Aluminum alloy thermal insulation curtain wall and manufacturing process thereof

A technology of heat insulation and aluminum alloy, which is applied in the direction of walls, building structures, building components, etc., can solve the problems of poor heat insulation of glass curtain walls and high energy consumption of air conditioners, so as to enhance the effect of heat insulation and reduce heat transfer , The effect of reducing the heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

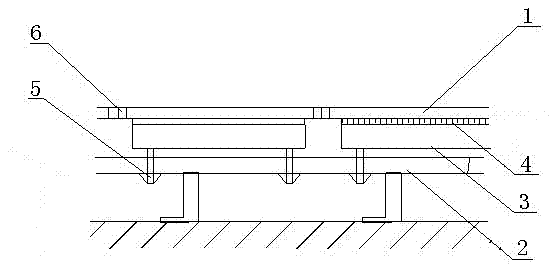

[0020] Describe technical scheme of the present invention in further detail below in conjunction with accompanying drawing: as figure 1 As shown, the aluminum alloy heat insulation curtain wall includes glass 1 and aluminum alloy sash system 2, the aluminum alloy sash system 2 is fixed on the surface of the building exterior wall, glass 1 is pasted on the glass frame 3 by structural glue 4 On the surface, the glass frame 3 is fixedly installed on the aluminum alloy sash system 2 through bolts 5, wherein the glass 1 is surrounded by rubber strips 6 for sealing and shock absorption.

[0021] The glass 1 is double-layer hollow coated glass.

[0022] The structural glue 4 is a silicone sealant.

[0023] The glass frame 3 is a honeycomb aluminum alloy heat-insulating broken bridge profile.

[0024] The rubber strip 6 is EPDM rubber.

[0025] The aluminum alloy thermal insulation curtain wall and its manufacturing process are characterized in that it includes the following steps:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com