Ultrasonic positioning sampling puncture system

A technology of ultrasonic positioning and puncture needles, which is applied in puncture needles, stereotaxic surgical instruments, inoculation and ovulation diagnosis, etc. It can solve the problem that the sample tissue cannot be extracted by conventional means, the samples obtained cannot meet the needs, and the puncture needles are difficult to take successfully. To achieve stable and controllable operation process, reduce dependence on experience, and facilitate rehabilitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

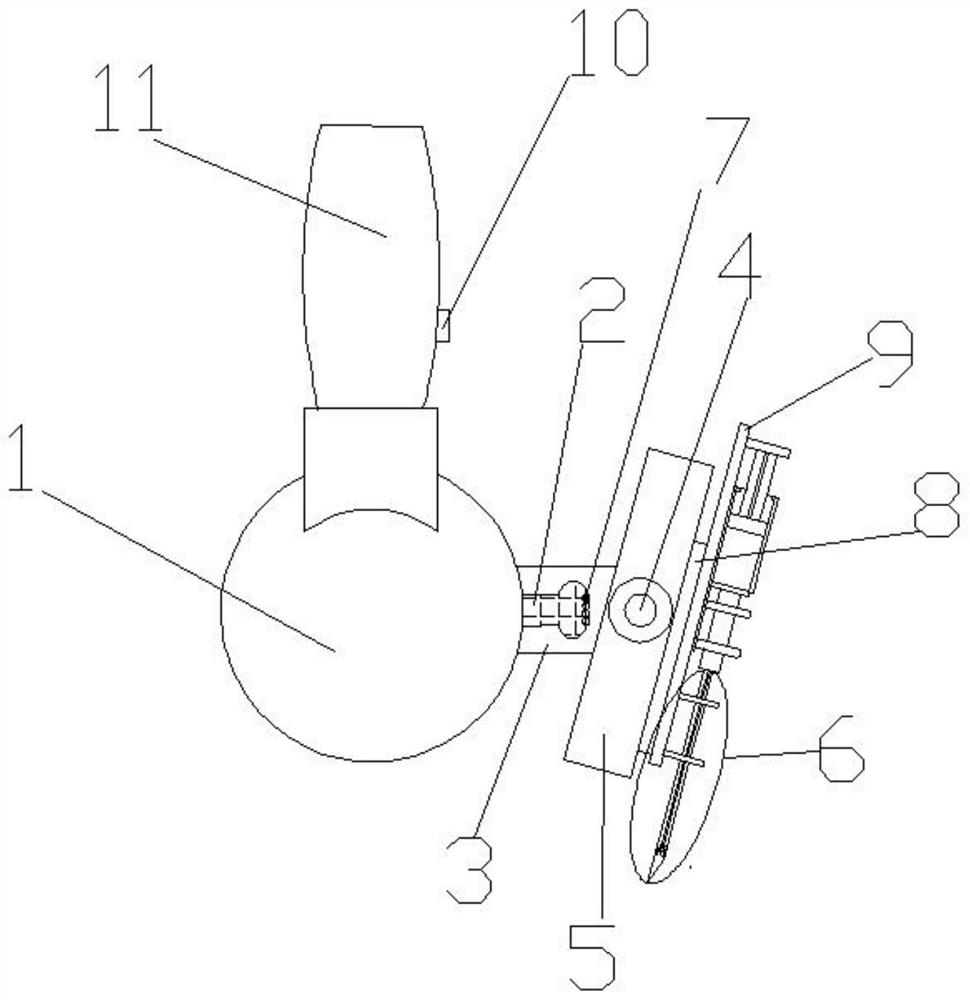

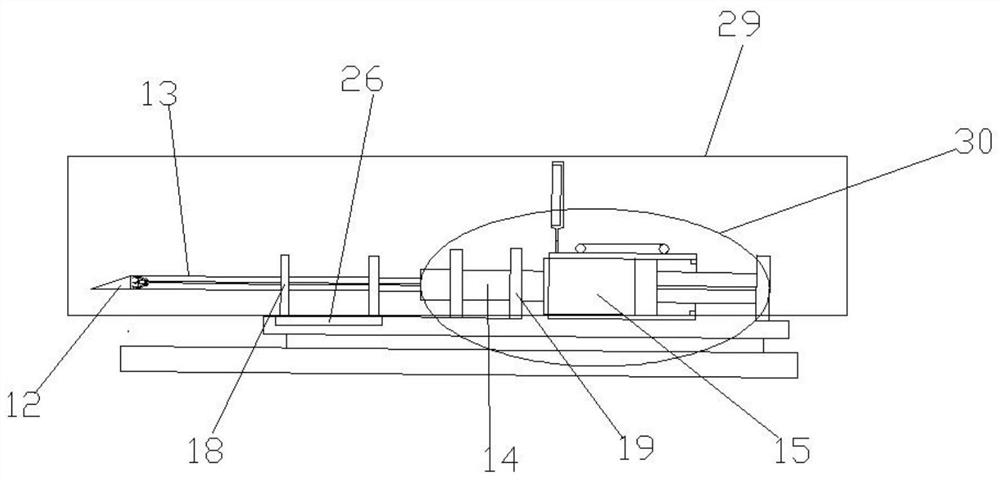

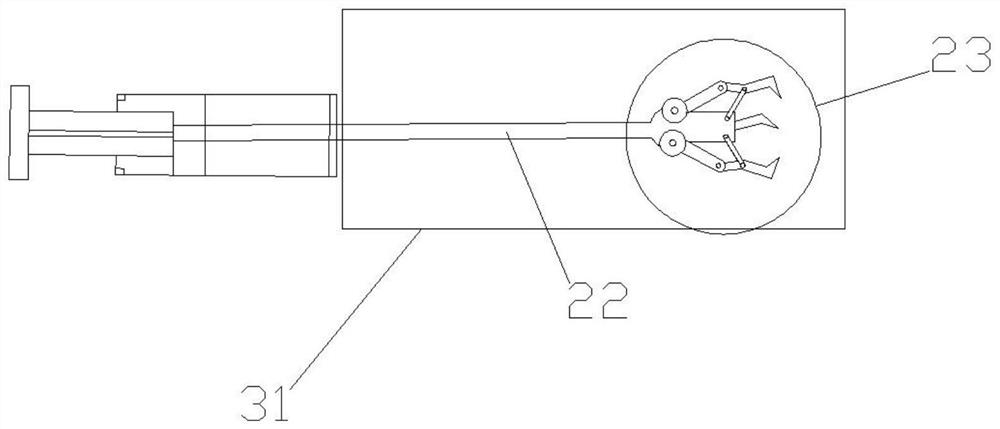

[0032] Example: see Figure 1-3 as shown,

[0033]An ultrasonic positioning and sampling puncture system, comprising an ultrasonic probe 1, the right side of the ultrasonic probe 1 is fixedly connected to an external fixed end 2, the external fixed end 2 is provided with a connecting body 3, the connecting body 3 is fixedly connected to a turret 5, and the center of the turret 5 is The position is provided with a rotating shaft 4, and the right side of the turret 5 is fixedly connected with a slide rail 8, the rotating shaft 4 is connected with a deceleration drive motor and rotates axially, the right side of the sliding rail 8 is fixedly connected with a moving seat 9, and the right side of the moving seat 9 A sampling puncture needle 29 is fixedly connected, and the sampling puncture needle 29 includes a needle tube 30. The front end of the needle tube 30 is movably connected with a puncture needle body 6, and the puncture needle body 6 moves along its length on the turret. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com