Patents

Literature

38results about How to "Improve current resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

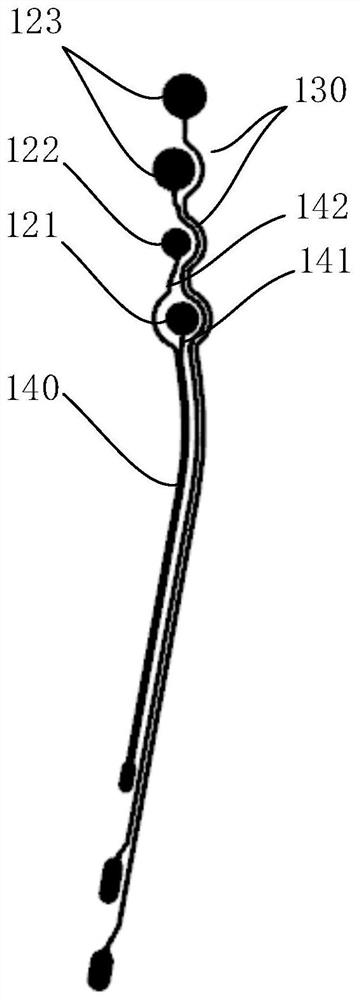

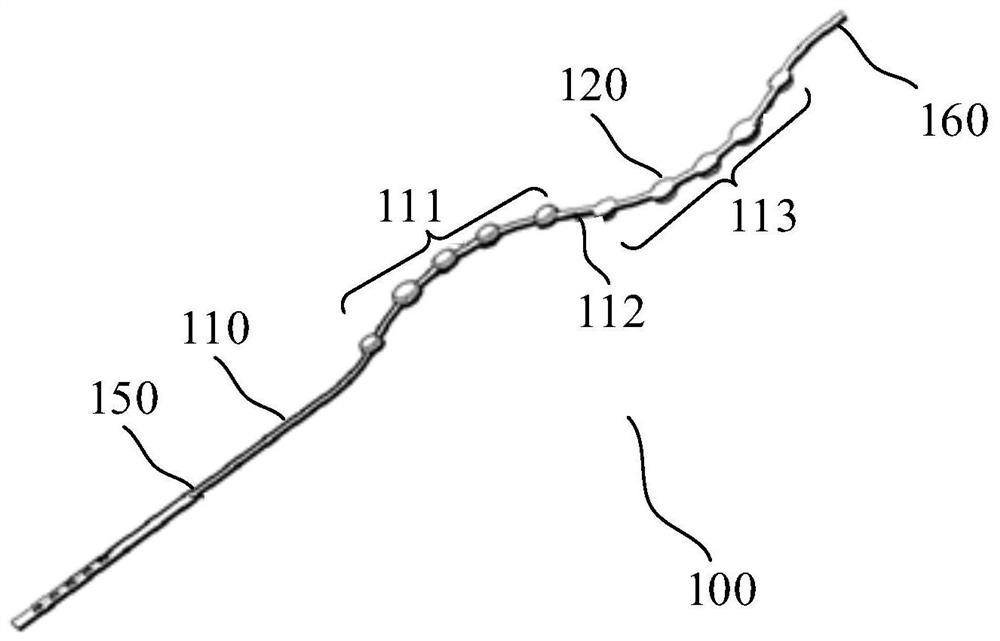

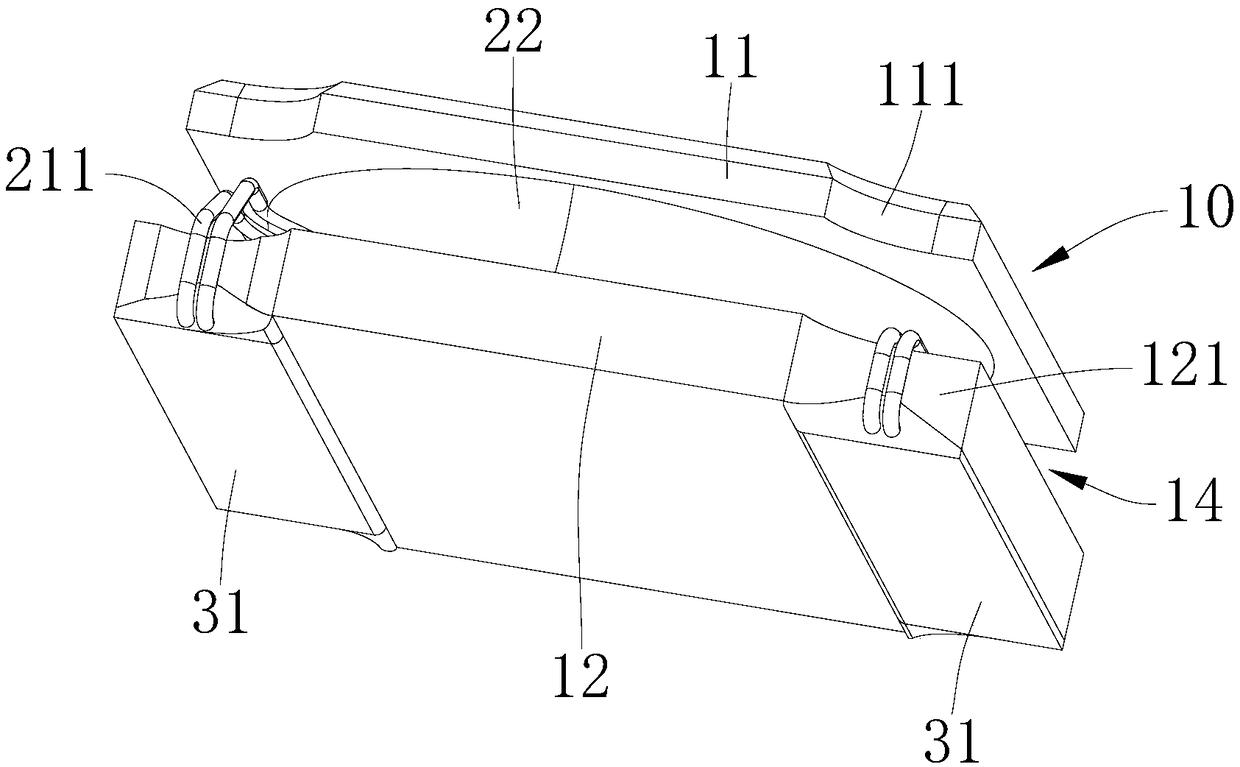

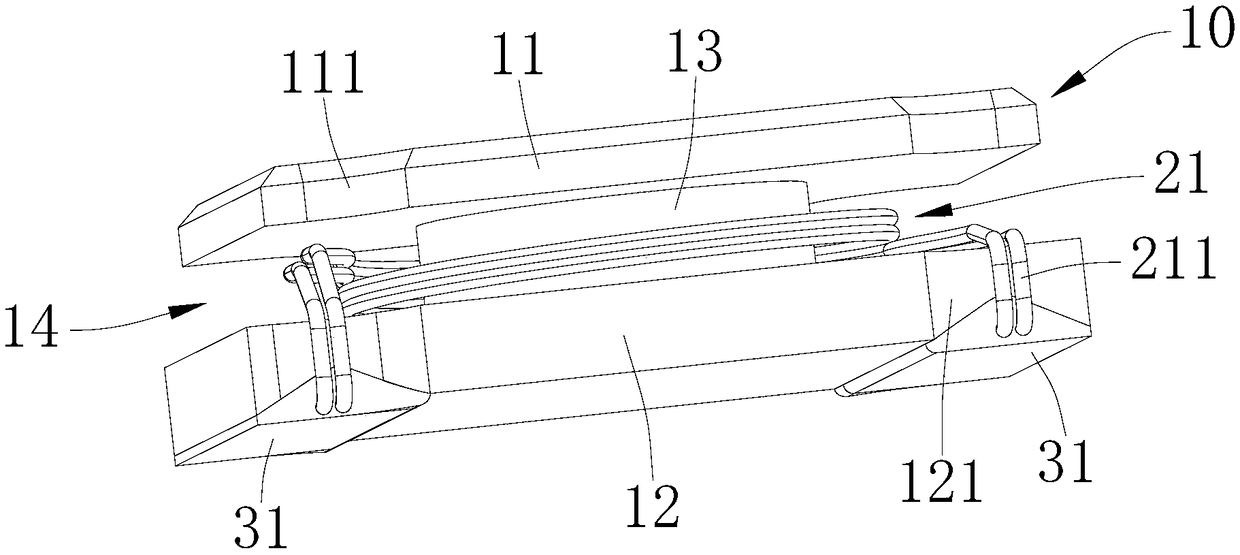

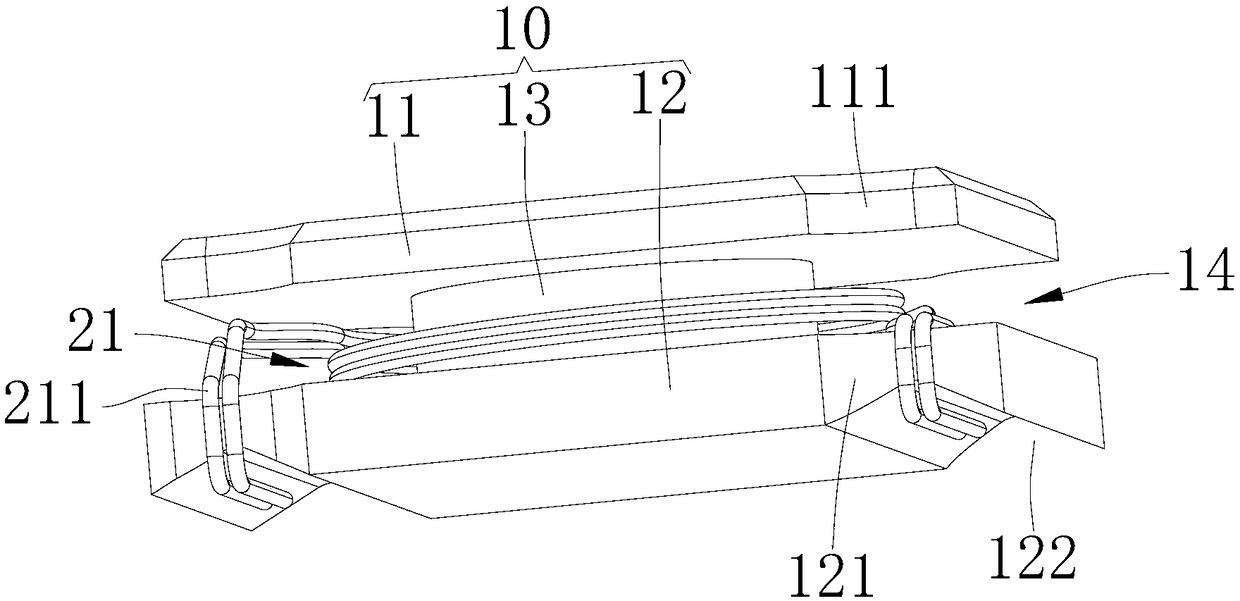

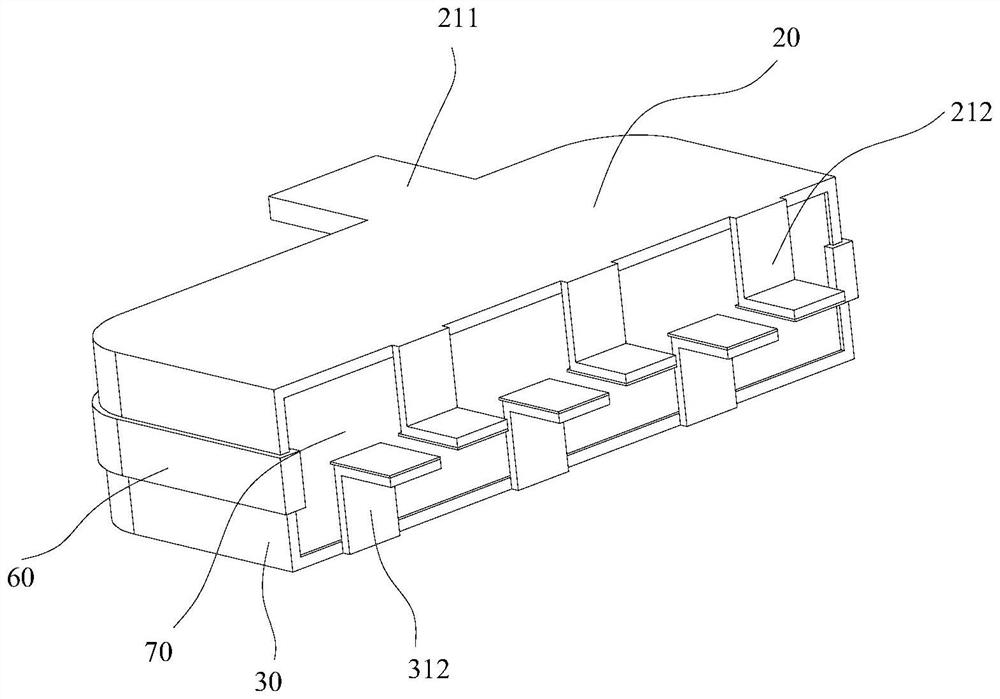

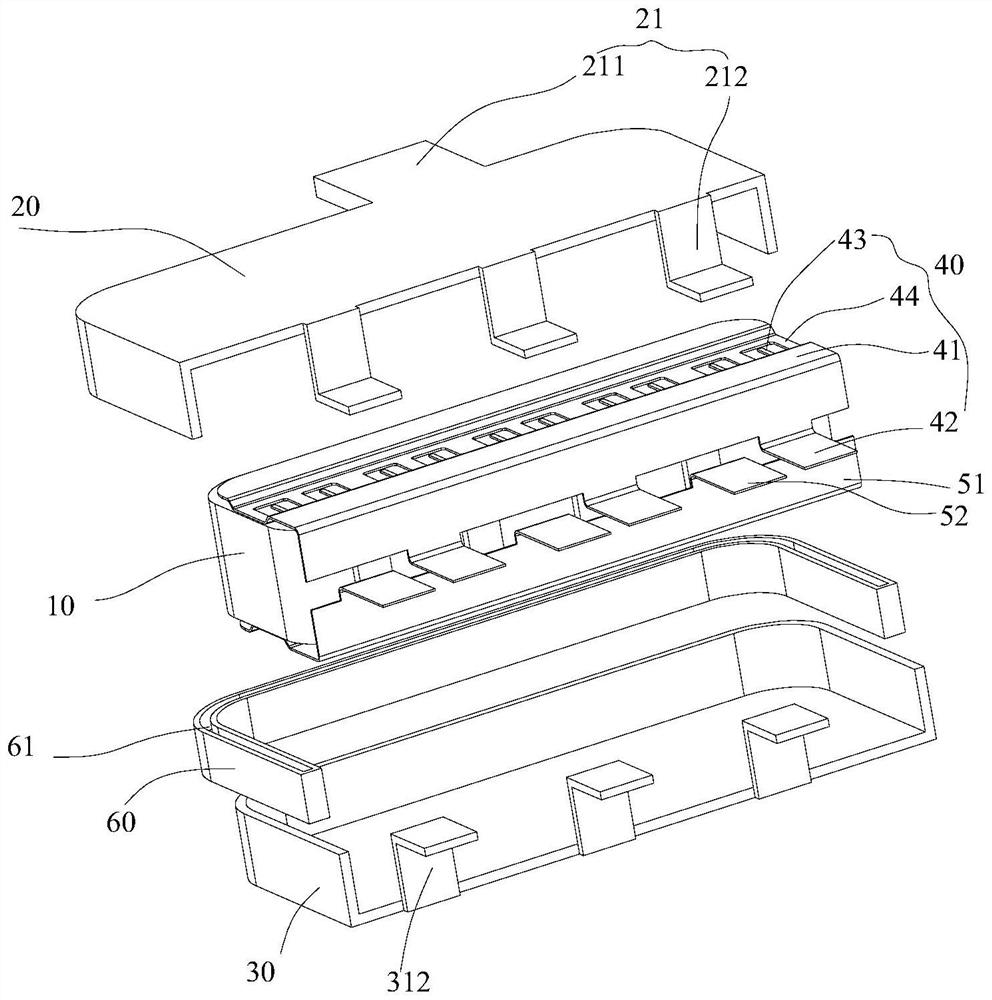

Electrode assembly, electrophysiological catheter and electrophysiological system

PendingCN113274124ALower resistanceImprove current resistanceDiagnostic recording/measuringSurgical instruments for heatingCatheterElectro physiology

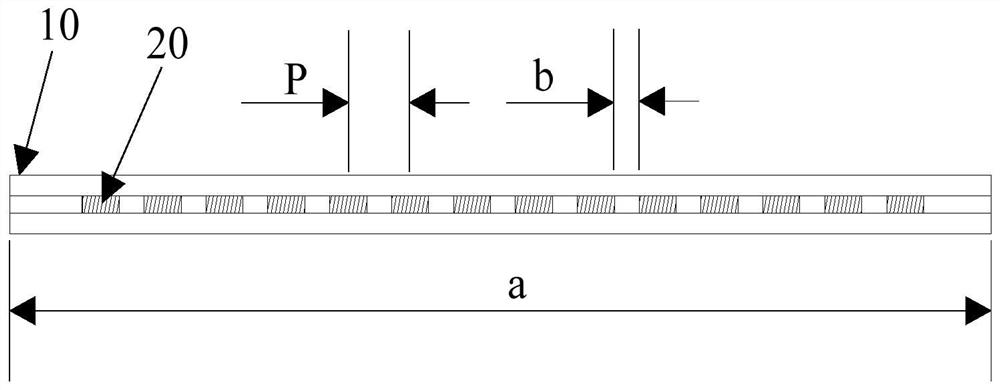

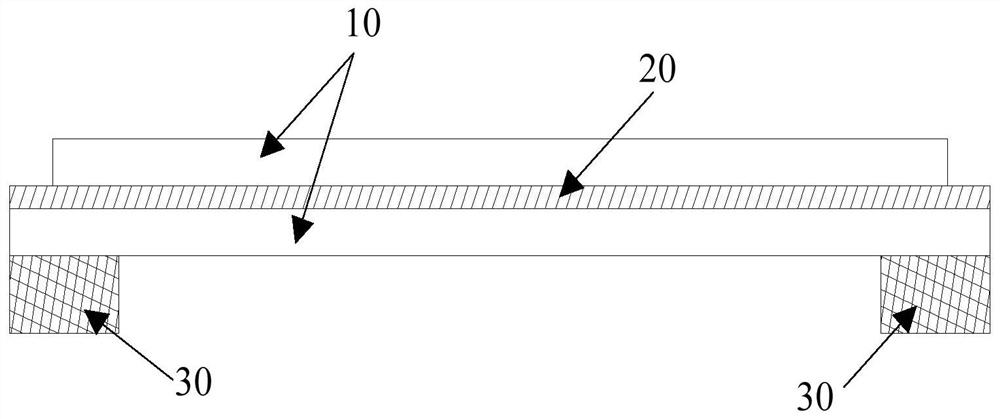

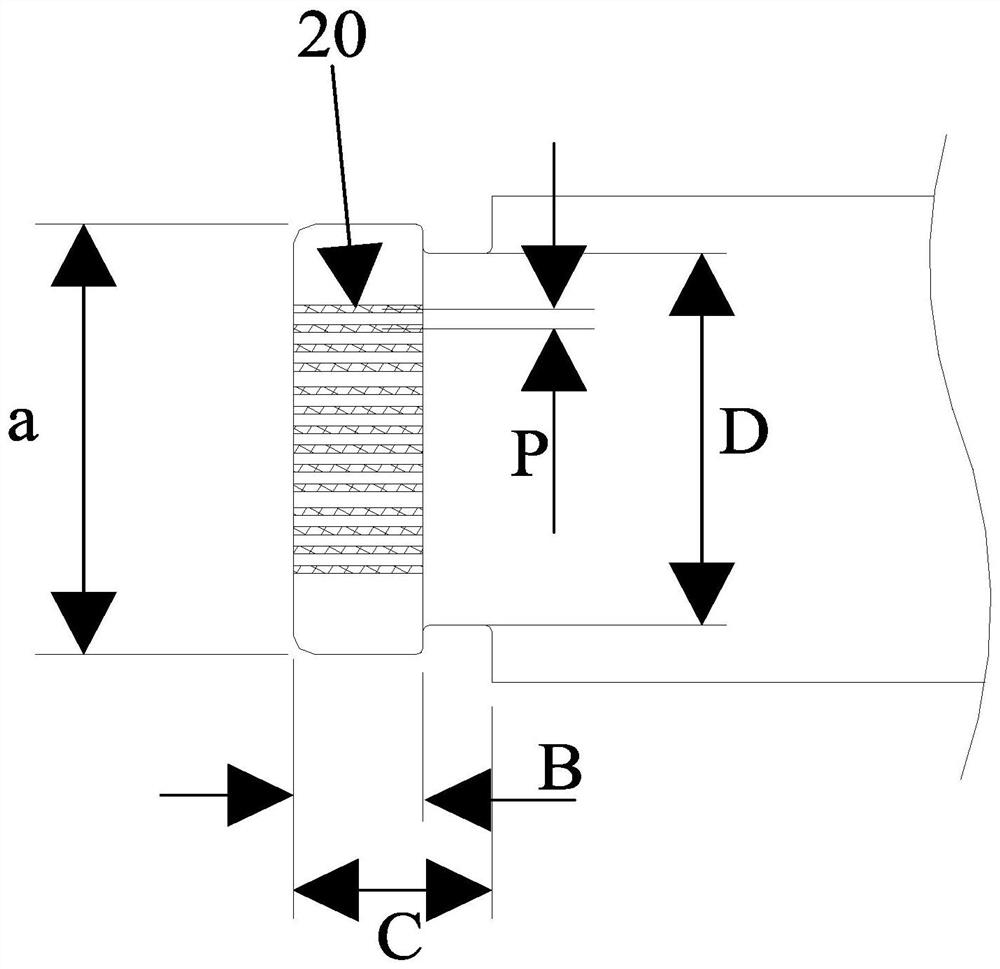

The invention provides an electrode assembly, an electrophysiological catheter and an electrophysiological system. The electrode assembly comprises an electrode main body, a sub-electrode assembly and an electric transmission line, wherein the sub-electrode assembly and the electric transmission line are arranged on the electrode main body; the electric transmission line comprises a plurality of ablation lines; the sub-electrode assembly comprises a plurality of first ablation electrodes and a plurality of second ablation electrodes; each ablation line comprises a transmission main line, a first transmission branch line and a second transmission branch line; the first ablation electrodes and the second ablation electrodes are electrically connected with the output ends of the corresponding first transmission branch lines and the output ends of the corresponding second transmission branch lines respectively; and the input ends of the first transmission branch lines and the input ends of the second transmission branch lines are intersected at the transmission main lines. The transmission branch lines of different ablation electrodes are arranged in a parallel manner, so that the resistance value of the ablation lines is reduced, the current resistance of the ablation lines is improved, meanwhile, the ablation boundary of the catheter is also improved, and the ablation depth is increased.

