Self control adjustable steel frame greenhouse

An adjustable, steel frame technology, applied in horticulture, greenhouse cultivation, climate change adaptation, etc., can solve the problems of increased labor intensity, poor thermal insulation, and many columns in the shed, so as to improve work efficiency and reduce labor intensity. , Good lighting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

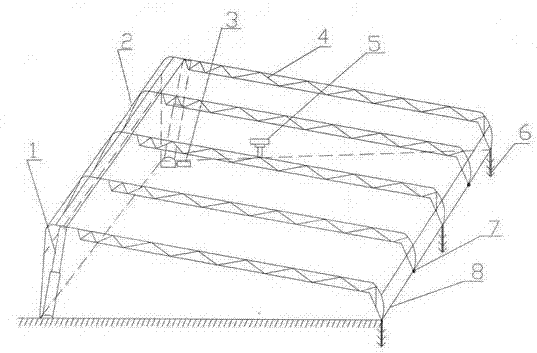

[0012] refer to figure 1 , the present invention includes a telescopic support 3, a steel frame 4, a hydraulic roof 1, a greenhouse, a solar ray tracer 5, a covering film, and an earth shaft 7, the steel frame 4 is installed on the telescopic support 3, and a covering film is provided above the telescopic support 3 , the solar ray tracker 5 is fixed on the steel frame 3, the outer side of the covering film, and the bottom of the telescopic support 3 is provided with a ground shaft 7, and the ground shaft 7 is inserted into the ground through the ground spear 6, and the telescopic support 3 is fixed on the ground. The bottom of the spear 6 is provided with a barb, and a hydraulic jack 1 is provided in the telescopic bracket 3, and one end of the hydraulic jack 1 is connected with the telescopic bracket 3, and the other end is connected with the hydraulic pump 2 through a shaft. Its working principle is: when a round of red sun is rising in the morning, we can turn on the power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com