A quenched and tempered low temperature steel and its manufacturing method

A technology for low-temperature use of steel and a manufacturing method, applied in the direction of temperature control, etc., can solve the problems of insufficient low-temperature crack resistance of steel plates, little low-temperature toughness in the heat-affected zone, low low-temperature toughness, etc., and achieve excellent resistance to welding reheat cracks. Performance and hot and cold processing performance, excellent welding processability, high and low temperature toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

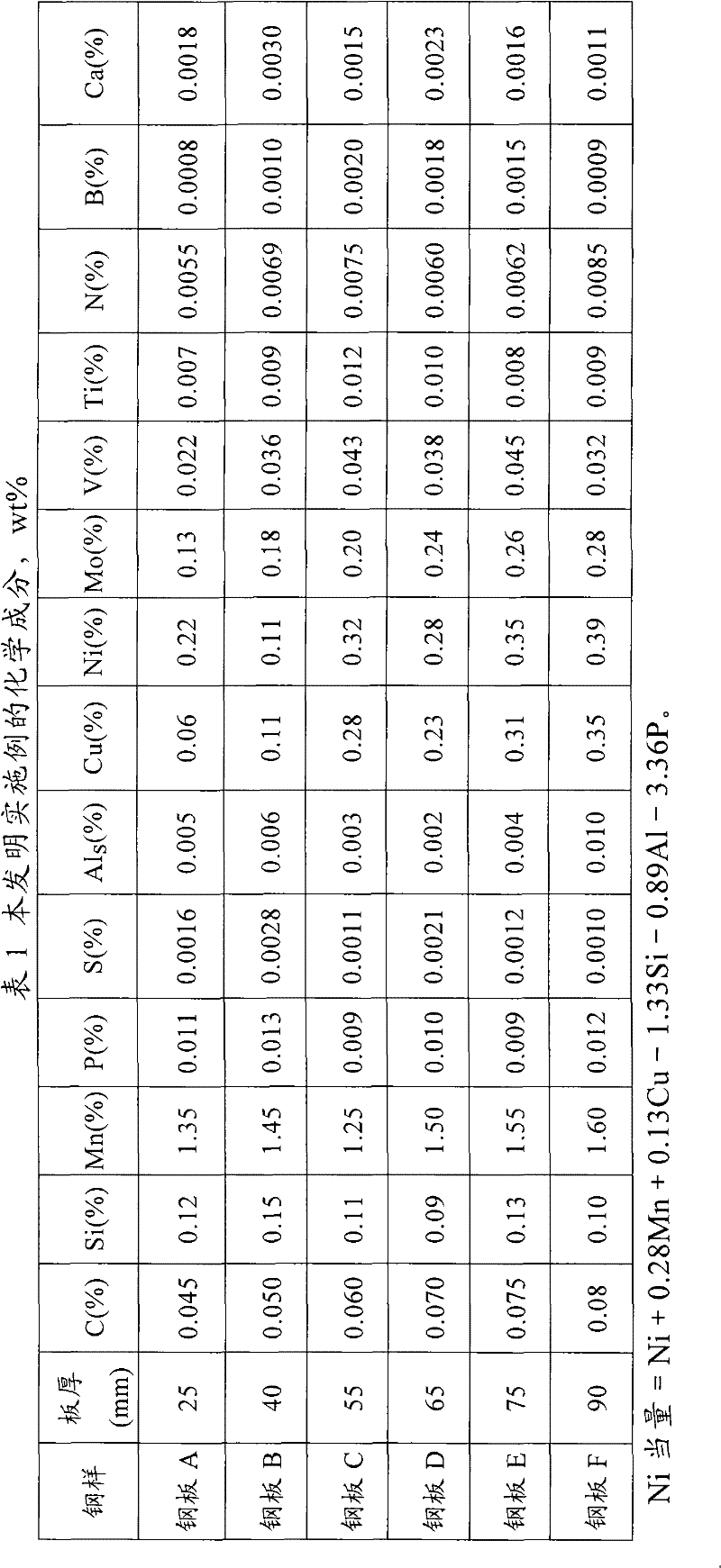

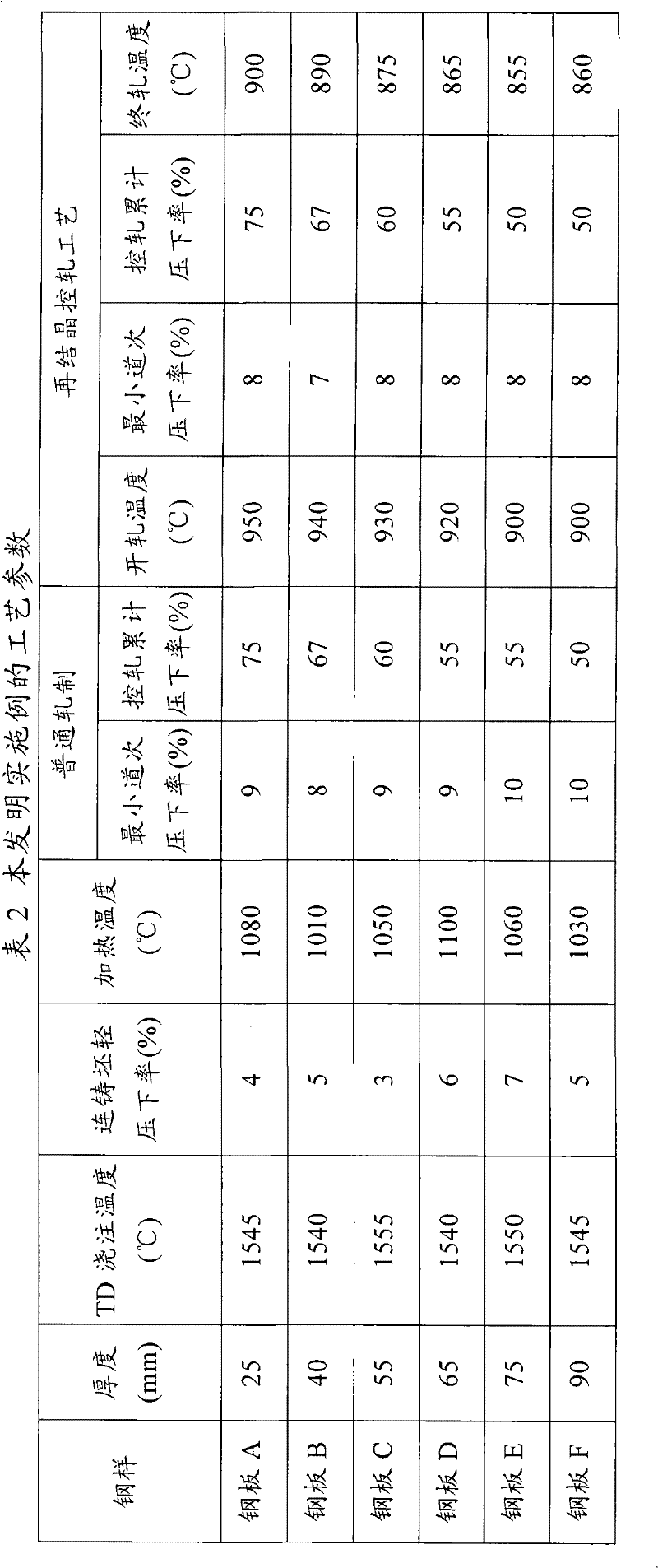

[0060] The present invention is described in more detail below through examples.

[0061] The present invention starts from the alloy combination design and creatively adopts a low-alloy steel composition system of low C-high Mn-ultra-low Als-medium N-a small amount of (Cu+Ni+Mo) alloying-ultrafine (Ti+B) treatment As a basis, reduce the acid-soluble Als content in steel to ≤0.01%, control Ni equivalent to ≥0.25%, B≥0.714 (N-0.292Ti-0.518Als) and 15≤Mn / C≤30, a small amount of (Cu+Ni+Mo ) alloying, Ca treatment and the Ca / S ratio is controlled between 1.0 and 3.0 and 1.0×10 -4 ≤(%Ca)×(%S) 0.28 ≤1.5×10 -3 , optimized recrystallization controlled rolling, online direct quenching and subsequent tempering heat treatment process, while obtaining high strength and excellent low temperature toughness, the steel plate can withstand large heat input welding, especially suitable for manufacturing low temperature storage tanks, low temperature pressure steel pipes, ice Sea area offshor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com