Continuous vacuum drying roasting method for small crystal grain 5A molecular sieve

A technology of vacuum drying and molecular sieve, which is applied in the field of roasting and activation, and new drying, which can solve the problems of affecting the performance of the adsorbent, destroying the structure of the molecular sieve, and difficult temperature control, etc., and achieves the effect of excellent product quality, precise temperature control and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

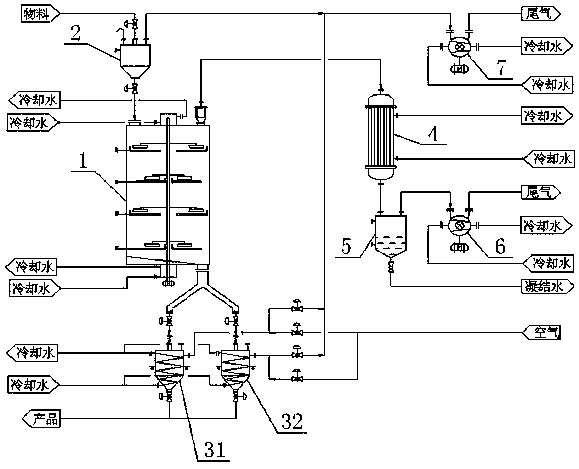

[0028] Such as figure 1 As shown, a method for continuous vacuum drying and roasting of small-grain 5A molecular sieves comprises the following steps:

[0029] (1) Open the self-control valve Ⅰ on the feed port Ⅰ of the feed tank 2, and close the self-control valve Ⅱ of the discharge port Ⅰ of the feed tank 2, and start filling the material 5A molecular sieve until the filling is completed;

[0030] (2) Start the vacuum pump II7, and vacuum the feed tank 2 through the exhaust port I, so that the vacuum degree is not less than -0.08MPa (G);

[0031] (3) Start the vacuum pump Ⅰ6 to evacuate the vertical disc rotary vacuum roasting furnace 1 to make the vacuum degree not less than -0.08MPa (G); at this time, open the automatic control valve Ⅱ of the discharge port Ⅰ of the feeding tank 2 to The 5A molecular sieve is sucked into the vertical disc rotary vacuum roaster 1;

[0032] The 5A molecular sieve enters the first-level heating section, which is the first heating zone. When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com