Owner:SHANGHAI ARTECHMED MEDICAL TECH CO LTD

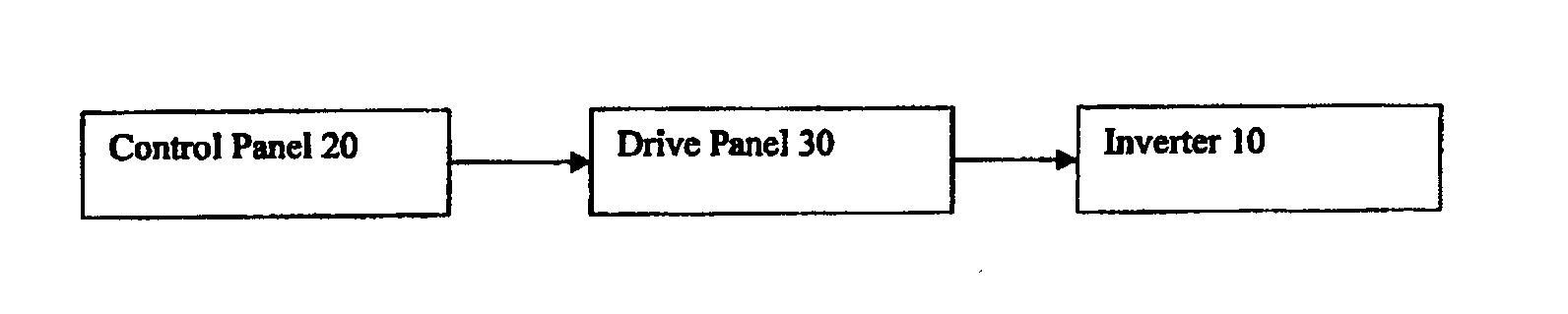

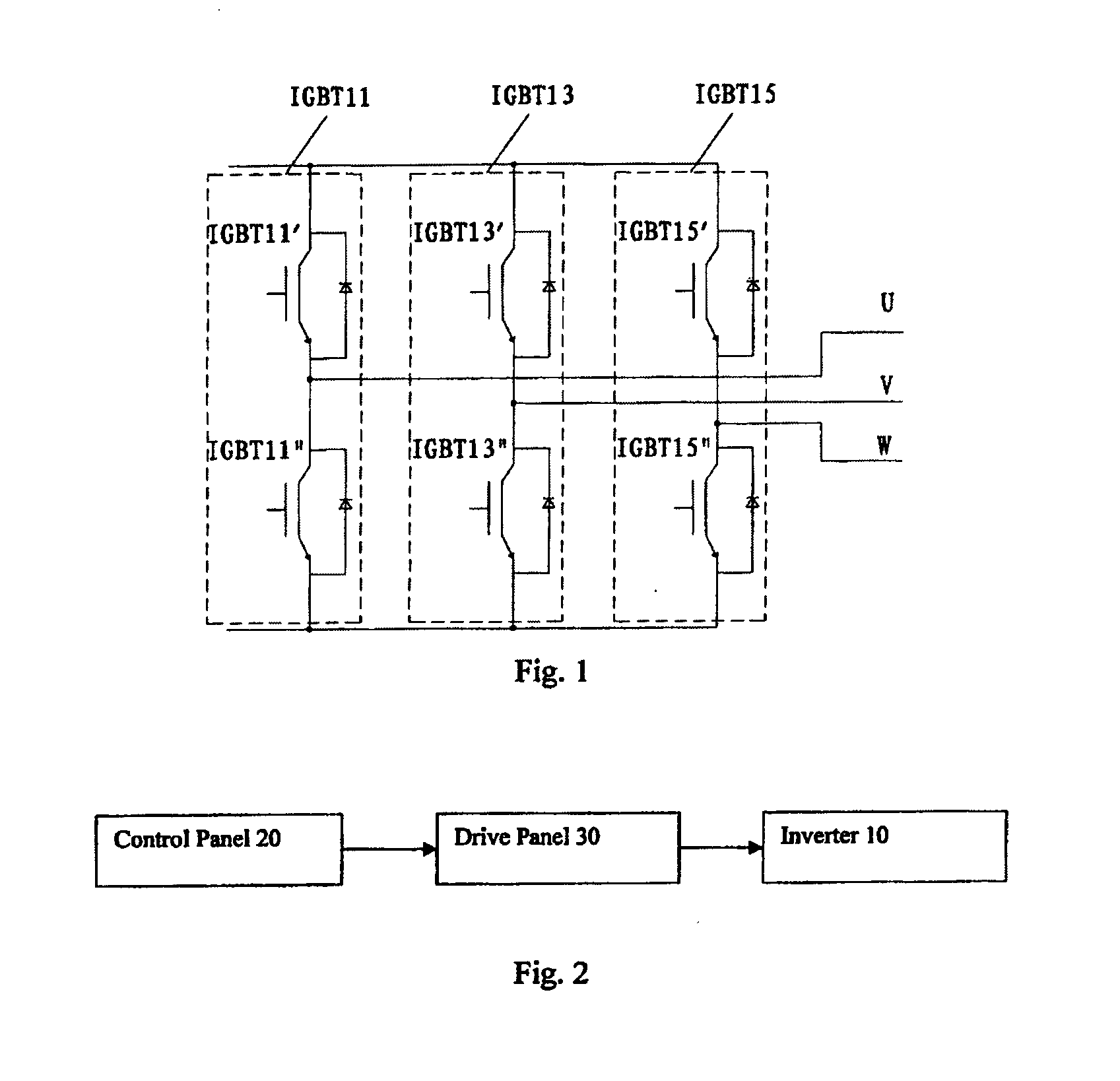

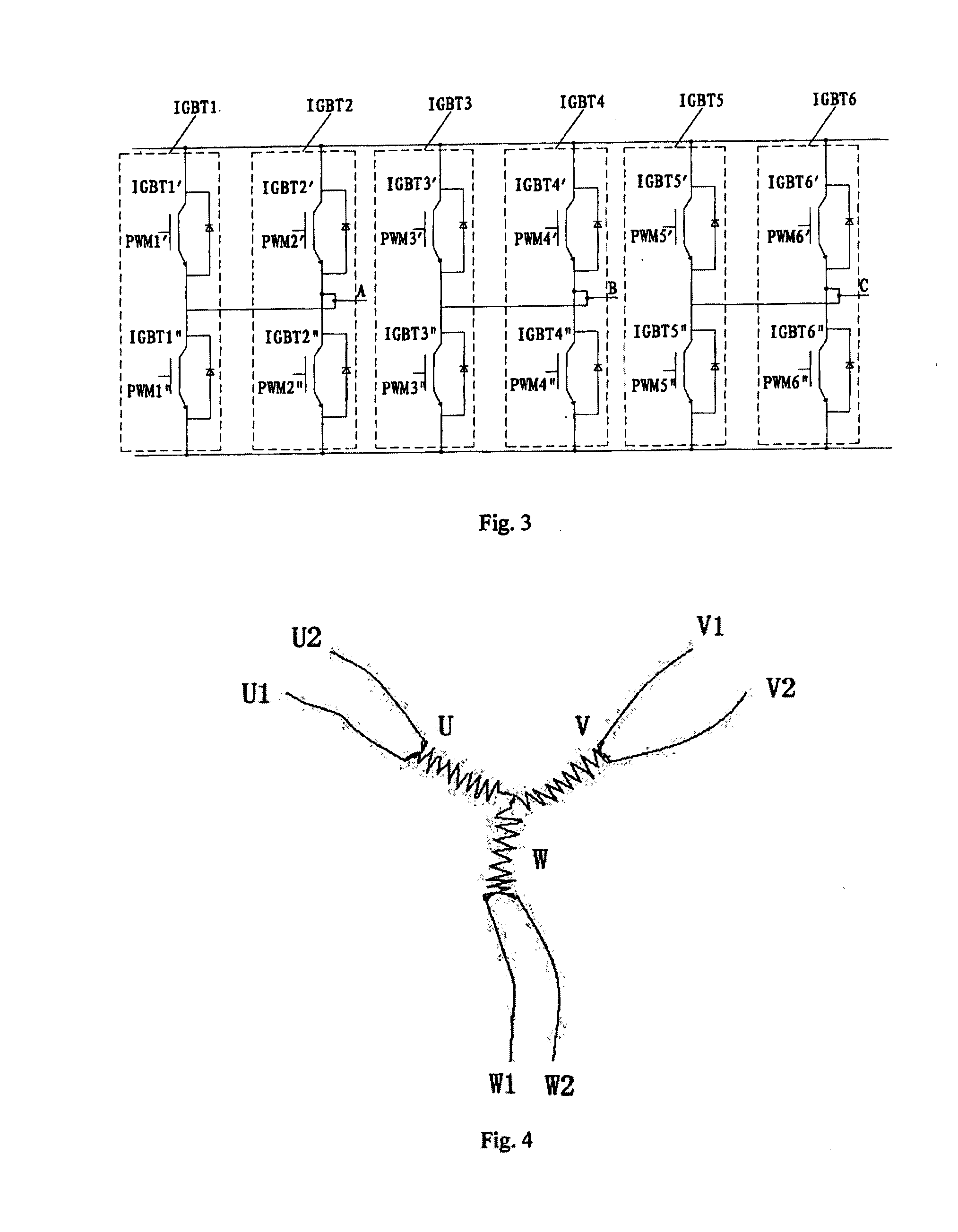

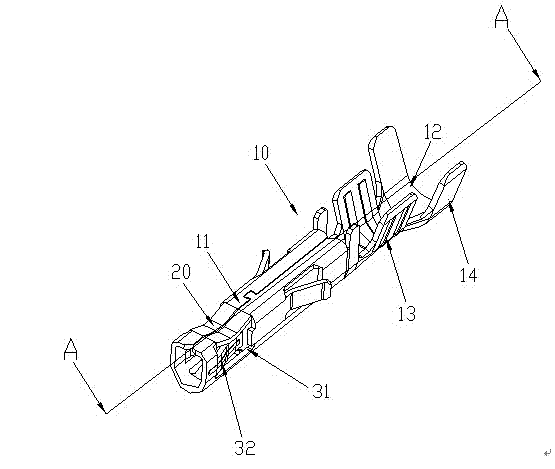

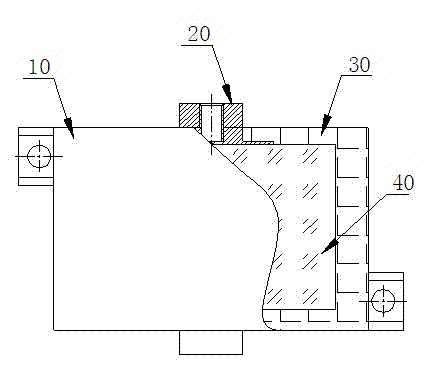

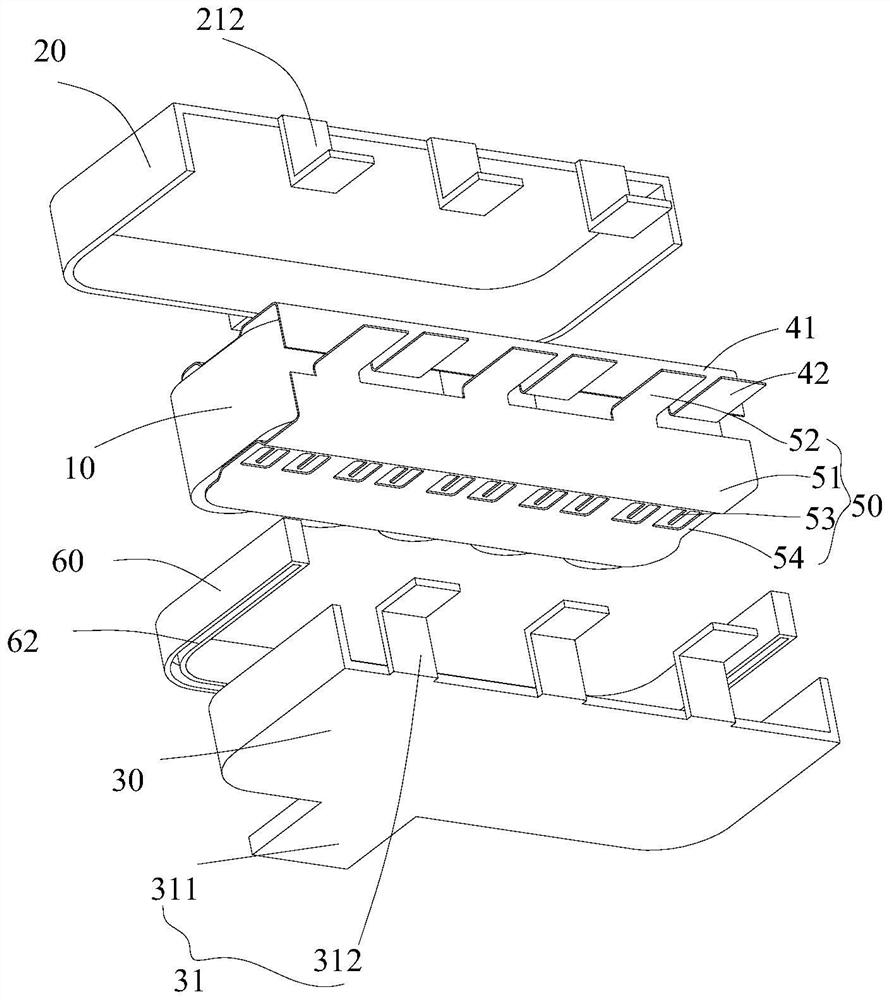

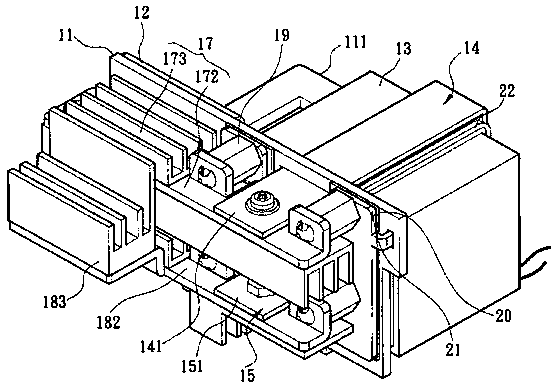

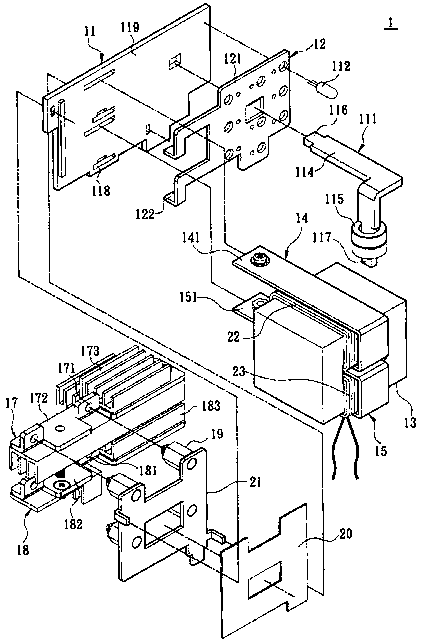

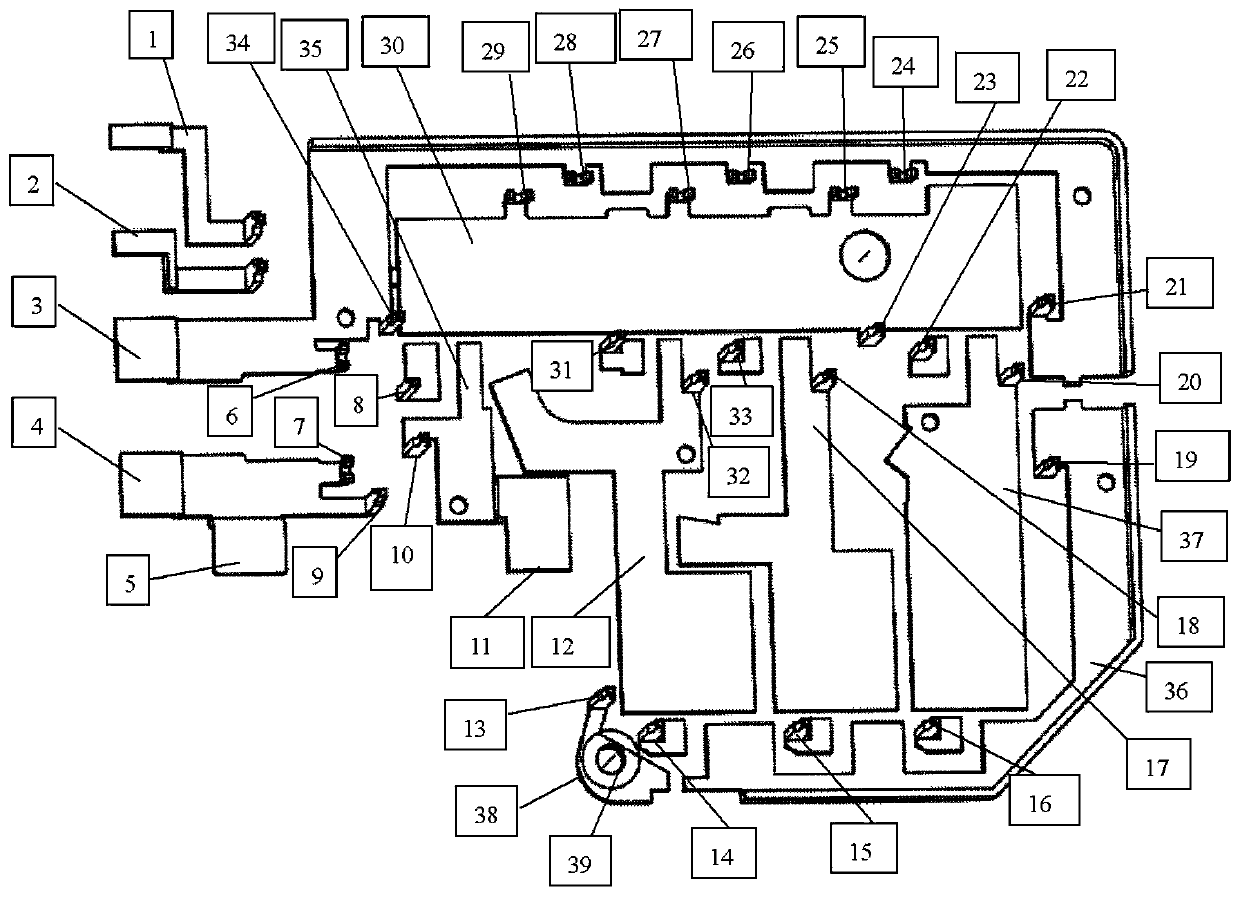

Controllable rectification device and electric motor comprising the same

ActiveUS20120038296A1Low costIncrease powerConversion with intermediate conversion to dcEmergency protective circuit arrangementsVoltageElectric motor

The present invention discloses a controllable rectification comprising an inverter (10), a control panel (20) and a drive panel (30). The inverter (10) may comprise three switch element groups connected in parallel. Each switch element group may comprise at least two switch elements connected in parallel. Each switch element may comprise an upper bridge-arm switch and a lower bridge-arm. The control panel (20) may generate a PWM waveform. The drive panel (30) may generate a drive voltage according to the PWM waveform to drive the upper bridge-arm switch and the lower bridge-arm switch of each switch element to conduct or break respectively, and to make the upper bridge-arms of the same switch element group to conduct or break simultaneously, and to make the lower bridge-arms of the same switch element group to conduct or break simultaneously. The present invention further discloses an electric motor comprising the same.

