Double-phase temperature control type protective sleeve for electronic element

A technology for electronic components and protective sleeves, which is applied in the field of dual-phase temperature-controlled protective sleeves for electronic components, which can solve problems such as hindering heat dissipation of electronic components and damage to electronic components, so as to reduce the impact on electronic components, improve practicability, and avoid damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

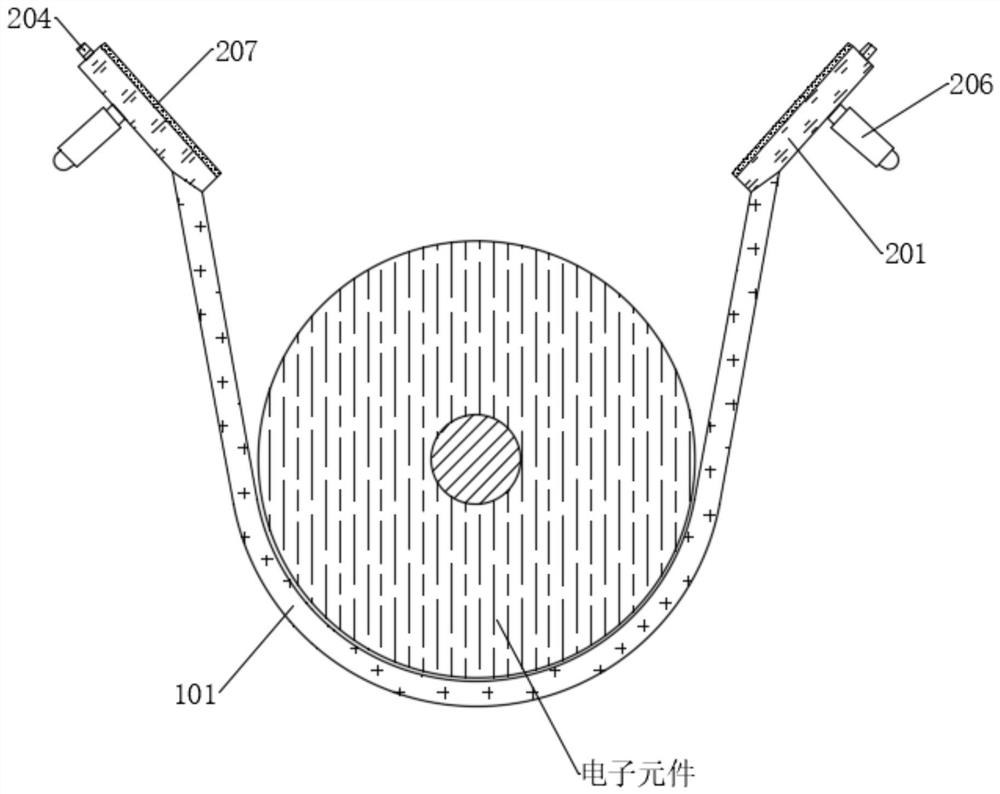

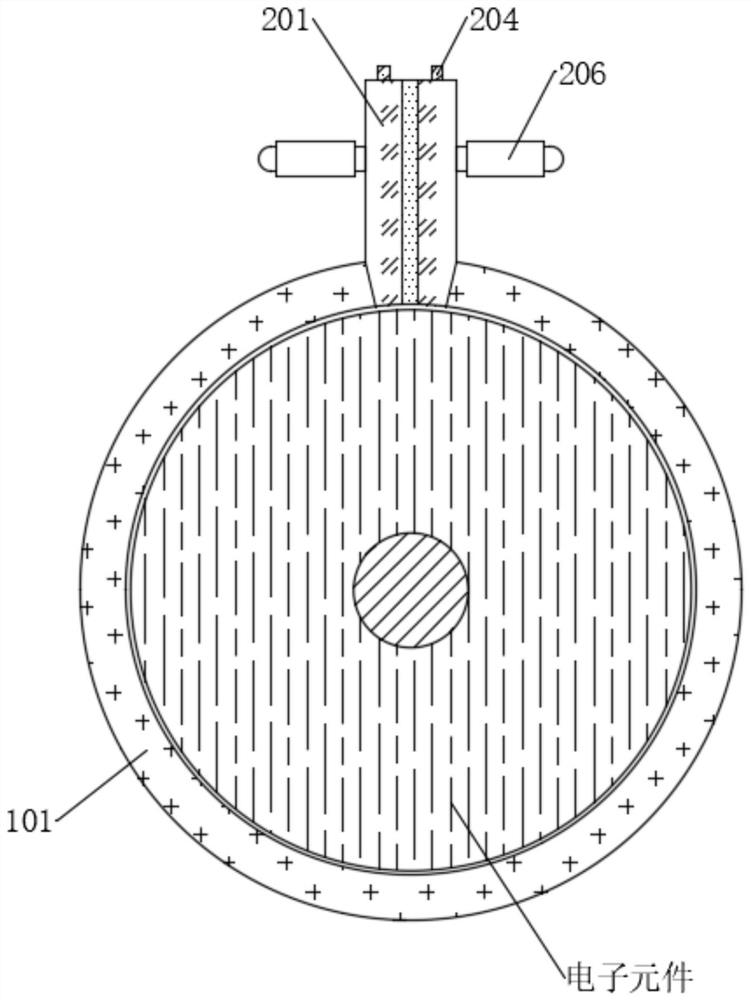

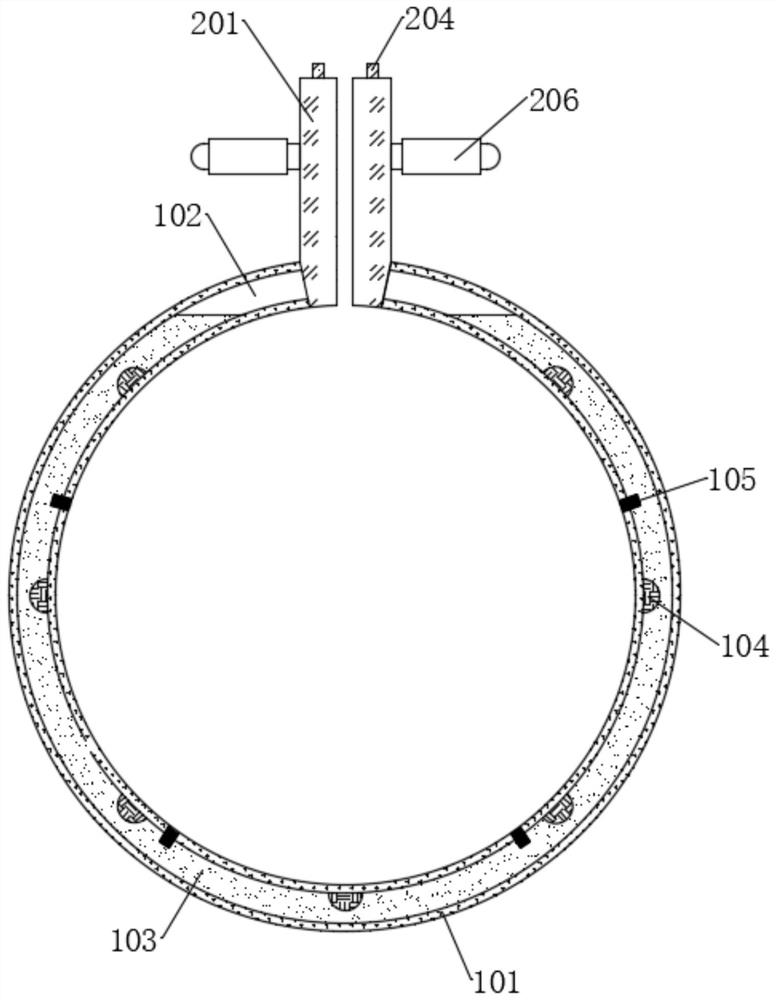

[0043] see Figure 1-7 , a dual-phase temperature-control protective cover for electronic components, including a flexible thermal insulation cover 101, both ends of the flexible thermal insulation cover 101 are fixedly connected with thermal insulation connection terminals 201, and a sealed annular cavity 102 is opened in the flexible thermal insulation cover 101 , the annular cavity 102 is filled with a phase change temperature control body 103, and the inner wall of the flexible insulation cover 101 is inlaid with a plurality of heat conduction blocks 105, and the heat conduction blocks 105 penetrate the outer wall of the flexible insulation cover 101 and extend into the phase change temperature control body 103 Among them, the phase change temperature control body 103 is made of powdery phase change heat storage material. When the electronic components generate a lot of heat due to work, the heat conduction block 105 can conduct the heat on the electronic components to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com