Method for continuously producing environment-protection light gypsum wall material by using industrial residue

A technology of industrial waste residue and wall materials, applied in chemical instruments and methods, manufacturing tools, solid waste management, etc., to achieve good weather resistance, strong corrosion resistance, and reduce energy consumption

Inactive Publication Date: 2010-12-01

洪光

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

So far, although there have been many methods for the comprehensive utilization of various industrial wastes, there have been no reports on the comprehensive use of more than several types of industrial waste residues and the large-scale production of gypsum lightweight wall materials by mechanized assembly lines.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Login to View More

Abstract

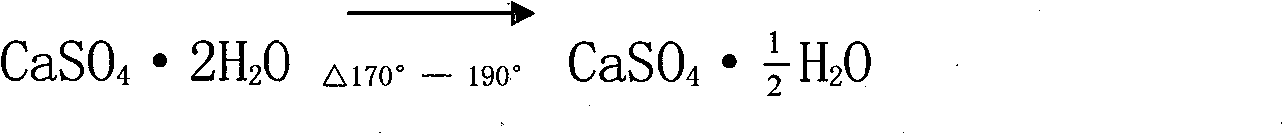

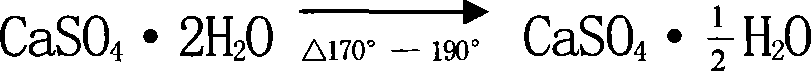

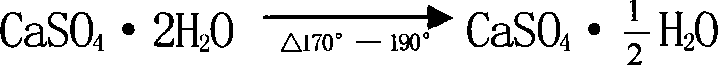

The present invention discloses process of producing light wall material with industrial solid waste, carbon residue, fly ash, natural gypsum, lime, cement and small amount of chemical material in a continuous production line. The production process includes the following steps: washing ardealite, adding lime for neutralizing, mixing ardealite in 70 wt% and natural gypsum in 30 wt%, dewatering, air drying, calcining, grinding, ageing and other step to prepare beta type semi-hydrated gypsum powder; mixing semi-hydrated gypsum powder, phosphate slag or carbon residue, fly ash, cement and small amount of chemical material in certain weight proportion; adding water to form slurry and forming light wall block.

Description

Method for continuously producing environment-friendly lightweight gypsum wall material by utilizing industrial waste residue technical field The invention relates to a new type of lightweight wall material, in particular to a large-scale production of a new type of light weight wall material by using various industrial waste residues, certain natural gypsum ore and trace chemical raw materials through mechanized production lines. It belongs to the field of building materials. Background technique At present, there is no large-scale application of phosphogypsum, and a large number of piles have been formed in many areas, while various other industrial wastes are also increasing. polluted environment. For this reason, people are also constantly exploring new methods and new ways to effectively utilize various industrial wastes. Although there have been many methods to comprehensively utilize various industrial wastes so far, there have been no reports on the comprehensive...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B28B15/00C04B28/14C04B11/02C04B11/26B28C7/04B28C5/08B28B3/12

CPCC04B2111/00017C04B2111/40C04B14/365C04B28/02Y02W30/91C04B18/145C04B22/148C04B40/0028C04B18/067C04B20/023

Inventor 洪光

Owner 洪光

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com