Owner:BYD CO LTD

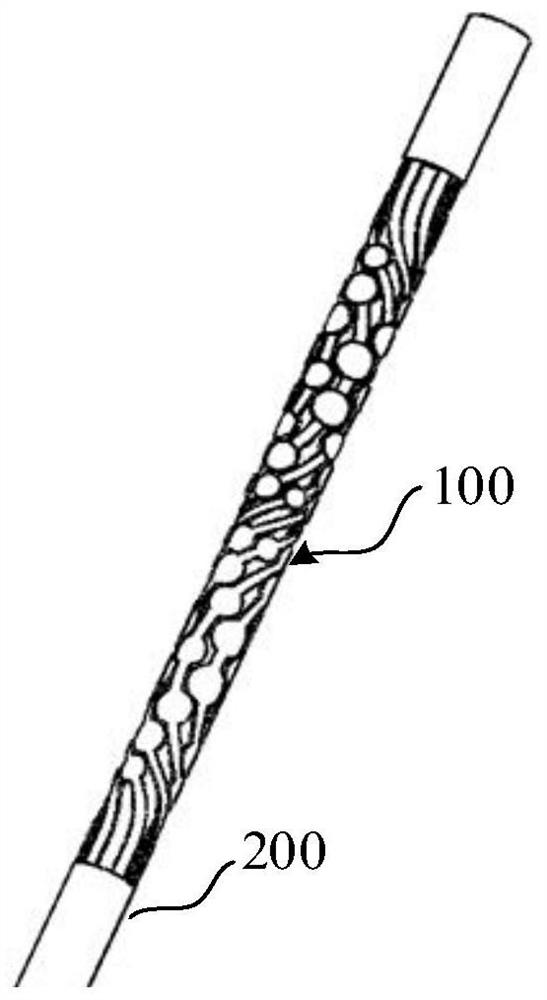

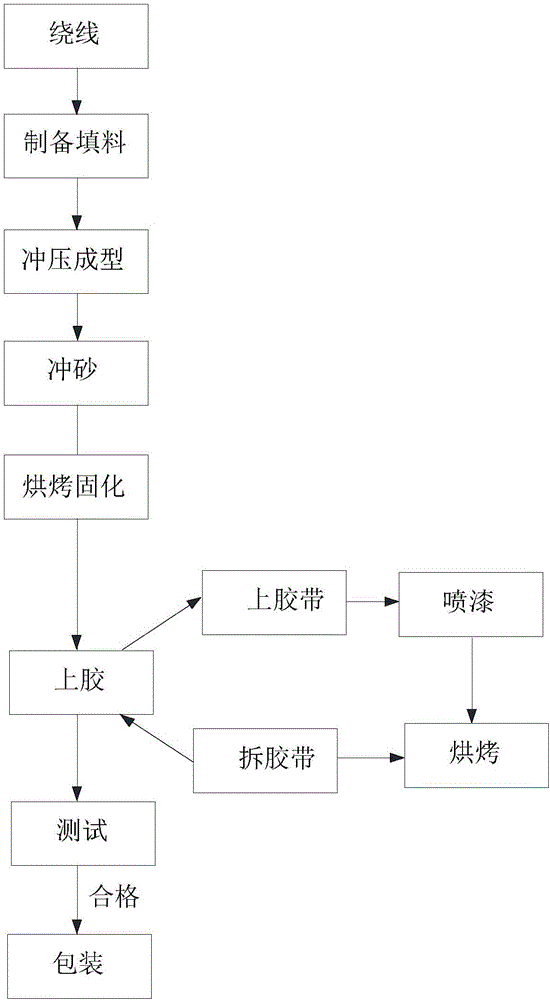

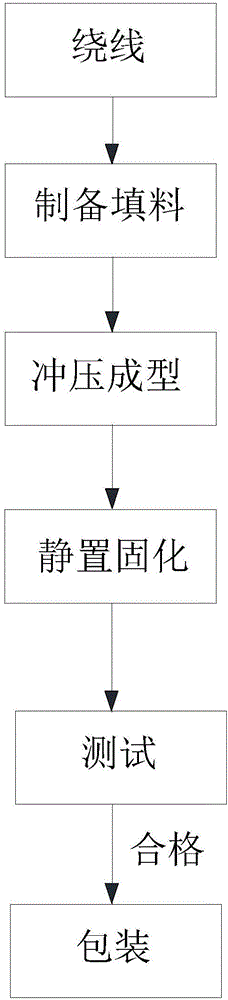

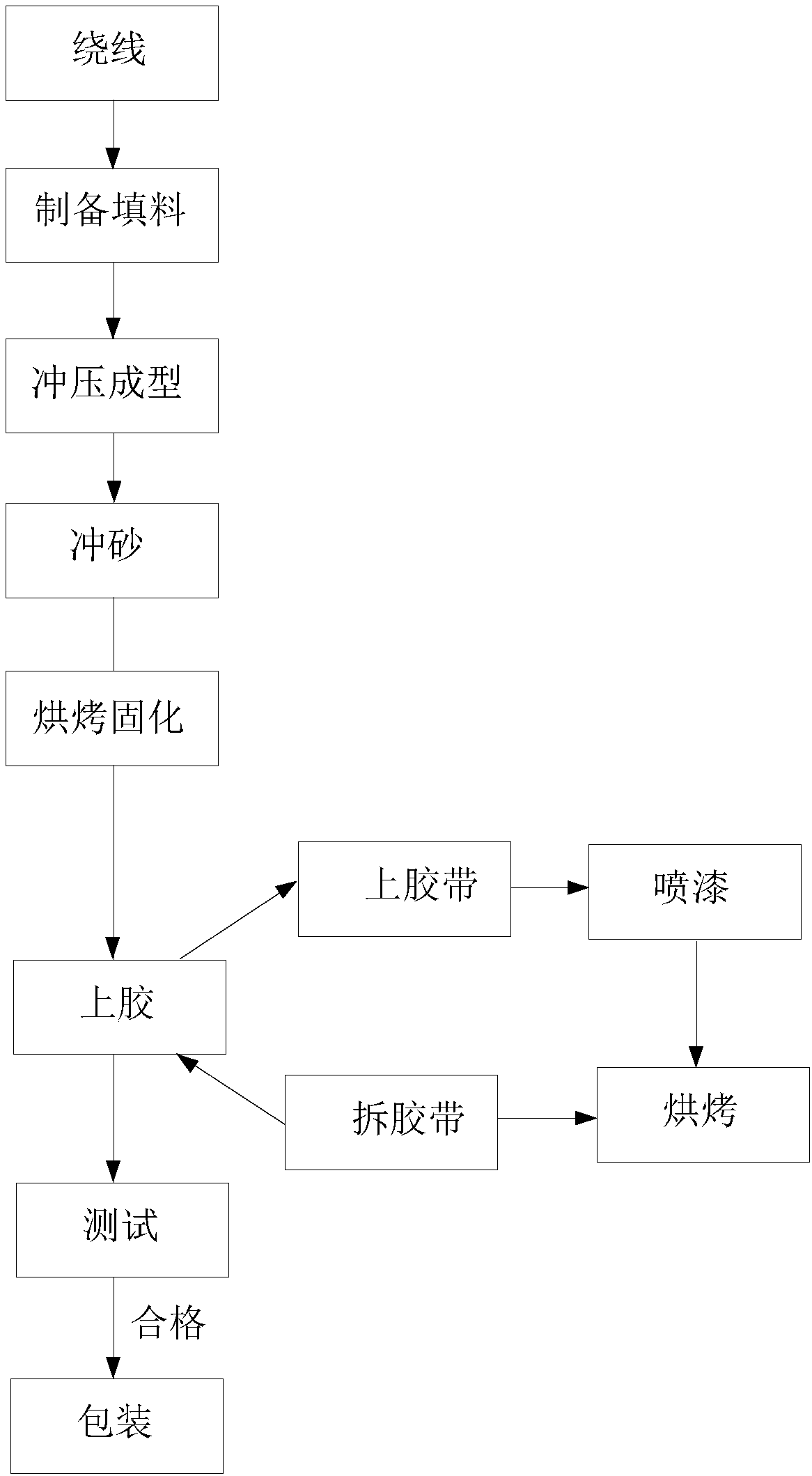

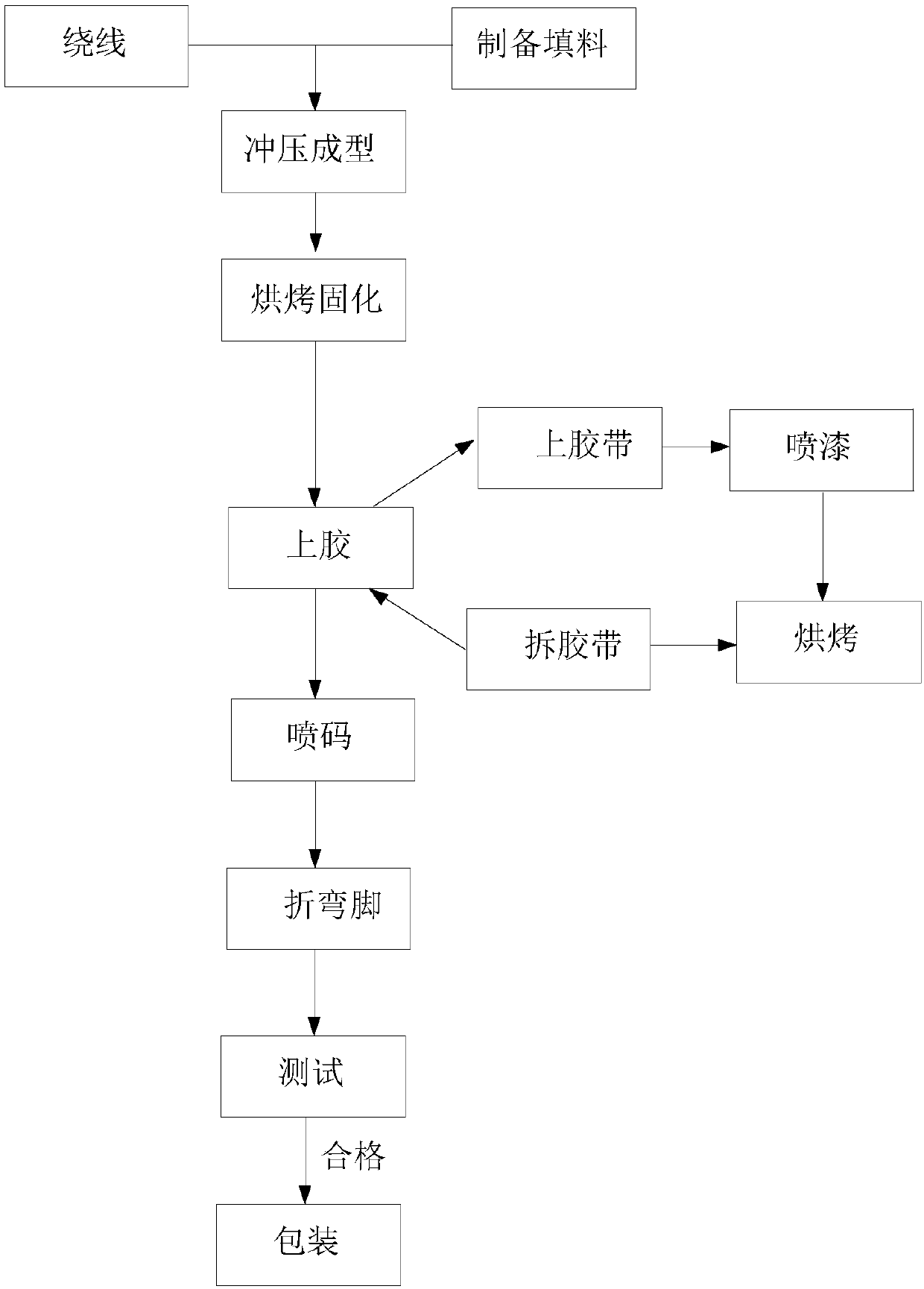

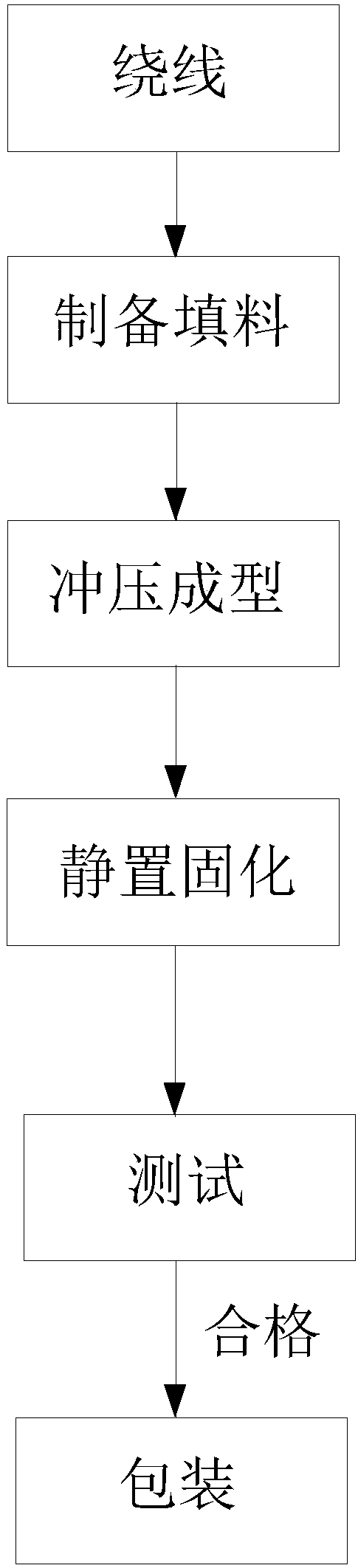

Integrally molded inductor and manufacturing method thereof

ActiveCN106252055AImprove current resistanceStable structureTransformers/inductances magnetic coresInductances/transformers/magnets manufactureSilicone GelsMass ratio

The invention provides a manufacturing method of an integrally molded inductor, and belongs to the technical field of inductance elements. The method comprises the steps of winding a copper wire into a coil and electrically connecting the coil and an electrode pin; mixing a magnetic-conducting material with liquid silicone gel evenly at the mass ratio of 100:(2-15) to form a filler and carrying out heat preservation on the filler under the condition that the temperature is 70-80 DEG C for 0.2-1 hour; and putting the coil connected with the electrode pin into a mold, filling the mold with the filler and carrying out integral stamping to form the integrally molded inductor. The manufacturing method is simple; and the technological process is saved. Furthermore, the invention further provides the integrally molded inductor manufactured by the manufacturing method. The current resistance of the integrally molded inductor is significantly improved; the inductor is stable in structure; the magnetic loss can be reduced; and the noise at work can be reduced.

Owner:重庆金籁科技股份有限公司

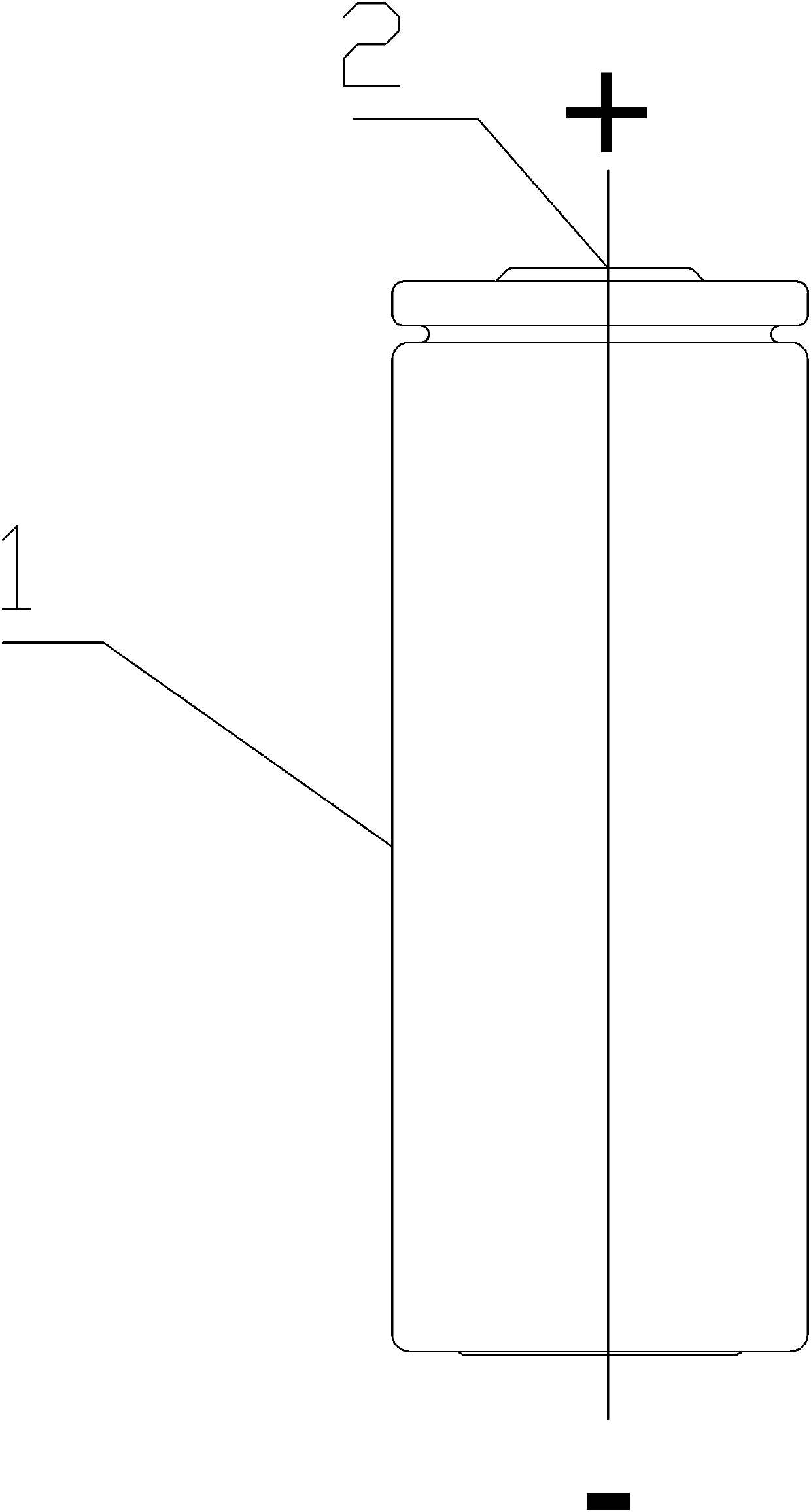

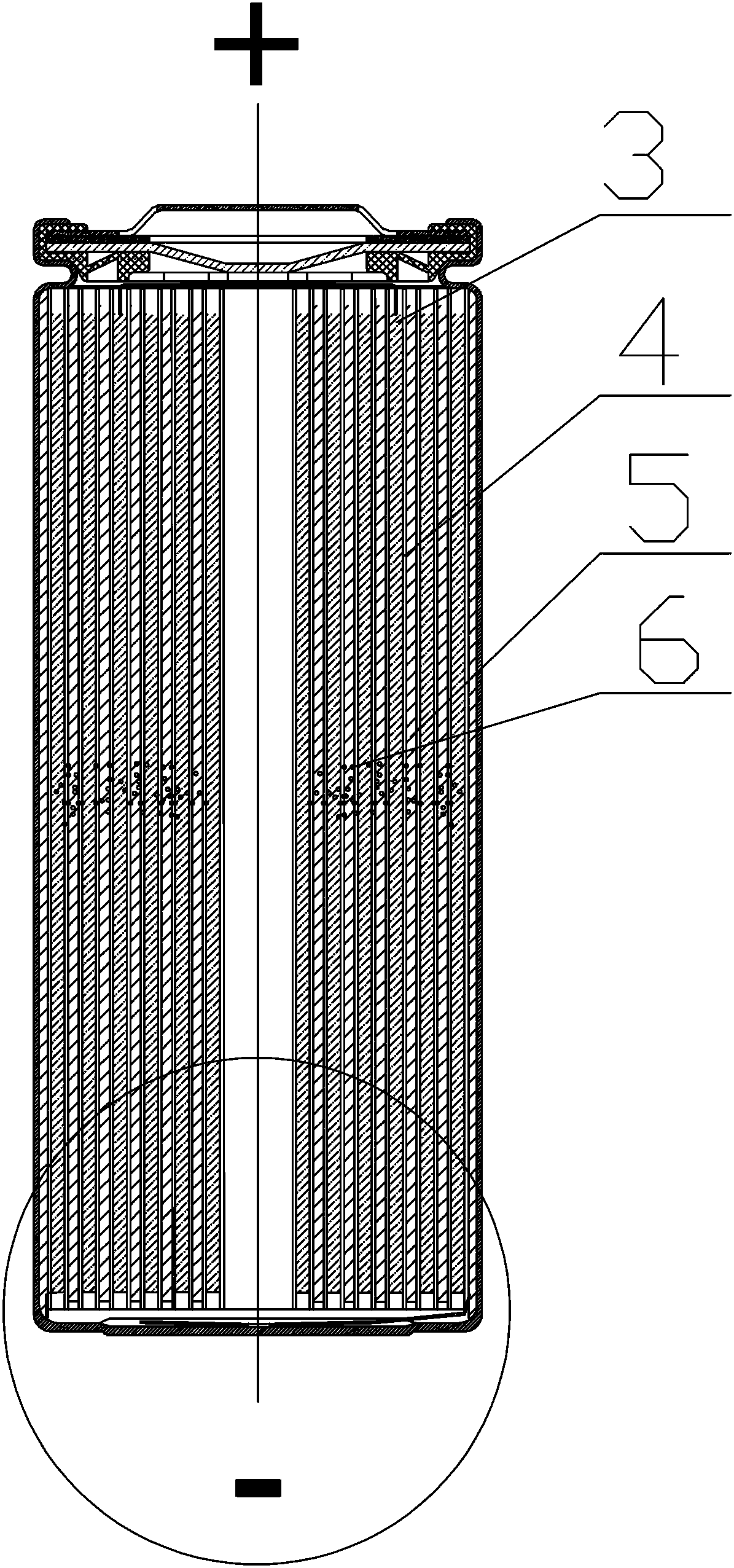

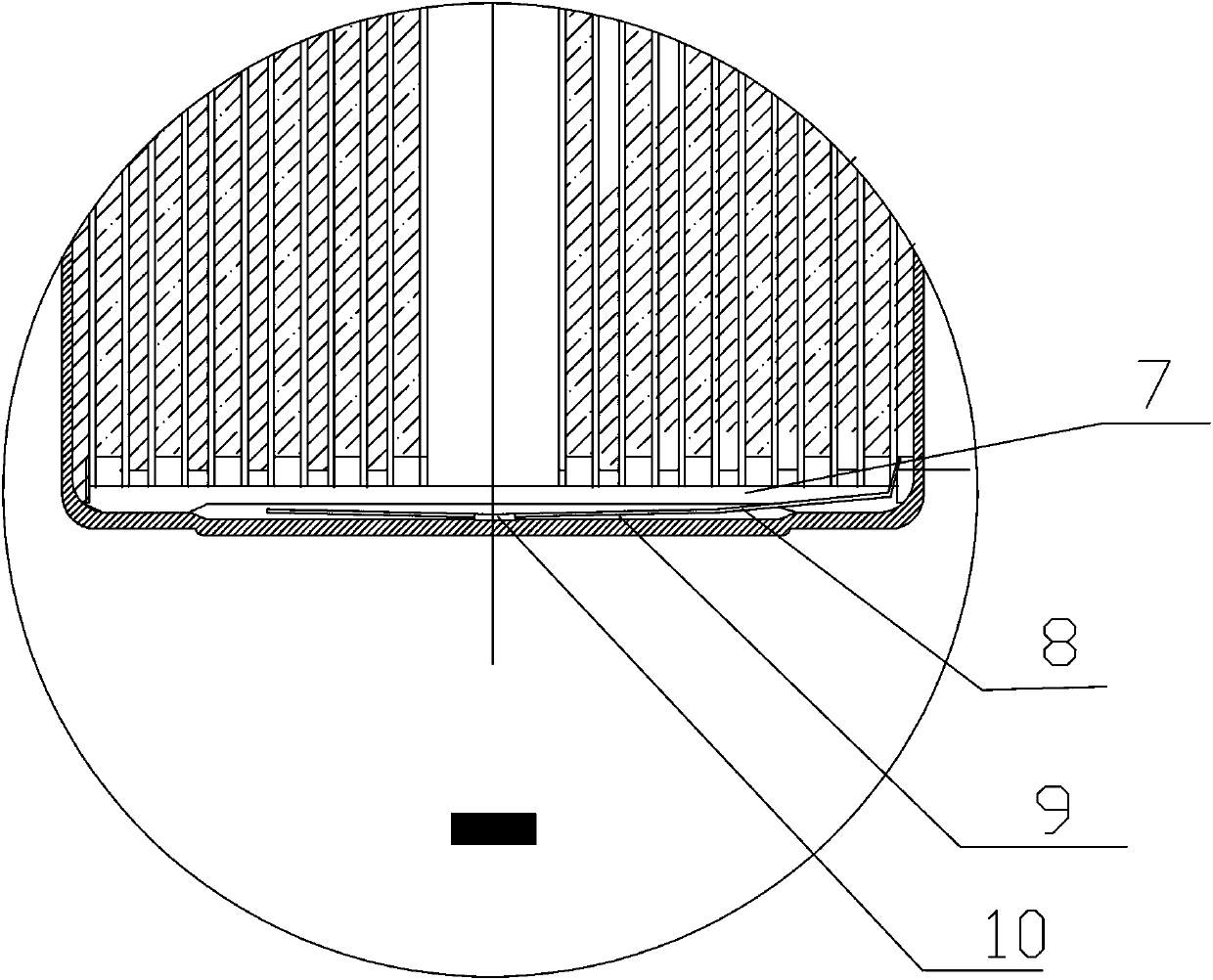

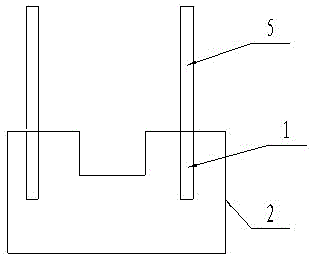

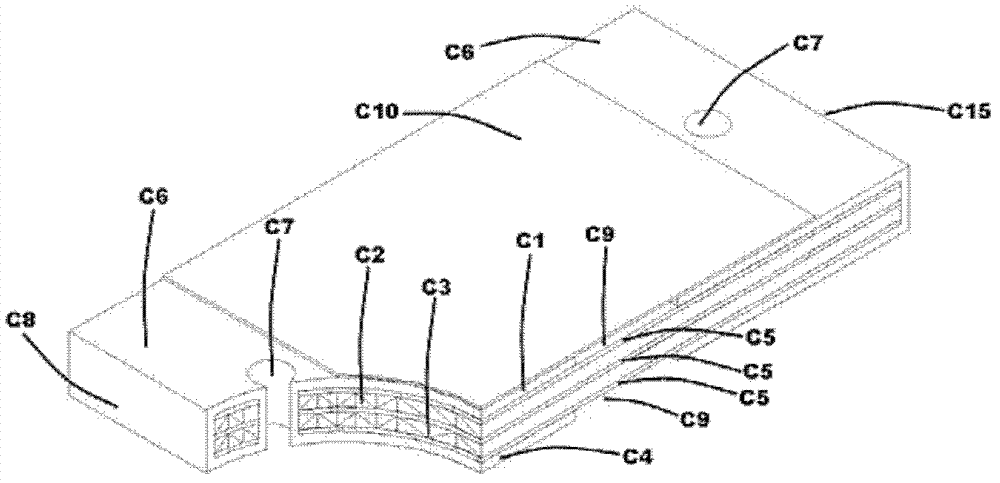

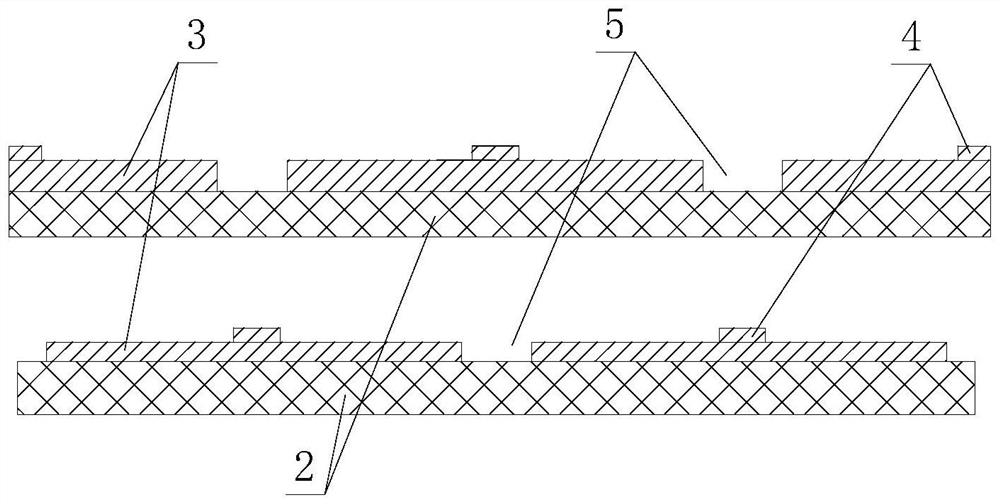

Cylindrical lithium ion battery having internal heat dissipation and tab fixing structure, and preparation method thereof

