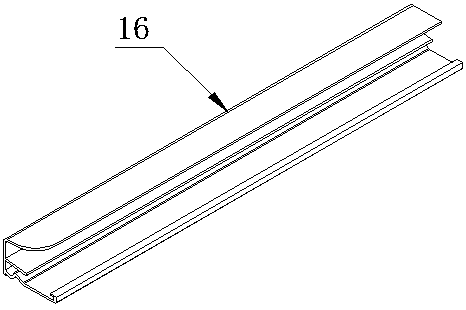

A window frame installation structure for passive house windows

ActiveCN106854960BImprove waterproof performanceReduce manual levelingFrame fasteningSills/thresholdThermal insulationGraphite

The invention discloses a passive window frame installation structure of house windows. The outer end surface of the wall body is fixed to a graphite polyphenyl support body. A vertical wall of an L-shape metal fixing plate is fixed to an upper part between the graphite polyphenyl support body and the outer end surface of the wall body. The upper end of a horizontal wall is fixed to a non-metal fixing block. A layer of waterproof breathable film is fixed between the non-metal fixing block and the graphite polyphenyl support body. A batch plate is abutted on the upper end of the graphite polyphenyl support body. The indoor side is fixed to the outer side wall of the non-metal fixing block. Pre-pressure expansion sealing belts are fixed between the indoor side lower end and the waterproof breathable film and the graphite polyphenyl support body. The outdoor side and the outer edge of the graphite polyphenyl plate are fixedly provided with pre-pressure expansion sealing belts. The upper end of the wall body is fixedly provided with an indoor windowsill plate. The window frame is buckled in two buckling hooks of the non-metal fixing block, and is fixed to the non-metal fixing block. The window using the passive window frame is not prone to generate cracks, and has good air tightness and water tightness, the leakage possibility is low, the thermal insulation property is strong, and the coefficient of heat transfer is low.

Owner:HEBEI ORIENT SUNDAR WINDOW

Environment-friendly building material

InactiveCN108715691AExtended service lifeImprove water absorptionEnvironmental resistanceThermal insulation

The invention discloses an environment-friendly building material. The environment-friendly building material is prepared by, by weight, 10-15 parts of rubber particles, 20-22 parts of coal ash, 8-10parts of quick lime, 10-12 parts of zirconium dioxide, 7-16 parts of xanthan gum, 18-25 parts of mint, 6-12 parts of fumaric acid diester, 5-8 parts of foam and the balance water. The building material is long in service life, green, environmentally friendly, high in water absorption, high in flame retardance, high in strength and high in thermal insulation performance.

Owner:HAO WEI ENVIRONMENTAL TECH NANTONG CO LTD

High-molecular polymer material for external wall thermal insulation

ActiveCN113860817AImprove insulation effectImprove stabilitySilicaSolid waste managementFiberPolymer science

