A method of using Luoyang shovel to carry out lateral soil extraction of roadbed

A Luoyang shovel and roadbed technology, applied in the field of basic soil survey, infrastructure engineering, construction, etc., can solve the problems affecting the social service function and service life of highways, low soil borrowing efficiency, and difficulty in ensuring the safety of workers themselves. Achieve the effect of low cost, simple tools and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0014] Specific implementation mode one: combine Figure 4 and Figure 5 Describe this embodiment mode, a kind of method of utilizing Luoyang shovel to carry out embankment lateral soil extraction described in this embodiment mode is realized through the following steps:

[0015] Step 1. Select the stake number of the borrow mouth: the subgrade height of the borrow mouth is 1m higher than the highest borrow mouth;

[0016] Step 2. Clean up the slope and do the distribution: Use a shovel to clean up the weeds and surface soil on the slope, and then do the distribution;

[0017] Step 3. Make the water platform: Excavate the platform at each borrow mouth, pour a cement concrete water platform with a length, width, and height of 50cm, 15cm, and 5cm outside the borrow mouth, and measure it with a level ruler. A buckle is embedded in the front and rear respectively;

[0018] Step 4. Preservation of the concrete water platform: keep the poured concrete water platform for at least ...

specific Embodiment approach 2

[0023] Specific implementation mode two: combination Figure 4 and Figure 5 To illustrate this embodiment, the specific steps of arranging points in step 2 of the method of using a Luoyang shovel to carry out lateral soil removal from the subgrade described in this embodiment are as follows:

[0024] Step A, Longitudinal soil intake layout: select the heights of 0.10m, 0.30m, 0.50m, and 0.70m from the top of the subgrade work area as the soil intake, and select two pile numbers to select soil at the same height The distance between the three borrow ports along the route should be kept at least 15m;

[0025] Step B. Arrangement of soil borrow points in the horizontal direction: in the direction of the vertical route, take the outer edge of the hard shoulder as the reference point, set a soil borrow point every 1.0m inward, and select 6 to 8 soil borrow points.

