Patents

Literature

40results about How to "No destruction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing fluorine-containing acrylate

ActiveCN102010334ANo destructionExcellent water and oil repellencyPreparation from carboxylic acid halidesVegetal fibresHuman healthBioaccumulation

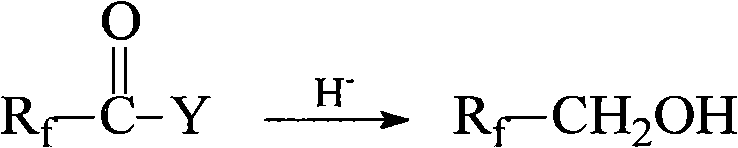

The invention belongs to the technical field of textile fabric finishing agents, and relates to a method for preparing an intermediate fluorine-containing acrylate monomer of a water-proof and oil-proof organic fluorine fabric finishing agent. The method is characterized by comprising the following steps of: (1) in the presence of a reducing agent, preparing polyfluoroalcohol by using a perfluoroalkylacyl compound as a raw material; and (2) slowly dripping (methyl) acryloyl chloride to prepare fluorine-containing acrylate in the presence of a catalyst by using the polyfluoroalcohol prepared in the step (1) and using phenothiazine as a polymerization inhibitor. The number of long-chain perfluoroalkyl carbon atoms in the prepared fluorine-containing acrylate is less than 8, and the fluorine-containing acrylate can be degraded and has no biological accumulation. The fluorine-containing acrylate has no hidden dangers of long-chain perfluoroalkyl to destroy the environment and harm human health. Fluorine-containing acrylate copolymer emulsion prepared by using the prepared fluorine-containing acrylate monomer is used as a water-proof and oil-proof finishing agent for textiles, and the finished textiles have excellent water-proof and oil-proof performance.

