Composite self-insulation concrete block and production method thereof

A technology for a concrete block and a production method, applied in the field of concrete, can solve problems such as poor thermal insulation performance, and achieve the effects of strong thermal insulation performance and improved thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

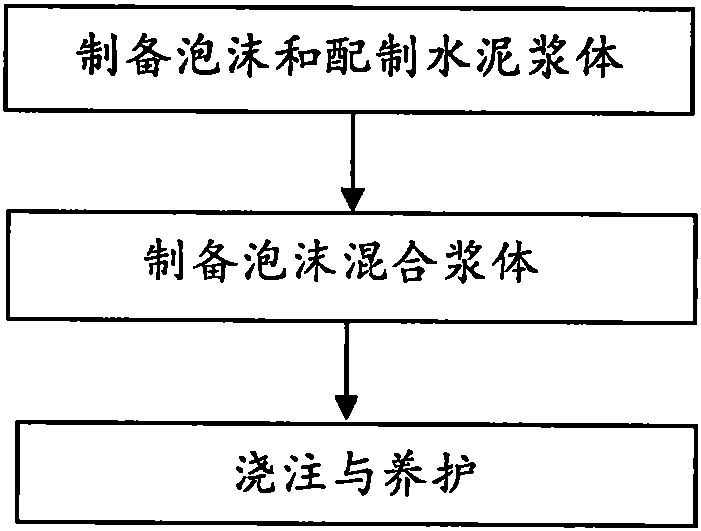

[0042] Step 1, preparation of foam and preparation of cement slurry:

[0043] Foam preparation: measure the foaming agent before making foam, add water to dilute according to the specified ratio, make an aqueous solution, and then add it to the foaming machine to make uniform and stable foam;

[0044] Preparation of cement paste: The composition of cement paste and the mass ratio of each component are cement: water: admixture = 1: 0.2-0.4: 0.015-0.04, and the cement, water and admixture are added to the mixer according to the proportion and stirred Uniformly, get cement slurry;

[0045] Step 2, preparation of foam mixed slurry:

[0046] Add the cement slurry prepared in step 1 and the prepared foam into the mixer according to the volume ratio of 1:4-8, and stir until the foam and the cement slurry are evenly mixed to form a foam mixed slurry;

[0047] Step 3, pouring and curing:

[0048] The foam mixed slurry prepared in step 2 is poured into the cavity of the concrete holl...

Embodiment 1

[0093] A composite self-insulating concrete block with a dry bulk density of 1000-1200kg / m 3 The concrete hollow block and the dry bulk density in its cavity are 300-500kg / m 3 The inner filling core material composition, wherein the inner filling core material is low-density foam concrete, the raw material composition of this low-density foam concrete includes cement slurry and foam foam, and the volume ratio between cement slurry and foam foam is cement Slurry: foam foam = 1:4, the composite self-insulating concrete block is formed by mixing foam foam and cement paste and then pouring it into the cavity of the concrete hollow block for natural curing. The specific preparation method is as follows:

[0094] Step 1, preparation of foam and preparation of cement slurry:

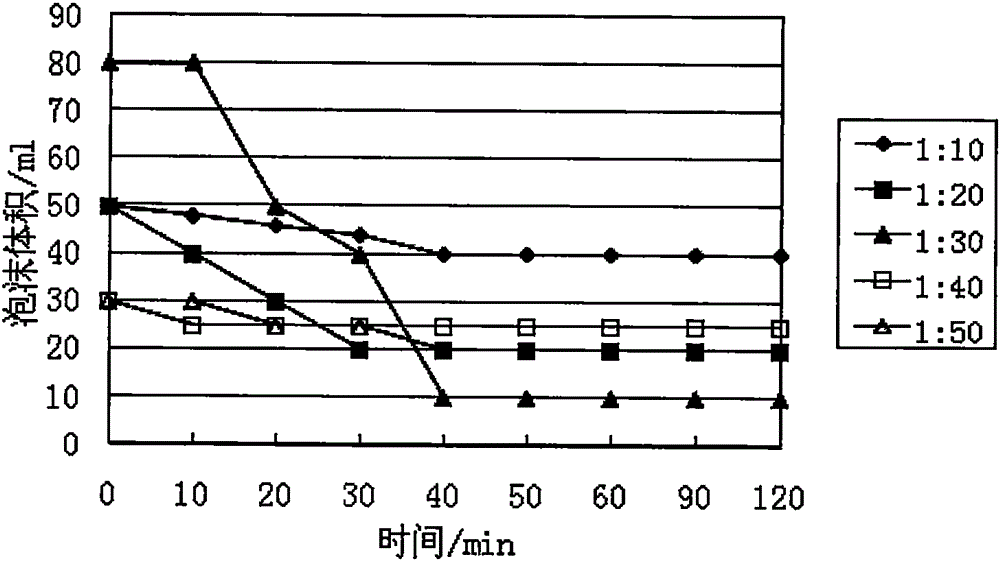

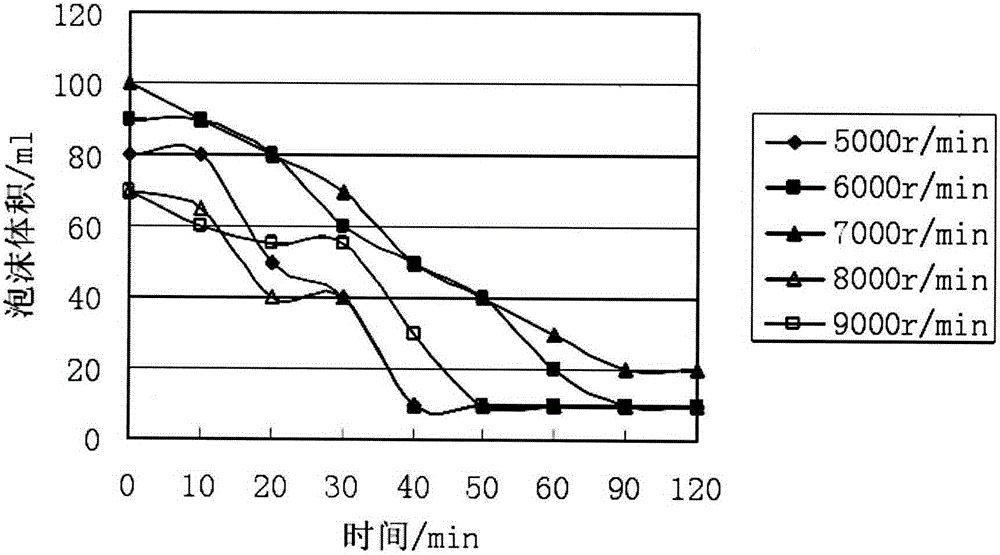

[0095] Foam preparation: use ZY-101 high-efficiency cement foaming agent produced by Zhumadian City Yongtai Building Energy-saving Material Equipment Co., Ltd. as the foaming agent used in the embodiment of t...

Embodiment 2

[0102] A composite self-insulating concrete block with a dry bulk density of 1000-1200kg / m 3 The concrete hollow block and the dry bulk density in its cavity are 300-500kg / m 3 The inner filling core material composition, wherein the inner filling core material is low-density foam concrete, the raw material composition of this low-density foam concrete includes cement slurry and foam foam, and the volume ratio between cement slurry and foam foam is cement Slurry: foam foam = 1:6, the composite self-insulating concrete block is formed by mixing foam foam and cement paste and then pouring it into the cavity of the concrete hollow block for natural curing. The specific preparation method is as follows:

[0103] Step 1, preparation of foam and preparation of cement slurry:

[0104] Foam preparation: use ZY-101 high-efficiency cement foaming agent produced by Zhumadian City Yongtai Building Energy-saving Material Equipment Co., Ltd. as the foaming agent used in the embodiment of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com