InactiveCN109860725AIncrease contactImprove current resistanceFinal product manufactureSecondary cellsPower applicationAdhesive

The invention discloses a cylindrical lithium ion battery having an internal heat dissipation and tab fixing structure, and a preparation method thereof. The lithium ion battery is characterized in that the structure of the battery includes a steel shell (1), a cover cap (2), positive plates (3), diaphragms (4), negative plates (5), an electrolyte (6), an insulating layer (7) and a conducting layer (9); and a negative tab (8) of the battery can form a soldering point (10) after spot bottom welding. The contact of the tab and a shell bottom can be significantly improved by fixing the tab through a conductive adhesive, so that current resistance capabilities can be enhanced, and the lithium ion battery is suitable for large power application batteries; risks of tab dropping caused by violentvibration can be solved through the fixation of the conductive adhesive; and through the insulating layer and the conducting layer, the heat generated during large current discharging of the batterycan be rapidly dissipated.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

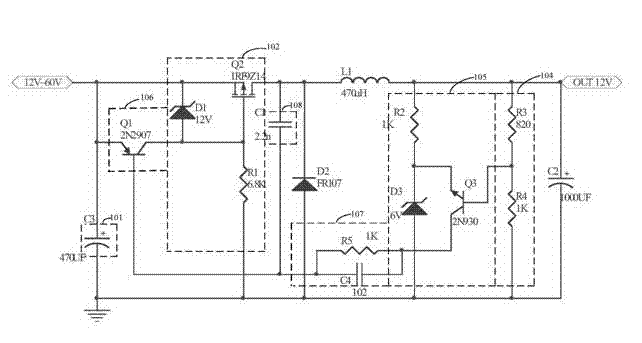

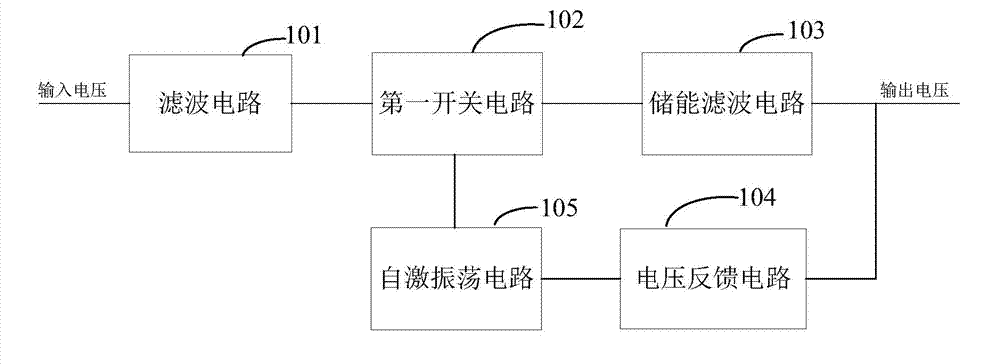

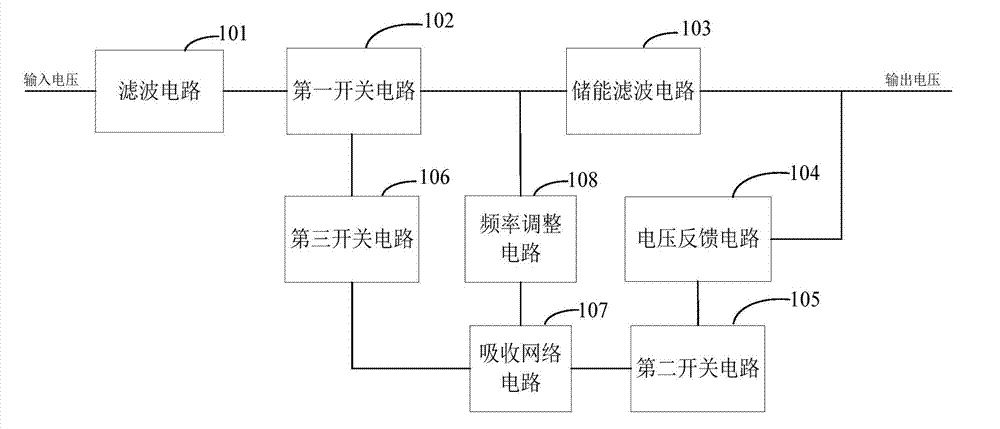

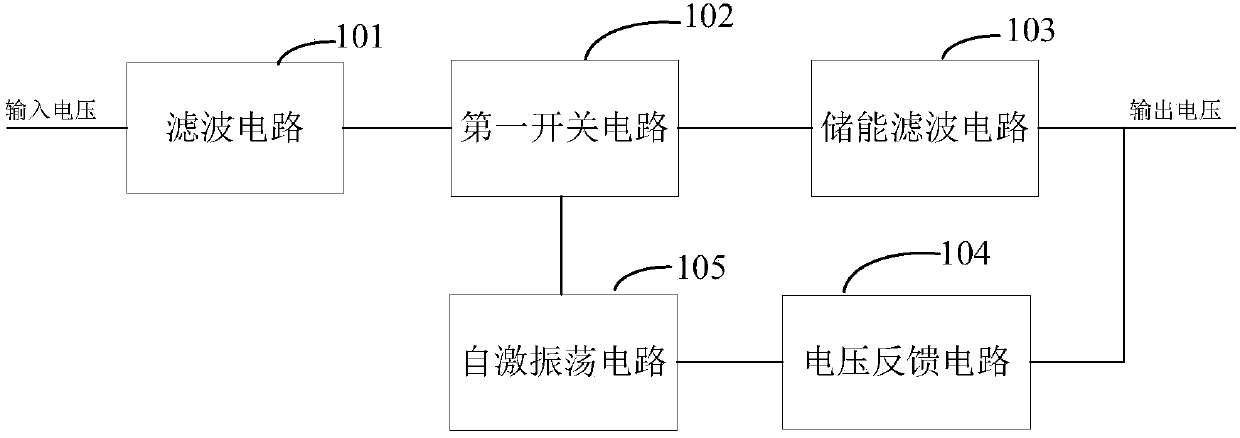

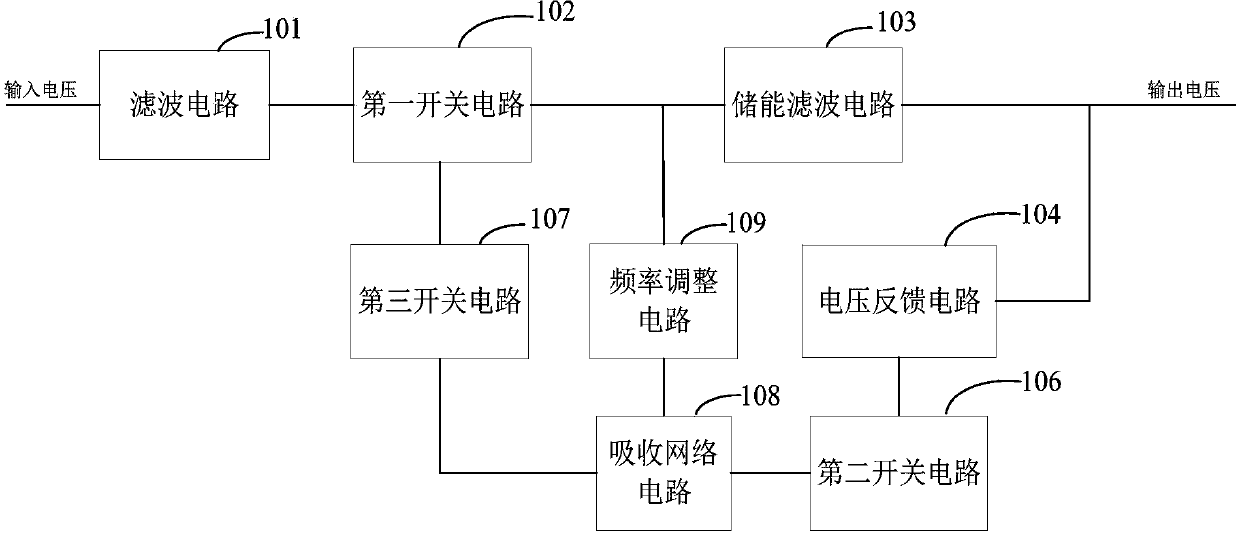

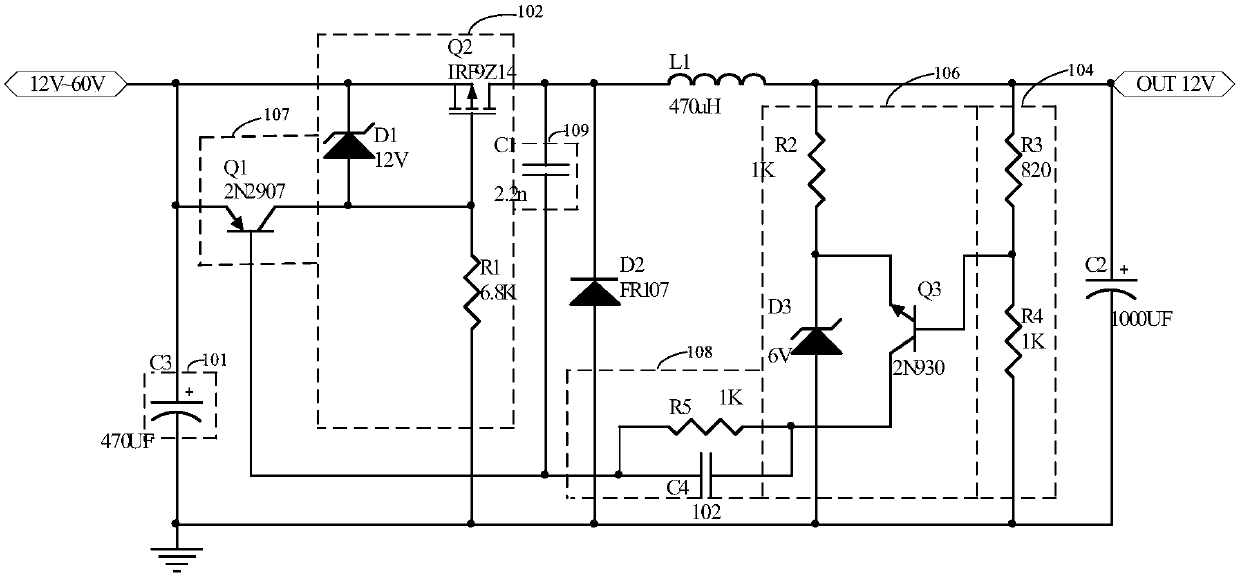

Stabilized switching power supply

ActiveCN104716832AImprove current resistanceFeedback link design is simple and reliableDc-dc conversionElectric variable regulationCurrent elementEngineering

The invention belongs to the field of power supplies, and provides a stabilized switching power supply. A switching type DC-DC voltage stabilizer power source is formed by independent electronic elements, a wide-input voltage range is provided, the work state of an overall circuit is automatically adjusted according to input voltage, the output voltage is stable and can be set by adjusting element parameters, and the output current is determined by the input end and a circuit element. A large current element can be selected to improve the current resistance of the circuit, and the feedback link of the circuit is simple and reliable in design. As no integrated chip is used, the situation that when the voltage of a circuit of an integrated chip is used, the current parameters are basically fixed is avoided.

Owner:SHENZHEN OCEANS KING LIGHTING ENG CO LTD +1

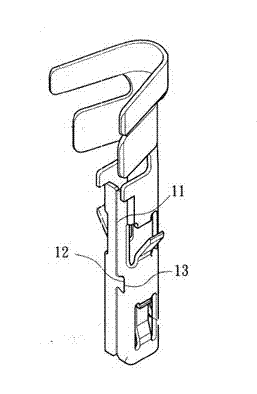

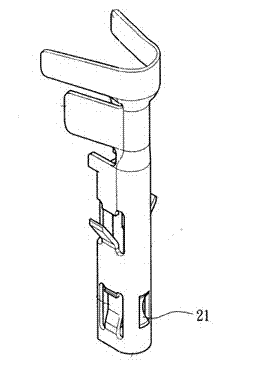

Terminal structure

InactiveCN102780107AReduce contact surfaceSmall amount of deformationCoupling contact membersPunchingPower flow

The invention discloses a terminal structure which is integrally formed by punching and comprises a hollow terminal head which is formed on a side wall with a butt seam and provided with a butting portion recessed toward the interior of a hollow terminal, a hollowed-out position is arranged on a side wall opposite to the butting portion and provided with an elastic limiting piece, a root of the elastic limiting piece is fixedly connected with an edge of the hollowed-out position, and the other end of the elastic limiting piece extends toward the interior of the hollow terminal in a suspended manner. The butting portion and the elastic limiting piece are simultaneously arranged on the head of the hollow terminal, so that the requirement of close contact of a plug and the terminal is met, plug in-and-out force is more stable when the plug is plugged in and out, and poor contact is avoided. In addition, contact area of the plug and the terminal is increased, so that heat concentration is eased while larger current can be resisted with no heat generated, and the service life of the terminal is effectively prolonged.

Owner:萧至仁

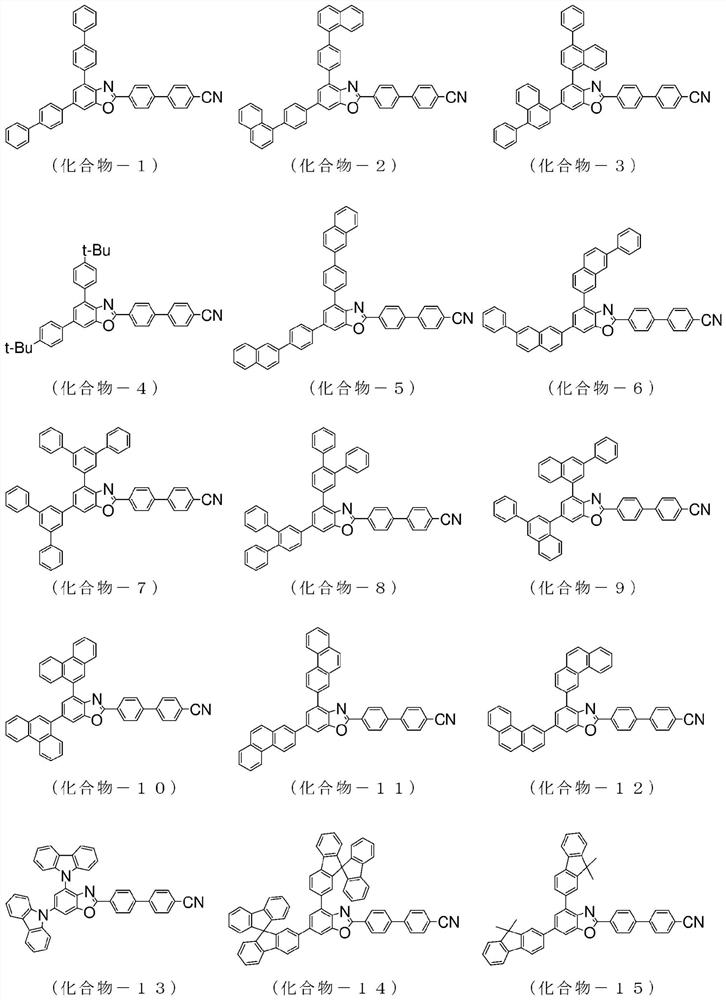

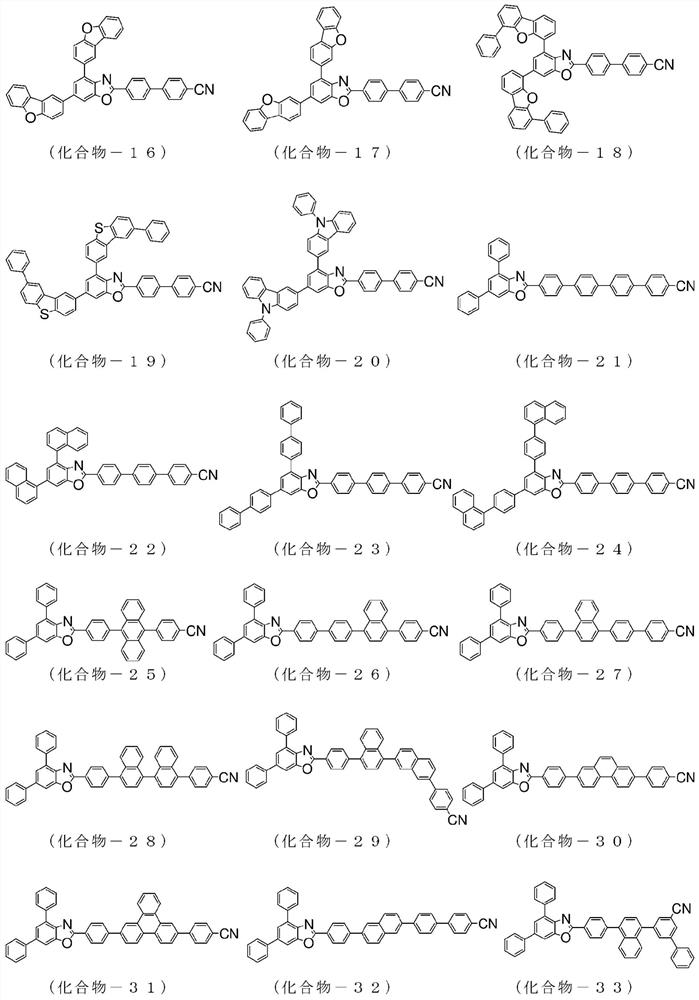

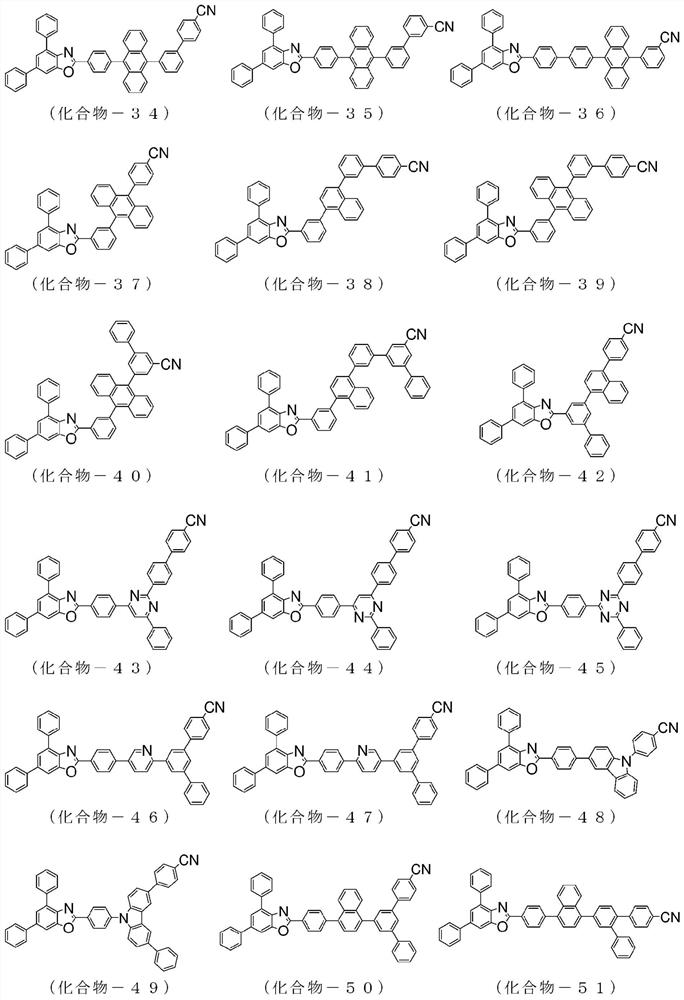

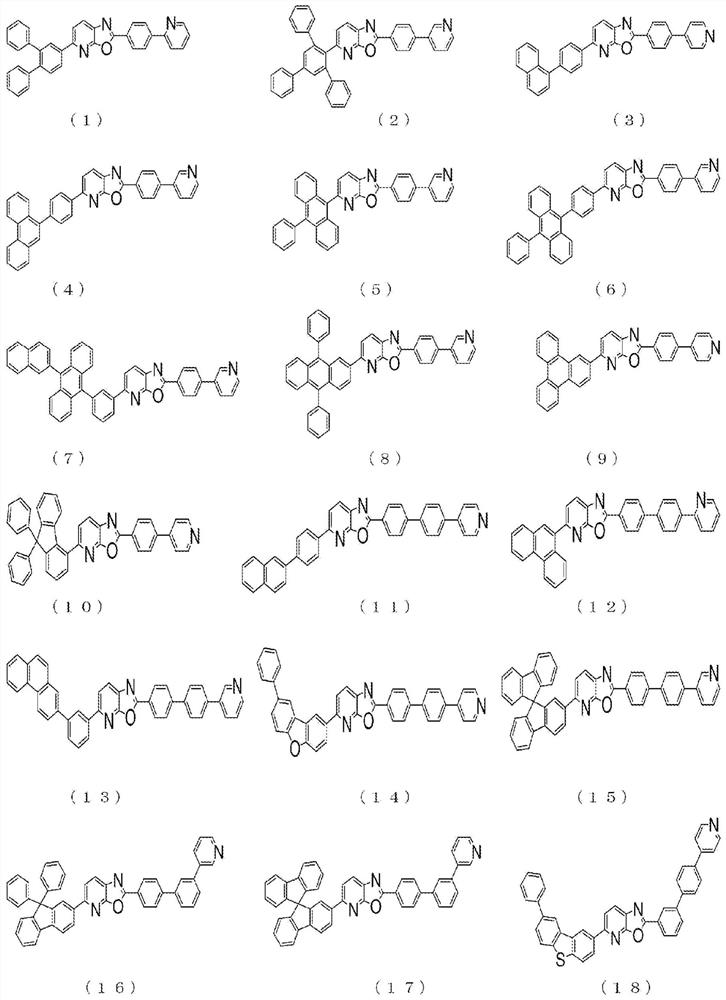

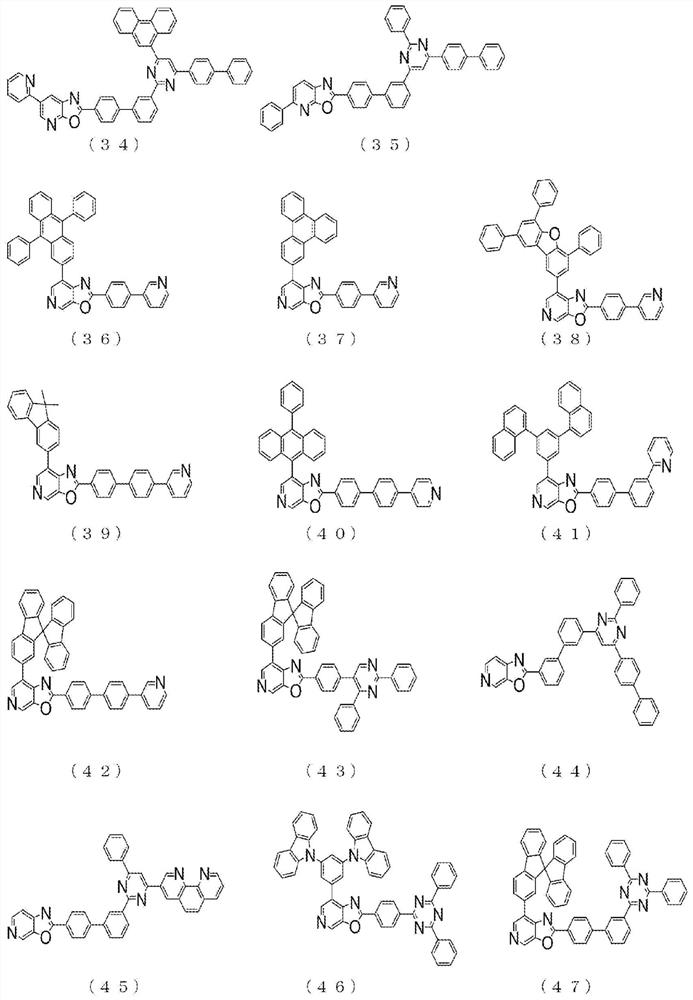

Compound having benzazole ring structure, and organic electroluminescent device

PendingCN113195482AIncreased durabilityImprove stabilityOrganic chemistrySolid-state devicesBenzoxazoleChemical synthesis

The purpose of the present invention is to provide, as a material for a high-efficiency and high-durability organic EL element, an organic compound having excellent electron injection / transport performance, hole blocking ability, and excellent characteristics of high stability in a thin film state, and to provide a high-efficiency and high-durability organic EL element using the compound. According to the present invention, various compounds having a benzoxazole ring structure are designed and chemically synthesized by focusing on the ability of a nitrogen atom of the benzoxazole ring structure having electron affinity to coordinate with a metal and having excellent heat resistance, and an organic EL element is trial-produced using these compounds, and as a result, characteristics are evaluated. It was found that an organic EL element having excellent characteristics can be obtained by using a compound having a specific benzoxazole ring structure.