Owner:江苏梅兰化工有限公司

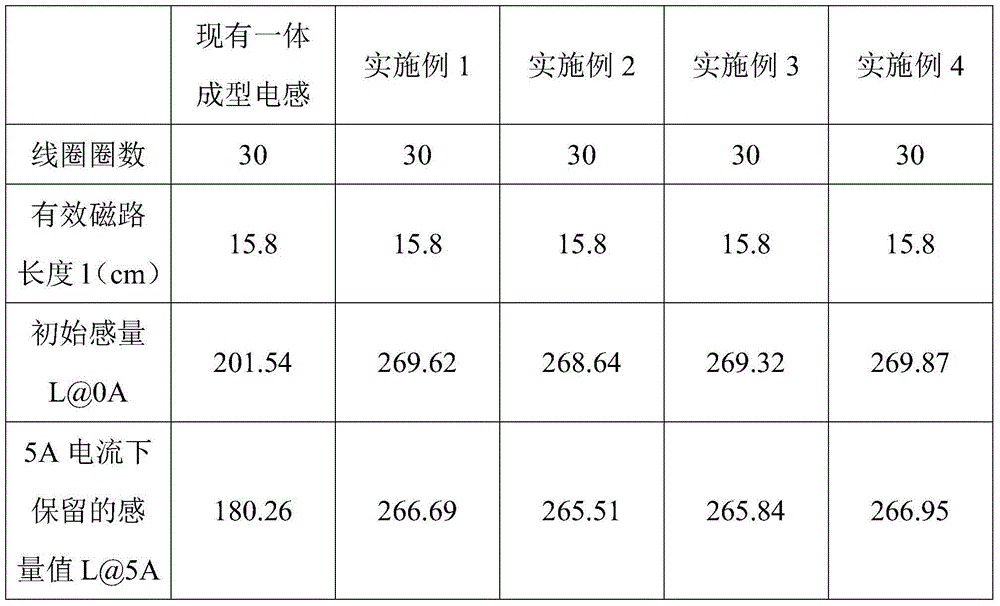

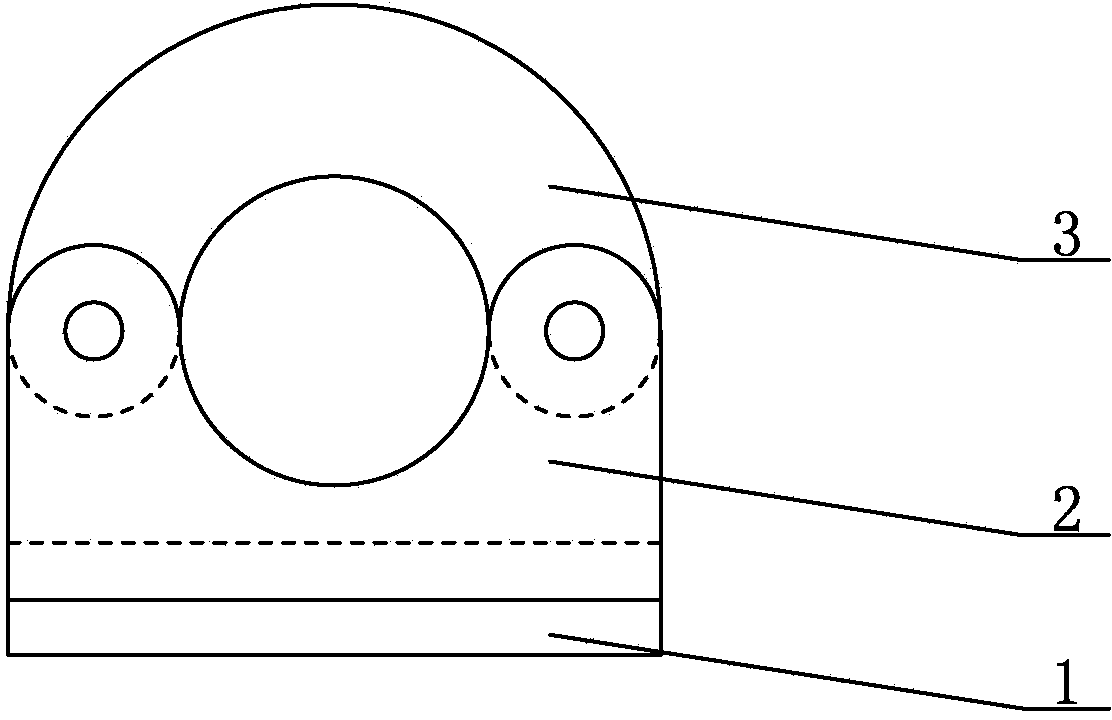

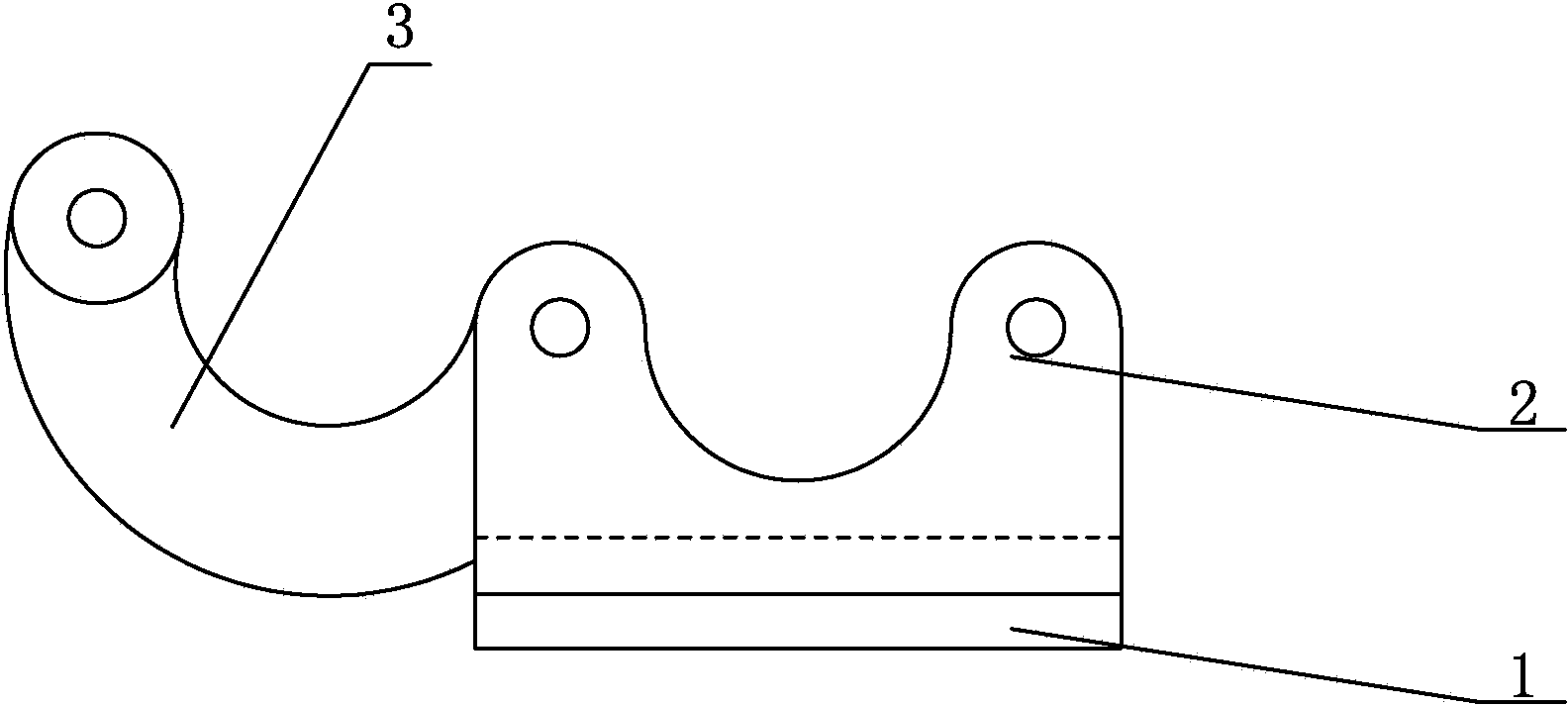

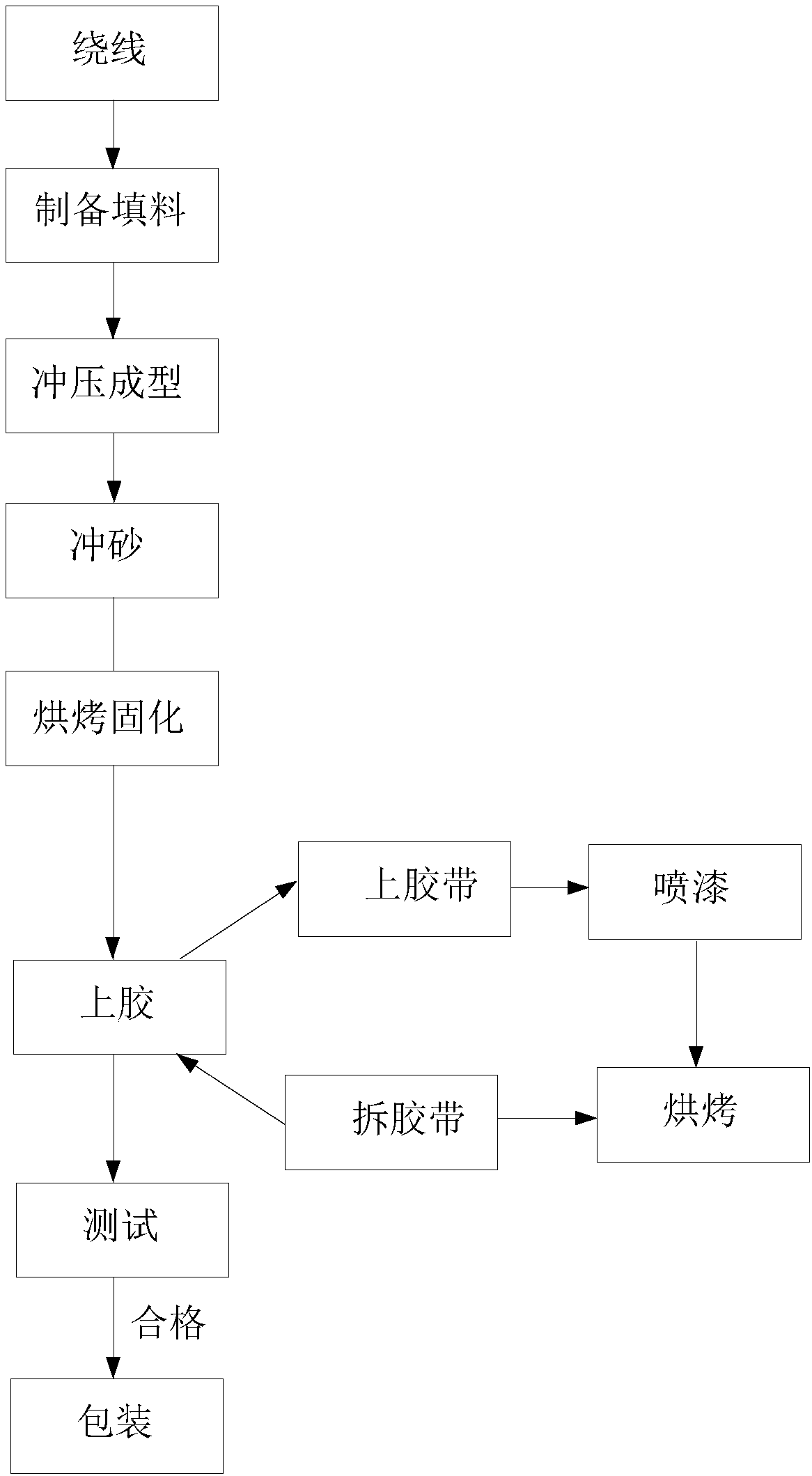

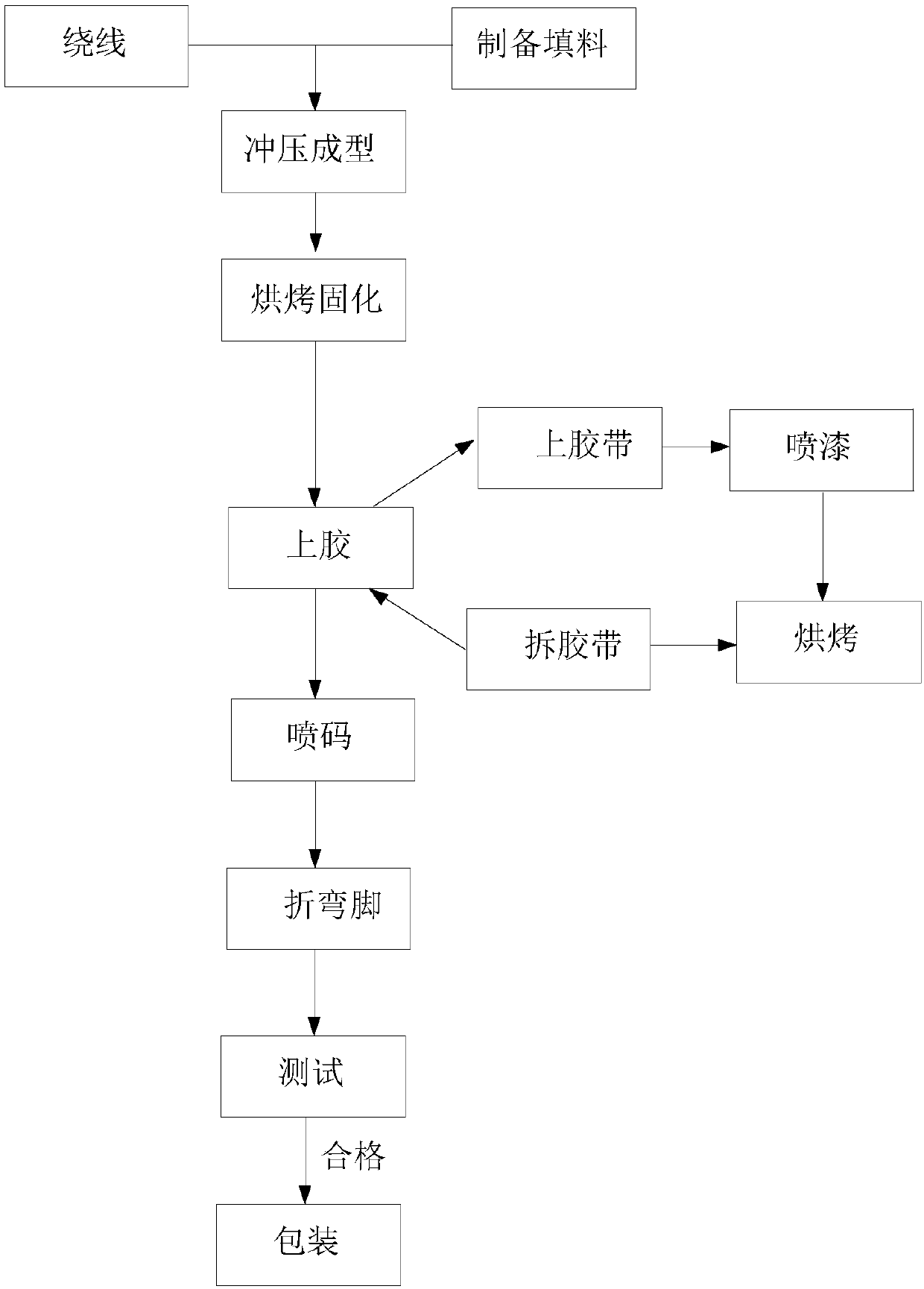

Inductor manufacturing method

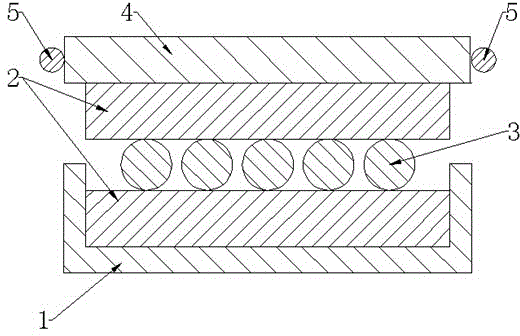

InactiveCN104200981ASimple production processRealize automated manufacturingInductances/transformers/magnets manufactureInductance with magnetic coreInductorInductance

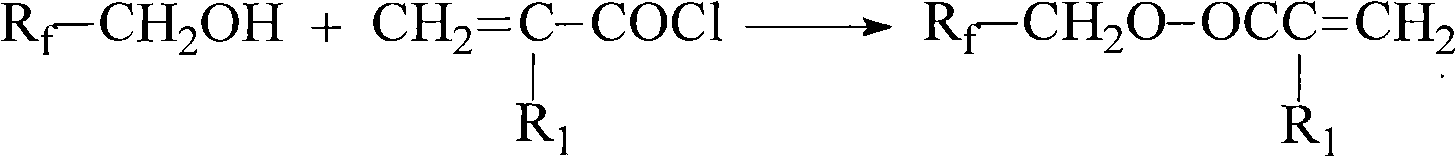

The invention provides an inductor manufacturing method. The method includes the following steps that first, an enameled wire coil is wound; second, first ferromagnetic powder is pressed into a magnetic core; third, the magnetic core is installed in a hollow cavity of the coil; fourth, the coil is installed in an injection mold; fifth, second ferromagnetic powder and high-temperature resin are evenly stirred and mixed power can be obtained; sixth, the mixed powder is injected into the injection mold and formed so that an outer magnet can be obtained, and it is guaranteed that the density of the outer magnet is smaller than that of the magnetic core; seventh, cooling and demolding are performed so that an inductor can be obtained. The inductor manufactured according to the scheme has the advantages that the inductor is good in thermal conductivity and long in service life; the density of the magnetic core is different from that of the outer magnet, a totally-sealed magnetic shielding structure is achieved as a whole, and the EMI effect of the inductor is better compared with that of an existing integrally formed inductor; the problem that a coil is damaged by mechanical stress in the original integrally formed inductor is solved, and in other words, the insulating capacity of the original coil is not weakened.

Owner:POCO HLDG CO LTD

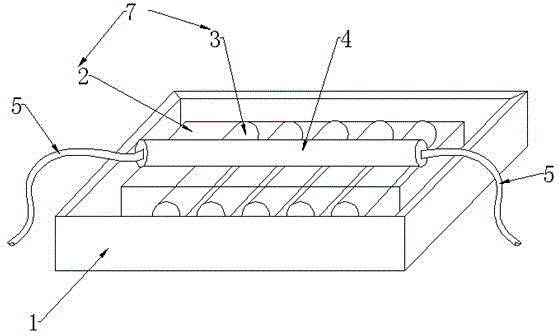

A production device of graphene and a preparing method

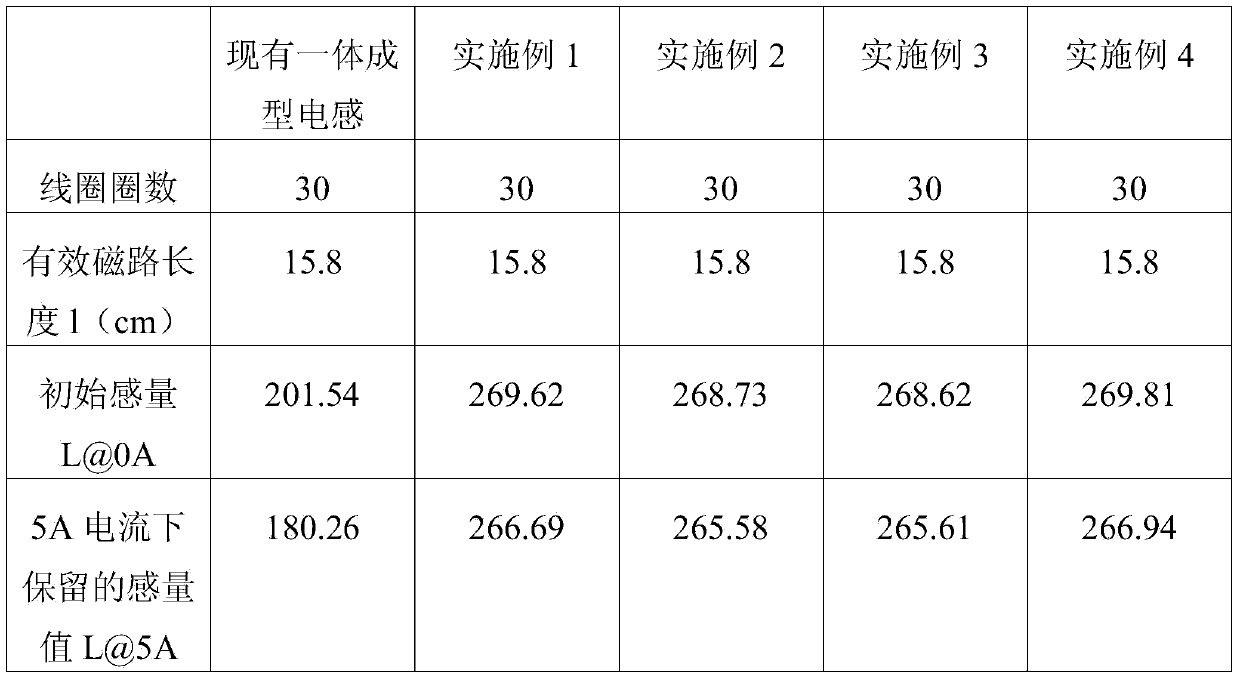

The invention relates to a production device of graphene. The device is characterized in that the device comprises a reaction kettle (1) and a motor (2), the motor is mounted at the top of the reaction kettle (1), the output end of the motor (2) is connected to a shearing machine (3), the top of the reaction kettle (1) is provided with a feeding port (4), a pressure gage (5) and a temperature meter (6), the inner wall of the reaction kettle (1) is provided with shearing slots (7), a material discharging port (8) is disposed in the middle and lower part of the reaction kettle (1), and a jacket (9) is disposed outside the reaction kettle (1) and is provided with a hot-medium inlet and an outlet. When the device is used for graphene production, the yield is high, the cost is low and the prepared graphene is high in quality.

Owner:江苏碳谷二维世界科技有限公司

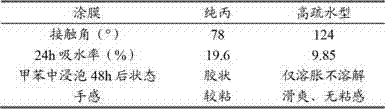

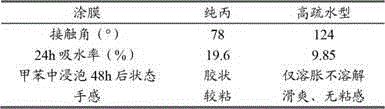

Preparation method of high-hydrophobicity leather coating agent

InactiveCN102924649AImprove water resistanceFeel smoothCoatingsLeather surface finishingSolventWeather resistance

The invention relates to a preparation method of a high-hydrophobicity leather coating agent. The acrylate leather coating agent has excellent film-forming property, light stability, weather resistance and binding property, but has some defects, such as poor water resistance, poor solvent resistance, lack of functionality and the like, due to the linear structure of the acrylate resin. In order to overcome the defects above, the invention provides a semicontinuous seed emulsion polymerization method for preparing the core-shell acrylate resin: the shell is properly cross-linked, so that the acrylate resin is converted into a reticular structure from the linear structure, thereby enhancing the water resistance and solvent resistance of the acrylate resin; and besides, organic fluorine is introduced into the shell, so that the acrylate resin has high hydrophobicity. After the high-hydrophobicity leather coating agent forms a film, the contact angle with water is up to 124 degrees, and the film feels smooth and not sticky; the 24-hour water absorptivity is less than 10%; and after being soaked in methylbenzene for 48 hours, the film only swells, but is not dissolved.

Owner:SHAANXI UNIV OF SCI & TECH

Copious cooling fast freezing infrared drying technology

InactiveCN109780821AImprove protectionNo pollution in the processDrying solid materials without heatLiquid waterFreeze-drying

The invention discloses a copious cooling fast freezing infrared drying technology and belongs to the technical field of chemical engineering and light industry machining. The copious cooling fast freezing infrared drying technology is characterized in that a gas turbine expanding refrigerating technology is adopted for performing copious cooling fast freezing on materials, compressed air at 0.5-0.9 Mpa is used, the initial air expanding pressure intensity ratio is 3-9, and fresh product vegetables and fruits and traditional Chinese medicinal materials except mineral drug are fast cooled to minus 20- minus 120 DEG C within 5-30 min, so that liquid water in a raw material organization structure fast solidifies, and becomes extremely micro ice crystal; and then, the materials are fed into aninfrared vacuum freezing drying bin to be heated, so that solid water in the materials sublimates into vaporous water, and the water content of the materials is lowered to 0-10%. The copious coolingfast freezing infrared drying technology has the characteristics of being high in freezing speed, low in cooling temperature, high in drying speed, uniform in material heating, uniform in material product quality and good in drying effect.

Owner:海尔生物医疗科技(成都)有限公司

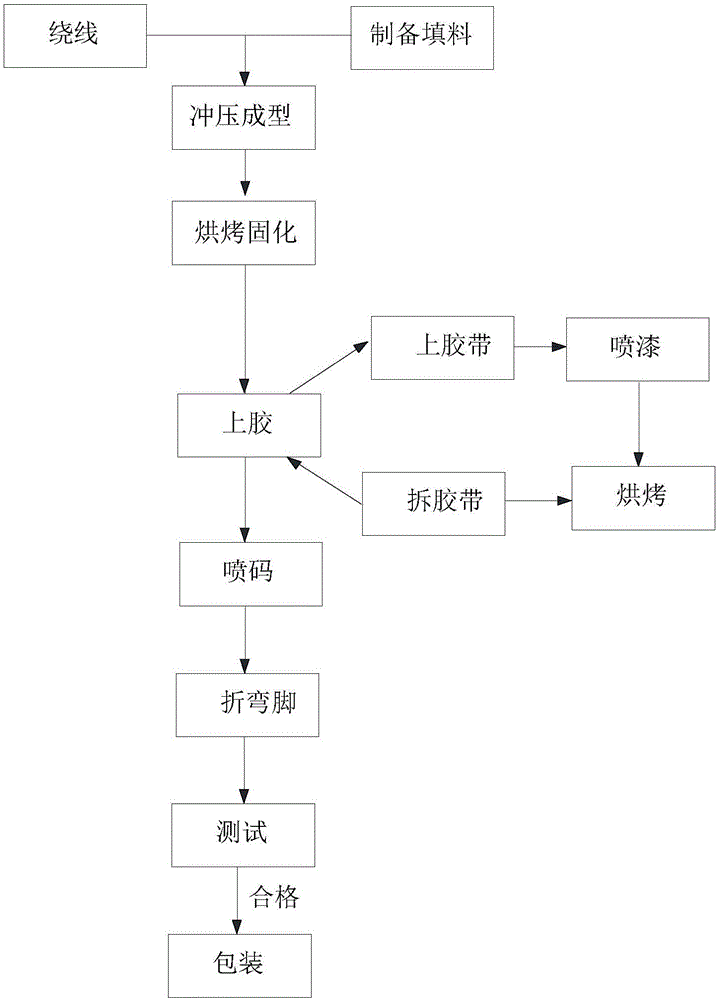

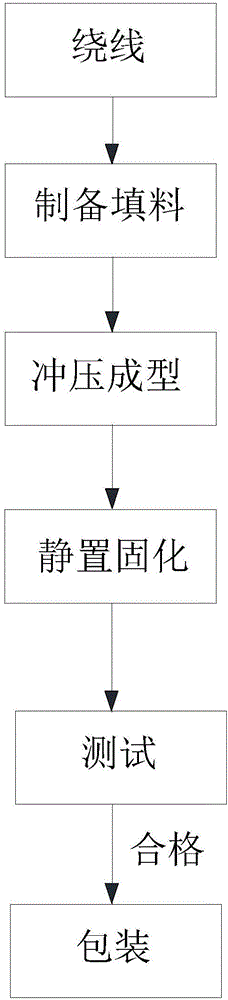

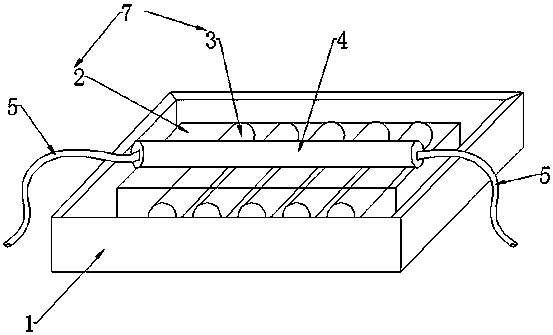

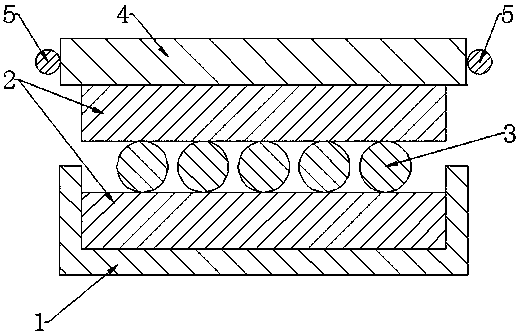

Novel high density integrated electric inductance manufacturing method

ActiveCN104900390ASimplify the winding processRealize automated productionInductances/transformers/magnets manufactureMagnetic materialsMagnetic coreElectrical and Electronics engineering

The invention discloses a novel high density integrated electric inductance manufacturing method, which comprises: (1) winding an varnished wire coil into a spiral shape; (2) making first iron magnetic powers into a magnetic core through mechanical pressing; (3) packing the magnetic core into a hollow cavity of the varnished wire coil; (4) packing the varnished wire coil packed with the magnetic core into an injection mold; (5) uniformly mixing and blending resin adhesive, coupling agent and accelerant to obtain high temperature resin adhesive; (6) uniformly mixing and blending the second iron magnetic powers and the high temperature resin adhesive to obtain magnetism composite material; (7) injecting the magnetism composite material into a mold cavity of the injection mold to mold, and solidifying to obtain external magnetic body; and (8) cooling and stripping to obtain molded electric inductance. According to the invention, the volume of the electric inductance manufactured with the method provided herein is small; the density is high; the relative magnetic conductivity is high; the cooling performance is good; the service life is long; the electric inductance is molded as a whole; and the manufacturing method of the electric inductance is simple, thus reducing the production cost.