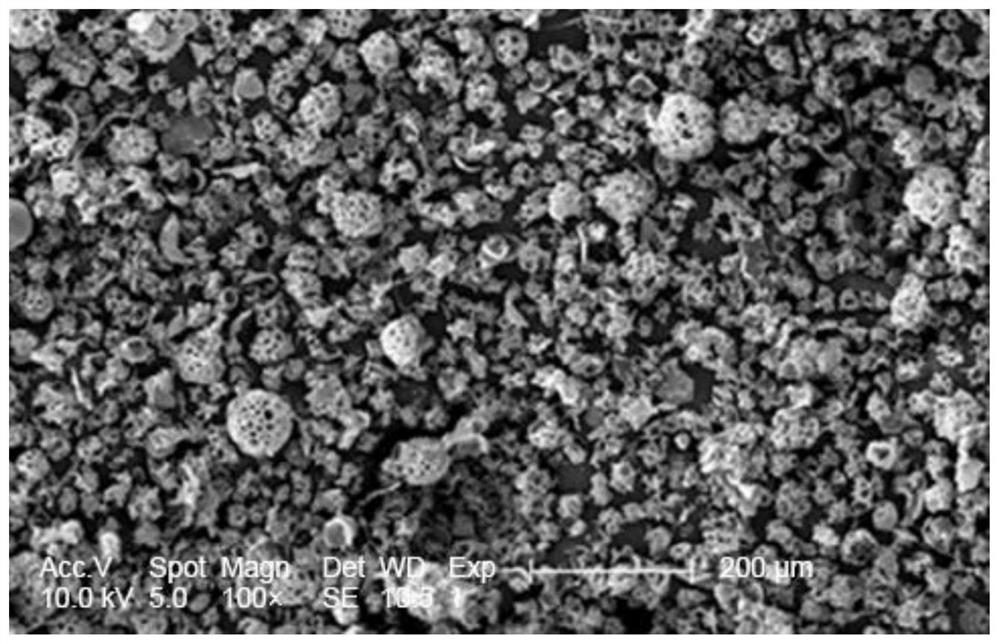

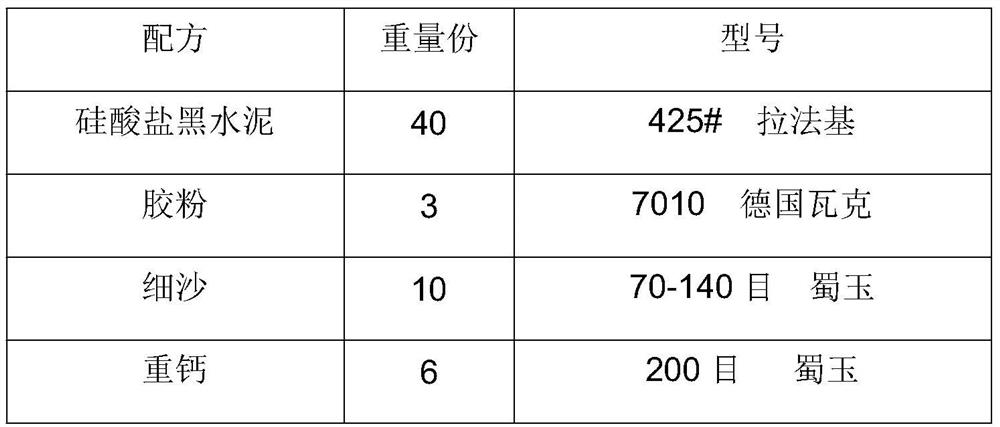

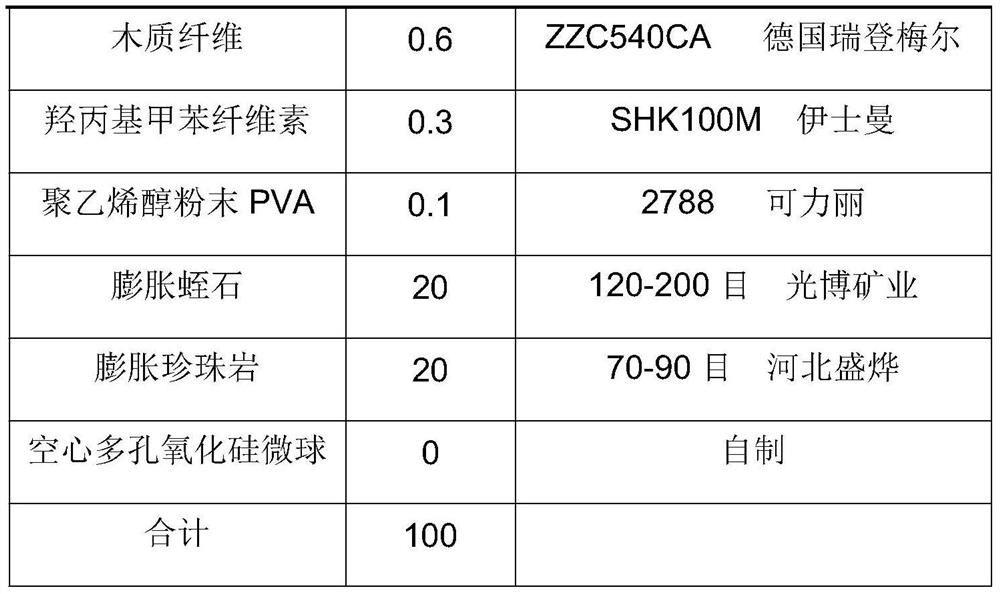

The invention discloses a high-molecular polymer material for external wall insulation. The material comprises the following components in percentage by weight: 30%-40% of black cement, 1%-3% of rubber powder, 5%-10% of fine sand, 5%-10% of ground calcium carbonate, 0.3%-0.8% of wood fiber, 0.3%-0.8% of hydroxypropyl methyl cellulose, 0.1%-0.3% of polyvinyl alcohol powder PVA, 10%-20% of expanded vermiculite, 10%-20% of expanded perlite and 10%-15% of hollow porous silicon oxide microspheres.

Owner:CHENGDU HONRE PAINT MAKING CO LTD

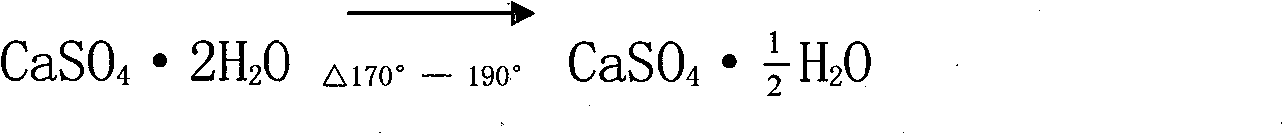

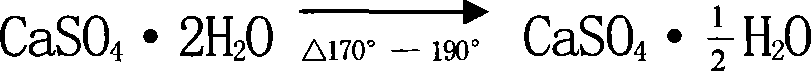

Method for continuously producing environment-protection light gypsum wall material by using industrial residue

InactiveCN101134345BGood weather resistanceStrong weather resistanceSolid waste managementMixing operation control apparatusSlagSlurry

The present invention discloses process of producing light wall material with industrial solid waste, carbon residue, fly ash, natural gypsum, lime, cement and small amount of chemical material in a continuous production line. The production process includes the following steps: washing ardealite, adding lime for neutralizing, mixing ardealite in 70 wt% and natural gypsum in 30 wt%, dewatering, air drying, calcining, grinding, ageing and other step to prepare beta type semi-hydrated gypsum powder; mixing semi-hydrated gypsum powder, phosphate slag or carbon residue, fly ash, cement and small amount of chemical material in certain weight proportion; adding water to form slurry and forming light wall block.