Owner:HODOGOYA CHEMICAL CO LTD

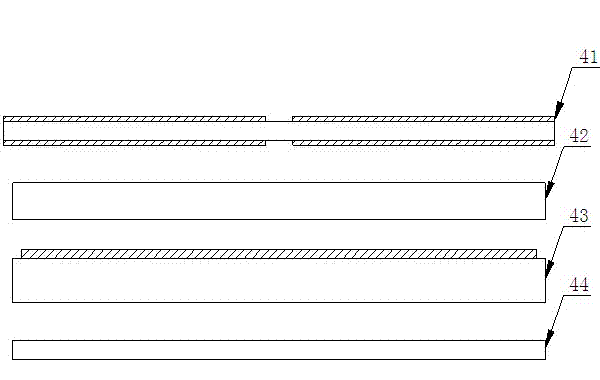

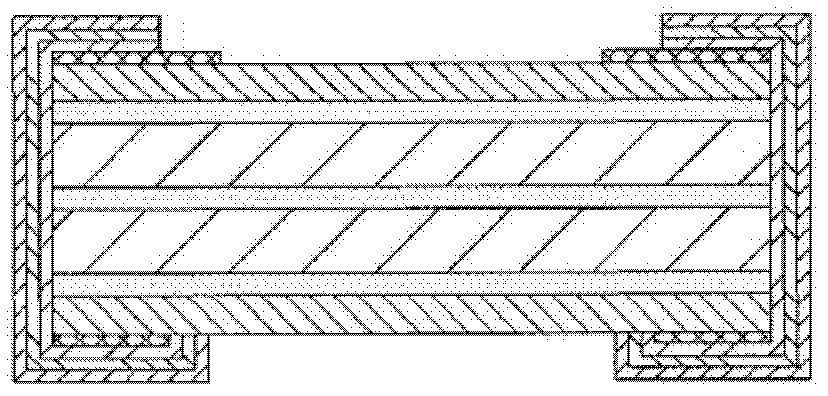

High-frequency absorptive film of capacitor

InactiveCN103680944AReduce volumeImprove current resistanceFixed capacitor electrodesEngineeringMetallised film

The invention relates to a high-frequency absorptive film of a capacitor. Four layers of films are wound coaxially to form a capacitor core; the film comprises a first metallized film, a second metallized film, a third metallized film and a fourth metallized film sequentially from inside to outside; the first metallized film is a two-side metallized film; the third metallized film is a single-side metallized film; the second metallized film and the fourth metallized film are optical films. According to the high-frequency absorptive film of the capacitor disclosed by the invention, the volume of the capacitor is smaller than that of a capacitor which is formed from a conventional winding structure in a winding manner at the presence of the same voltage-tolerant strength; in addition, the current tolerance of the capacitor is increased, the high-frequency impact tolerance is also increased a lot, and the practical use requirements are satisfied.

Owner:ANHUI SAFE ELECTRONICS

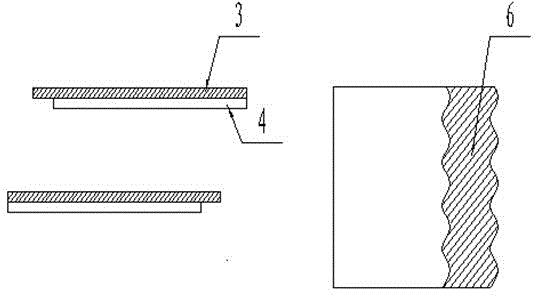

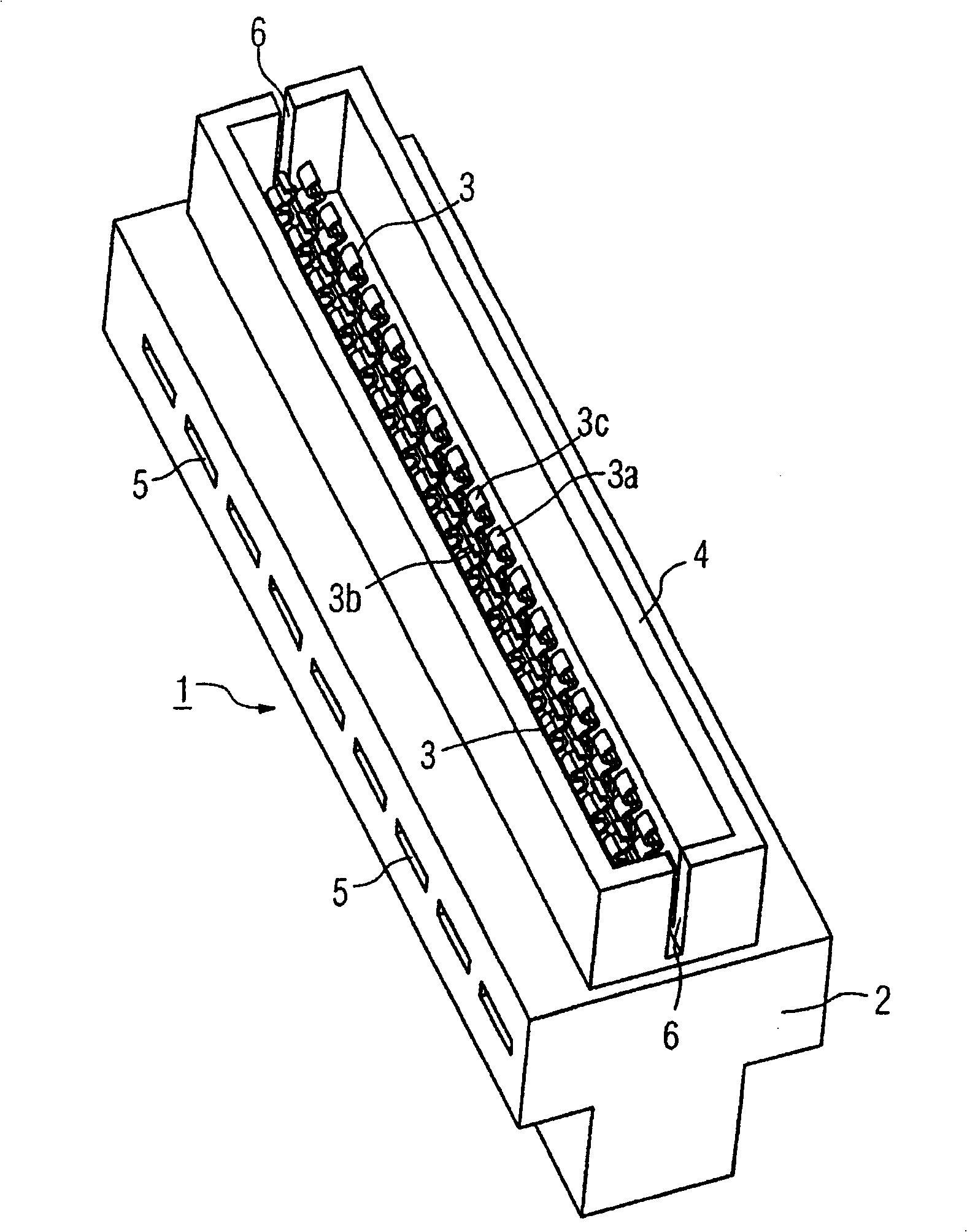

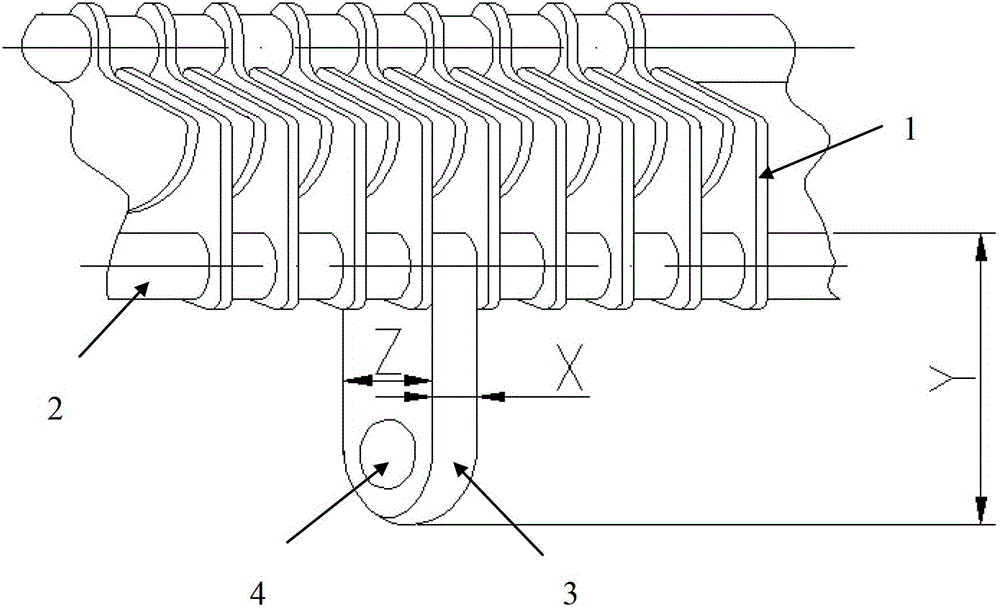

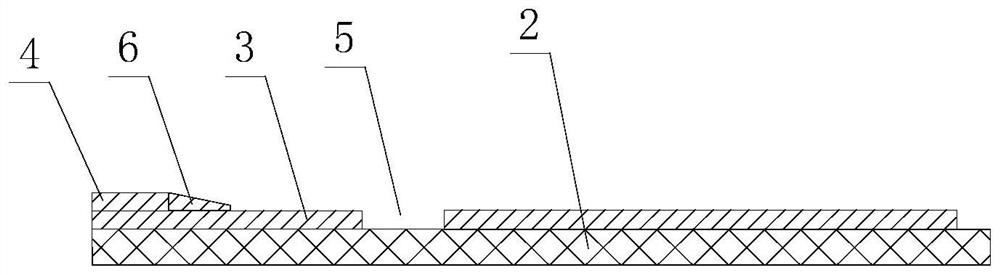

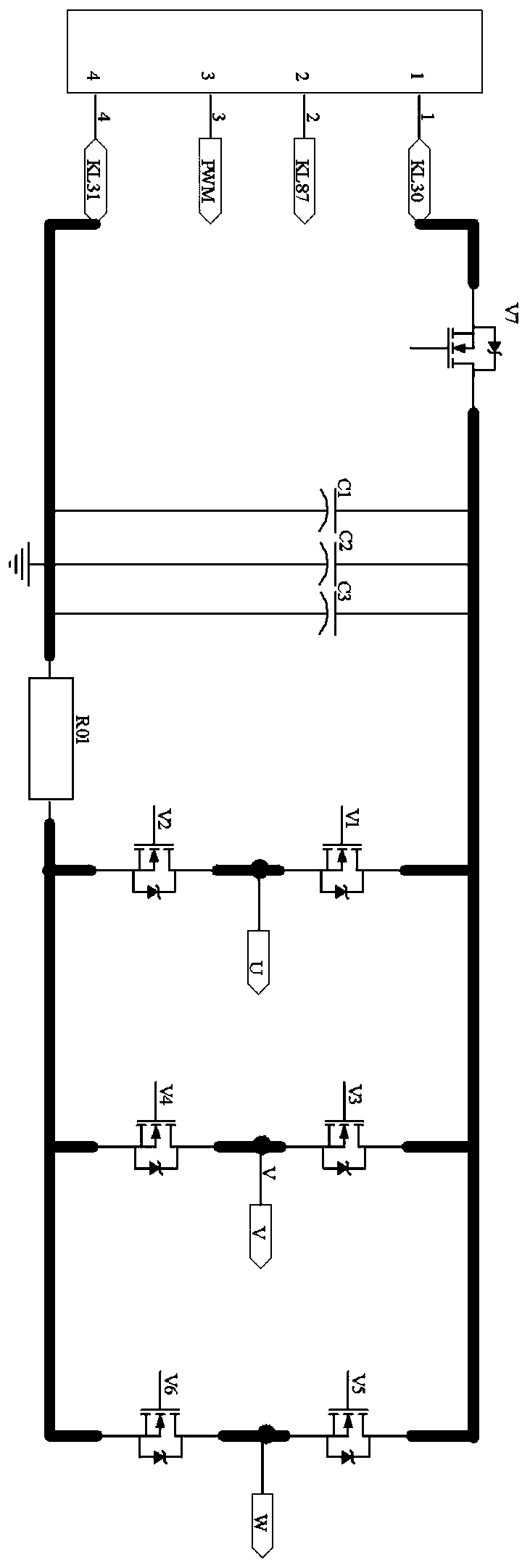

Wave-cut remaining edge type thin-film capacitor

InactiveCN105632760AImprove current resistanceIncrease the effective contact areaThin/thick film capacitorFixed capacitor electrodesDielectricMetal coating

The invention discloses a wave-cut remaining edge type thin-film capacitor, which comprises a capacitor core 1 and a capacitor body 2. The capacitor core 1 is composed of four parts which are two layers of parallel thin-film dielectric 3, a metal coating electrode 4 located on the thin-film dielectric 3, a metal spraying layer on the surface of the metal coating electrode 4 and a lead 5 welded on the metal spraying layer. The right side of the metal coating electrode 4 and the right side of the thin-film dielectric 3 are both of a wave-shaped structure formed in a wave-cut manner. A remaining edge 6 is disposed between the right side of the metal coating electrode 4 and the right side of the thin-film dielectric 3. The invention has the beneficial effects of enhanced current resistance, low loss, safety and environmental protection, simple structure and high practicality.

Owner:FOSHAN CITY XINYUAN ELECTRONICS CO LTD

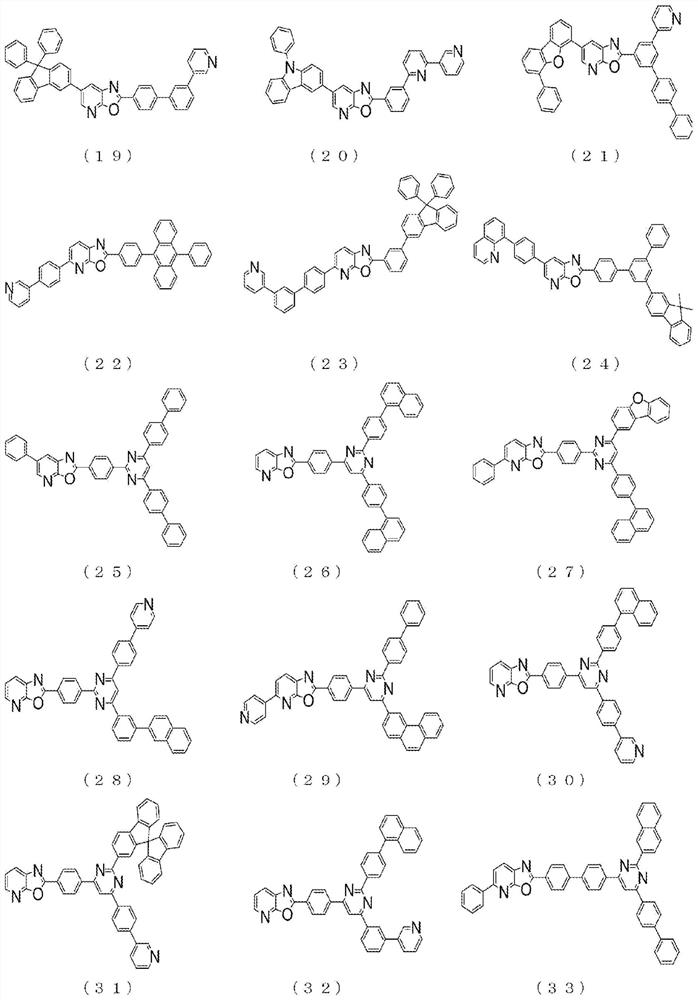

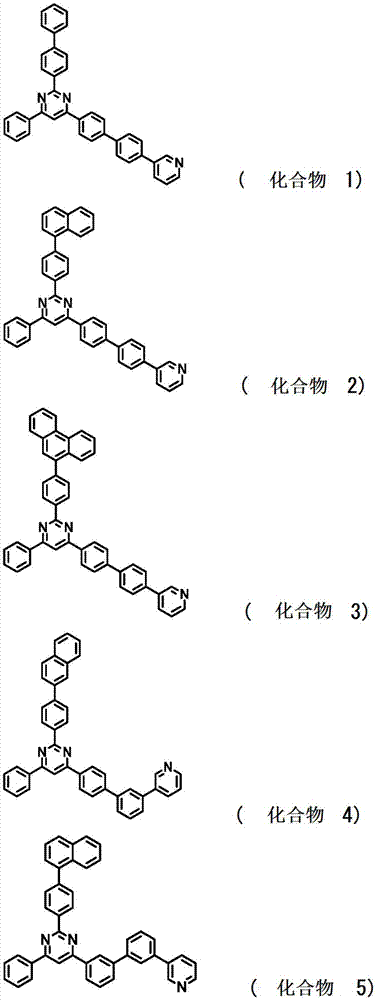

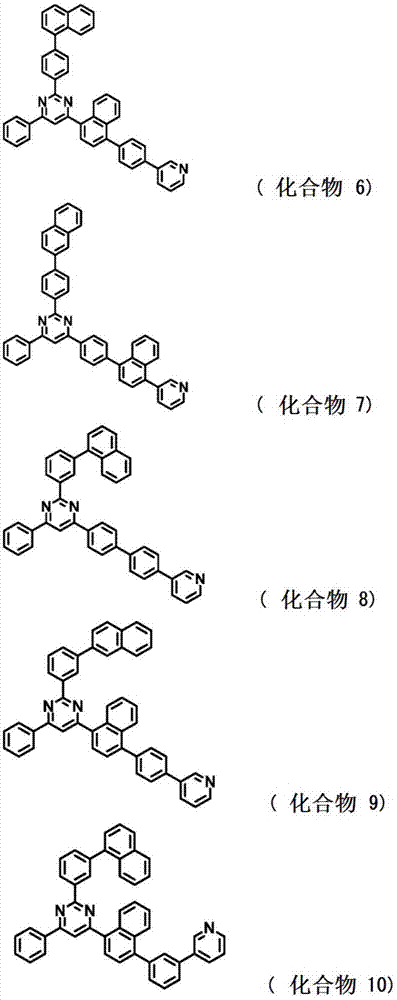

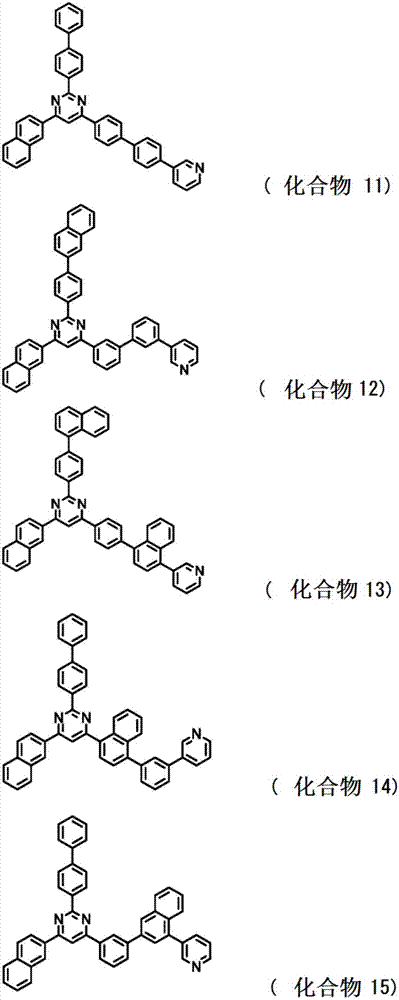

Compound having azabenzoxazole ring structure and organic electroluminescent element

PendingCN112805845AIncreased durabilityImprove transmission efficiencyOrganic chemistrySolid-state devicesElectron holeSimple Organic Compounds

A purpose of the present invention is to provide, as a material for organic EL elements having high efficiency and high durability, an organic compound which has excellent characteristics including excellent electron injection / transport performance, hole blocking ability and high stability in the form of a thin film; and another purpose of the present invention is to provide an organic EL element having high efficiency and high durability with use of this compound. A compound having an azabenzoxazole ring structure according to the present invention exhibits excellent heat resistance, while having good electron transport ability. An organic EL element which uses this compound in an electron transport layer, a hole blocking layer, a light emitting layer and an electron injection layer has exhibited good element characteristics.