Owner:POCO HLDG CO LTD +2

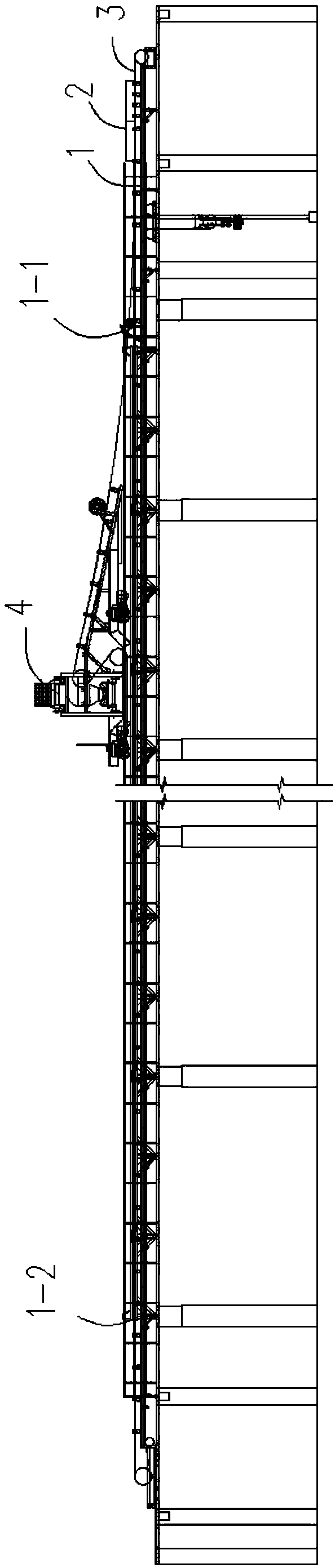

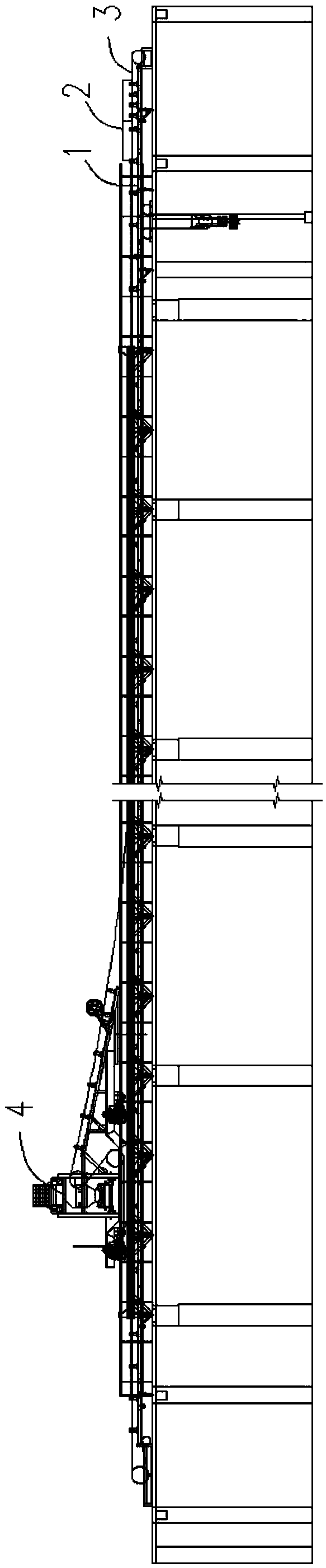

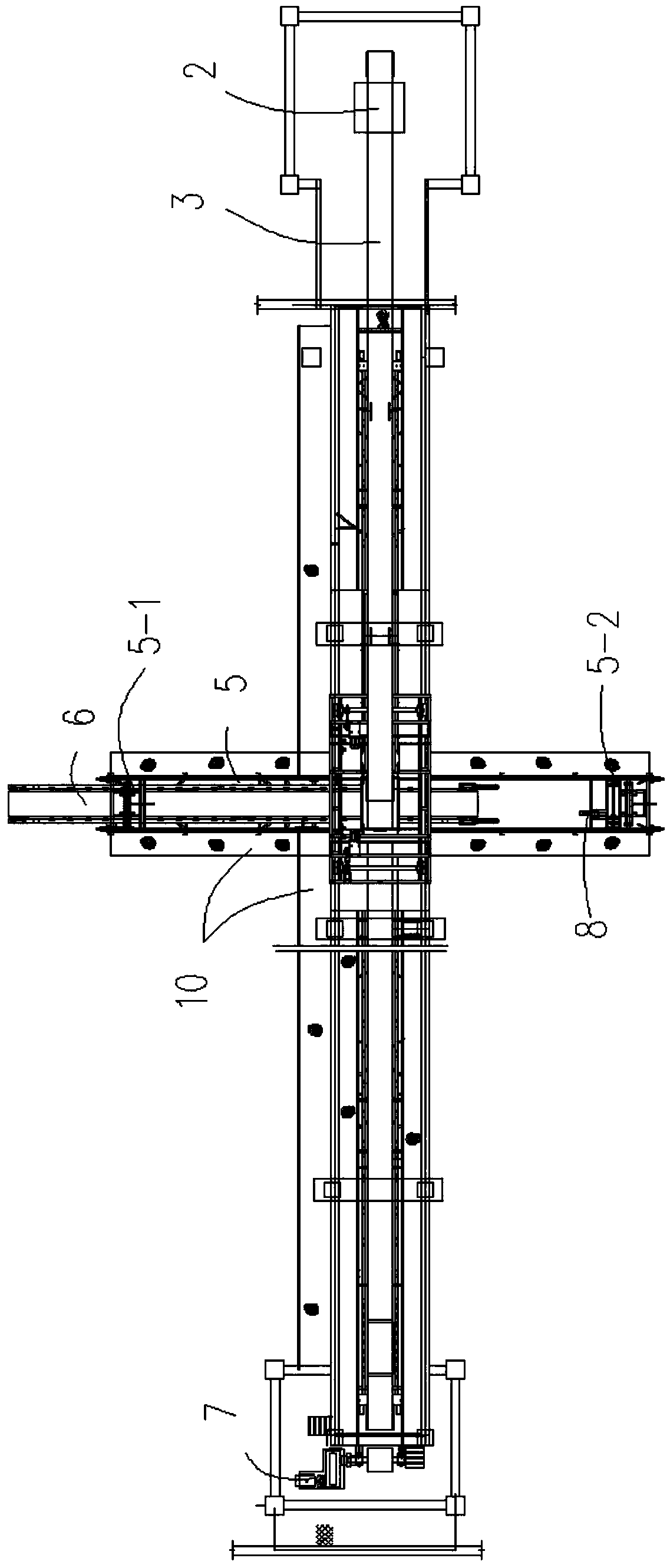

Intelligent all-coverage bulk material unloading distributor

PendingCN108313750ASimple structureGuaranteed continuityLoading/unloadingEngineeringReciprocating motion

The invention discloses an intelligent all-coverage bulk material unloading distributor, and relates to the technical field of distributors. The intelligent all-coverage bulk material unloading distributor comprises a transverse conveying frame fixedly mounted in a warehouse; the transverse conveying frame is provided with a transverse conveying belt; one end of the transverse conveying belt extends out of the warehouse to cooperate with a feed port; the transverse conveying frame is provided with an unloading car for performing a reciprocating motion on the transverse conveying frame; the unloading car is provided with a longitudinal conveying frame orthogonal to a conveying direction of the transverse conveying frame; the longitudinal conveying frame is provided with an unloading belt mechanism capable of performing a reciprocating motion along the longitudinal conveying frame; the longitudinal conveying frame is provided with a limiting mechanism A and a limiting mechanism B for limiting front and back limit positions of the unloading belt mechanism; and the transverse conveying frame is provided with a limiting mechanism C and a limiting mechanism D for limiting left and rightlimit positions of the unloading car. The intelligent all-coverage bulk material unloading distributor has the advantages of simple structure and no-dead-angle full coverage of a stockyard.

Owner:SICHUAN DONGLIN MINE TRANSPORT MACHINERY

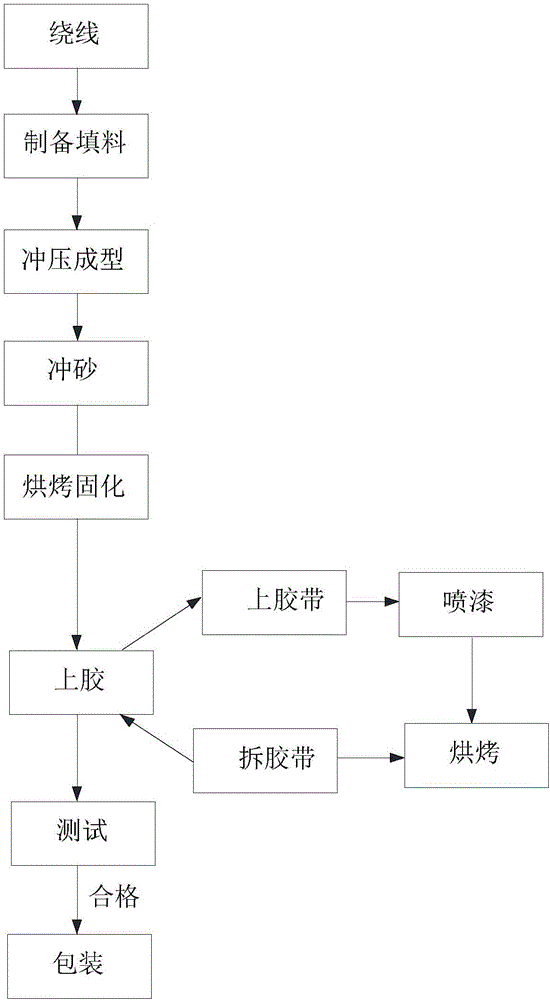

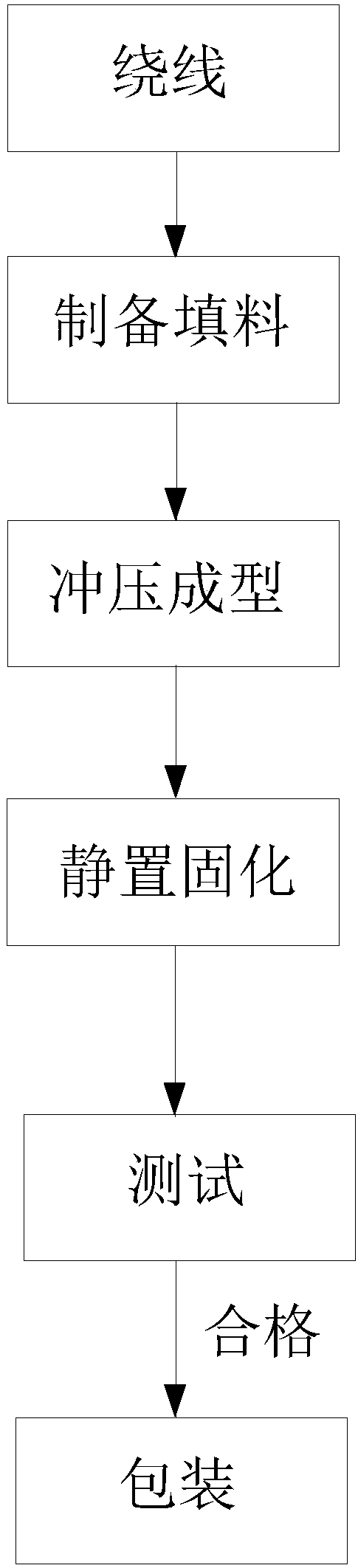

Integrally molded inductor and manufacturing method thereof

ActiveCN106252055AImprove current resistanceStable structureTransformers/inductances magnetic coresInductances/transformers/magnets manufactureSilicone GelsMass ratio

The invention provides a manufacturing method of an integrally molded inductor, and belongs to the technical field of inductance elements. The method comprises the steps of winding a copper wire into a coil and electrically connecting the coil and an electrode pin; mixing a magnetic-conducting material with liquid silicone gel evenly at the mass ratio of 100:(2-15) to form a filler and carrying out heat preservation on the filler under the condition that the temperature is 70-80 DEG C for 0.2-1 hour; and putting the coil connected with the electrode pin into a mold, filling the mold with the filler and carrying out integral stamping to form the integrally molded inductor. The manufacturing method is simple; and the technological process is saved. Furthermore, the invention further provides the integrally molded inductor manufactured by the manufacturing method. The current resistance of the integrally molded inductor is significantly improved; the inductor is stable in structure; the magnetic loss can be reduced; and the noise at work can be reduced.