Owner:洪光

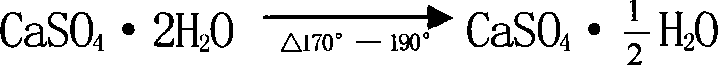

Preparation method of high-strength refractory brick

The invention discloses a preparation method of a high-strength refractory brick, comprising the steps of: mixing materials and agitating, preparing brick blanks, drying, sintering, and carrying out air-blast quenching and the like. Shale and soft sandstone are used for replacing traditional clay, so that damages to cultivated lands and vegetations cannot be caused, and the shale and the soft sandstone are sufficiently utilized to change waste into wealth; environment-friendly effect is achieved and the resource is saved; micro-silicon powder is added to enhance the microcosmic density beforewater is added to be agitated, and trace components including quick lime, enhanced fibers, binding agent and the like are added at the same time, so that the strength of brick blanks and finished bricks is greatly enhanced and the comprehensive mechanical property is greatly improved; suitable amount of calcium silicate is added to perform modification so that the obtained product has the advantages of high heat-resisting temperature (capable of reaching 1050 DEG C), strong heat-insulating performance, small volume weight, high specific strength and good durability; an air-blast quenching process is additionally arranged based on a traditional process, so that the inner stress for sintering the finished bricks is sufficiently eliminated, the brittleness is greatly reduced, and the breakage rate in the process of transporting or using is greatly reduced.

