Prefabricated building with good heat insulation performance

A prefabricated and heat-retaining technology, applied in heat preservation, construction, building components, etc., can solve the problems of poor transportation and storage, inability to achieve vertical fastening, and inability to fold and press down, so as to improve convenience and enhance Assembly efficiency, rapid construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

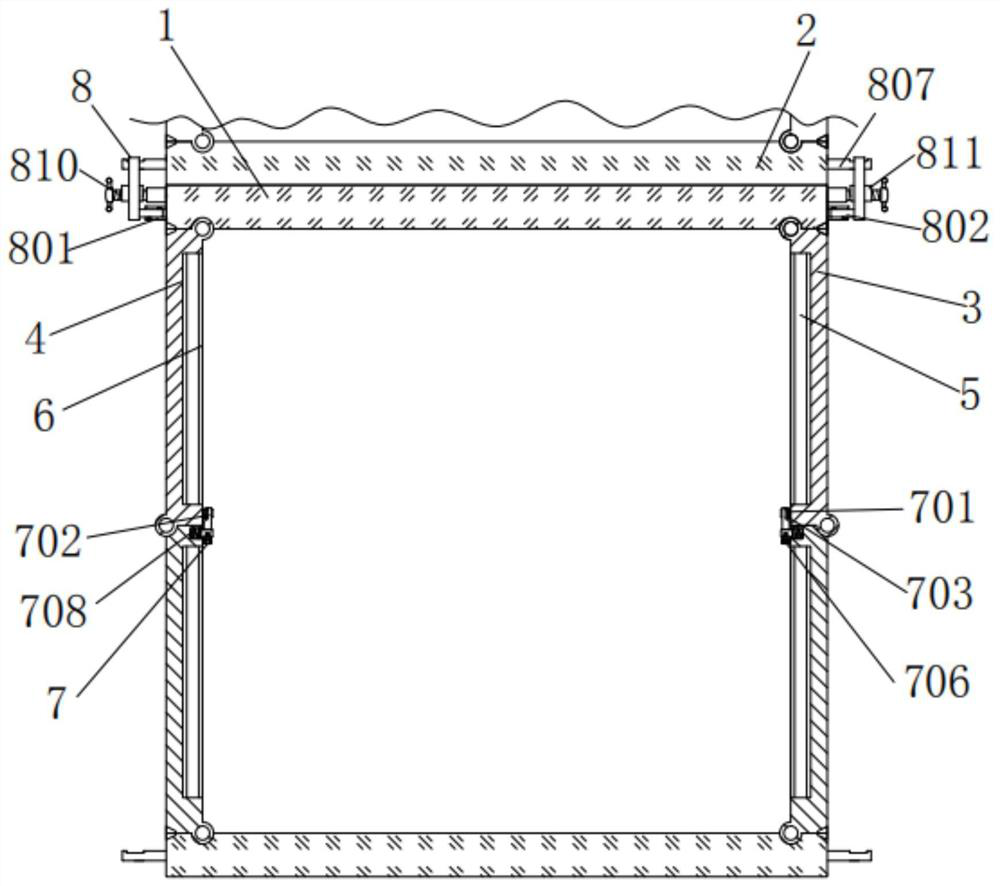

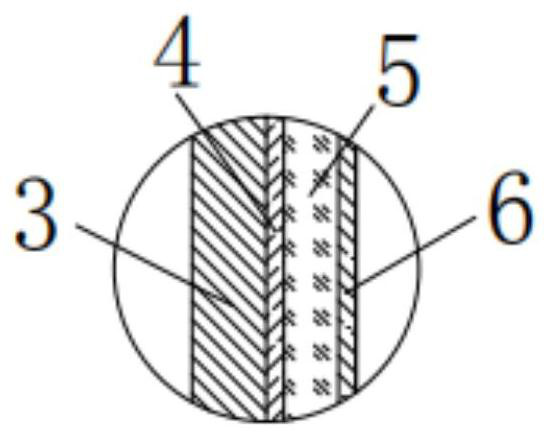

[0037] A prefabricated building with good thermal insulation, comprising a base plate 1, a top plate 2 is provided on the top of the base plate 1, and side plates 3 are rotationally connected to the inner and outer sides of the base plate 1 and the top plate 2, and the side plates 3 are arranged symmetrically both horizontally and vertically, so that The design allows the side panel 3 to be turned and folded inward, so that the top panel 1 and the bottom panel 2 can be stored and transported, and the inner ends of the side panels 3 on the same side are rotatably connected, and the inner end of the side panel 3 is coated with an adhesive layer 4 in the preset groove , the inner end of the adhesive layer 4 is pasted with a thermal insulation board 5, the inner end of the thermal insulation board 5 is fixedly connected with a decorative board 6, the decorative board 6 makes the inner end of the side board 3 more beautiful, and the inner end of the side board 3 is provided with a lo...