Owner:重庆金籁科技股份有限公司

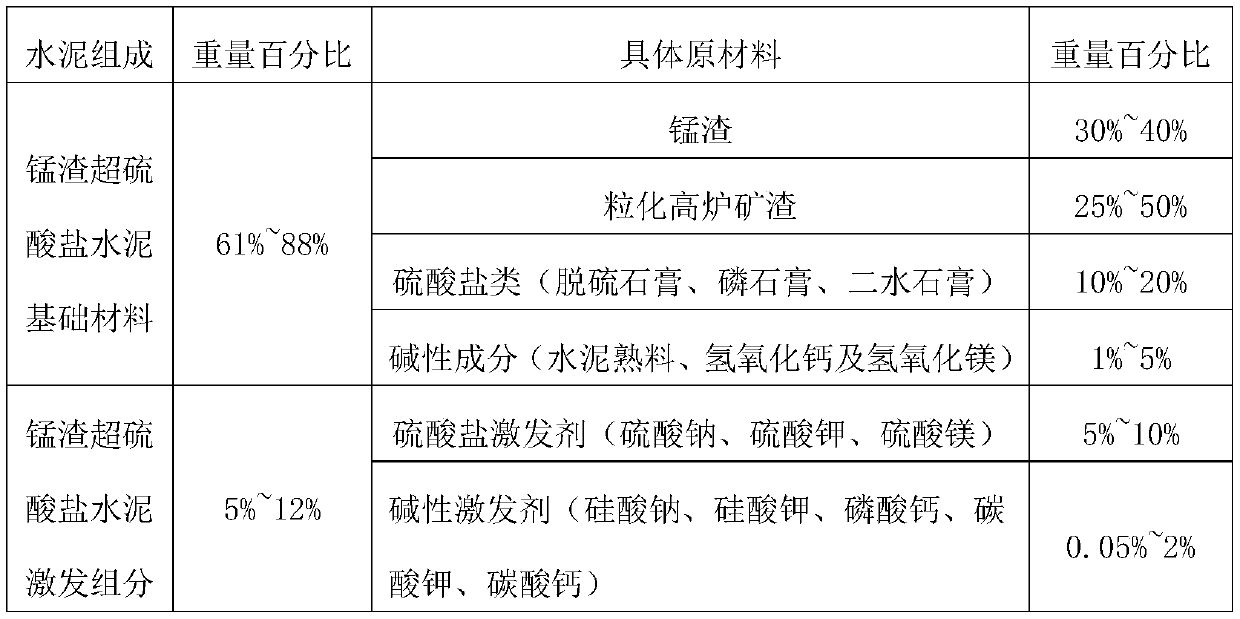

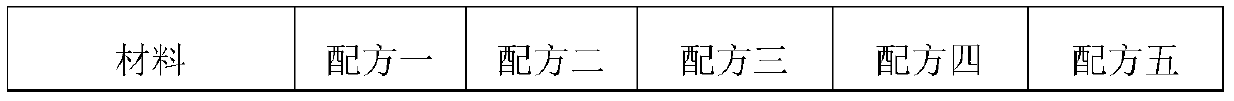

Manganese slag supersulfate cement and preparation method thereof

The invention belongs to the technical field of special cement, and particularly relates to a manganese slag supersulfate cement and a preparation method thereof. The manganese slag supersulfate cement is prepared from the components in percentage by weight: 30-40% of manganese slag, 25%-50% of granulated blast furnace slag powder, 10-20% of sulfates, 5%-10% of a sulfate activator, 1-5% of an alkaline component and 0.05-2% of an alkaline activator. The manganese slag which is a high-temperature slag waste discharged during the blast furnace smelting process of manganese iron or silicomaganeseis used as a main raw material, a material science principle is combined, the mineral characteristics of manganese slag and slag are taken as a basis, the potential hydration activity of the manganeseslag is activated by using sulfates and alkaline environment to form the initial strength, and novel manganese slag supersulfate cement with excellent properties is further designed.

Owner:中建西部建设新疆有限公司 +1

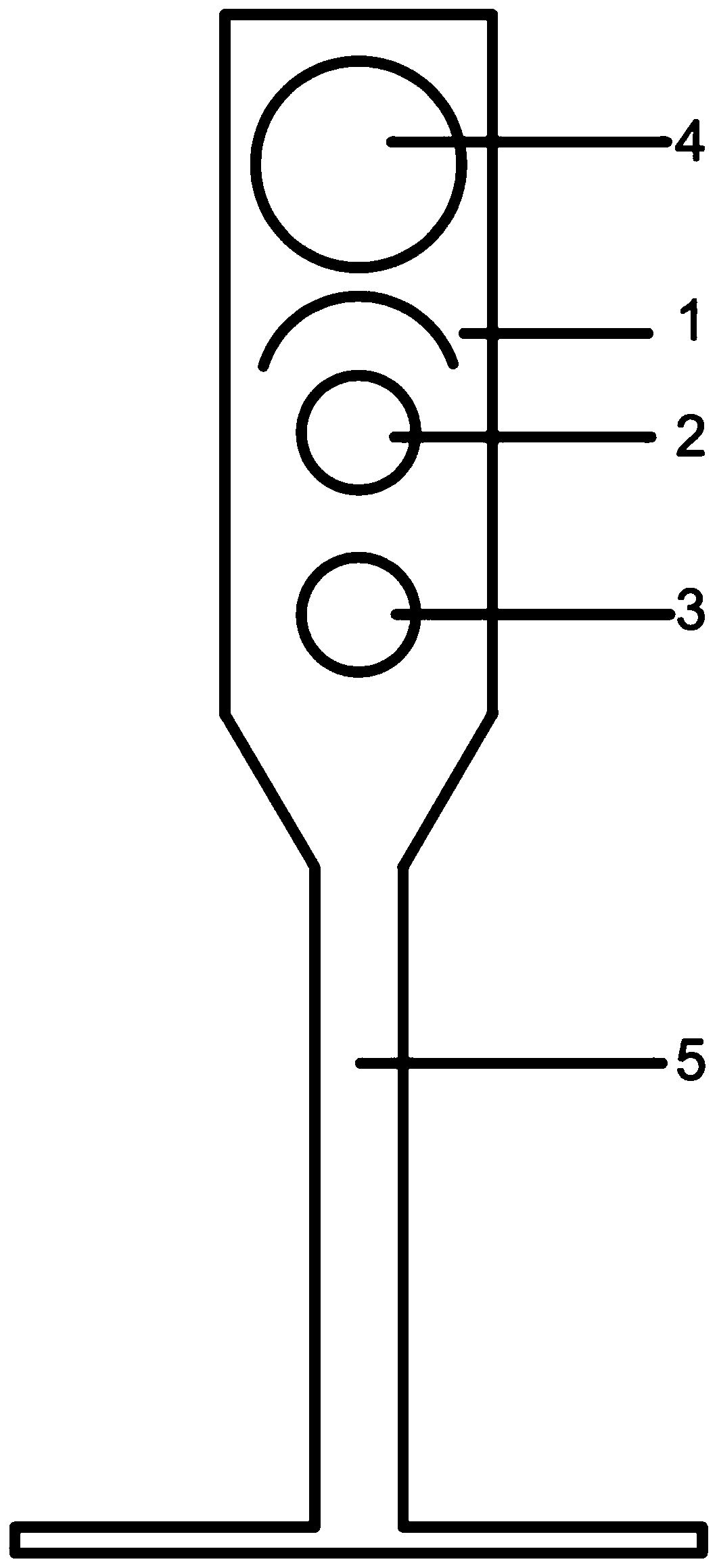

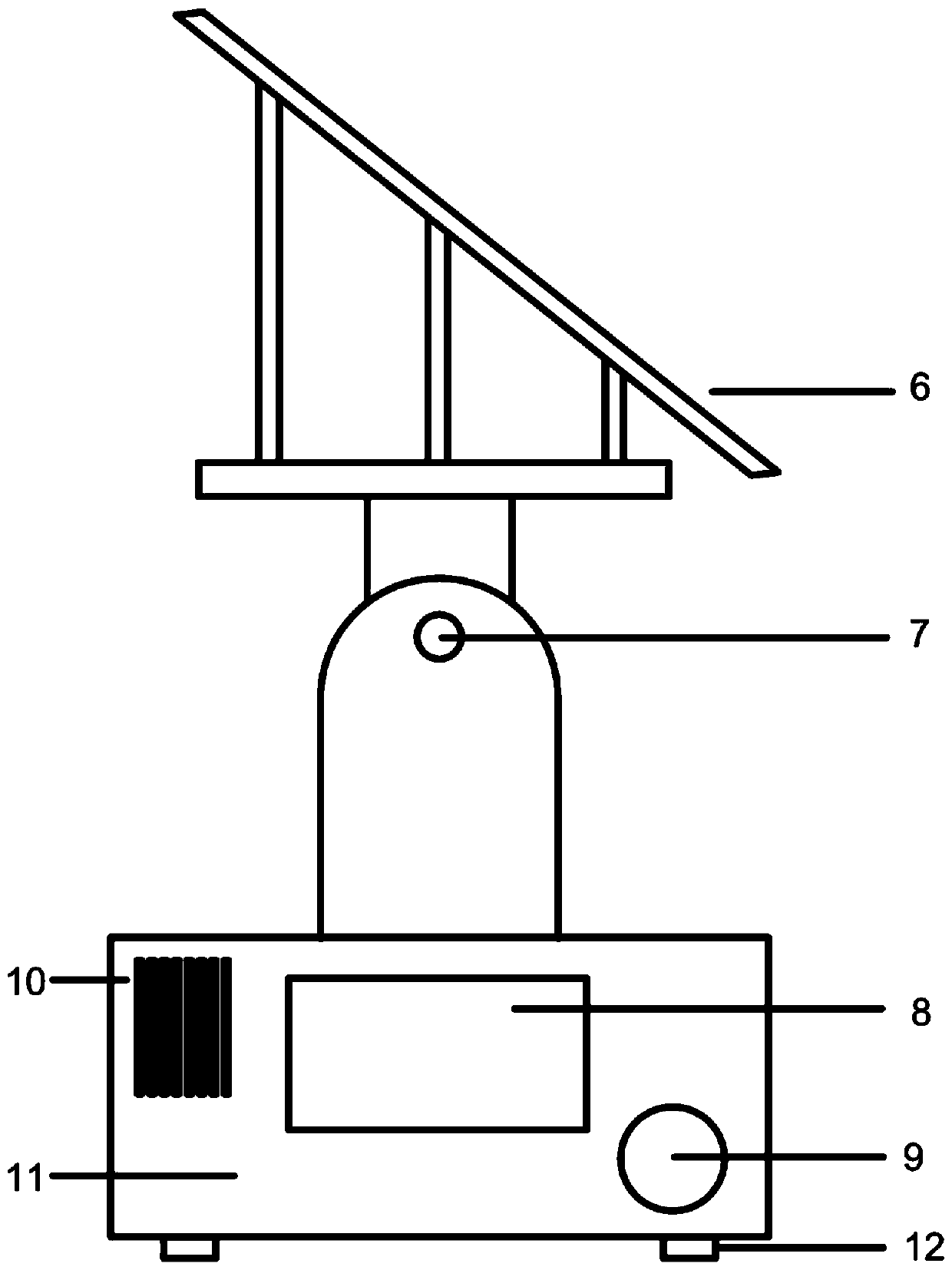

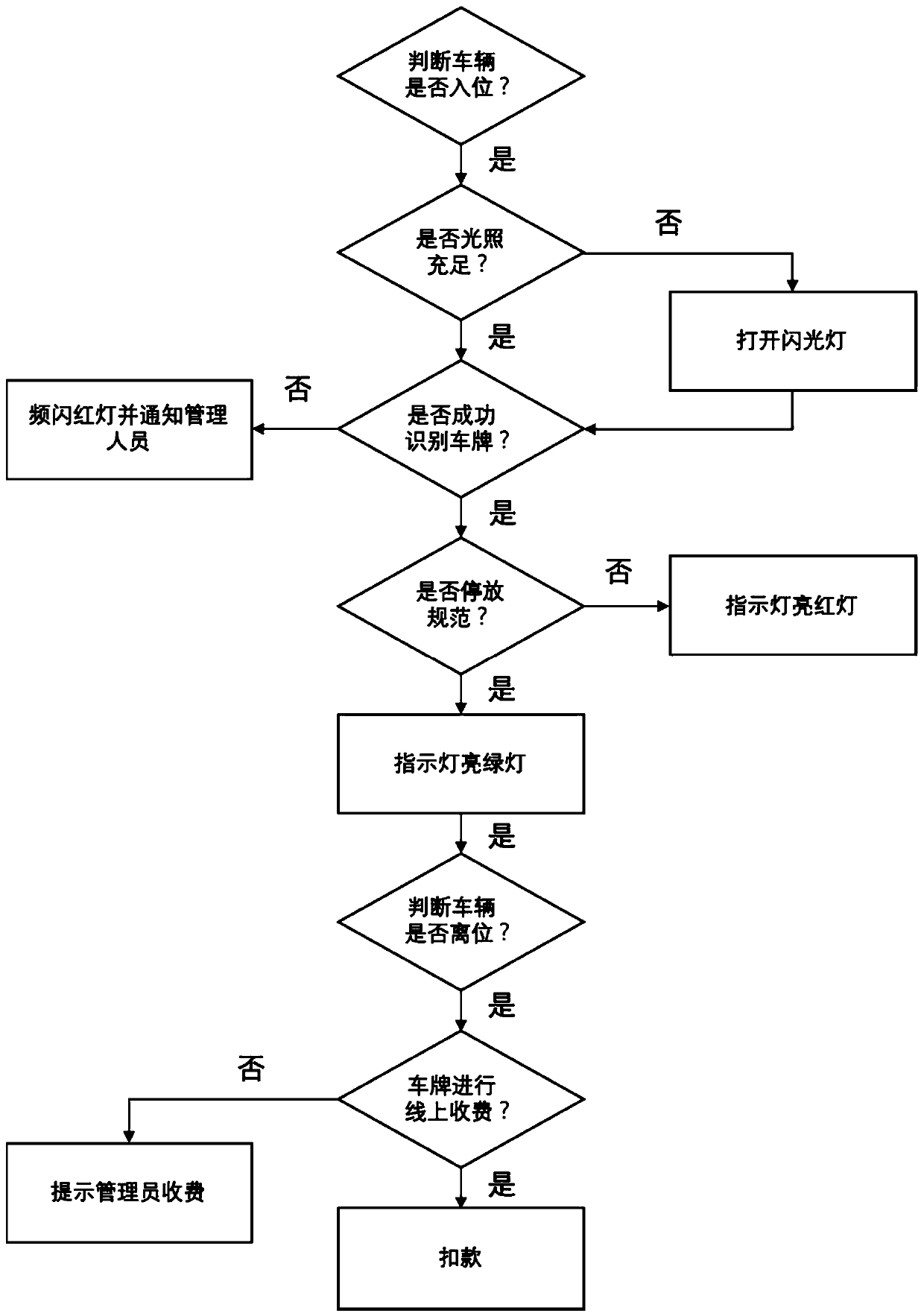

Parking video pile based on light storage-charging

InactiveCN110533920ASmall sizeEasy to installDetection of traffic movementClosed circuit television systemsComputer moduleParking space

The invention relates to a parking video pile based on light storage-charging arranged at one side corner along with a road rock of the corresponding roadside parking space. The parking video pile comprises a main body structure which is a vertical cylinder or rectangular rod, and used for providing support; a video identification module arranged in a preset mounting hole on the main body structure and used for detecting the vehicle entering and departure behavior, identifying the vehicle parking normality, identifying the license plate and performing the charging operation; and a light storage-charging module arranged at the side of the main body structure and used for providing ongoing electric energy for the video identification module and interacting data with the video identificationmodule. Compared with the prior art, the parking video pile disclosed by the invention has the advantages of being convenient to operate and long in service life.