Owner:HODOGOYA CHEMICAL CO LTD

Pyrimidine derivative and organic electroluminescence element

ActiveCN107406415AImprove electron injection performanceImprove stabilityOrganic chemistrySolid-state devicesHeat resistanceOrganic electroluminescence

Owner:HODOGOYA CHEMICAL CO LTD

Large-power wire-wound plate type inductor

PendingCN108766741AImprove impact resistanceFor a stable installationTransformers/inductances coils/windings/connectionsInductance with magnetic coreMiniaturizationEngineering

The invention provides a large-power wire-wound plate type inductor. The large-power wire-wound plate type inductor comprises a magnetic core and a coil wound on the magnetic core; two mounting pins are arranged at the bottom surfaces of the magnetic core at interval, two ends of the coil are electrically connected with two mounting pins, and a ring slot is arranged around the magnetic core; the coil is wound on the magnetic core and arranged in the ring slot; the coil comprises two conductors; two conductors are wound on the magnetic core in parallel; two ends of each conductor are electrically connected each of two mounting pins. The ring slot is arranged around the magnetic core to hold the coil, thereby guaranteeing that the coil is stably arranged on the magnetic core, and the impactresistance of the manufactured inductor is improved; two conductors are wound on the magnetic core in parallel to form the coil, the DC resistance can be reduced, the current resistance is greatly improved under the same volume, and then the miniaturization and the large power are realized.

Owner:SHENZHEN ZHENHUA FU ELECTRONICS +1

SMD type PTC thermistor preparation method

The invention relates to a SMD type PTC thermistor preparation method, and belongs to the field of electronic component preparation. The preparation method comprises: mixing BaTiO3, SrCO3, MnO2, Y2O3, SiO2 and graphite to prepare a spare material, and carrying out ball milling by using a 200 kg mill ball, wherein the ball milling media uses agate balls; pre-burning, wherein the pre-burning process uses a tunnel furnace; granulating, carrying out pressing molding after completing the granulating, and sintering by using a bell furnace; and finally welding an electrode by using a reflux welding manner to prepare the thermistor. According to the present invention, through the process improvement, the small size sheet-like surface adhesion type ceramic overcurrent protection element is prepared, such that the area of the circuit board is substantially reduced, the assembly process is simplified, and the circuit density is improved; and by adding the graphite, the micro-pores are formed in the ceramic so as to increase current resistant of the ceramic sheet.

Owner:SHAANXI SHENGMAI PETROLEUM

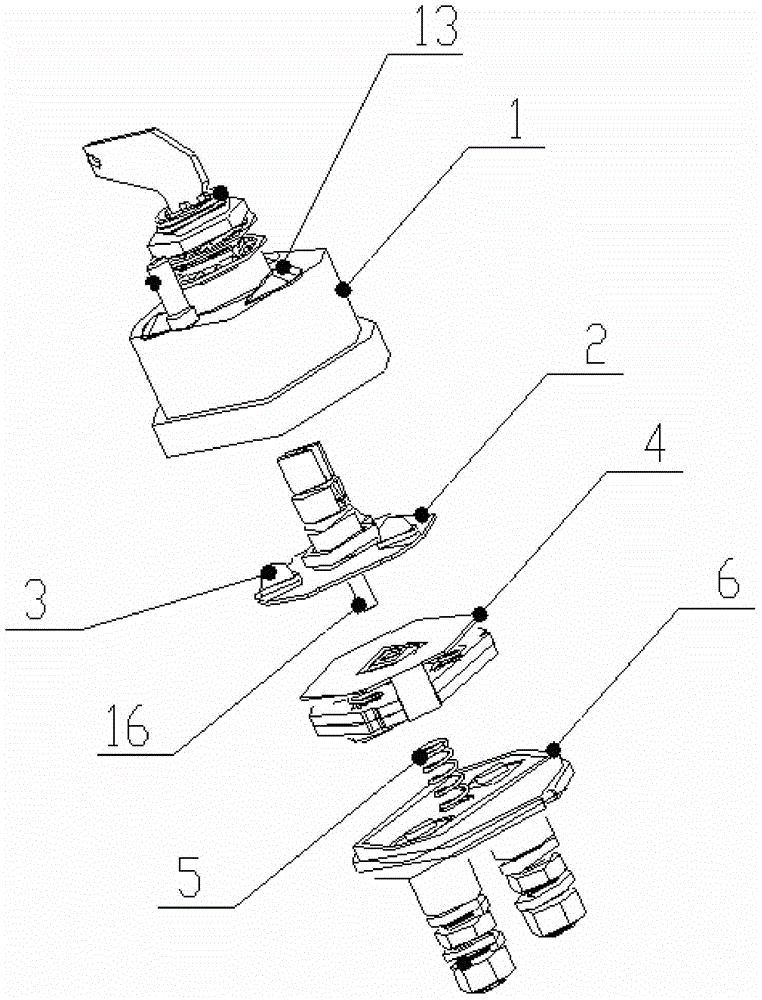

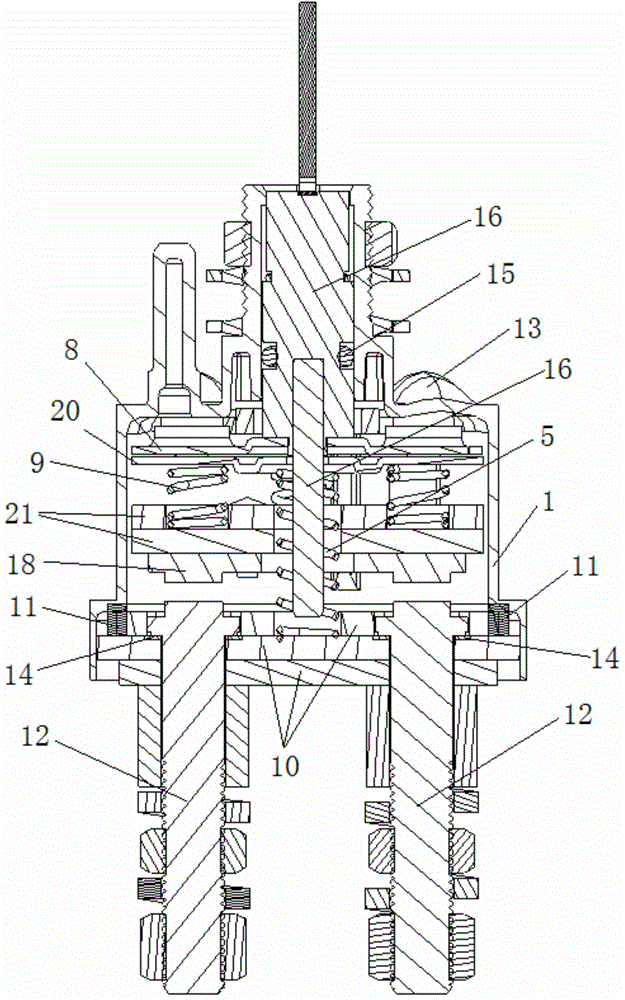

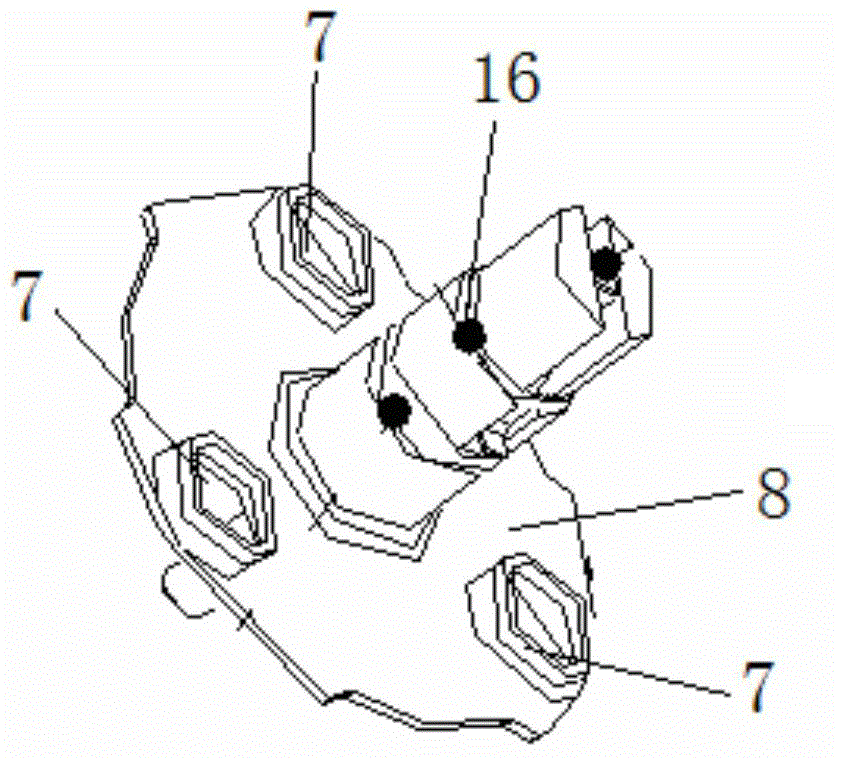

High current resistance vehicle power off switch

ActiveCN104966631AImprove current resistanceImprove sealingContact driving mechanismsCopperUltimate tensile strength

The invention discloses a high current resistance vehicle power off switch. The high current resistance vehicle power off switch comprises a casing body, a movable contact assembly and a static contact assembly, wherein the movable contact assembly and the static contact assembly are arranged in the casing body. The high current resistance vehicle power off switch further comprises a rotating shaft assembly which controls the movable contact assembly move up and down. The movable contact assembly comprises a copper plate and a pair of silver contact which is arranged on the copper plate. The static contact assembly comprises two wiring terminals. Each wiring terminal is provided on a silver contact. The diameter of each silver contact is between 9 and 10mm. The high current resistance vehicle power off switch provided by the invention has the advantages of high structural strength and great tightness, can meet harsh environment requirements, can withstand high current and high voltage, can meet the performance requirement of power on and off of a vehicle, and can be widely used in the field of the resistance vehicle power off switch.

Owner:昌辉汽车电器(黄山)股份公司

A temperature-resistant high-strength capacitor plastic case

The invention discloses a temperature-resistant high-strength plastic case for a capacitor, and belongs to the technical field of capacitors. The temperature-resistant high-strength plastic case is specifically prepared from the following materials of polycarbonate, polyethersulfone resin, polyfluoroalkoxy, polyether ether ketone, modified mullite powder, hydroxy propyl distarch phosphate, rock wool, nano rare earth powder, coal ash, n-butyl alcohol, polyanionic cellulose, a thickener, a defoamer, a dispersant, sodium dodecyl benzene sulfonate, disodium hydrogen phosphate and soybean oil. The prepared plastic case is good in processing characteristics, high in integral strength, high in dielectric strength, high in noise reduction performance and high in temperature resistance, and has very high popularization and application values.

Owner:宁国市大荣电器有限公司

Thin film capacitor

PendingCN114334456AImprove current resistanceGood cooling abilityThin/thick film capacitorFixed capacitor electrodesThin membraneEngineering

The invention discloses a thin film capacitor, which comprises a capacitor core, at least one first metal shell, at least one second metal shell, a first connecting sheet and a second connecting sheet, the first metal shell and the second metal shell are spliced together through an insulator to jointly define an accommodating cavity; the first metal shell is provided with a first leading-out terminal, and the second metal shell is provided with a second leading-out terminal; the first connecting sheet is connected with the capacitor core and the first metal shell; the second connecting sheet is connected with the capacitor core and the second metal shell; the capacitor core, the first connecting sheet and the second connecting sheet are arranged in the accommodating cavity and are sealed through pouring sealant; therefore, the capacitor has better heat dissipation capability while the current resistance capability is improved, and the thermal resistance of the product is greatly reduced.

Owner:XIAMEN FARATRONIC

A switching power supply

ActiveCN104716832BImprove current resistanceFeedback link design is simple and reliableDc-dc conversionElectric variable regulationCurrent elementPower flow

The invention belongs to the field of power supplies, and provides a stabilized switching power supply. A switching type DC-DC voltage stabilizer power source is formed by independent electronic elements, a wide-input voltage range is provided, the work state of an overall circuit is automatically adjusted according to input voltage, the output voltage is stable and can be set by adjusting element parameters, and the output current is determined by the input end and a circuit element. A large current element can be selected to improve the current resistance of the circuit, and the feedback link of the circuit is simple and reliable in design. As no integrated chip is used, the situation that when the voltage of a circuit of an integrated chip is used, the current parameters are basically fixed is avoided.

Owner:SHENZHEN OCEANS KING LIGHTING ENG CO LTD +1

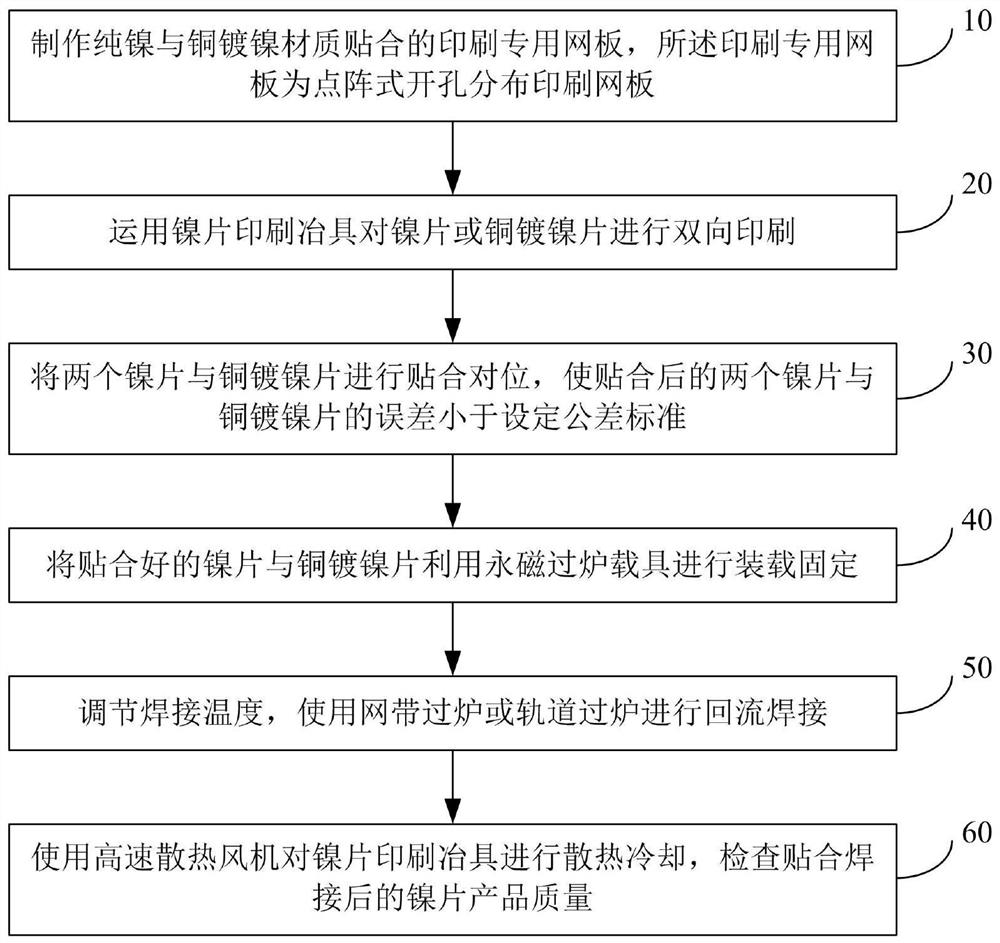

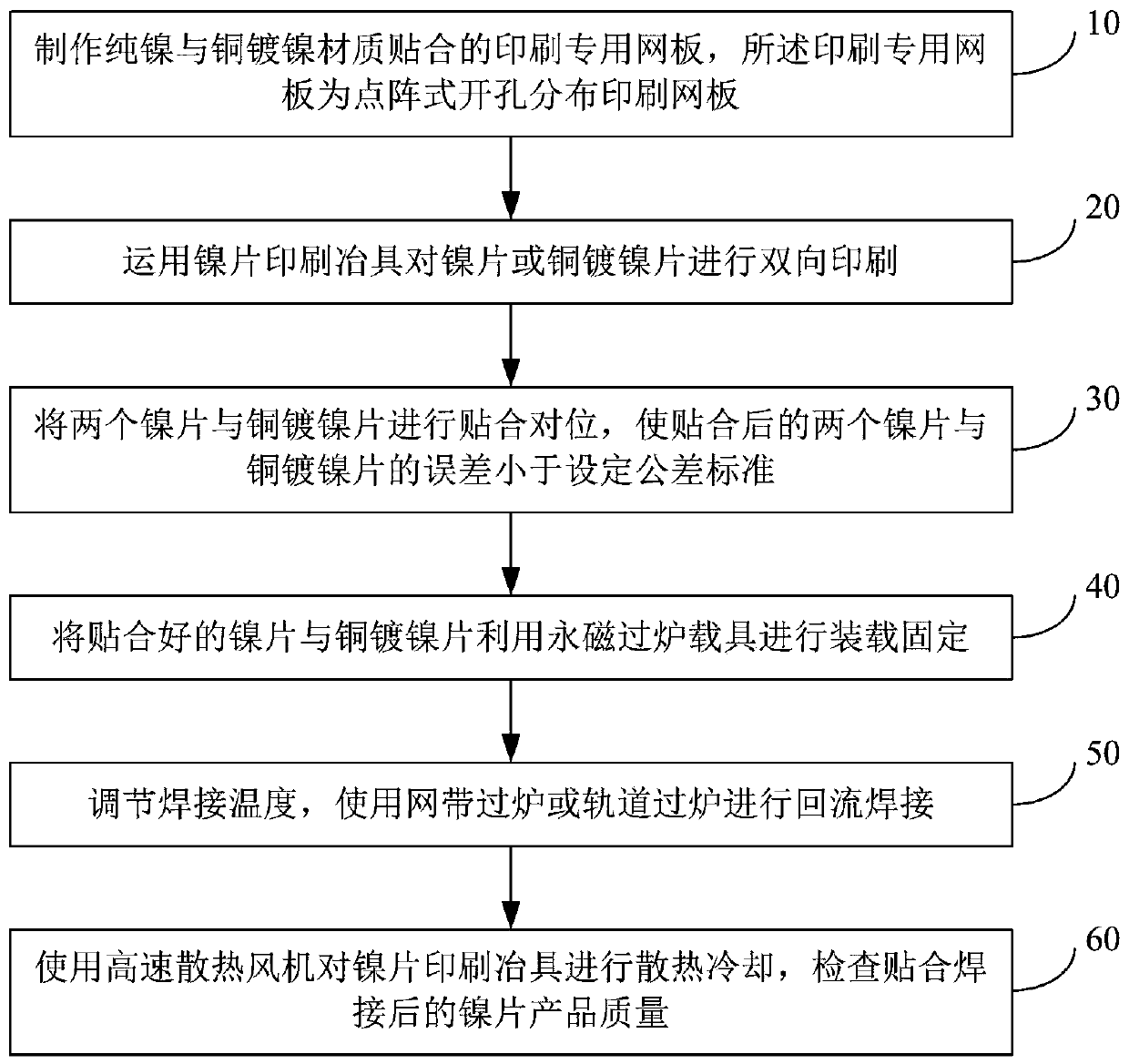

Solder paste welding process of pure nickel and nickel-plated copper material

ActiveCN110497055BImprove current resistanceHigh quality and reliabilitySoldering apparatusPrinted circuitsManufacturing cost reductionCopper

The invention discloses a solder paste welding process for laminating pure nickel and nickel-plated copper materials, comprising: making a special printing screen for laminating pure nickel and nickel-plated copper materials; two-way printing of the sheet; align the two nickel sheets with the nickel-plated copper sheet, so that the error between the two nickel sheets and the nickel-plated copper sheet after lamination is less than the set tolerance standard; Mount and fix the nickel-plated copper sheet with a permanent magnet furnace carrier; adjust the welding temperature, use a mesh belt furnace or track furnace for reflow soldering; use a high-speed heat dissipation fan to cool the nickel sheet printing tool, and check the bonding welding After the nickel sheet product quality. The invention can improve the current resistance performance of the nickel sheet, ensure the welding quality, and have a wider range of product use, especially for the design of lithium battery packs, which greatly reduces the manufacturing cost and equipment investment, and the development of new varieties is fast, with less investment and high quality. High reliability.

Owner:GUANG DONG GREENWAY TECH CO LTD

Welding technology for pure nickel and nickel plated brass material laminated solder paste

ActiveCN110497055AImprove current resistanceHigh quality and reliabilitySoldering apparatusPrinted circuitsHeat sinkSolder paste

The invention discloses a welding technology for pure nickel and nickel plated brass material laminated solder paste. The welding technology comprises the following steps of producing a special pure nickel and nickel plated brass material laminated screen board for printing; performing bidrectional printing on nickel sheets or copper cladding nickel sheets by applying a nickel sheet printing fixture; laminating and aligning two nickel sheets with the copper cladding nickel sheets, and allowing the error of the two nickel sheets and the copper cladding nickel sheets after laminating to be smaller than a set tolerance standard; loading and fixing the laminated nickel sheet and copper cladding nickel sheet by using a permanent magnet solder pallet carrier; adjusting the welding temperature, and performing reflow soldering by using a mesh belt solder pallet or a rail solder pallet; and performing heat-sink cooling on the nickel sheet printing fixture by using a high-speed cooling fan, andchecking the quality of laminated and welding nickel sheet products. The welding technology for the pure nickel and nickel plated brass material laminated solder paste can improve the current resistance of the nickel sheets and ensure the welding quality and has wider use range of products; in particular to the design of a lithium battery pack, the manufacturing cost is greatly reduced, and equipment investment is reduced; and in addition, the development speed of new products is high, the investment is low and the quality reliability is higher.

