Vertical vacuum-tight "dry-calcination" method for px spherical adsorbents

An adsorbent, airtight technology, applied in the field of vertical vacuum airtight "drying-roasting", can solve the problems of harsh temperature and residence time, affecting the adsorption strength and adsorption capacity of the adsorbent, and achieve the improvement of adsorption strength and adsorption capacity, Prevent the leakage of high-temperature powder and high-temperature gas, and the effect of excellent product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

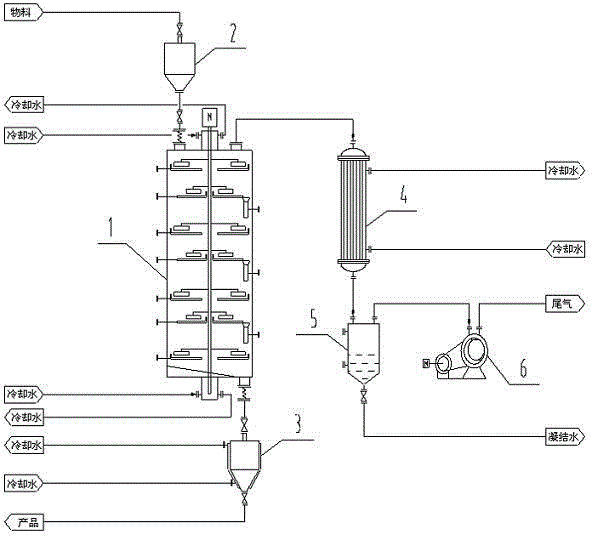

[0025] Such as figure 1 As shown, the vertical vacuum-tight "drying-roasting" method for PX spherical adsorbent includes the following steps:

[0026] (1) At room temperature, after the feed tank 2 is filled with materials, close the inlet and outlet valves, turn on the vacuum pump 6 in the vertical vacuum-sealed "drying-roasting" system, and vacuum the vertical disc rotary vacuum roasting furnace 1 to make it Vacuum to 0.09MPa; then open the outlet valve of the feed tank 2 under this vacuum condition, and suck the PX spherical adsorbent to be dried and roasted into the vertical disc rotary vacuum roaster 1 .

[0027] in:

[0028] The vertical vacuum-sealed "drying-roasting" system includes a vertical disc rotary vacuum roasting furnace 1, a feeding tank 2, a product silo 3, and a vacuum pump 6. The top of the feed tank 2 is provided with a feed inlet with a feed valve, and its bottom is provided with a discharge port I with an outlet valve, which is connected to the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com