Owner:TONGJI UNIV

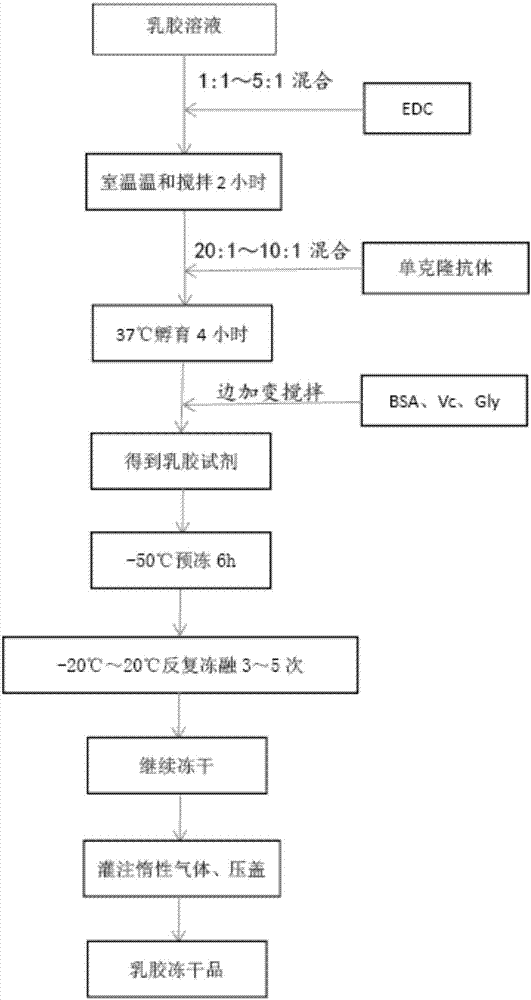

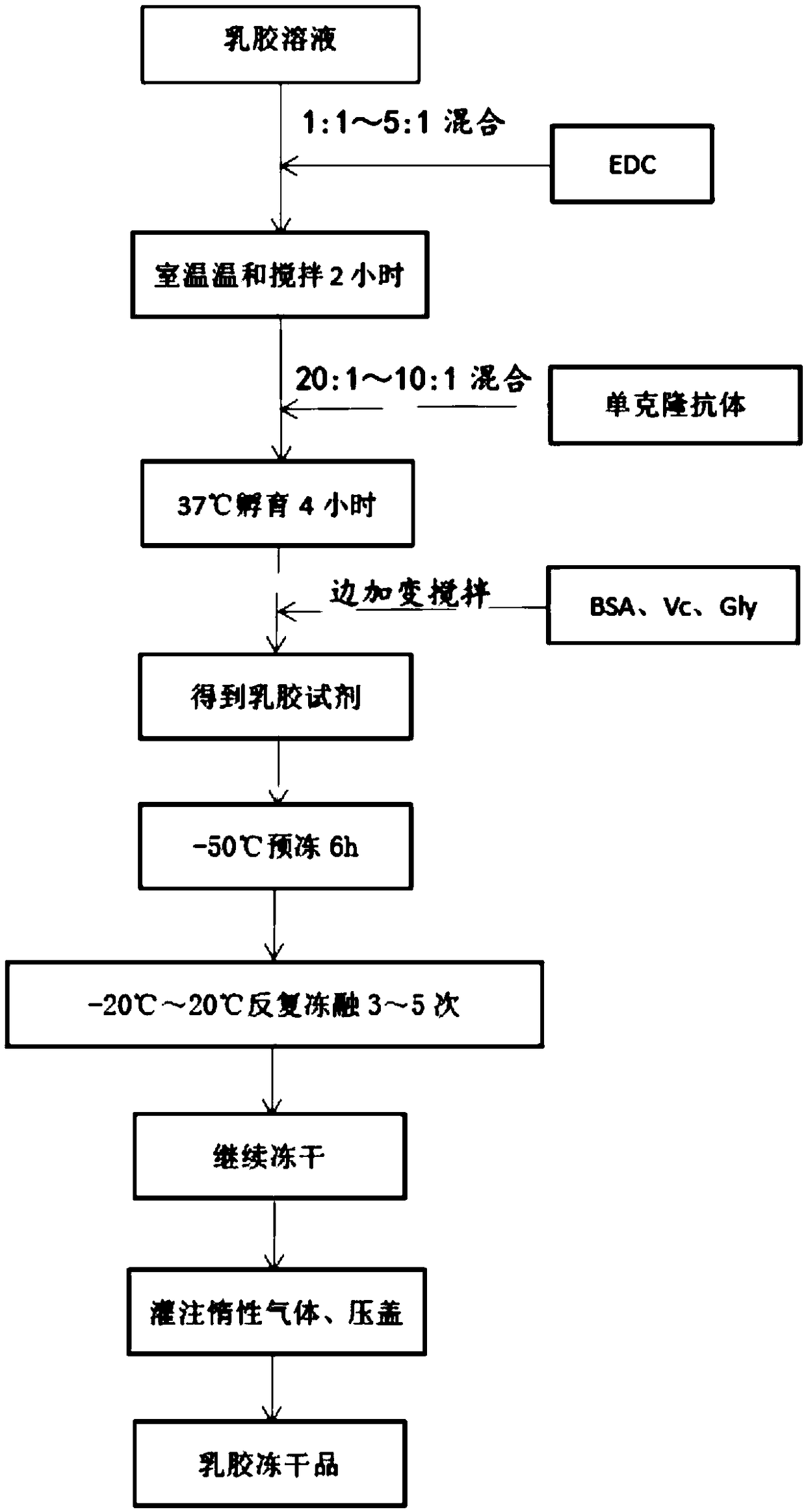

Latex turbidimetry freeze-drying reagent and preparation method thereof

ActiveCN107255727AImprove the coupling effectImprove stabilityBiological testingVitamin CFreeze-drying

The invention discloses a latex turbidimetry freeze-drying reagent and a preparation method thereof. The method comprises the following steps: coupling latex particles and monoclonal antibodies, and then adding a protective agent, so as to obtain a latex antibody reagent, and ensuring that the protective agent comprises bovine serum albumin, vitamin C and glycine; performing low-temperature vacuum freeze drying on the latex antibody reagent, so as to obtain a lyophilized product, and ensuring that low-temperature vacuum freeze drying is realized through repeated freezing and thawing; sealing the lyophilized product in an inert gas atmosphere, so as to obtain the latex turbidimetry freeze-drying reagent. The latex turbidimetry freeze-drying reagent prepared through the method is good in stability, fast to redissolve and good in uniformity, without suspended solids; after the latex turbidimetry freeze-drying reagent is redissolved, the performance of the latex turbidimetry freeze-drying reagent is not affected, the latex turbidimetry freeze-drying reagent is rapid in reaction with a whole blood sample, a result can be reported within 1 minute, the repeatability is very good, and the result is accurate and reliable.

Owner:深圳优迪生物技术有限公司

Method for artificially synthesizing sapphire

InactiveCN102011185AProportionally largeGood dispersionPolycrystalline material growthSingle crystal growth detailsWhite powderSeed crystal

The invention belongs to the technical field of a preparation method of an artificial crystal material, in particular relating to a method for artificially synthesizing sapphire and aiming to solve the technical problem of providing a preparation method of the artificially synthesized pure white sapphire with stable product quality. The preparation method of artificially synthesizing the sapphirecomprises the following steps: adding a raw material; inserting seed crystals; and sintering crystals, wherein, the step of sintering the crystals comprises the procedures of crystallizing chemical materials, centering, expanding the crystals and performing equal-diameter growth; the adopted raw material is aluminum oxide pure white powder, the purity is at least 99.996%, the particle size is 2.1mu m-5.7mu m, and the density is 1.14-1.86g / m<3>; and crystal roots (Phi3-5mm and L5-8mm) grow before expanding the crystals. In the invention, the pure white high-purity superfine aluminum oxide powder is used to replace aluminum oxide powder containing an ammonium ferric sulfate oiling agent and an ammonium fluorotitanate oiling agent to obtain the artificially synthesized pure white sapphire without impurities.

Owner:四川鑫通新材料有限责任公司

Transverse earth borrowing method applied to roadbed by Luoyang shovel

The invention relates to a transverse earth borrowing method applied to a roadbed by a Luoyang shovel, belonging to the technical field of roadway maintenance. The method solves the problems of existing earth borrowing devices and methods applied to the roadbed that the social work function and service life of the road are affected, personal security of workers is hard to ensure, and the earth borrowing efficiency is low. The method specifically comprises the following steps: ensuring that the roadbed at an earth borrowing opening is 1m higher than the highest earth borrowing opening; cleaning weed and surface capping mass away from a side slope by a shovel, and the distributing points; digging a platform at each earth borrowing opening, pouring a cement concrete horizontal table which is 50cm long, 15cm wide and 5cm high outside each earth borrowing opening, measuring by adopting a leveling instrument, and burying a snap joint at each of the front and rear ends of the horizontal table; preserving the poured concrete horizontal table for at least 7 days; starting borrowing earth when the Luoyang shovel reaches a specified earth borrowing opening; and filling earth blocks in a prepared aluminum box from at the middle part of the head of the Luoyang shovel and finally sealing the aluminum box. The method provided by the invention is used for transversely borrowing earth for the roadbed.

Owner:HARBIN INST OF TECH

High-manganese steel smelting process and high-manganese steel casting

ActiveCN1320148CNot easily oxidizedReduce exposureProcess efficiency improvementElectric furnaceElectricitySmelting process

This invention relates to a smelting technology for high Mn steel and the cast poured with said technology, in which, the basic element is Fe, the main elements are Mn (10-14%) C (1-1.4%) and FeMn, broken electrode carbon and steel rods are the raw materials characterizing in putting FeMn and broken electrode carbon in the furnace at lump-sum first under the protection of a covering agent, then putting steel rods on the FeMn and broken electrodes then to feed electricity to melt them with high power, the melt is always under the protection of the covering agent during the smelting process, the liquid surface is not allowed to be stored up.