[0026] Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

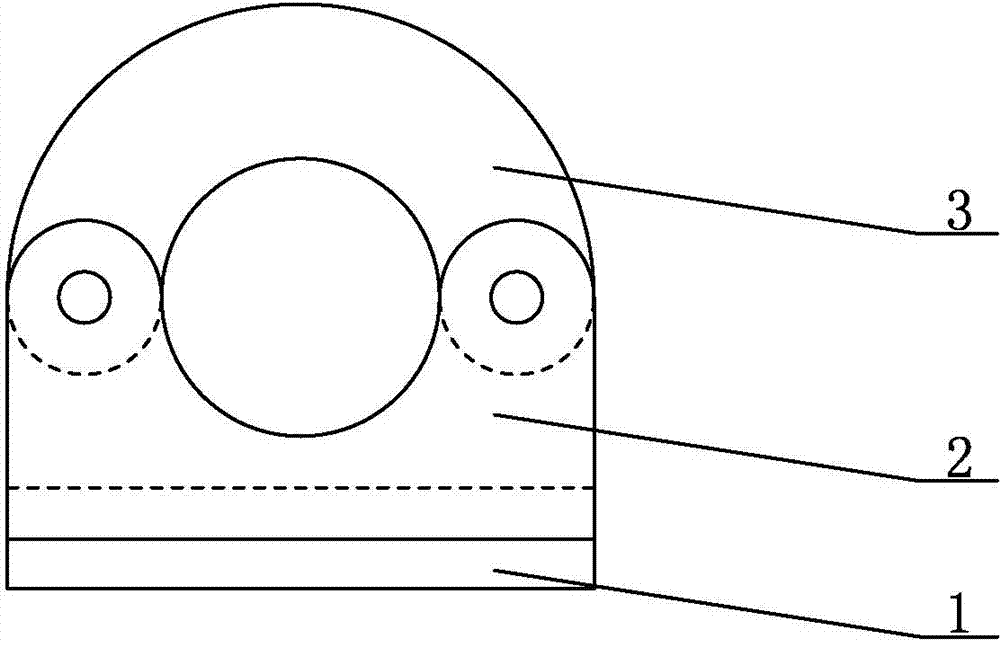

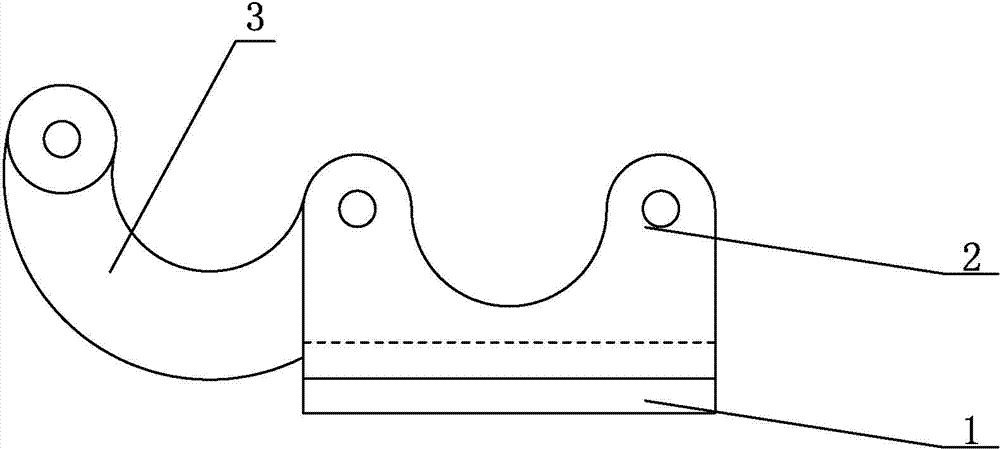

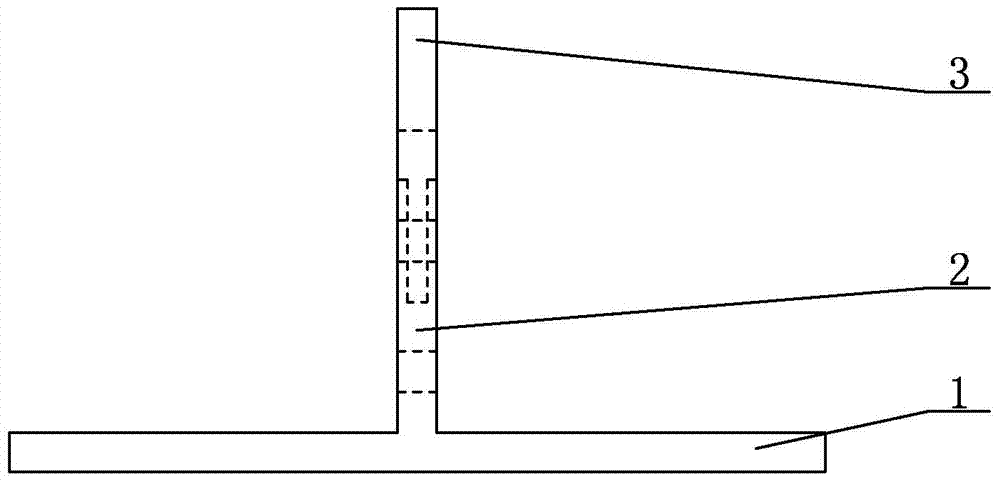

[0027] Specific implementation mode three: combination figure 1 , figure 2 and image 3 This embodiment is described. The buckle in step 3 of the method of using a Luoyang shovel to carry out lateral soil removal from the subgrade described in this embodiment includes a base 1, a lower semicircle clamp 2 and an upper semicircle clamp 3, and the lower semicircle clamp 2 One end is rotatably connected to one end of the upper semicircle clamp 3, the other end of the lower semicircle clamp 2 is detachably connected to the other end of the upper semicircle clamp 3, and the lower semicircle clamp 2 and the upper semicircle clamp 3 are closed to form a circular clamp Buckle, the circular buckle is welded on the upper surface of the base 1, and embedded in the concrete level platform to pour health. The entire buckle base is embedded in the concrete platform, and the bottom of the buckle forming a ring exceeds the surface of the concrete platform by 10mm.

[0028] The technical ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com