High-molecular polymer material for external wall thermal insulation

A high molecular polymer and external wall thermal insulation technology, which is applied in the field of external wall thermal insulation, can solve problems such as shedding, increased falling accidents, and large casualties, and achieves the effects of strong stability, good thermal insulation performance, and strong thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

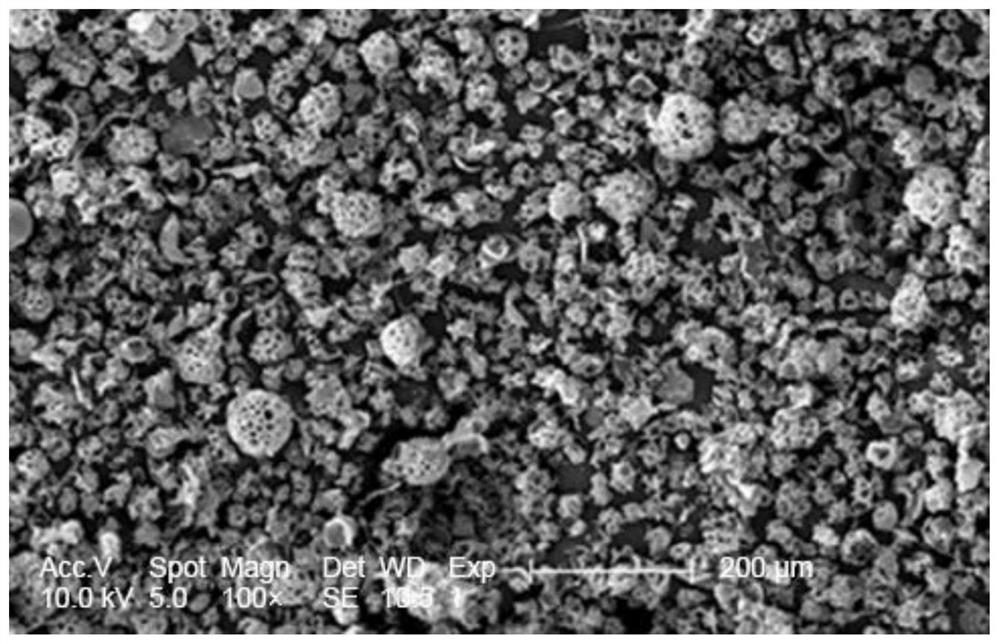

Image

Examples

Embodiment 1

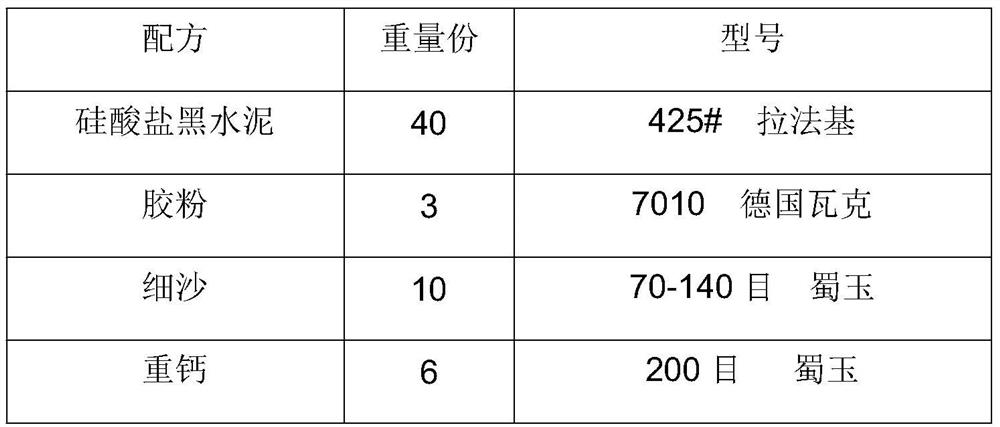

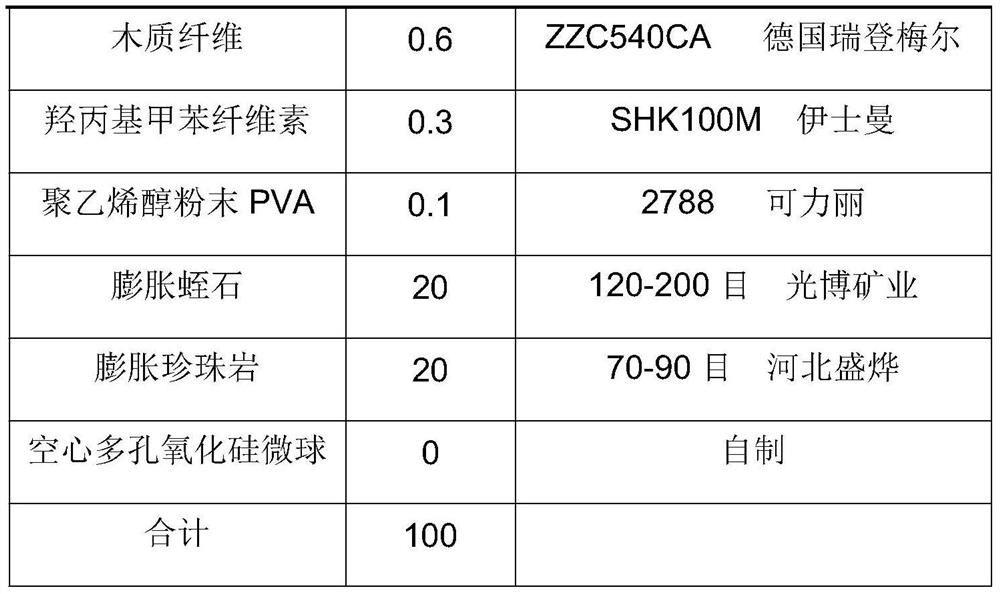

[0025]

[0026]

[0027] Adopt above raw material, prepare high molecular polymer material as follows:

[0028] 1. Mix Portland black cement, rubber powder, fine sand, heavy calcium, wood fiber, hydroxypropyl toluene cellulose, and polyvinyl alcohol powder PVA together, and stir evenly;

[0029] 2. Add expanded vermiculite and expanded perlite, and stir evenly.

Embodiment 2

[0031]

[0032]

[0033] Adopt above raw material, prepare high molecular polymer material as follows:

[0034] 1. Mix Portland black cement, rubber powder, fine sand, heavy calcium, wood fiber, hydroxypropyl toluene cellulose, and polyvinyl alcohol powder PVA together, and stir evenly;

[0035] 2. Add expanded vermiculite and expanded perlite, and stir evenly.

Embodiment 3

[0037] formula parts by weight model Portland black cement 35 425# Lafarge rubber powder 2.6 7010 Wacker Germany fine sand 5 70-140 mesh Shu jade heavy calcium 16 200 mesh Shu jade wood fiber 0.3 ZZC540CA German Ruidenmeier Hydroxypropyl Toluene Cellulose 0.8 SHK100M Eastman Polyvinyl alcohol powder PVA 0.3 2788 Ke Lili Expanded Vermiculite 15 120-200 eyeball mining expanded perlite 15 70-90 mesh Hebei Shengye Hollow Porous Silica Microspheres 10 self made total 100

[0038] Adopt above raw material, prepare high molecular polymer material as follows:

[0039] 1. Mix Portland black cement, rubber powder, fine sand, heavy calcium, wood fiber, hydroxypropyl toluene cellulose, and polyvinyl alcohol powder PVA together, and stir evenly;

[0040] 2. Add expanded vermiculite and expanded perlite, and stir evenly;

[0041] 3. Add hollow porous silica microspheres and stir evenly....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com