Owner:XIAN AIRCRAFT BRANCH OF XIAN AIRCRAFT INT

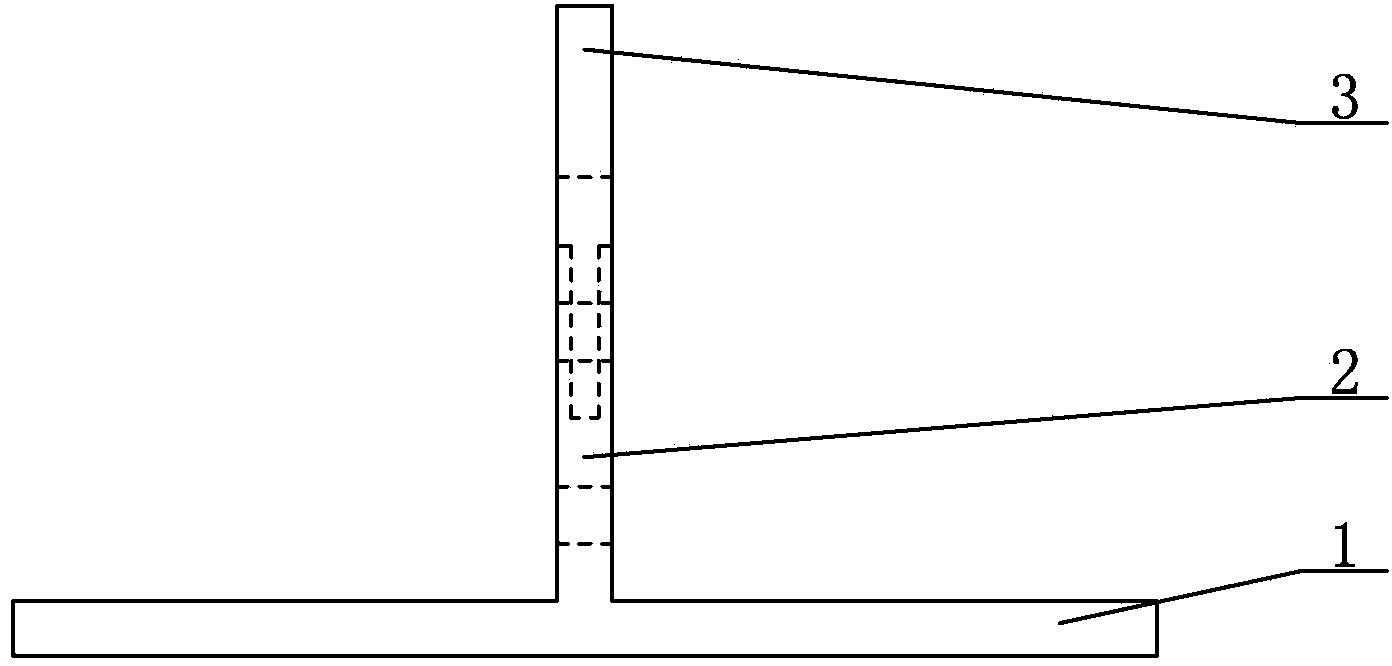

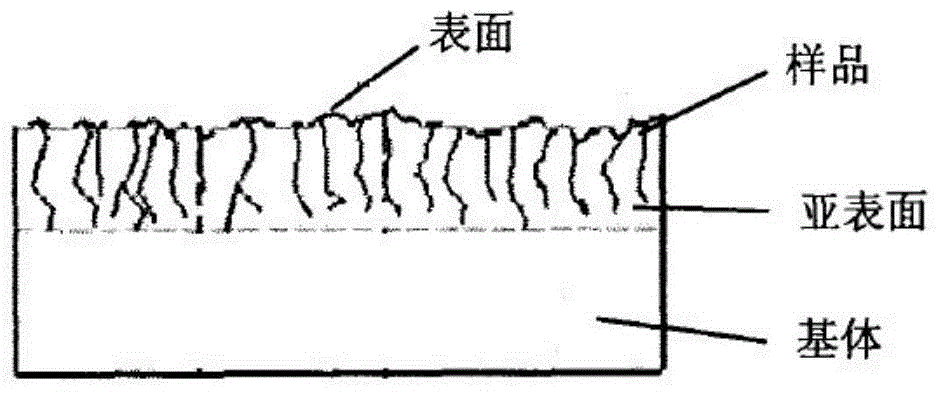

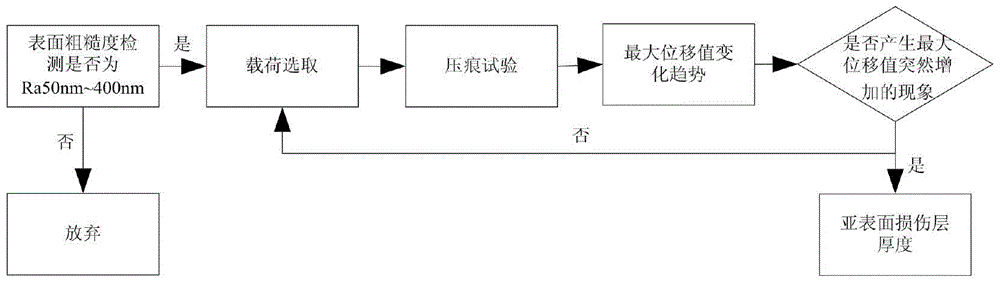

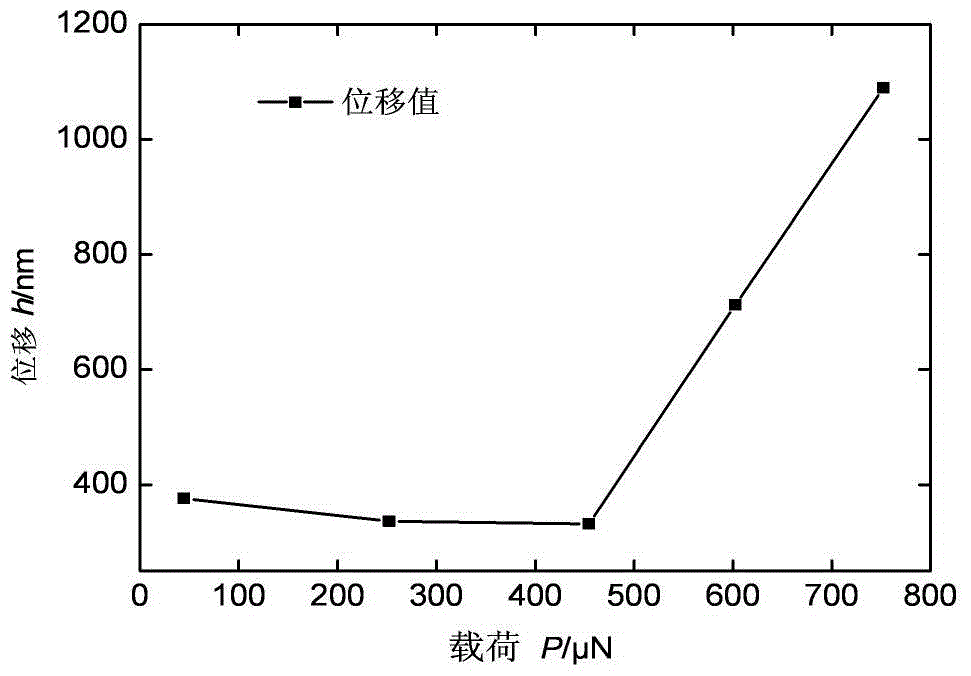

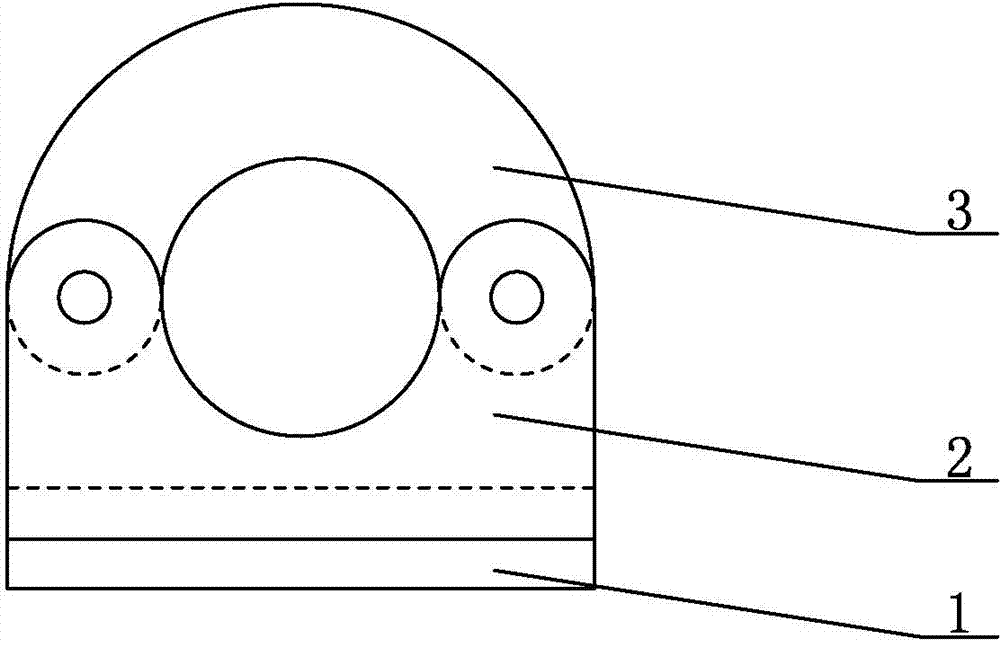

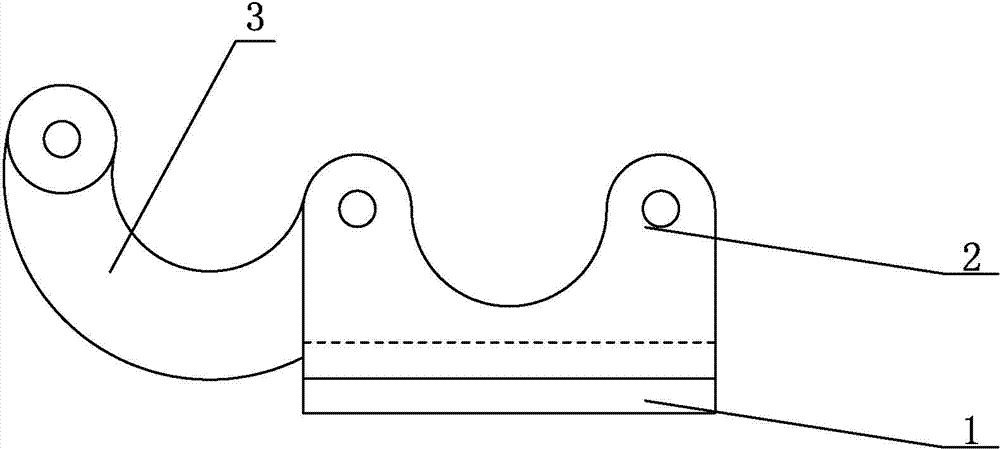

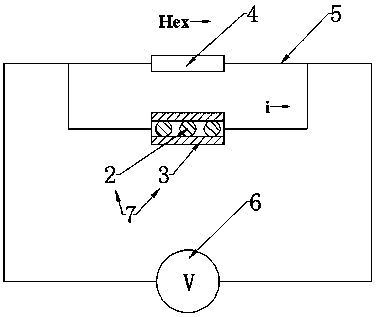

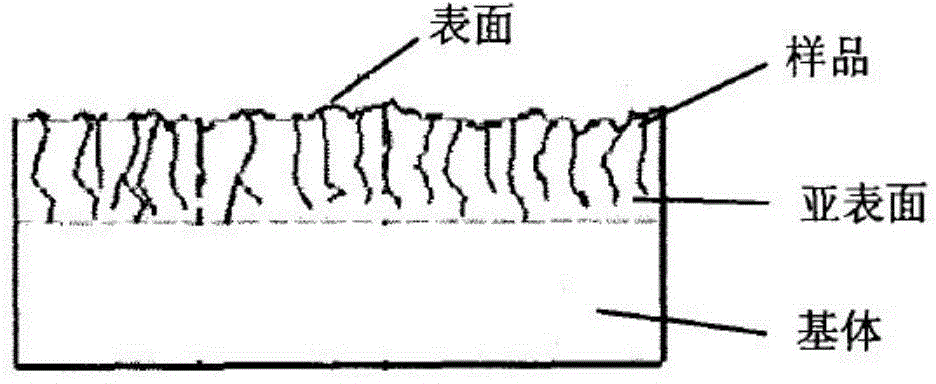

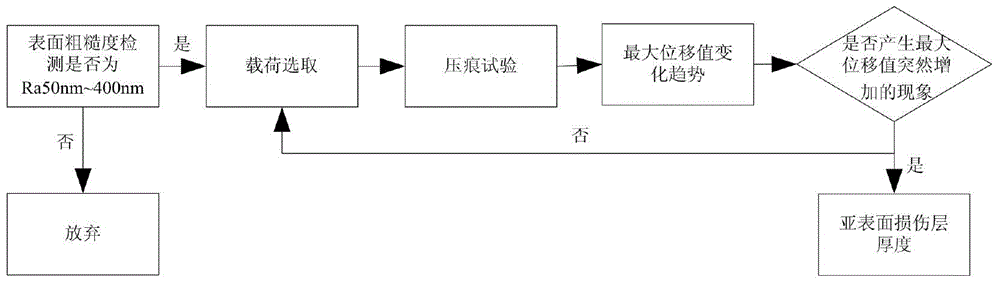

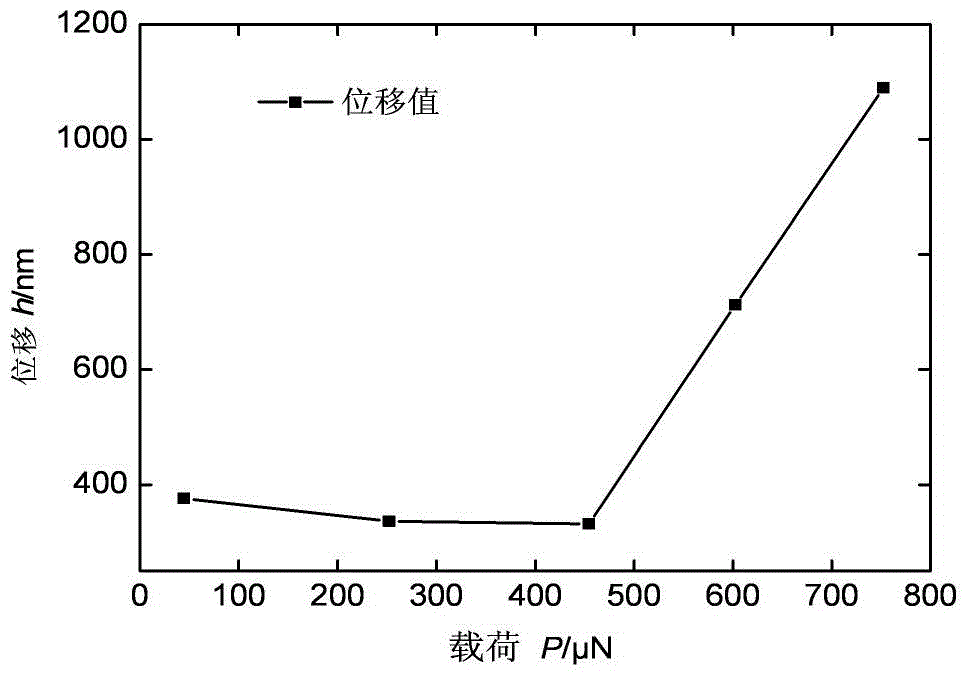

A Method for Evaluating the Thickness of Material Subsurface Machining Damaged Layer

ActiveCN104458463BNo destructionWide applicabilityInvestigating material hardnessMicrometer scaleMachining

The invention belongs to the technical field of material surface machining quality evaluation and in particular relates to a method for evaluating material sub-surface machining damage layer thickness. By utilizing an indentation test, the sub-surface damage layer thickness is evaluated by virtue of a displacement change rule generated by a pressure head under the actions of different loads; when the increment of the maximum displacement value of the selected load is greater than 50 percent compared with the maximum displacement value of the previous load, the maximum displacement value generated by the selected load is the evaluation value of the sub-surface damage layer thickness; the increment of the selected load can be changed according to the requirements of different processes, so that the accuracy of the evaluation value of the sub-surface damage layer thickness is adjusted; and the evaluation value of the sub-surface damage layer thickness is determined in the shortest time. With the adoption of the method, the value of the sub-surface damage layer thickness is evaluated, although an accurate value of the sub-surface damage layer thickness cannot be obtained and a certain damage of the material surface is generated, indentation in a micrometer scale is generated on the material surface only, the damage degree is obviously smaller than that in a corroding and sectioning method, and destruction of the environment is not caused.

Owner:SHENYANG AEROSPACE UNIVERSITY

Preparation method for alpha-aluminium oxide monocrystal

InactiveCN101942698AImprove pass rateReduce scrap ratePolycrystalline material growthSingle crystal growth detailsChemistrySeed crystal

The invention belongs to the techncial field of preparation methods for synthetic sapphire crystals, and especially realtes to a preparation method for an alpha-aluminium oxide monocrystal, aiming to solve the technical problems on providing the preparation method for the alpha-aluminium oxide monocrystal with the characteristics of environment protection and stable product quality. The preparation method of the alpha-Al2O3 monocrystal comprises the steps of adding raw materials; inserting a seed crystal; sintering the crystal; crystallizing the chemical materials; expanding the center and the crystal; and carrying out isodiametric growth and the like, wherein the raw materials are delta-Al2O3 and the crystal for inserting is a seed crystal with the crystal orientation of 75-degree axis A. The invention can ensure that the qualification rate of the alpha-Al2O3 monocrystal is enhanced; the rejection rate is reduced; and the production cost is saved.

Owner:四川鑫通新材料有限责任公司

A new manufacturing method of high-density integrated molded inductor

ActiveCN104900390BSimple winding processRealize automated productionInductances/transformers/magnets manufactureMagnetic materialsHigh densityResin adhesive

The invention discloses a novel high density integrated electric inductance manufacturing method, which comprises: (1) winding an varnished wire coil into a spiral shape; (2) making first iron magnetic powers into a magnetic core through mechanical pressing; (3) packing the magnetic core into a hollow cavity of the varnished wire coil; (4) packing the varnished wire coil packed with the magnetic core into an injection mold; (5) uniformly mixing and blending resin adhesive, coupling agent and accelerant to obtain high temperature resin adhesive; (6) uniformly mixing and blending the second iron magnetic powers and the high temperature resin adhesive to obtain magnetism composite material; (7) injecting the magnetism composite material into a mold cavity of the injection mold to mold, and solidifying to obtain external magnetic body; and (8) cooling and stripping to obtain molded electric inductance. According to the invention, the volume of the electric inductance manufactured with the method provided herein is small; the density is high; the relative magnetic conductivity is high; the cooling performance is good; the service life is long; the electric inductance is molded as a whole; and the manufacturing method of the electric inductance is simple, thus reducing the production cost.

Owner:POCO HLDG CO LTD +2

A method for controlling Lepidoptera pests of Amomum tsao-ko by using natural enemies

PendingCN114051871AProtect biodiversityLow cost of long-term controlPlant protectionAnimal husbandryEcologyPest insect

The invention relates to the technical field of biological control in production of traditional Chinese medicinal materials, in particular to a method for controlling Lepidoptera pests of Amomum tsao-ko by using natural enemies. According to the method for controlling the Lepidoptera pests of the amomum tsao-ko by using the natural enemies, the control natural enemies adopts cantheconidea furcellata, the cantheconidea furcellata is put twice every year, the appropriate time for the first-time putting is from late April to early May, the appropriate time for the second-time putting is from late June to late July, and the cantheconidea furcellata is released before ten o'clock in the morning and after five o'clock in the evening in cloudy days or sunny days. The release density of the cantheconidea furcellata is 30-100 / mu, and the release method is a scatter release method. According to the particularity of an amomum tsao-ko planting area, organic and ecological food is an inevitable trend of modern food production and development, and lepidoptera pests are the most important pests of amomum tsao-ko; by comprehensively considering the above aspects, the method for controlling the Lepidoptera pests of the Amomum tsao-ko by using the natural enemies is provided, which is ecological and safe and can reduce the damage of the Lepidoptera pests of the Amomum tsao-ko to be below a control threshold of the Amomum tsao-Ko economy.

