Thermal insulating coating and preparation method thereof

A thermal insulation and coating technology, which is applied in fireproof coatings, antifouling/underwater coatings, coatings, etc., can solve problems such as poor bonding performance and mechanical mechanical properties, and achieve excellent aging resistance, good weather resistance, Effect of increasing mechanical properties and electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

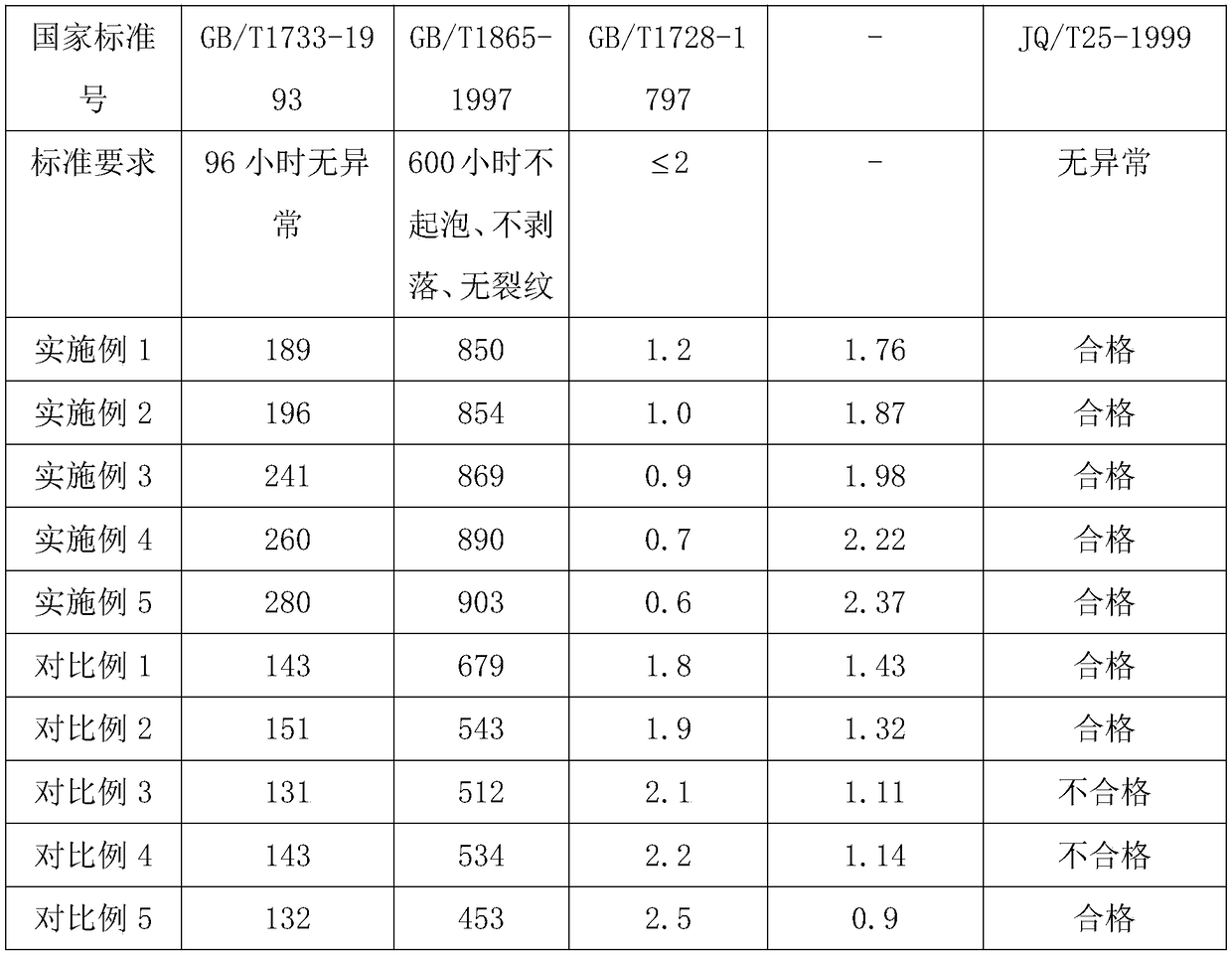

Embodiment 1

[0026] This embodiment relates to a thermal insulation coating, including the following raw materials in parts by weight: 60 parts of silicone modified styrene-acrylic emulsion, 25 parts of modified nano glass fiber, 12 parts of sodium hydroxymethyl cellulose, 8 parts of zirconia, 4 parts of pure iron powder, 8 parts of crosslinking agent, 10 parts of auxiliary agent, 3 parts of film forming agent, 4 parts of fluorocarbon surfactant, and 1 part of dimethylhexylamine.

[0027] Wherein, the preparation method of the silicone-modified styrene-acrylic emulsion is: add vinyltriethoxysilane and emulsifier into the reactor according to the mass ratio of 3:1, stir evenly to obtain material A, and raise the temperature to 45 ℃, add 1 times of styrene-acrylic emulsion by weight of material A and vinyl acetate solution of 30% by weight of styrene-acrylic emulsion, stir for 40 minutes at a speed of 160r / min, then add 10% bentonite by weight of styrene-acrylic emulsion, 6 % of propylene gl...

Embodiment 2

[0036] This embodiment relates to a thermal insulation coating, including the following raw materials in parts by weight: 80 parts of silicone modified styrene-acrylic emulsion, 40 parts of modified nano glass fiber, 20 parts of sodium hydroxymethyl cellulose, 14 parts of zirconia, 6 parts of pure iron powder, 12 parts of crosslinking agent, 18 parts of auxiliary agent, 9 parts of film forming agent, 10 parts of fluorocarbon surfactant, and 5 parts of dimethylhexylamine.

[0037] Wherein, the preparation method of the silicone-modified styrene-acrylic emulsion is: add vinyltriethoxysilane and emulsifier into the reactor according to the mass ratio of 3:1, stir evenly to obtain material A, and raise the temperature to 50 ℃, then add 2 times of styrene-acrylic emulsion by weight of material A and vinyl acetate solution of 40% by weight of styrene-acrylic emulsion, stir for 60 minutes at a speed of 240r / min, then add bentonite, 6% by weight of styrene-acrylic emulsion % propylene g...

Embodiment 3

[0046] This embodiment relates to a thermal insulation coating, including the following raw materials in parts by weight: 62 parts of silicone modified styrene-acrylic emulsion, 27 parts of modified nano glass fiber, 14 parts of sodium hydroxymethyl cellulose, 10 parts of zirconia, 4.2 parts of pure iron powder, 9 parts of crosslinking agent, 12 parts of auxiliary agent, 5 parts of film forming agent, 6 parts of fluorocarbon surfactant, and 2 parts of dimethylhexylamine.

[0047] Wherein, the preparation method of the silicone-modified styrene-acrylic emulsion is: add vinyltriethoxysilane and emulsifier into the reactor according to the mass ratio of 3:1, stir evenly to obtain material A, and raise the temperature to 45 ℃, add 1 times of styrene-acrylic emulsion by weight of material A and vinyl acetate solution of 30% by weight of styrene-acrylic emulsion, stir for 40 minutes at a speed of 160r / min, then add 10% bentonite by weight of styrene-acrylic emulsion, 6 % of propylen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com