Flip LED chip and production method thereof

A LED chip and flip-chip technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of reducing product reliability, easy to fall off, and high refractive index of GaN, so as to increase contact ability, improve brightness and current resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

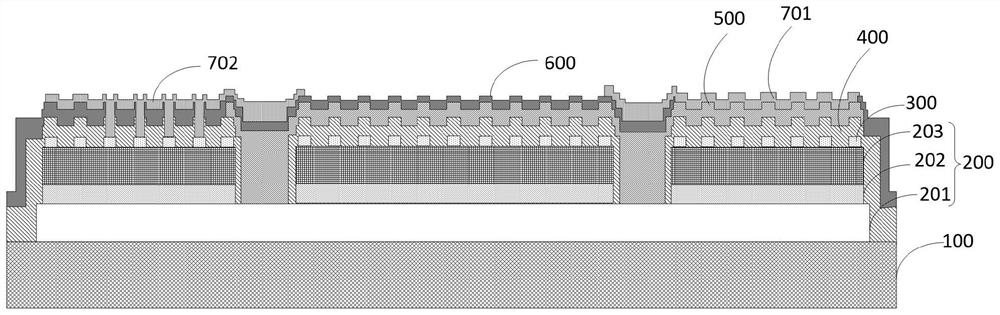

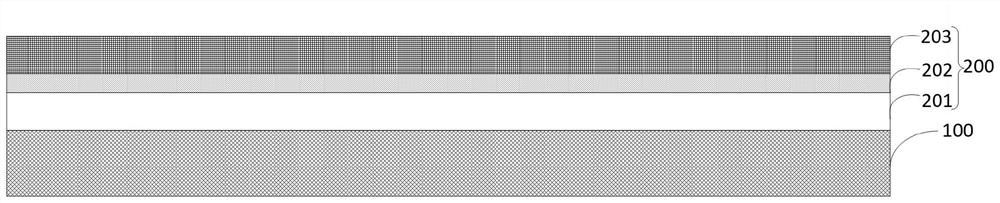

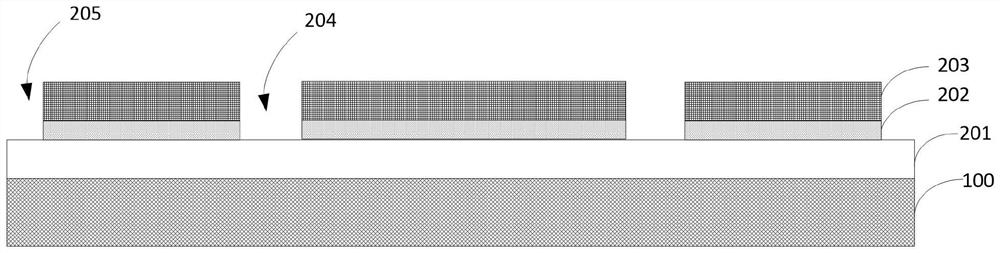

[0065] Flip-chip light-emitting diodes can be divided into two processes, namely the flip-chip DBR reflector process and the flip-chip metal reflector process. The flip-chip DBR mirror process uses ITO (Indium Tin Oxides, indium tin oxide) as the current spreading layer. The DBR mirror has high reflectivity, high brightness, and strong adhesion to other film layers, but the current spread is uneven. The flip-chip metal mirror technology uses a silver (Ag) mirror as the current spreading layer. The metal has a strong current spreading ability, but its adhesion to other film layers is weak, and it is easy to fall off. For the flip-chip metal mirror process, in order to increase the adhesion, a transparent adhesive layer is usually added between the metal reflective layer and the underlying film layer, but the increase of the adhesive layer greatly reduces the reflectivity of the metal reflective layer.

[0066] In order to make full use of the advantages of the flip-chip DBR and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com