A window frame installation structure for passive house windows

It is an installation structure and passive technology, which is applied in the direction of windows/doors, frame fixing, building components, etc. It can solve the problems of airtightness, watertightness deterioration, hole size deviation, and poor thermal insulation of windows, etc., to achieve good watertightness and reduce The effect of small broken bridge heat insulation and thermal insulation performance is strong

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

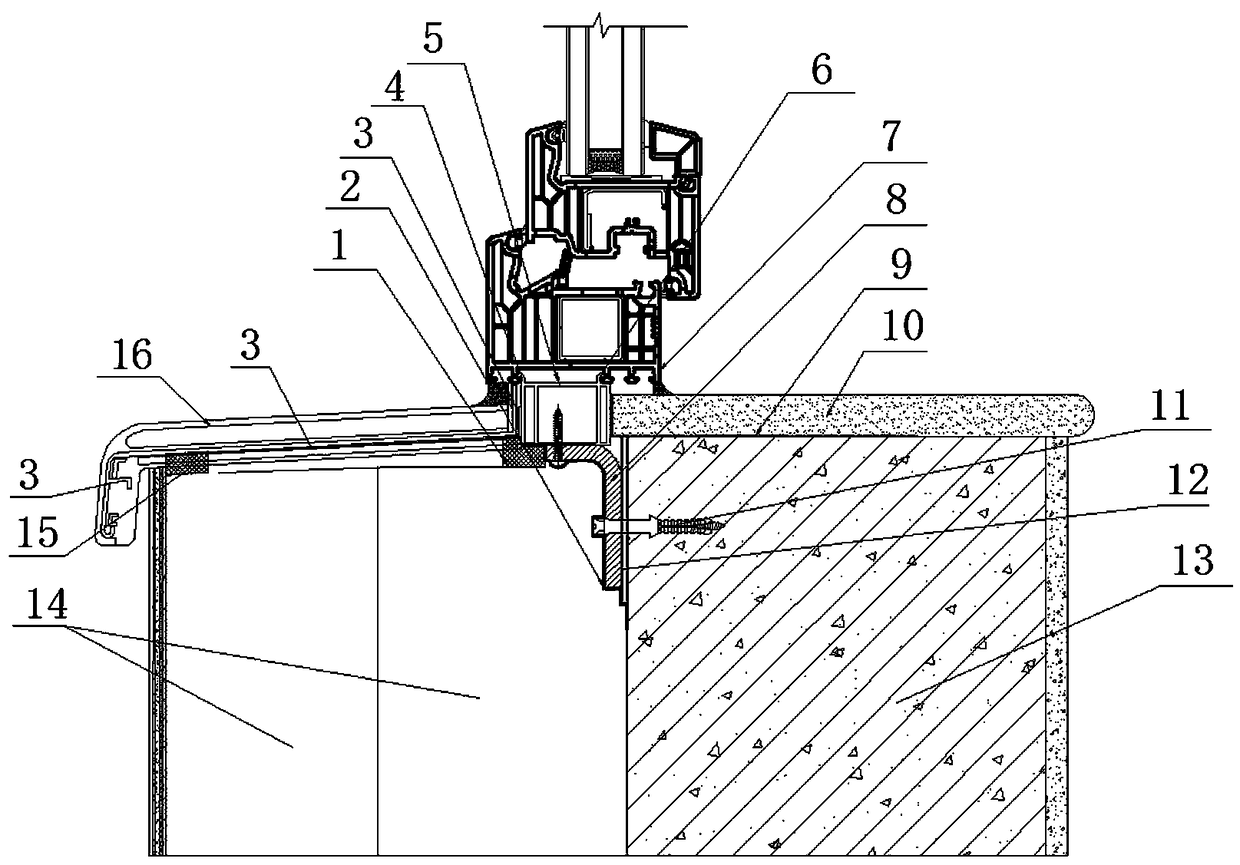

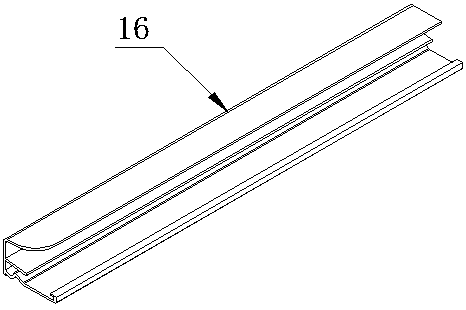

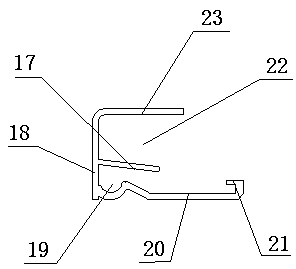

[0015] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, this embodiment includes a graphite polyphenylene support body 14, an L-shaped metal fixing plate 8, a non-metal fixing block 5, an indoor window sill plate 10, a waterproof and breathable membrane 2, a pre-compressed expansion sealing tape 1, 15, and a water draping plate 3 and two end plugs 16. Non-metallic fixed block 5 adopts materials such as PVC, nylon and fiberglass to make. The outer end surface of the wall body 13 at the reserved opening is fixed with a graphite polyphenylene support body 14 . The vertical wall of the L-shaped metal fixing plate 8 is clamped and fixed on the upper end between the graphite polyphenylene support body 14 and the outer end surface of the wall, and the upper end of its transverse wall is fixed on the non-metallic fixing block 5 by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com