Embodiment 2

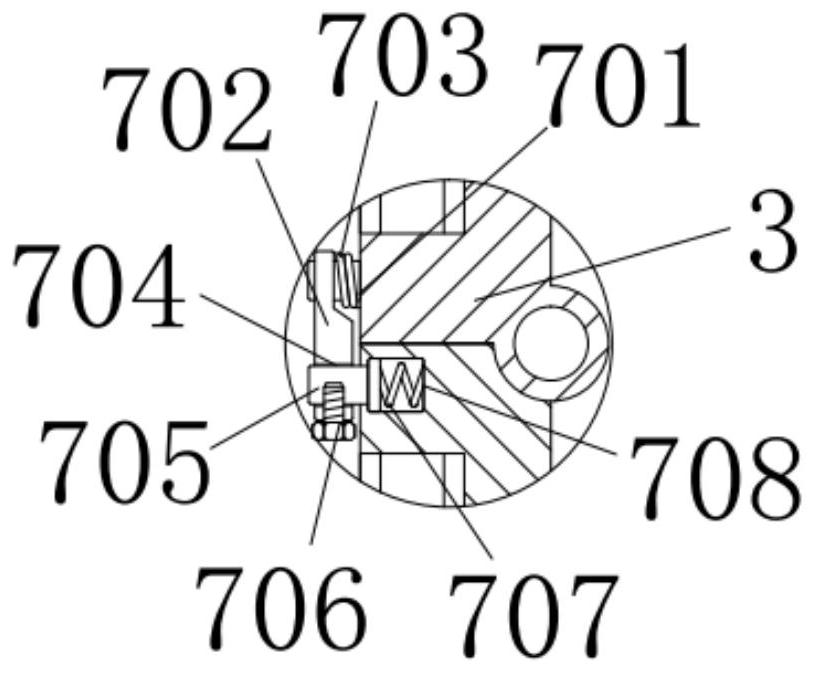

[0039] As an option, see figure 1 , 3 And 4, a prefabricated building with good thermal insulation, the clamping component 7 includes a round bar 701, a vertical bar 702, a torsion spring 703, a through hole 704, a clamping bar 705, a bolt 706, a transverse groove 707 and a compression spring 708, and the round bar 701 The outer end of the round bar 701 is fixedly connected to the inner end of the upper side plate 3, the outer wall of the round bar 701 is fixedly connected with a vertical bar 702, and the outer wall of the round bar 701 is sleeved with a torsion spring 703, and the torsion spring 703 gives the vertical bar 702 a horizontal force , the inner and outer ends of the torsion spring 703 are engaged with the vertical bar 702 and the upper side plate 3 respectively, and the inner lower part of the vertical bar 702 is fitted with a clamping rod 705 through the through hole 704. The position of the clamping rod 705 corresponds to the through hole 704 Set, design like t...

Embodiment 3

[0042] As an option, see figure 1 , 5And 6, a prefabricated building with good thermal insulation, the outside of the bottom plate 1 and the top plate 2 is provided with a connecting assembly 8, the connecting assembly 8 includes a sleeve 801, a cross bar 802, a slider 803, a chute 804, a curved bar 805, and a through groove 806, pole 807, groove 808, cylinder 809, screw rod 810 and cam 811, the inner end of sleeve 801 is fixedly connected with the outer end of top plate 2, and the inner wall gap of sleeve 801 is matched with cross bar 802, and cross bar 802 A slider 803 is fixedly connected above the outer wall of the slider 803, and the outer wall of the slider 803 cooperates with the inner wall of the sleeve 801 through the chute 804. The chute 804 is arranged in a spiral shape, so that the cross bar 802 can be screwed in and out when it is rotated, and the horizontal bar 802 can be screwed in and out. The outer end of the rod 801 is fixedly connected with a curved rod 805...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com