Thin coating type water-based heat insulation and thermal isolation paint and preparation method thereof

A thermal insulation, thin coating technology, applied in anti-corrosion coatings, fire-retardant coatings, coatings, etc., can solve the problems of weak impact resistance, large drying shrinkage, poor thermal insulation ability, etc., to achieve strong thermal insulation performance, Easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

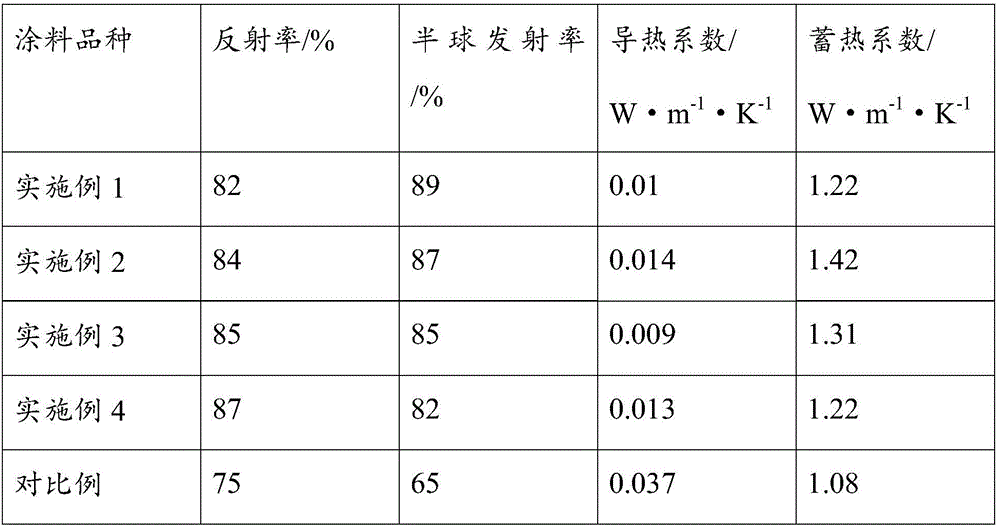

Examples

Embodiment 1

[0038] The thin-coated water-based thermal insulation coating provided in this embodiment is prepared from the following components:

[0039] 5kg of hydrophobically modified expanded vermiculite with a particle size of 25 microns and a thermal conductivity of 0.04W / m.K, 5kg of hollow glass beads with a particle size of 8 microns and a thermal conductivity of 0.05W / m.K, 20kg of styrene-acrylic emulsion, and 5kg of light calcium. Wetting agent 0.1kg, dispersant 0.1kg, polyacrylate 0.8kg, pH regulator 0.01kg, defoamer 0.01kg, bactericide 0.01kg and water 10kg.

[0040] The preparation method of the thin coating type water-based thermal insulation coating specifically comprises the following steps:

[0041] Add water, emulsion, pH regulator, thickener, wetting agent, dispersant, defoamer and bactericide in sequence, disperse and stir evenly, then add filler, hydrophobically modified expanded vermiculite and hollow glass microspheres, and mix well , to obtain the thin coating type...

Embodiment 2

[0043] The thin-coated water-based thermal insulation coating provided in this embodiment is prepared from the following components:

[0044] 20kg of hydrophobically modified expanded vermiculite with a particle size of 125 microns and a thermal conductivity of 0.07W / m.K, 20kg of hollow glass beads with a particle size of 80 microns and a thermal conductivity of 0.09W / m.K, 45kg of styrene-acrylic emulsion, and 15kg of light calcium. Wetting agent 1kg, dispersant 1.0kg, polyacrylate 1.5kg, pH regulator 0.05kg, defoamer 0.2kg, bactericide 0.2kg and water 30kg.

[0045] The preparation method of this thin-coated water-based thermal insulation paint is the same as that of Example 1.

Embodiment 3

[0047] The thin-coated water-based thermal insulation coating provided in this embodiment is prepared from the following components:

[0048] 10kg of hydrophobically modified expanded vermiculite with a particle size of 50 microns and a thermal conductivity of 0.05W / m.K, 10kg of hollow glass beads with a particle size of 50 microns and a thermal conductivity of 0.07W / m.K, 30kg of styrene-acrylic emulsion, and 10kg of light calcium. Wetting agent 0.5kg, dispersant 0.5kg, polyacrylate 1.0kg, pH adjuster 0.04kg, defoamer 0.1kg, bactericide 0.1kg and water 20kg,

[0049] Wherein, the preparation method of hydrophobically modified expanded vermiculite comprises the following steps:

[0050] Heat the expanded vermiculite to 110°C, keep it warm for 3 hours, and mix it with an anhydrous ethanol solution of zinc stearate (concentration: 15%) at a ratio of 2:1 after cooling to room temperature, heat to 65°C, and react for 0.5 hours, Then the temperature was raised to 90° C. to remove e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com