Owner:INST OF MEDICINAL PLANTS YUNNAN ACAD OF AGRI SCI

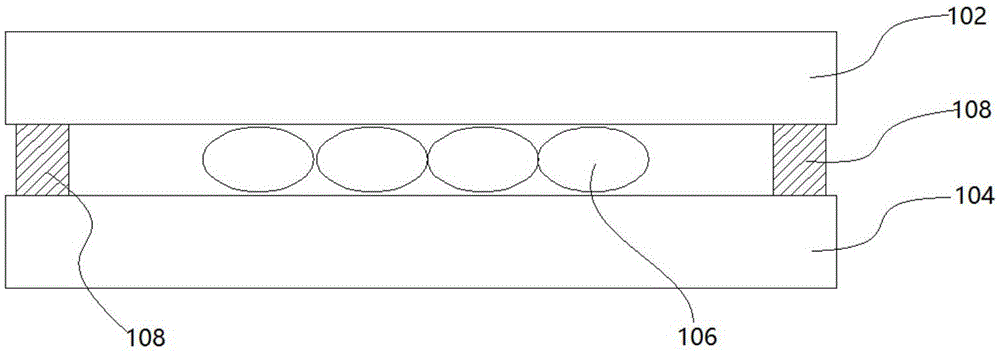

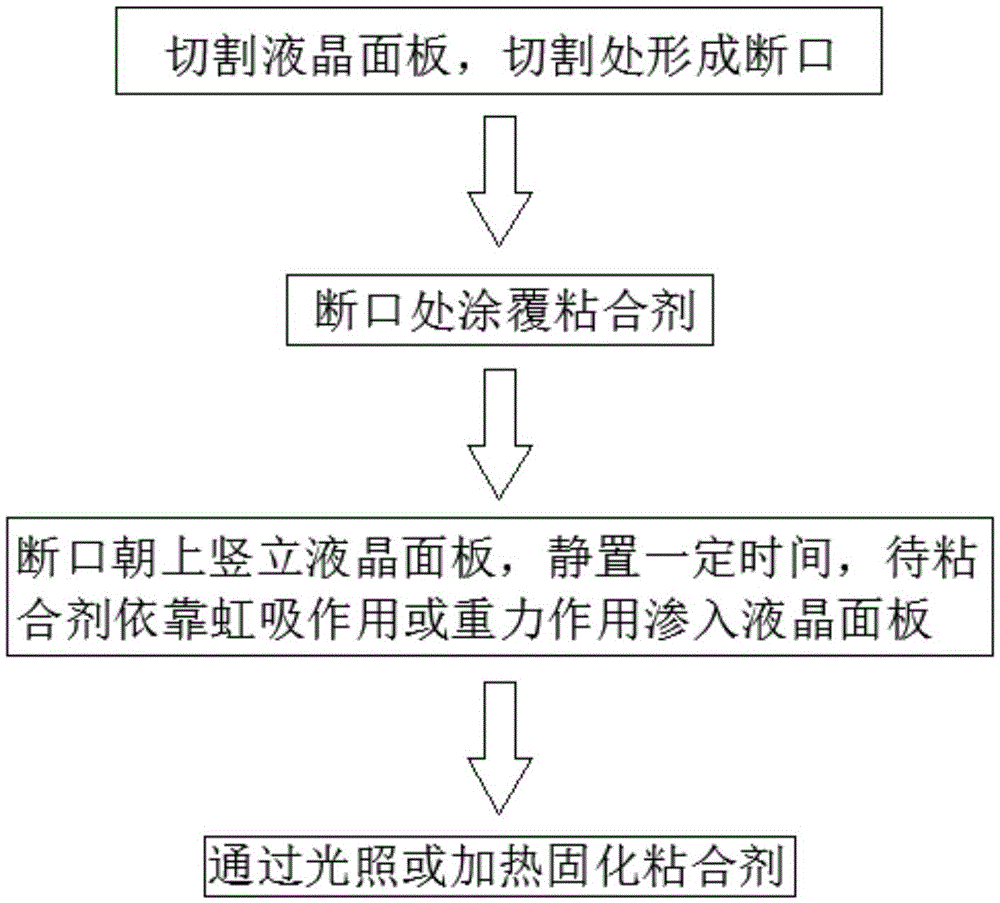

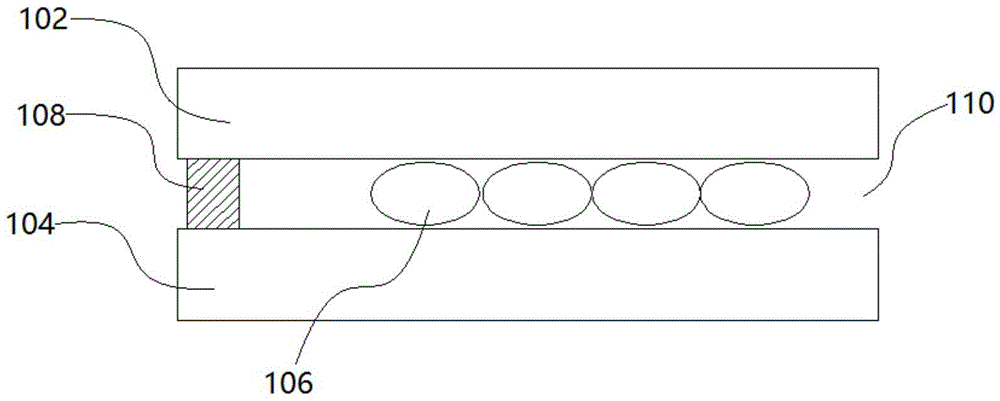

Method for adjusting size of liquid crystal panel

The invention discloses a method for adjusting the size of a liquid crystal panel. The liquid crystal panel comprises a color film substrate, an array substrate and liquid crystals filled between the color film substrate and the array substrate. The method for adjusting the size of the liquid crystal panel comprises the following steps: cutting the liquid crystal panel to form a fracture at the cutting position; coating the fracture with an adhesive; letting the adhesive partially or all penetrate into the color film substrate and the array substrate; and curing the adhesive. According to the method, the liquid crystal substrate is not squeezed, so that the risk of damage to the liquid crystal substrate is avoided. The adhesive coating mode is simple, easy to operate, high in coating success rate and high in production efficiency.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

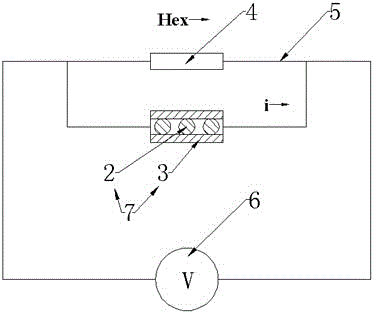

Magnetic field sensor probe sensitivity improving method

ActiveCN104931899AEnergy savingSimple adjustment processMagnetic measurementsTest objectMaterials science

A magnetic field sensor probe sensitivity improving method belongs to the sensor sensitive probe application field; a sensor probe is arranged in a bias magnetic field; a sensor probe easy magnetizing direction is vertical to a bias magnetic field easy magnetizing direction; two ends of the sensor probe are connected with a power supply. A soft-magnetic material can excite the bias magnetic field, so no extra power consumption is generated, thus saving energy; the bias magnetic field and a to be tested object are connected in a non fixed manner; a debug process is simple, dismounting is easy, and operation is simple; the magnetic field sensor probe sensitivity improving method uses the bias magnetic field to improve magnetic material GMI sensitivity, and no damage is caused to raw material, thus saving material.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Preparation method for alpha-aluminium oxide monocrystal

InactiveCN101942698BProportionally largeGood dispersionPolycrystalline material growthSingle crystal growth detailsCrystal orientationRejection rate

Owner:四川鑫通新材料有限责任公司

A method of using Luoyang shovel to carry out lateral soil extraction of roadbed

The invention relates to a transverse earth borrowing method applied to a roadbed by a Luoyang shovel, belonging to the technical field of roadway maintenance. The method solves the problems of existing earth borrowing devices and methods applied to the roadbed that the social work function and service life of the road are affected, personal security of workers is hard to ensure, and the earth borrowing efficiency is low. The method specifically comprises the following steps: ensuring that the roadbed at an earth borrowing opening is 1m higher than the highest earth borrowing opening; cleaning weed and surface capping mass away from a side slope by a shovel, and the distributing points; digging a platform at each earth borrowing opening, pouring a cement concrete horizontal table which is 50cm long, 15cm wide and 5cm high outside each earth borrowing opening, measuring by adopting a leveling instrument, and burying a snap joint at each of the front and rear ends of the horizontal table; preserving the poured concrete horizontal table for at least 7 days; starting borrowing earth when the Luoyang shovel reaches a specified earth borrowing opening; and filling earth blocks in a prepared aluminum box from at the middle part of the head of the Luoyang shovel and finally sealing the aluminum box. The method provided by the invention is used for transversely borrowing earth for the roadbed.

Owner:HARBIN INST OF TECH

One-piece molded inductor and manufacturing method thereof

ActiveCN106252055BImprove current resistanceStable structureTransformers/inductances magnetic coresInductances/transformers/magnets manufactureElectricitySilicone Gels

The invention provides a manufacturing method of an integrally molded inductor, and belongs to the technical field of inductance elements. The method comprises the steps of winding a copper wire into a coil and electrically connecting the coil and an electrode pin; mixing a magnetic-conducting material with liquid silicone gel evenly at the mass ratio of 100:(2-15) to form a filler and carrying out heat preservation on the filler under the condition that the temperature is 70-80 DEG C for 0.2-1 hour; and putting the coil connected with the electrode pin into a mold, filling the mold with the filler and carrying out integral stamping to form the integrally molded inductor. The manufacturing method is simple; and the technological process is saved. Furthermore, the invention further provides the integrally molded inductor manufactured by the manufacturing method. The current resistance of the integrally molded inductor is significantly improved; the inductor is stable in structure; the magnetic loss can be reduced; and the noise at work can be reduced.

Owner:重庆金籁科技股份有限公司

Preparation method of high-hydrophobicity leather coating agent

InactiveCN102924649BNo destructionHighly hydrophobicCoatingsLeather surface finishingWeather resistanceEmulsion polymerization

The invention relates to a preparation method of a high-hydrophobicity leather coating agent. The acrylate leather coating agent has excellent film-forming property, light stability, weather resistance and binding property, but has some defects, such as poor water resistance, poor solvent resistance, lack of functionality and the like, due to the linear structure of the acrylate resin. In order to overcome the defects above, the invention provides a semicontinuous seed emulsion polymerization method for preparing the core-shell acrylate resin: the shell is properly cross-linked, so that the acrylate resin is converted into a reticular structure from the linear structure, thereby enhancing the water resistance and solvent resistance of the acrylate resin; and besides, organic fluorine is introduced into the shell, so that the acrylate resin has high hydrophobicity. After the high-hydrophobicity leather coating agent forms a film, the contact angle with water is up to 124 degrees, and the film feels smooth and not sticky; the 24-hour water absorptivity is less than 10%; and after being soaked in methylbenzene for 48 hours, the film only swells, but is not dissolved.

Owner:SHAANXI UNIV OF SCI & TECH

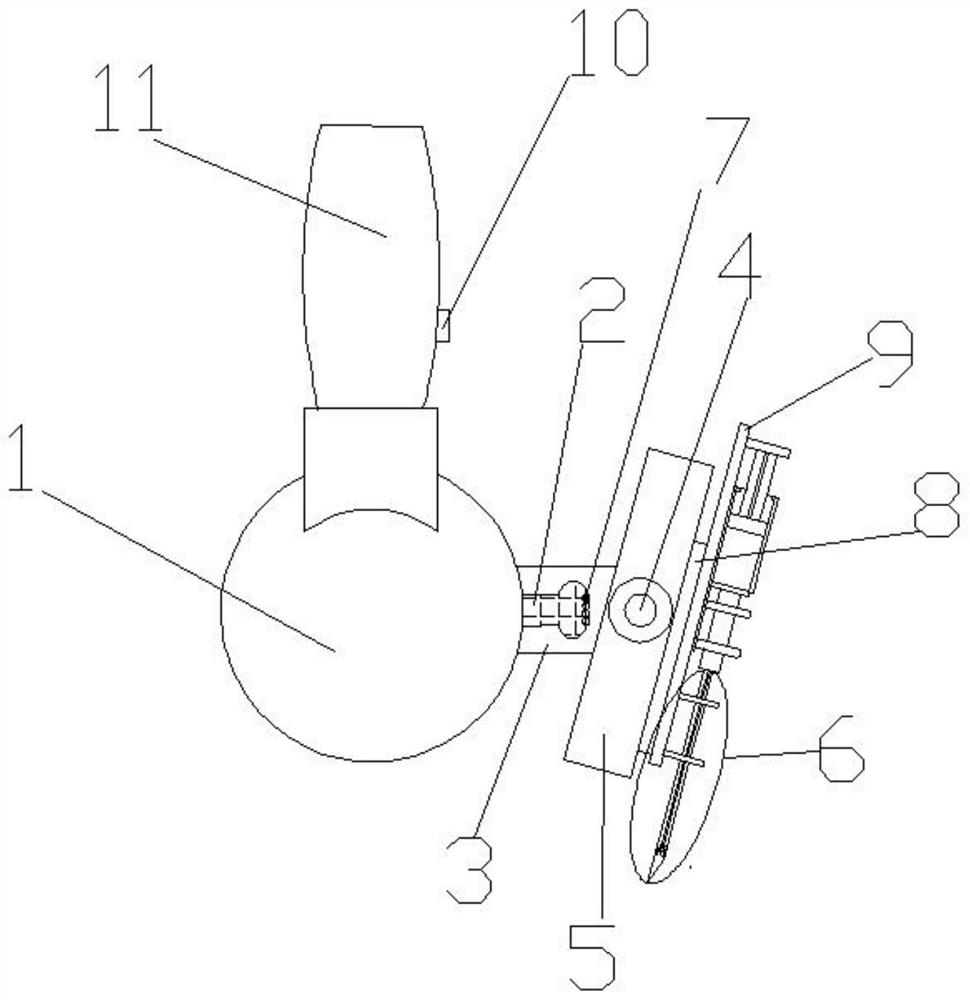

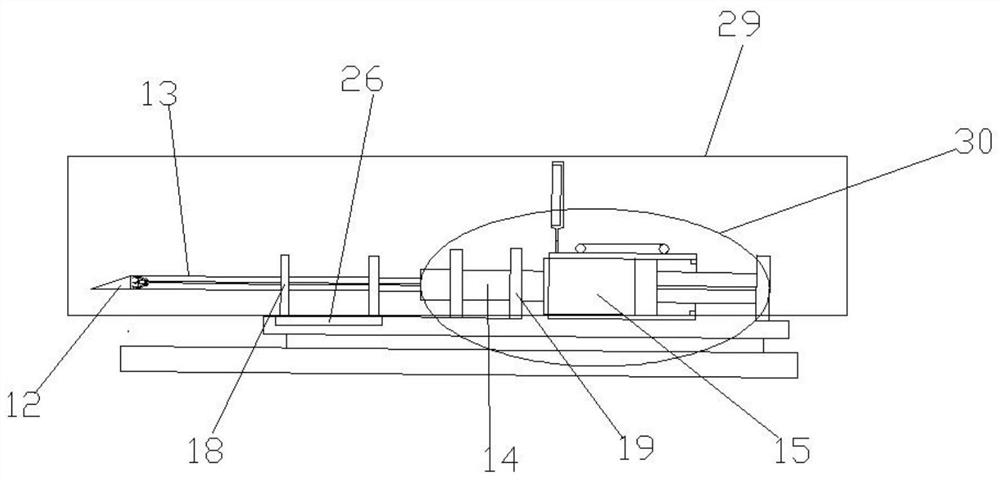

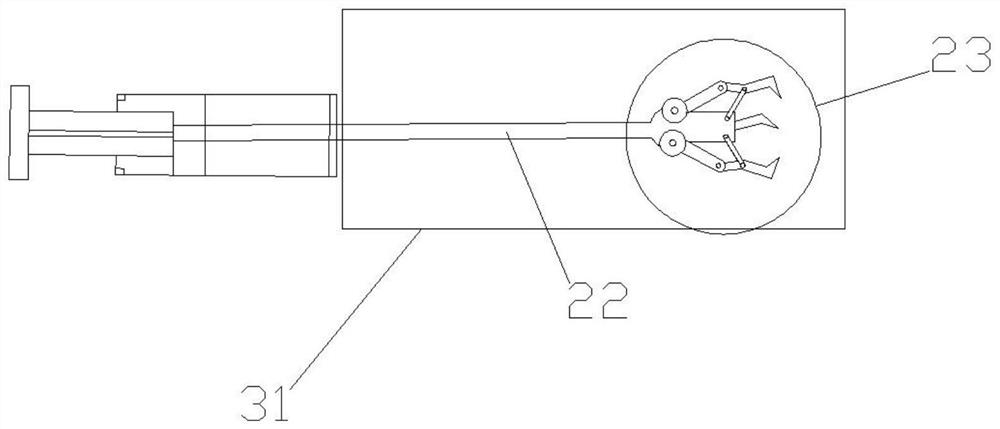

Ultrasonic positioning sampling puncture system

PendingCN113509214AHigh accuracyGood securityIncision instrumentsSurgical needlesPhysicsElectric machinery

The invention discloses an ultrasonic positioning sampling puncture system which comprises an ultrasonic probe, the right side of the ultrasonic probe is fixedly connected with an externally-hung fixed end, a handle is arranged at the upper end of the ultrasonic probe, a control switch is arranged on one side of the handle, a connecting body is arranged outside the externally-hung fixed end and fixedly connected with a rotating frame, and a rotating shaft is arranged in the center of the rotating frame. The right side of the sliding rail is fixedly connected with a moving seat, the right side of the moving seat is fixedly connected with a sampling puncture needle, the sampling puncture needle comprises a needle tube, the front end of the needle tube is movably connected with a puncture needle body, and the puncture needle body is pushed to move on the rotating frame in the length direction of the rotating frame; a grabbing mechanism is arranged in the puncture needle body and comprises a grabbing hand and a grabbing hand connecting pipe, the advantages of being high in target accuracy, good in safety and easy to operate can be achieved, and under the assistance of a computer, the target can be rapidly determined, the positioning process is simplified, the operation difficulty is lowered, dependence on the experience of an operator is reduced, and the working efficiency is improved.

