Method for preparing microbial inoculum carrier from cassava residues

A technology of cassava dregs and cassava starch dregs, applied in the direction of fixing on/in organic carriers, adapting to climate change, etc., can solve the problems of secondary pollution, high energy cost, high consumption, etc., and achieve cost saving and preparation process Simple, Inexpensive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

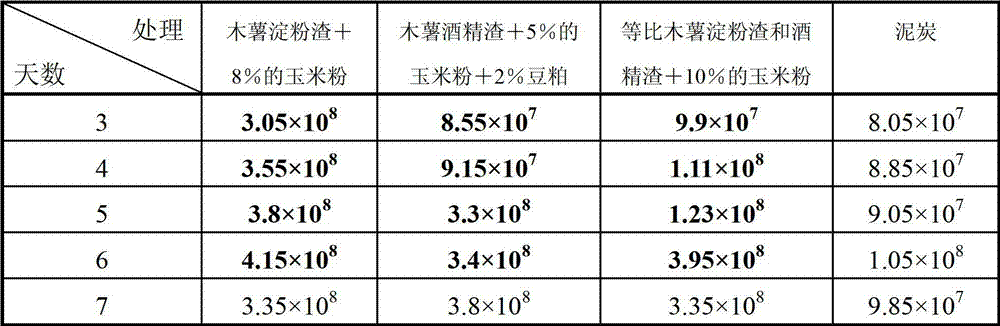

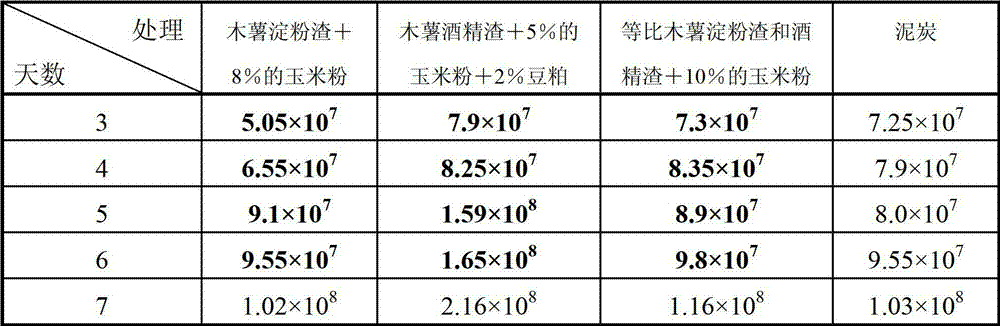

Embodiment 1

[0057]Embodiment 1, the preparation of inoculum carrier matrix

[0058] 1. Processing of raw materials: drying the tapioca starch residue in the sun, the moisture content is 8.4%, pulverizing the dried tapioca starch residue with a pulverizer, passing through a sieve with an aperture of 0.85 mm, and collecting the sieved tapioca starch residue;

[0059] The particle size of the sieved tapioca starch residue is less than 0.85mm, and the moisture content is 8.4%;

[0060] 2. Nutrient supplementation: add corn flour (also called corn flour) to the above-mentioned sieved product by 8% of the weight of the tapioca starch residue after sieving, and mix to obtain a mixed product;

[0061] 3. Drying: the moisture mass content of the above mixed product is dried to 8%, and the dried product is sterilized by steam at 110° C. for 60 minutes to obtain a bacterial agent carrier matrix.

Embodiment 2

[0062] Embodiment 2, the preparation of inoculum carrier matrix

[0063] 1. Raw material treatment: drying the cassava alcohol residue in the sun, the moisture content is controlled at 9%, pulverizing the dried cassava alcohol residue with a pulverizer, passing through a sieve with an aperture of 0.85 mm, and collecting the sieved cassava alcohol residue;

[0064] The particle size of the sieved cassava alcohol residue is less than 0.85mm, and the moisture content is 9%;

[0065] 2. Nutrient supplementation: adding corn flour and 2% soybean meal by weight of the cassava alcohol residue to the cassava alcohol residue after the sieving, and mixing to obtain a mixed product;

[0066] 3. Drying: the moisture mass content of the above mixed product is dried to 9%, and the dried product is sterilized by steam at 110° C. for 60 minutes to obtain a bacterial agent carrier matrix.

Embodiment 3

[0067] Embodiment 3, the preparation of inoculum carrier matrix

[0068] 1. Raw material treatment: The cassava starch residue and the cassava alcohol residue are dried in the sun respectively, and the moisture content is controlled at 9%. Sieved tapioca starch residue and sieved tapioca starch residue;

[0069] The particle size of the sieved cassava starch residue and the sieved cassava alcohol residue are both less than 0.85mm, and the moisture content is 9%;

[0070] 2. Nutrient supplementation: mix the sifted tapioca slag and the sifted tapioca slag in a mass ratio of 1:1 to obtain a mixed tapioca slag, add corn flour according to 10% of the weight of the mixed cassava slag, and mix to obtain a mixed product ;

[0071] 3. Drying: the moisture mass content of the above mixed product is dried to 9%, and the dried product is sterilized by steam at 120° C. for 40 minutes to obtain a bacterial agent carrier matrix.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com