Owner:GUANG DONG GREENWAY TECH CO LTD

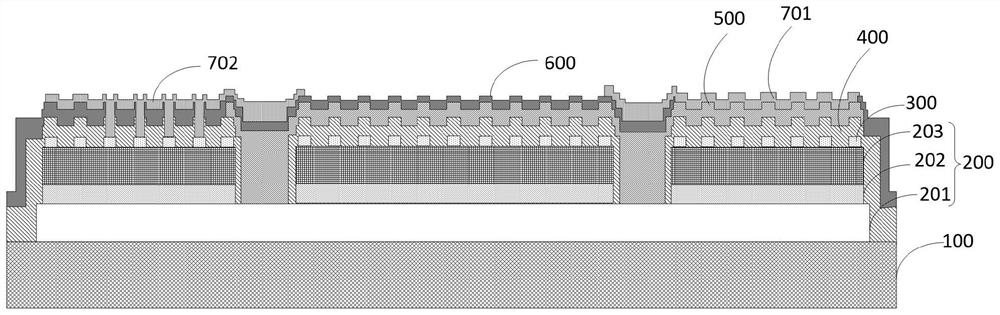

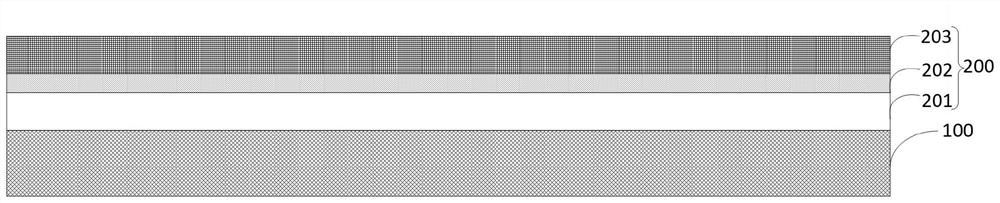

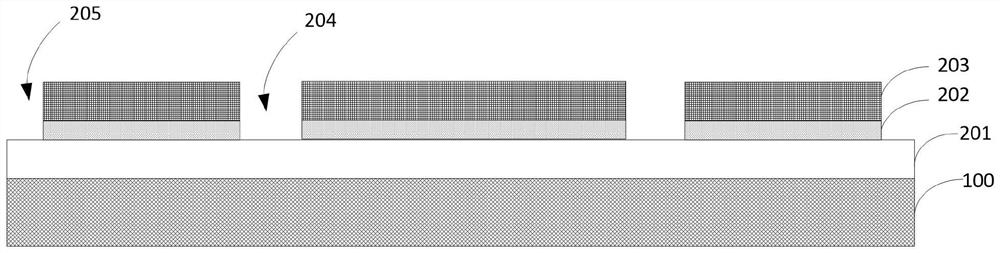

Flip LED chip and production method thereof

The invention provides a flip LED chip and a production method thereof. The flip LED chip comprises: a substrate, an epitaxial layer which is located on the substrate and comprises an N-type semiconductor layer, an active layer and a P-type semiconductor layer which are stacked in sequence, a metal reflecting layer, an insulating reflecting layer and a welding metal layer, wherein an N-type groove for exposing the N-type semiconductor layer is formed in the epitaxial layer; the metal reflecting layer is located on the P-type semiconductor layer and provided with a plurality of metal layer through holes, and the P-type semiconductor layer is exposed out of the metal layer through holes; the insulating reflecting layer is positioned on the metal reflecting layer, fills the metal layer through hole and covers the side wall of the N-type groove so that the insulating reflecting layer is in contact with the P-type semiconductor layer; and the welding metal layer is positioned on the insulating reflecting layer and comprises an N-type welding metal layer and a P-type welding metal layer. The metal layer through holes are formed in the metal reflecting layer so that the insulating reflecting layer is in contact with the P-type semiconductor layer, and the contact capacity of the metal reflecting layer and the P-type semiconductor layer is improved.

Owner:XIAMEN SILAN ADVANCED COMPOUND SEMICON CO LTD

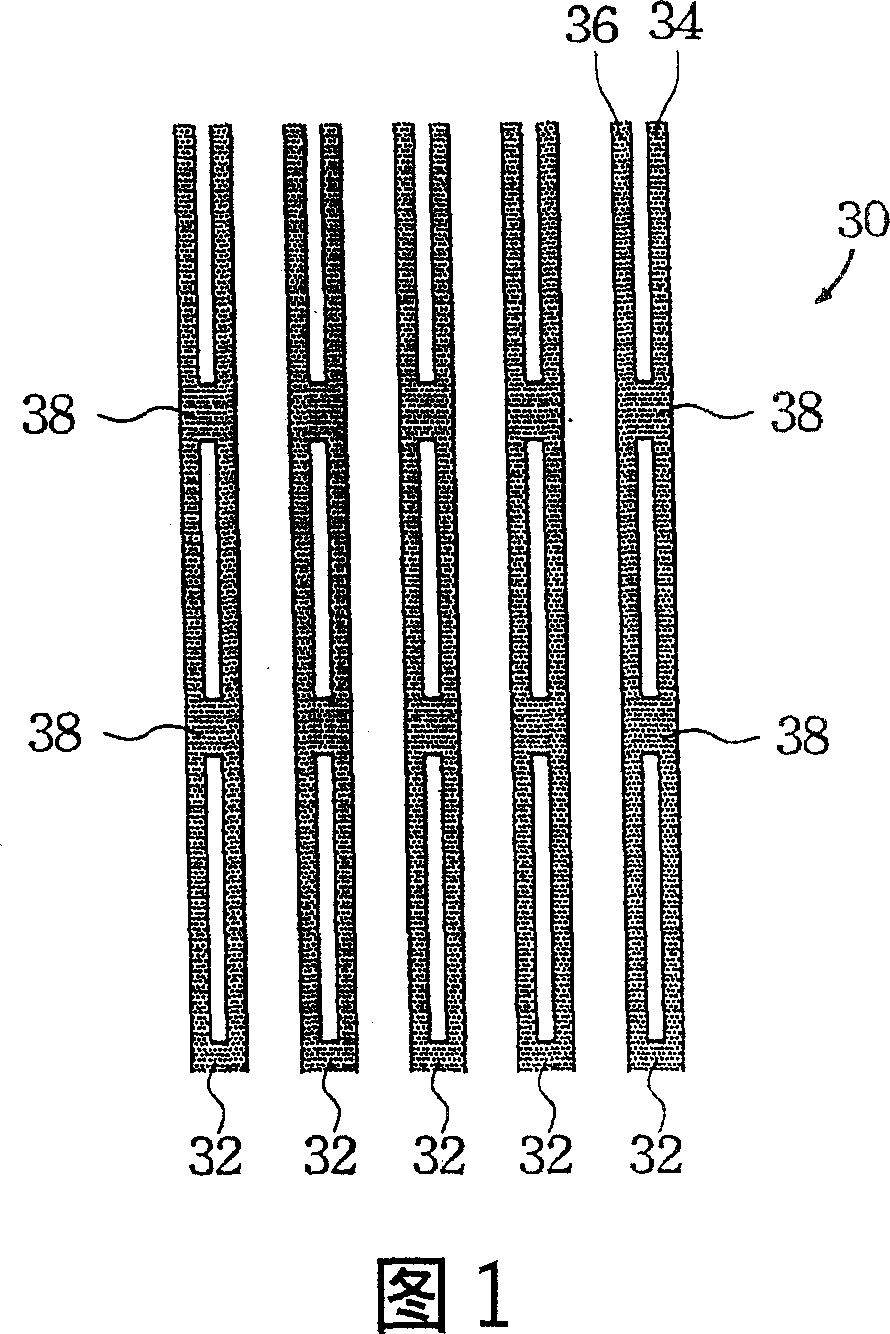

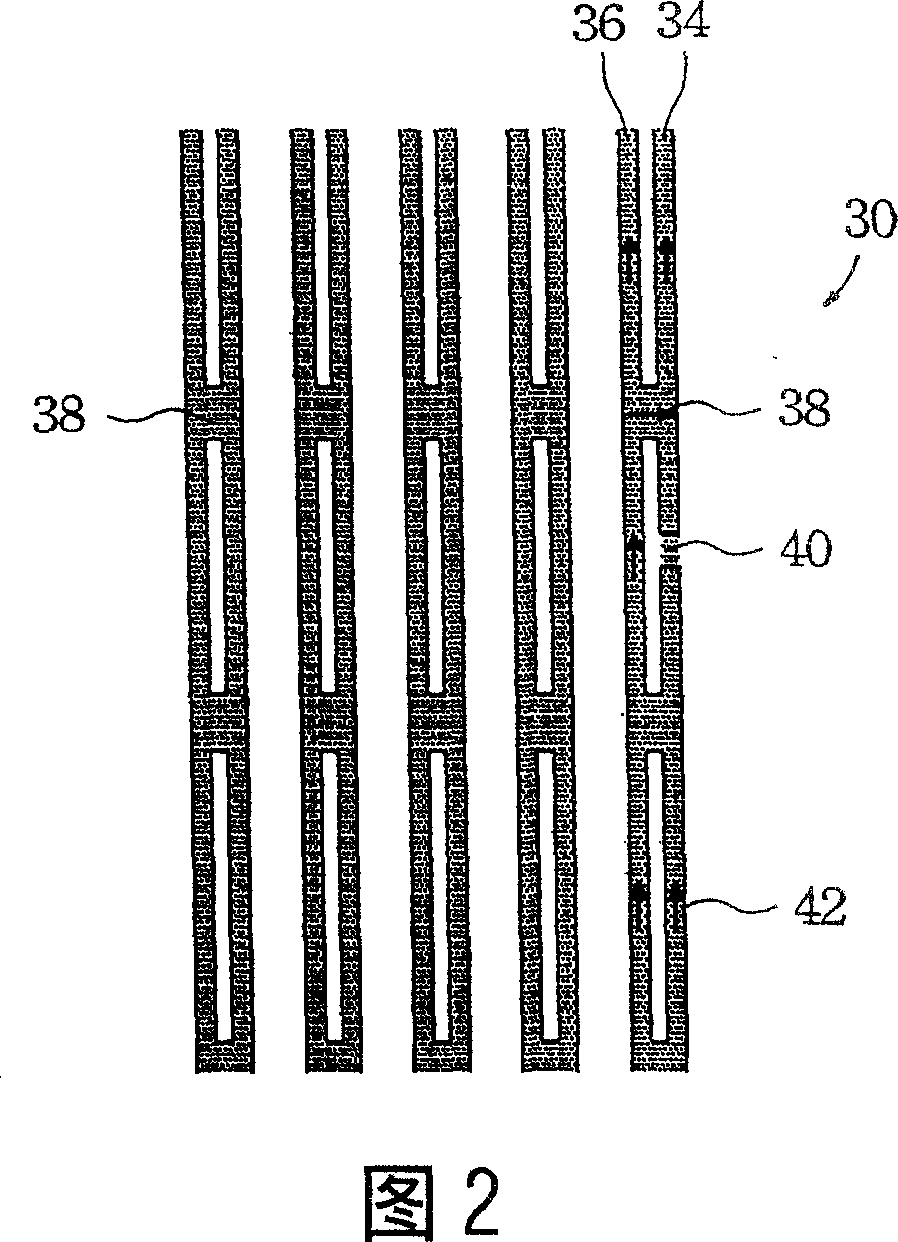

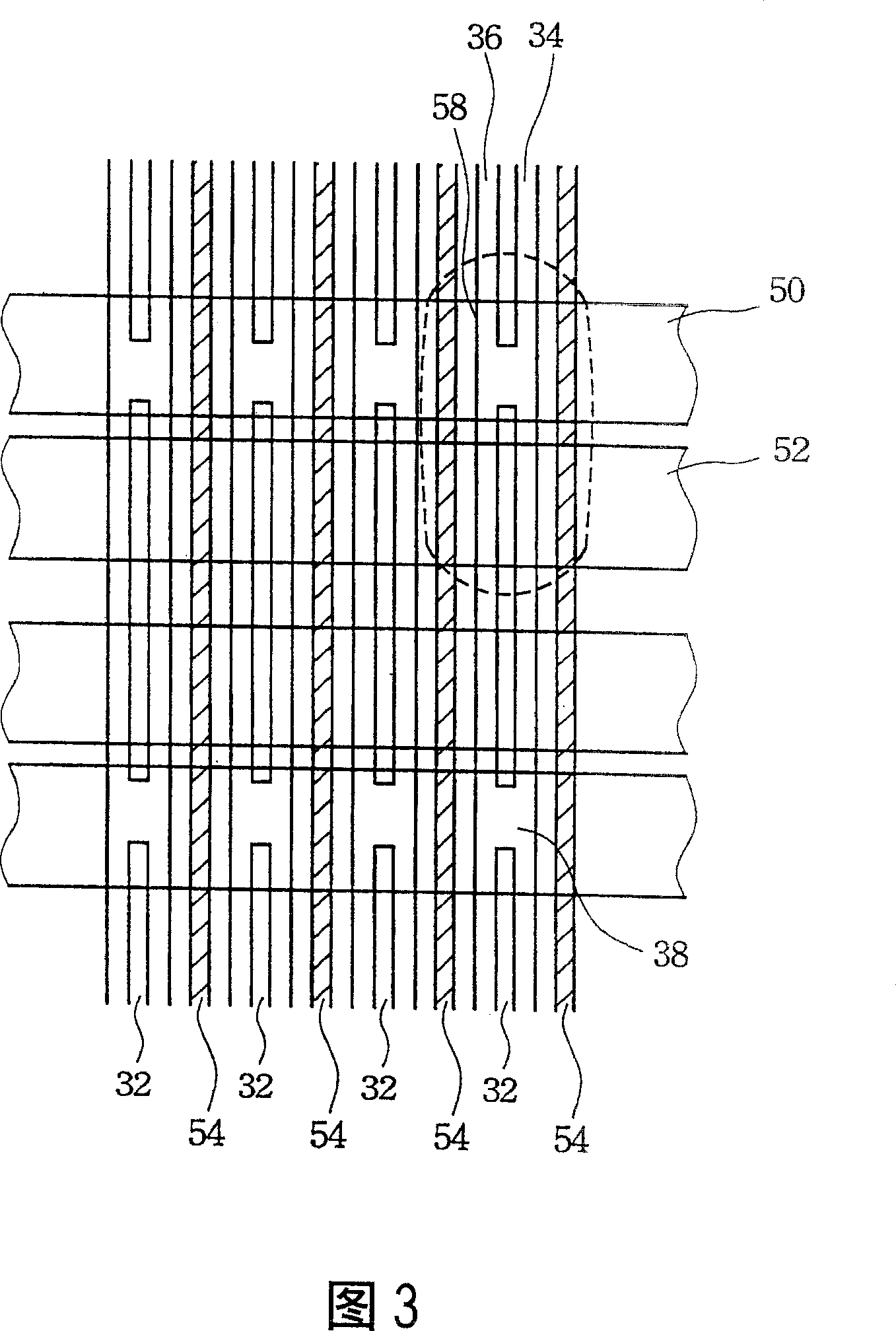

Structure for addressing electrodes in plasma panel display

InactiveCN1302505CImprove current resistanceIncrease write speedSolid cathode detailsCold-cathode tubesElectrical conductorDisplay device

Owner:CHUNGHWA PICTURE TUBES LTD

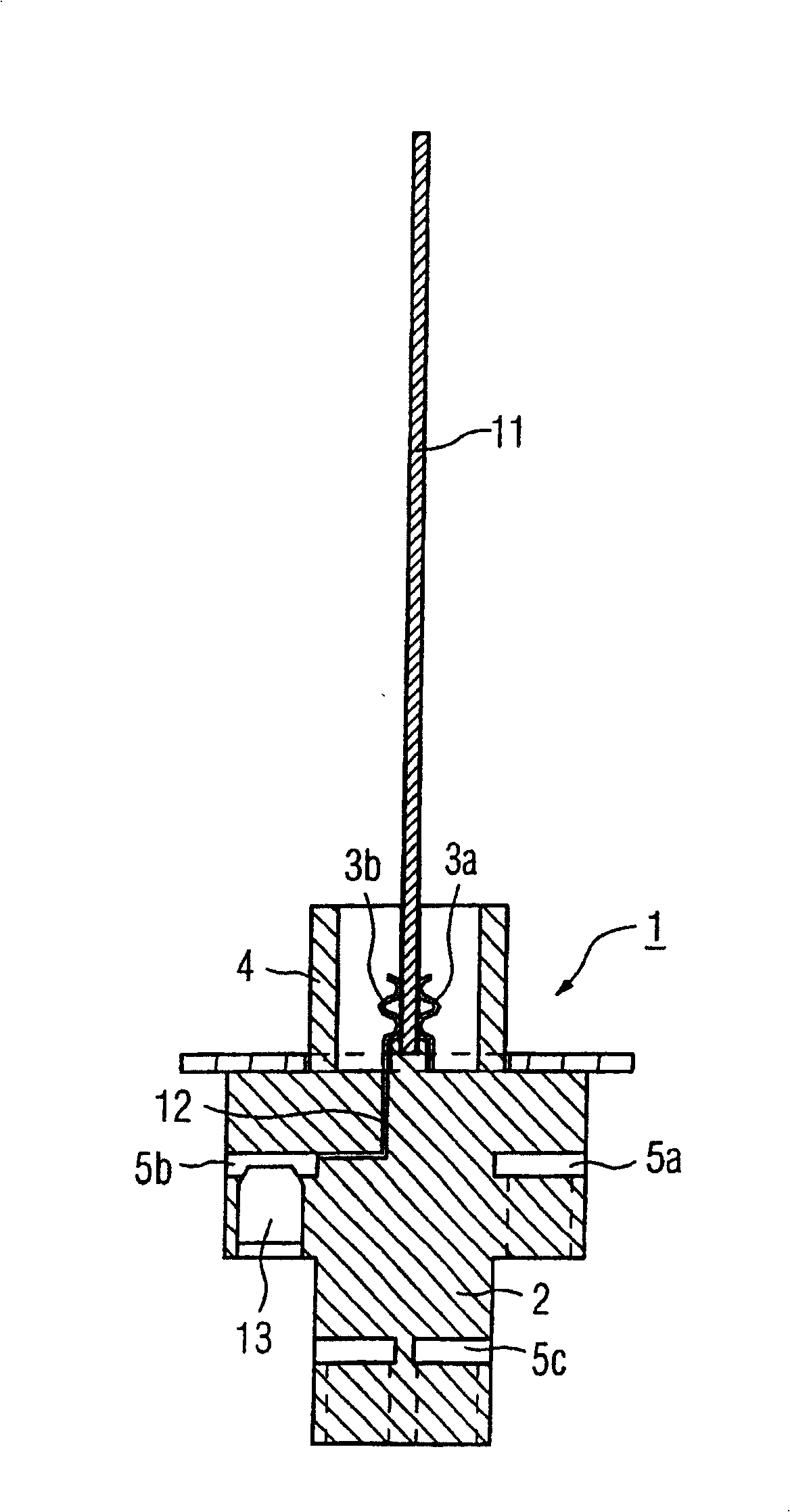

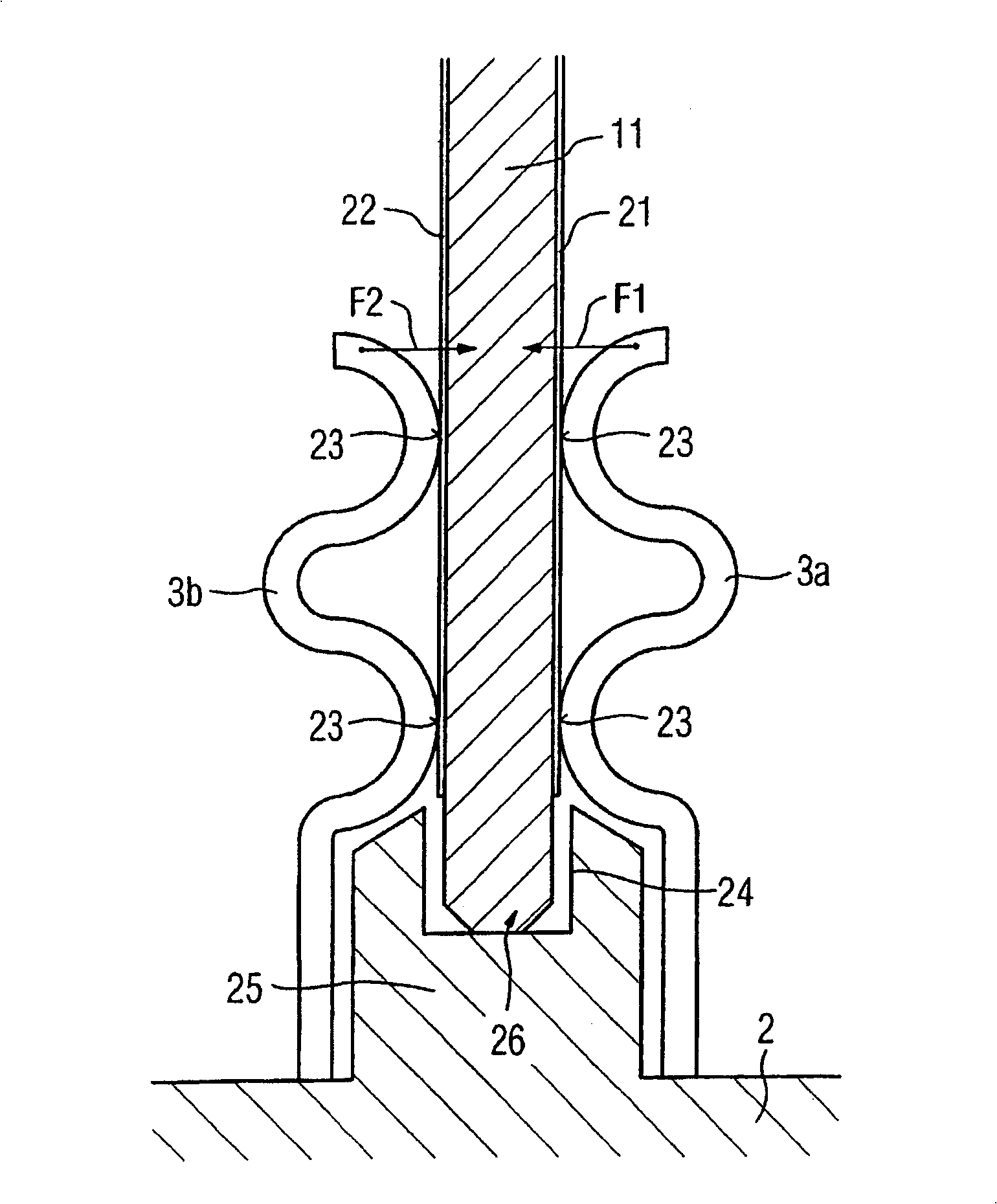

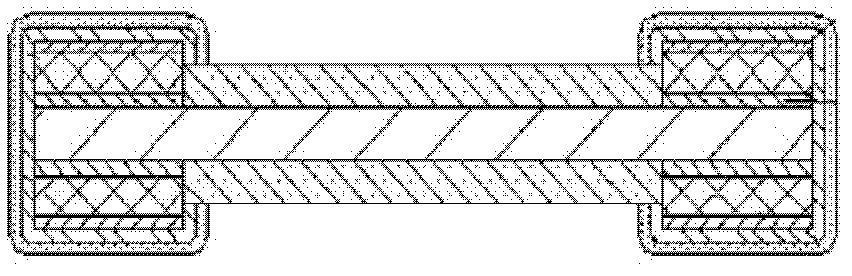

Multipoint plug for electrically connecting metal strip conductors arranged on both sides of a circuit board

InactiveCN100477390CExtend creepage distanceIncreased creepage distanceElectrically conductive connectionsCoupling contact membersElectric strengthElectric contact

The invention relates to a multipoint plug (1) for electrically connecting metallic strip conductors (21, 22) arranged on both sides of a circuit board (11) comprising a base body (2) provided with mutually opposite flexible contacts (3, 3a, 3b, 3c) which are longitudinally arranged in such a way that the front face of the circuit board (11) is insertable between said contacts (3, 3a, 3b, 3c), thereby producing electric contact thereof with the strip conductors (21, 22). The opposite contacts (3, 3a, 3b, 3c) are electrically insulated with respect to each other inside the base body (2). The aim of the invention is to develop a small-sized multipoint plug which exhibits as high electric strength as possible. For this purpose, a recess (24) is shaped between opposite contacts (3, 3a, 3b, 3c) in a longitudinal direction of the base body. When the circuit board (11) is inserted, said recess encompasses the frontal face thereof in such a way that an extended creepage distance is formed between opposite contacts (for instance, 3a, 3b).

