Preparation method of high-strength refractory brick

A refractory brick and high-strength technology, applied in the field of building materials preparation, can solve the problems of inability to meet the requirements of high-performance bricks, poor refractory and thermal insulation performance, high brittleness, etc., and achieve shortened sintering time, strong thermal insulation performance, and reduced brittleness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

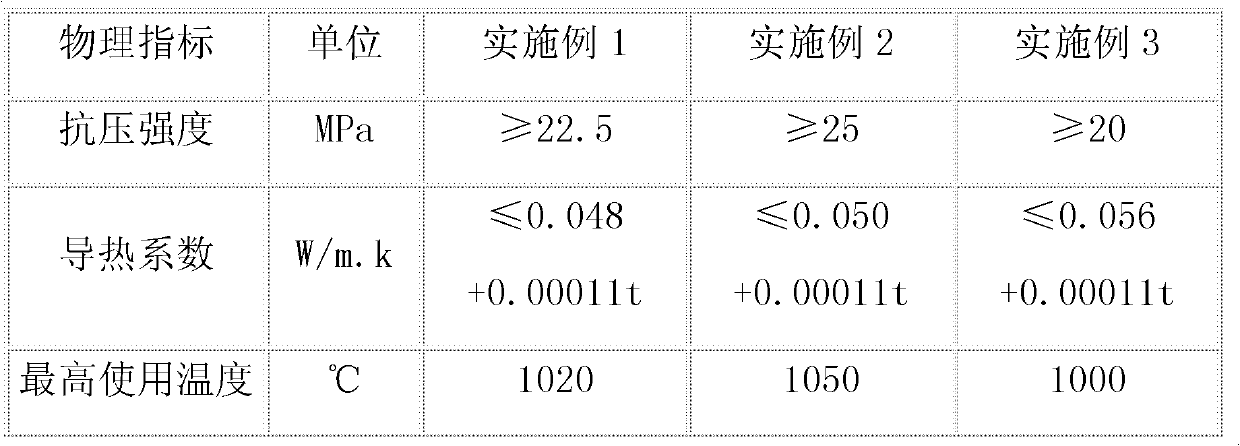

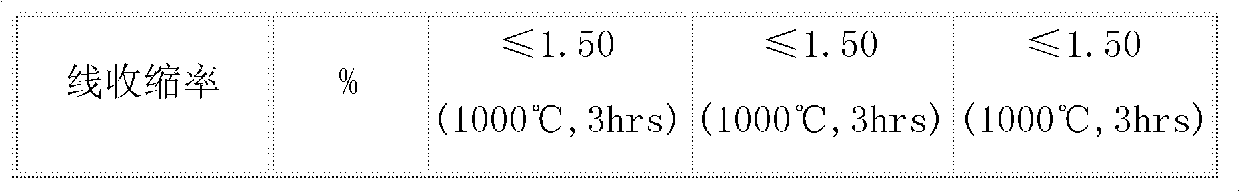

Embodiment 1

[0022] The preparation method of the high-strength refractory brick of the present embodiment may further comprise the steps:

[0023] a, mixing and stirring: by weight, take 55 parts of shale, 20 parts of sandstone, 5 parts of coal gangue, 1.2 parts of micro-silica fume, 1 part of quicklime, 5 parts of calcium silicate, 2 parts of reinforcing fiber, and 5 parts of binder (wherein: 4.0 parts of phenolic resin, 1.0 part of modified asphalt), pulverize the raw materials of each component until the fineness is less than or equal to 0.25 mm, fully mix them with a mixer, then add 15 parts of water by weight and continue to stir for 20 minutes;

[0024] b, preparing adobe: import the mixture made in a into a brick making machine to extrude mud strips to make adobe;

[0025] c, drying: put the adobe made in b into a 70°C oven and bake for 6 hours;

[0026] d, sintering: put the adobe dried in c into a brick kiln for sintering, the sintering temperature is 950°C, the sintering time i...

Embodiment 2

[0029] The preparation method of the high-strength refractory brick of the present embodiment may further comprise the steps:

[0030] a, mixing and stirring: in step a, take 60 parts of shale, 15 parts of arsenic sandstone, 7.5 parts of coal gangue, 1.2 parts of silica fume, 1.2 parts of quicklime, 4 parts of calcium silicate, and 2.5 parts of reinforcing fiber in parts by weight , 4.5 parts of binder (among them: 3.6 parts of phenolic resin, 0.9 part of modified asphalt); grind the raw materials of each component until the fineness is less than or equal to 0.25mm, and then fully mix them evenly with a mixer, then add 15 parts of water by weight and continue stirring for 20 minute;

[0031] b, preparing adobe: import the mixture made in a into a brick making machine to extrude mud strips to make adobe;

[0032] c, drying: put the adobe made in b into a 70°C oven and bake for 6 hours;

[0033] d, sintering: put the adobe dried in c into a brick kiln for sintering, the sinter...

Embodiment 3

[0036] The preparation method of the high-strength refractory brick of the present embodiment may further comprise the steps:

[0037] a, mixing and stirring: 60 parts by weight of shale, 15 parts of sandstone, 10 parts of coal gangue, 1 part of microsilica, 1.2 parts of quicklime, 3 parts of calcium silicate, 3 parts of reinforcing fiber, and 4.8 parts of binder (wherein: 3.84 parts of phenolic resin, 0.66 parts of modified asphalt), pulverize the raw materials of each component until the fineness is less than or equal to 0.25 mm, fully mix them with a mixer, then add 20 parts of water by weight and continue to stir for 15 minutes;

[0038] b, preparing adobe: import the mixture made in a into a brick making machine to extrude mud strips to make adobe;

[0039] c, drying: put the adobe made in b into an oven at 80°C and bake for 5 hours;

[0040] d, sintering: put the adobe dried in c into a brick kiln for sintering, the sintering temperature is 1050°C, the sintering time is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com