Prefabricated wallboard of multifunctional green building

A green building and prefabricated wall panel technology, applied in the field of prefabricated wall panels, can solve problems such as mechanical defects, unfavorable sustainable development of green buildings, and thermal insulation performance of the insulation layer, so as to achieve simple and convenient construction process and sustainable development , Strong thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

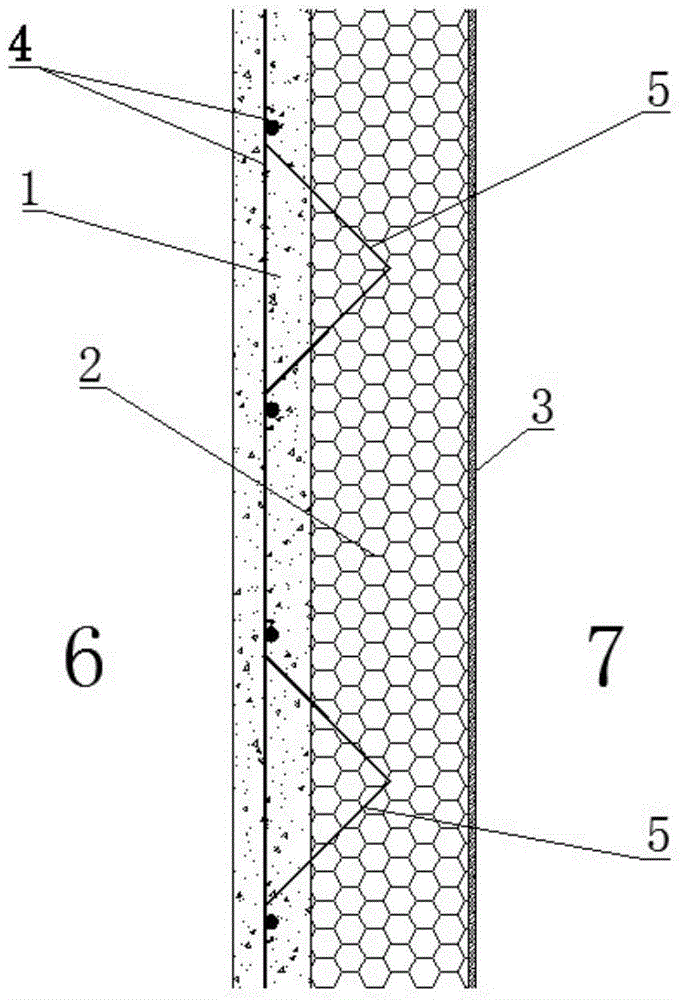

[0025] like figure 1 As shown, a multifunctional green building prefabricated wall panel includes a reinforced concrete layer 1 on the indoor side, a calcium silicate board layer 3 on the outdoor side, and a reinforced concrete layer 1 and the calcium silicate board layer 3 between the silicate board layers 3 Polystyrene particle layer 2. In the reinforced concrete layer 1, two layers of crisscrossing steel bars 4 are arranged to form a mesh reinforcement structure, and the steel bars are cold-rolled and ribbed CRB550 grade steel bars. Therefore, the wall panel of the present invention is greatly improved in durability and strength. The tensile strength of the steel bar 4 in the reinforced concrete layer 1 and the compression resistance of the calcium silicate board layer 3 form an effective internal bending moment to resist external loads. The concrete layer as well as the mesh reinforcement resist accidental impact loads, and the calcium silicate slabs enhance their corrosi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com