Owner:浙江壹康普麦医疗科技有限公司

Latex turbidimetric freeze-dried reagent and preparation method thereof

Owner:深圳优迪生物技术有限公司

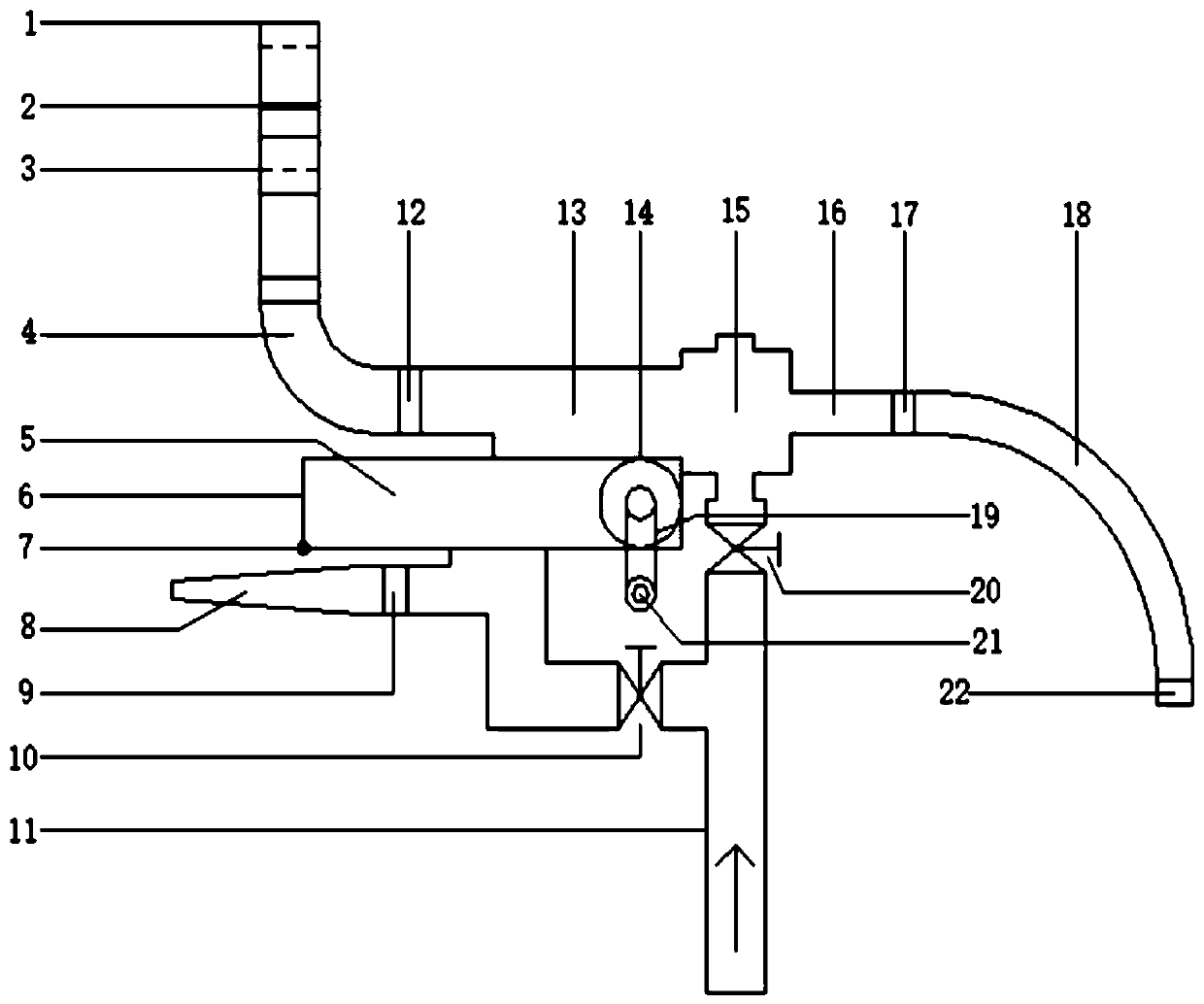

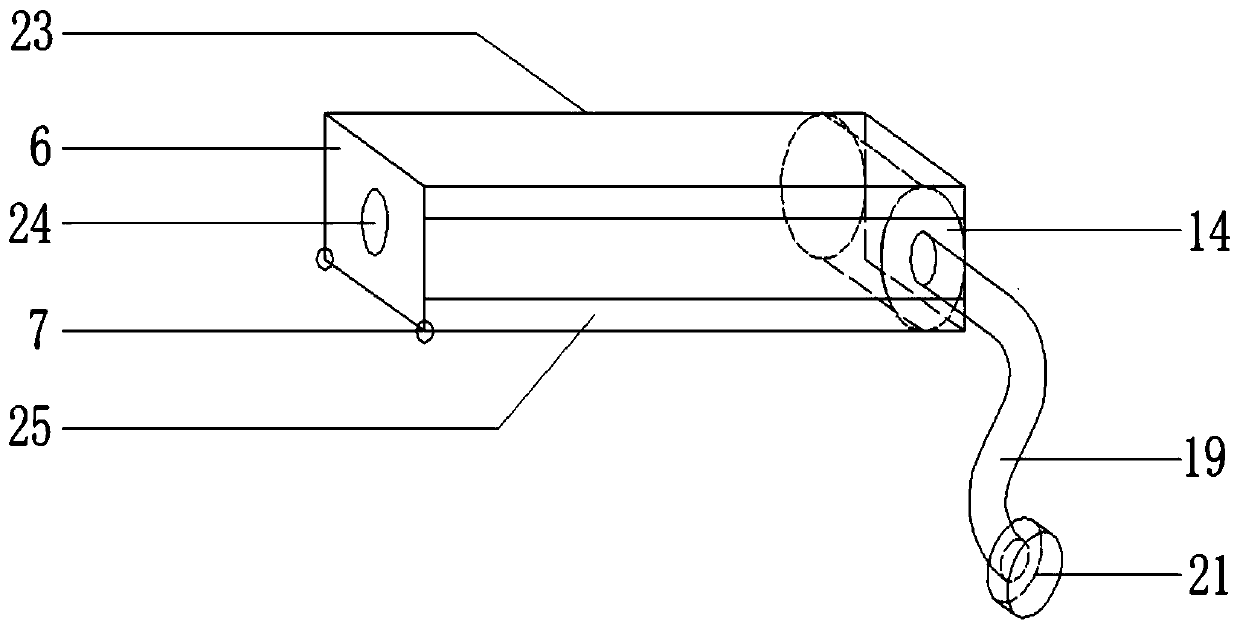

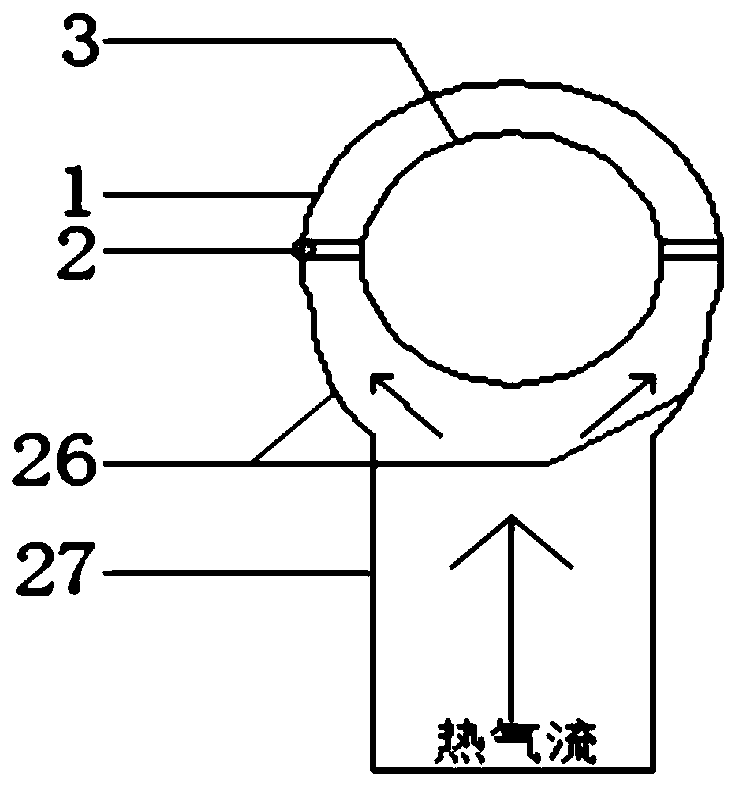

Engineering glue spray curing device based on vortex tube

ActiveCN110328116BEvenly heatedShort curing timeCompression machinesPretreated surfacesUniversal jointAdhesive glue

The invention relates to an engineering glue spraying curing device based on a vortex tube. The engineering glue spraying curing device comprises a horizontally-placed cylindrical annular heating curing device, the annular heating and curing device comprises an outer ring and an inner ring which are coaxially mounted on the same axis, a closed airflow channel is formed between the outer ring and the inner ring, and a plurality of pores are formed in the inner ring; an arc-shaped divergent gas outlet is formed in the lower part of the annular heating curing device; the arc-shaped divergent airoutlet is sequentially connected with a hot-air-flow air inlet pipeline, a hot-end elbow universal joint and a vortex tube hot end; the cold end of the vortex tube is connected with the universal joint of a cold end elbow, a cylindrical roller is arranged in a glue spraying cavity, the end part of the cylindrical roller is connected with a rocker, the rocker is connected with a rocker handle, anda cavity movable rotating plate is arranged at one end of the glue spraying cavity; the other end of a main body is connected with a compressed air inlet pipeline through a first valve; and the otherend of the main body is connected with a compressed air inlet pipeline and a vortex tube main body section through a first valve. The device integrates the functions of removing dust, removing dirt, spraying glue and heating and curing.

Owner:百成机电工程技术(湖北)有限公司

A Method of Improving the Sensitivity of Magnetic Field Sensor Probe

A method for improving the sensitivity of a magnetic field sensor probe belongs to the application field of sensor sensitive probes. The method is to place the sensor probe in a bias magnetic field, that is, the easy magnetization direction of the sensor probe is perpendicular to the easy magnetization direction of the bias magnetic field, and the two ends of the sensor probe are connected to a power supply. The present invention adopts the soft magnetic material itself to excite the bias magnetic field, and there is no extra power consumption, which saves energy; the non-fixed connection is adopted between the bias magnetic field and the object to be tested, the adjustment process is simple, the disassembly is convenient, and the operation is easy; the bias magnetic field is used Improve the GMI sensitivity of magnetic materials, without damage or damage to raw materials, and save materials.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for evaluating material sub-surface machining damage layer thickness

ActiveCN104458463ANo destructionWide applicabilityInvestigating material hardnessMicrometer scaleMinimum time

The invention belongs to the technical field of material surface machining quality evaluation and in particular relates to a method for evaluating material sub-surface machining damage layer thickness. By utilizing an indentation test, the sub-surface damage layer thickness is evaluated by virtue of a displacement change rule generated by a pressure head under the actions of different loads; when the increment of the maximum displacement value of the selected load is greater than 50 percent compared with the maximum displacement value of the previous load, the maximum displacement value generated by the selected load is the evaluation value of the sub-surface damage layer thickness; the increment of the selected load can be changed according to the requirements of different processes, so that the accuracy of the evaluation value of the sub-surface damage layer thickness is adjusted; and the evaluation value of the sub-surface damage layer thickness is determined in the shortest time. With the adoption of the method, the value of the sub-surface damage layer thickness is evaluated, although an accurate value of the sub-surface damage layer thickness cannot be obtained and a certain damage of the material surface is generated, indentation in a micrometer scale is generated on the material surface only, the damage degree is obviously smaller than that in a corroding and sectioning method, and destruction of the environment is not caused.

Owner:SHENYANG AEROSPACE UNIVERSITY

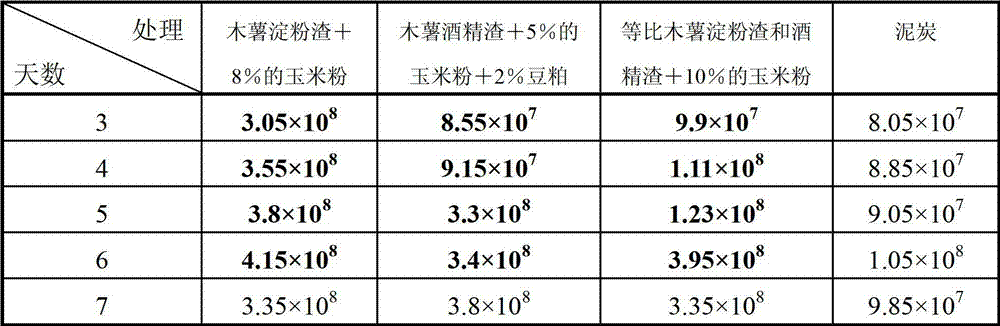

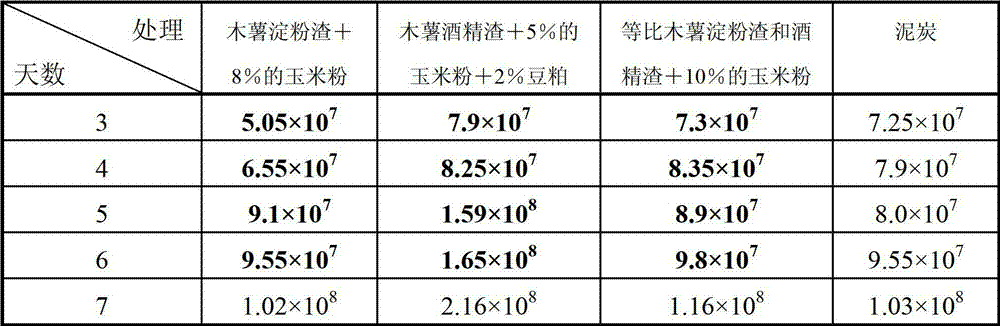

Method for preparing microbial inoculum carrier from cassava residues

ActiveCN102964150BSufficient raw materialsLow priceClimate change adaptationOn/in organic carrierAlcoholCorn flour

Owner:ENVIRONMENT & PLANT PROTECTION INST CHINESE ACADEMY OF TROPICAL AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com