Owner:SIEMENS AG

Precision current sensing element and manufacturing method thereof

ActiveCN102354590BSimple processLower resistanceResistor housing/enclosing/embeddingResistor manufactureElectrical resistance and conductanceEngineering

The invention belongs to the field of precision current sensing elements and particularly relates to a structure of a multi-layer structured precision current sensing element with a radiating layer, and a manufacturing method for the structure. The multi-layer structured precision current sensing element comprises at least one layer of resistor body, two layers of radiating sheets, electrodes, an insulation heat conduction adhesive layer, via holes and a protection layer, wherein an insulation slit is formed between the radiating sheets; the insulation heat conduction adhesive layer is arranged between one metal layer and another metal layer; the electrodes are arranged on two sides of a product; the electrodes are connected with the resistor body and the radiating sheets; a via hole is formed in each electrode; and the via holes are connected with the resistor body and the radiating sheets. In the manufacturing method, the thick resistor body is decomposed into a plurality of thin resistor bodies; the thin resistor bodies are subjected to resistance modification, and alloy sheets are connected in parallel with one another; each resistor body is at least provided with one radiating sheet for radiation, so the radiating property of the product is enhanced greatly; furthermore, a layer of protection layer is covered on the outer layer of the multi-layer structured precision current sensing element. The precision current sensing element is high in practicability.

Owner:NANJING SART SCI & TECH DEV

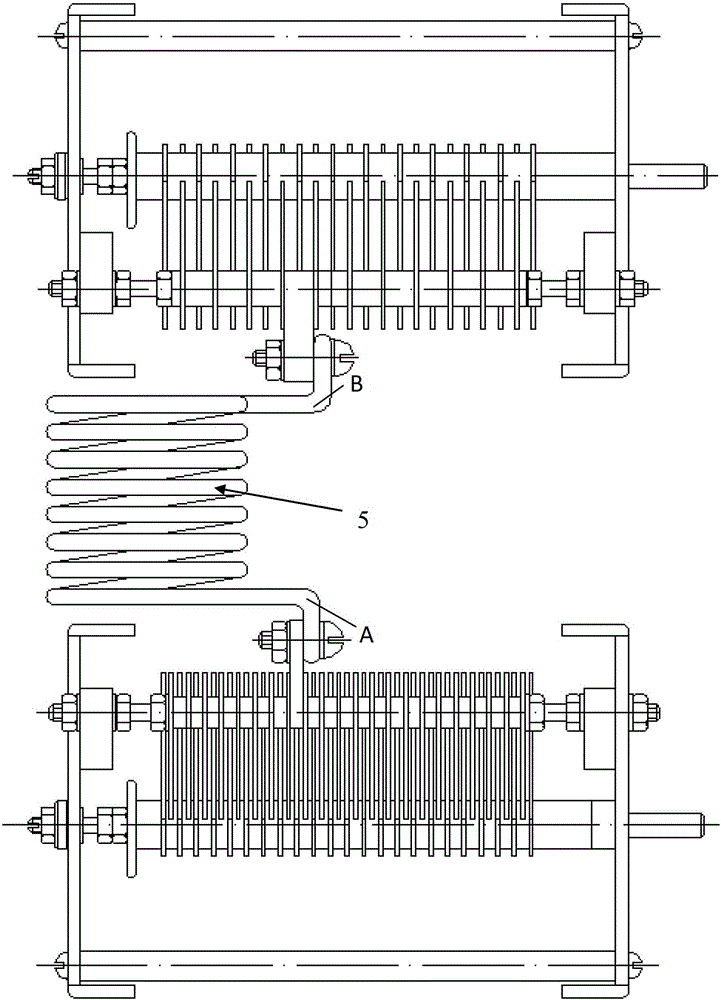

Transformer structure with effects of bearing large current and dissipating heat

InactiveCN110690035AImprove current resistanceIncrease cooling areaTransformers/inductances coolingTransformers/inductances coils/windings/connectionsTransformerElectrical connection

The invention discloses a transformer structure with effects of bearing large current and dissipating heat. The transformer structure includes a circuit board, a current bearing plate, a transformer core, two wire windings and two plate windings. A rectifying and filtering circuit is disposed on the circuit board and includes at least a filtering inductor, a filtering capacitor and a rectifying switch. The filtering inductor is composed of a deflector on the circuit board and an inductor core placed on the deflector. The current bearing plate is stacked on the circuit board and is electricallyconnected to the rectifying and filtering circuit. The transformer core is disposed on the circuit board. The two plate windings are made of electrode plate materials. At least one round of iron coreis wound around the transformer and fixed on the circuit board. The plate windings are electrically connected to the deflector and the current bearing plate to jointly bear the current flowing through the transformer structure.

Owner:徐州国力电力设备有限公司

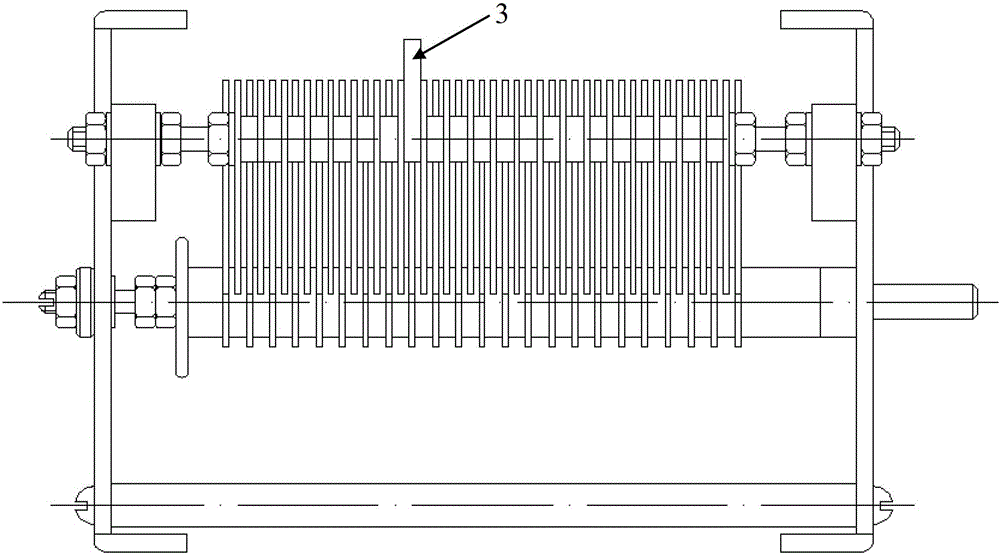

An air capacitor structure for matching equipment

ActiveCN103065791BExtended service lifeImprove current resistanceMultiple fixed capacitorsFixed capacitor terminalsCapacitancePlasma technology

The invention relates to the technical field of plasma etching and depositing equipment and specifically relates to an air capacitor structure for matcher equipment. The air capacitor structure comprises a capacitor piece and a connecting rod connected with the capacitor piece; a connecting column is fixedly arranged on the connecting rod; and a silver jacketed coil is connected with the connecting rod by the connecting column. Through arranging the connecting column on the connecting rod of the air capacitor, the heavy current running through the air capacitor in a plasma technology is distributed evenly, thus the current resistance of the capacitor is favorably improved, the capacity range of the capacitor is improved, the service life of the air capacitor is improved directly, the reliability of the matching property is enhanced and the service life of the total equipment is prolonged.

Owner:SOI MICRO CO LTD

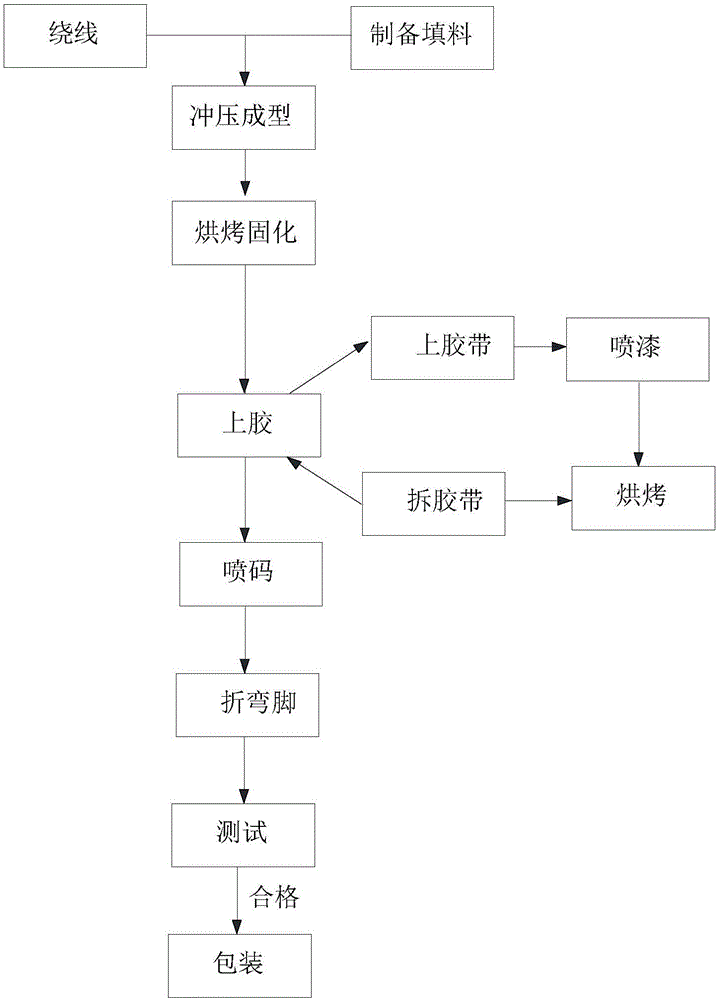

One-piece molded inductor and manufacturing method thereof

ActiveCN106252055BImprove current resistanceStable structureTransformers/inductances magnetic coresInductances/transformers/magnets manufactureElectricitySilicone Gels

The invention provides a manufacturing method of an integrally molded inductor, and belongs to the technical field of inductance elements. The method comprises the steps of winding a copper wire into a coil and electrically connecting the coil and an electrode pin; mixing a magnetic-conducting material with liquid silicone gel evenly at the mass ratio of 100:(2-15) to form a filler and carrying out heat preservation on the filler under the condition that the temperature is 70-80 DEG C for 0.2-1 hour; and putting the coil connected with the electrode pin into a mold, filling the mold with the filler and carrying out integral stamping to form the integrally molded inductor. The manufacturing method is simple; and the technological process is saved. Furthermore, the invention further provides the integrally molded inductor manufactured by the manufacturing method. The current resistance of the integrally molded inductor is significantly improved; the inductor is stable in structure; the magnetic loss can be reduced; and the noise at work can be reduced.

Owner:重庆金籁科技股份有限公司

Metallized film capacitor and metal layer spraying and heat treatment method thereof

PendingCN114373634AGuaranteed Dielectric StrengthIncrease the current-carrying cross-sectional areaMolten spray coatingVacuum evaporation coatingCapacitanceThin membrane

The invention relates to a metallized film capacitor and a metal layer spraying and heat treatment method thereof, the metallized film capacitor comprises a capacitor core, and the metallized film capacitor is characterized in that the capacitor core is of a round core type or a flat core type and is formed by winding at least one polypropylene film, and a plurality of metal layers are respectively sprayed at the upper end and the lower end of the capacitor core after the capacitor core is wound; wherein a plurality of evaporation aluminum layers are distributed on the surface of the polypropylene film, metal thickening layers are arranged on the evaporation aluminum layers, and reserved edges are arranged between the adjacent evaporation aluminum layers. And a plurality of different materials are adopted to spray the plurality of metal layers, so that the end face over-current capability and the heat dissipation capability of the capacitor product are effectively improved. Through cooperation of heat treatment and a hot pressing clamp, it can be effectively guaranteed that the temperature difference inside and outside the capacitor core is small, it is guaranteed that internal tension of the wound capacitor core is fully released, uniformity of internal tension of a polypropylene film is guaranteed, the application range is wide, and practicability is high.

Owner:佛山市肯博电子有限公司

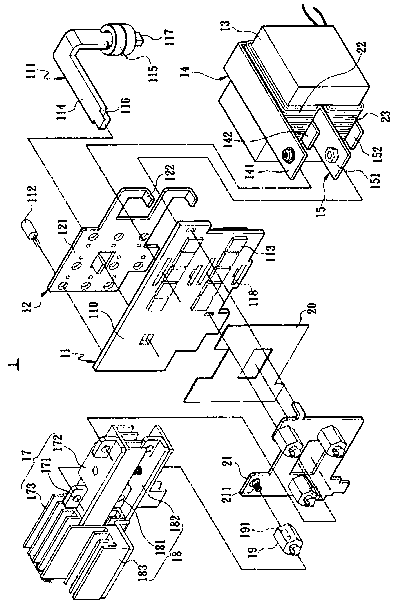

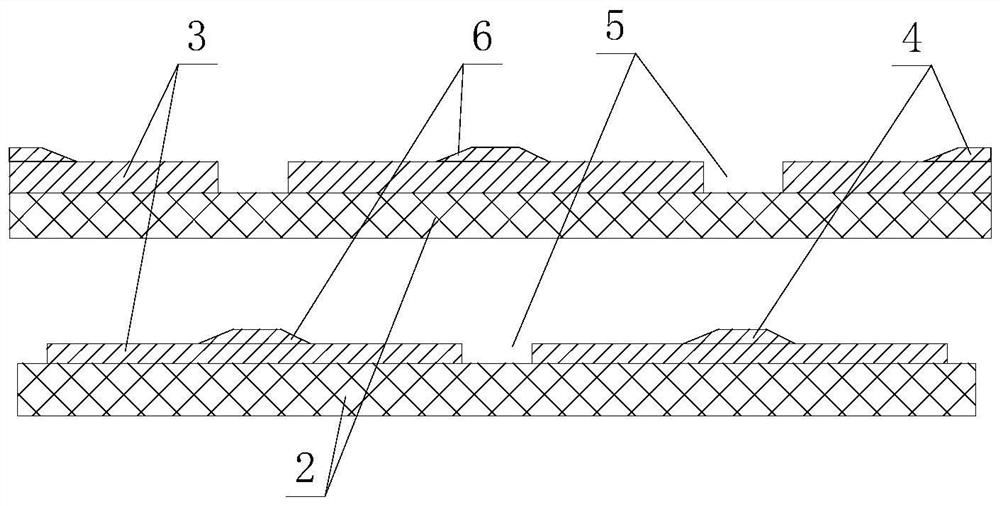

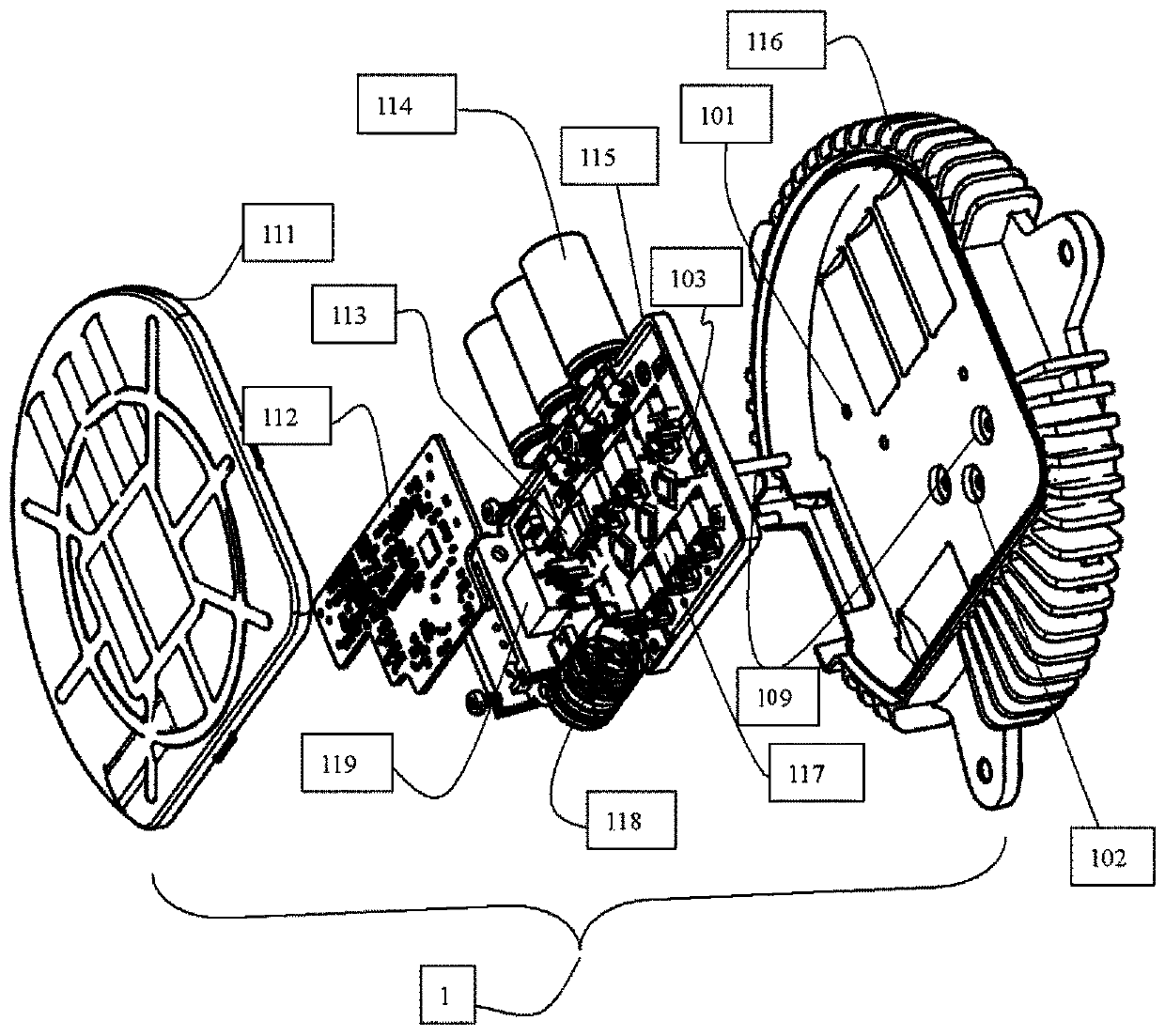

Structure of high-power brushless cooling fan power module

PendingCN111464046AImprove securityWith anti-reverse connection functionSingle motor speed/torque controlConversion constructional detailsElectric machineProcess engineering

The invention relates to the technical field of cooling fan controller assemblies, especially to a structure of a high-power brushless cooling fan power module. The reverse-connection-preventing structure for of the high-power brushless cooling fan power module effectively improves the current resistance of a system, saves a certain space, has a function of preventing reverse connection of a powersupply, improves heat dissipation efficiency, enhances the safety performance of a motor, is suitable for various motors in the automobile industry, ingenious in electronic and mechanical structure cooperation and easy to achieve, and presents good prospects.

Owner:龙城电装(常州)有限公司

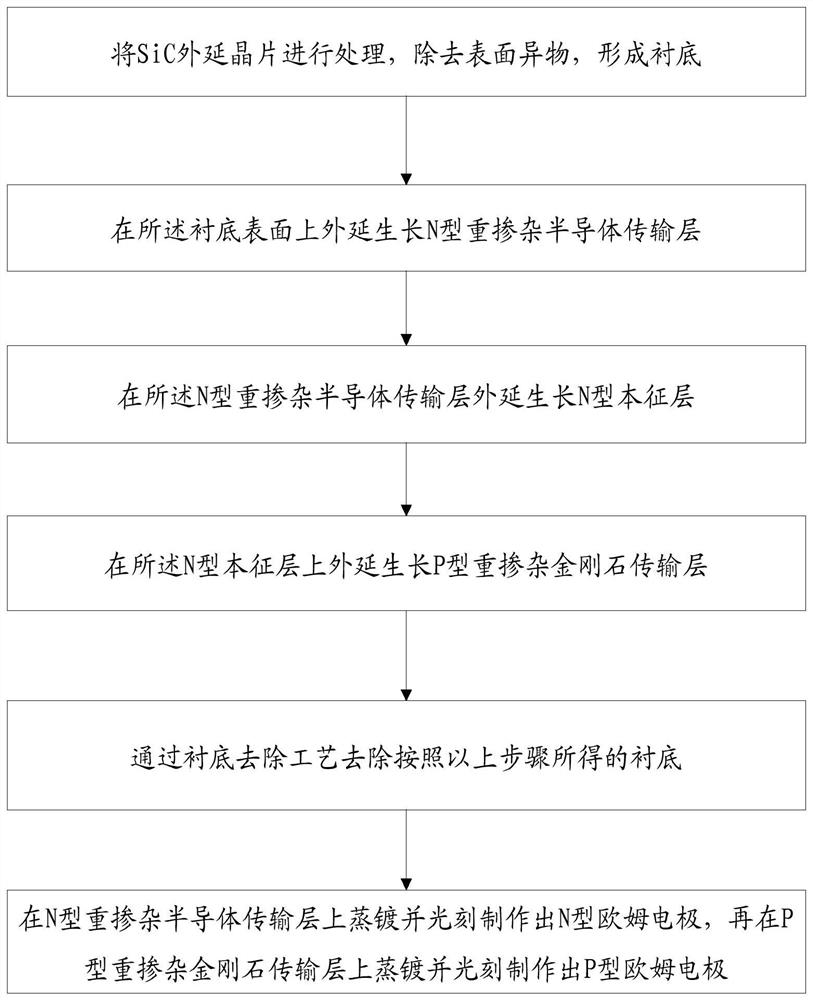

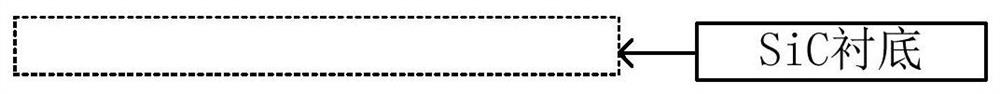

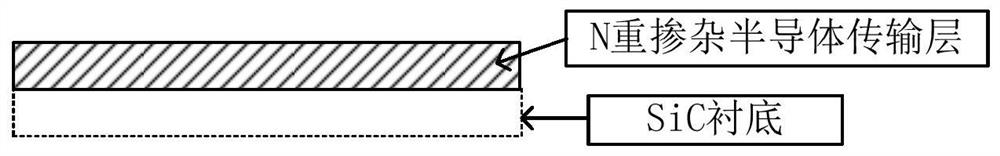

Low-thickness current-withstanding SiC PIN diode and manufacturing method thereof

PendingCN113964184AReduce thicknessImprove current resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductorMaterials science

The invention provides a low-thickness current-resistant SiC PIN diode and a manufacturing method thereof. The diode is characterized in that the lower side surface of an N-type heavily-doped semiconductor transmission layer is connected to the upper side surface of an N-type ohmic electrode; the lower side surface of an N-type intrinsic layer is connected to the upper side surface of the N-type heavily-doped semiconductor transmission layer; the lower side surface of a P-type heavily-doped diamond transmission layer is connected to the upper side surface of the N-type intrinsic layer; and the lower side surface of a P-type ohmic electrode is connected to the upper side surface of a P-type heavily-doped diamond transmission layer. Thus, the thickness of the diode is reduced, and current-withstanding capability is increased by four times.

Owner:GLOBAL POWER TECH CO LTD

Flexible flat cable

PendingCN114883035AImprove current resistanceIncrease widthStrip/foil conductorsCommunication cablesElectrical conductorMechanical engineering

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com