Owner:冯玉存

Thermal insulating coating and preparation method thereof

InactiveCN109181385AImprove insulation effectGood heat insulationFireproof paintsAntifouling/underwater paintsCarboxymethyl celluloseGlass fiber

The invention discloses a thermal insulating coating and a preparation method thereof and relates to the technical field of coatings. The coating comprises the following raw materials in parts by weight: 60-80 parts of organosilicone modified styrene-acrylic emulsion, 25-40 parts of modified nano glass fibers, 12-20 parts of carboxymethyl cellulose sodium, 8-14 parts of zirconia, 4-6 parts of pureiron powder, 8-12 parts of a cross-linking agent, 10-18 parts of additives, 3-9 parts of a film-forming agent, 4-10 parts of a fluorocarbon surfactant and 1-5 parts of dimethylhexylamine. The coatinghas very excellent thermal insulating property, heat-shielding performance as well as adhesive property and mechanical properties.

Owner:合肥久新不锈钢厨具有限公司

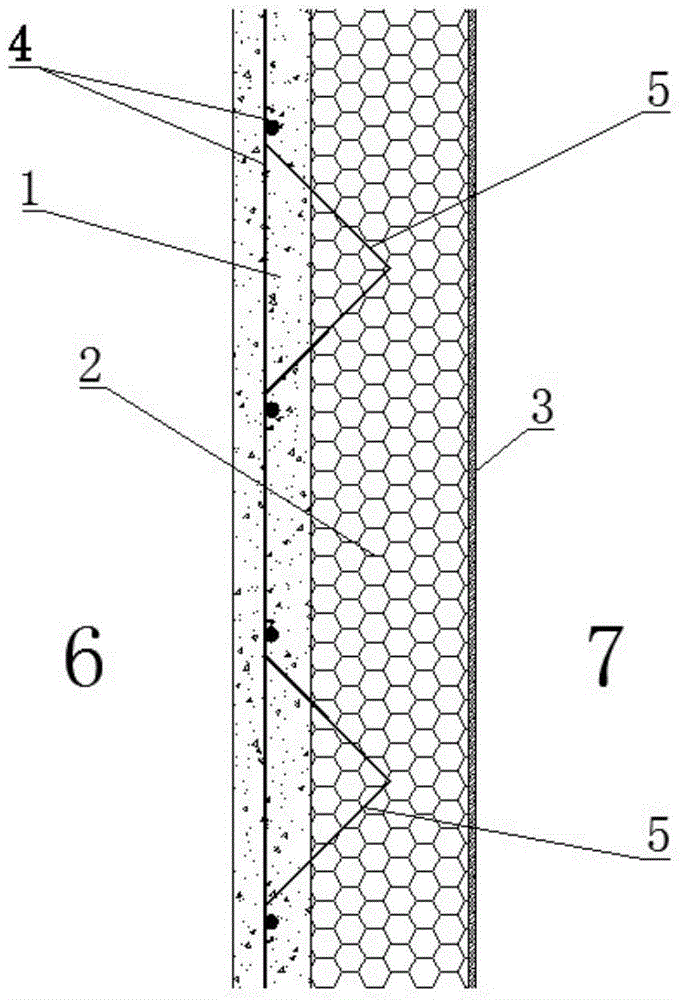

Sandwiched thermal-insulating wall and its production

InactiveCN101029508BExtended service lifeReduce pollutionCovering/liningsWallsReinforced concreteEngineering

This invention is a heating preservative wall and its construction method. The wall is composed in order by decorating layer, protective layer, heating preservative layer and base layer. The construction procedure is as: fabricate decorating layer frame and put molding plate around the frame; inject in protective layer into the frame; bolt fix heating preservative layer on the protective layer; concrete on the heating preservative layer; de-fabricate the molding plate and frame.

Owner:石雪

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com