Metallized film capacitor and metal layer spraying and heat treatment method thereof

A metallized film and capacitor technology, applied in the field of capacitors, can solve the problems that the air and water vapor in the film layer cannot be uniformly removed, the heat treatment consistency of the capacitor core is poor, and the film withstand voltage level cannot be improved, so as to improve the self-healing performance and increase the surface area. Diversified welding contacts, increasing the effect of end face flow capacity and heat dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

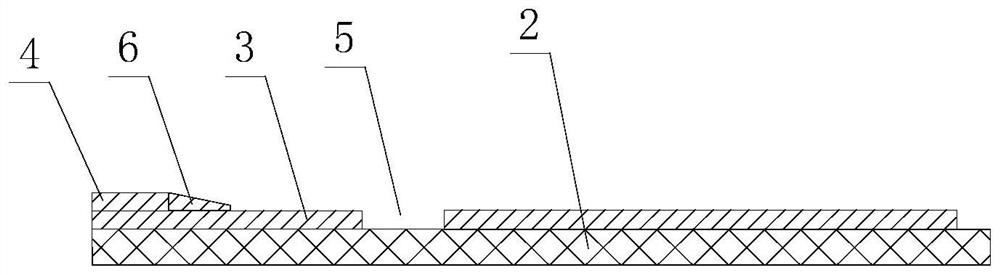

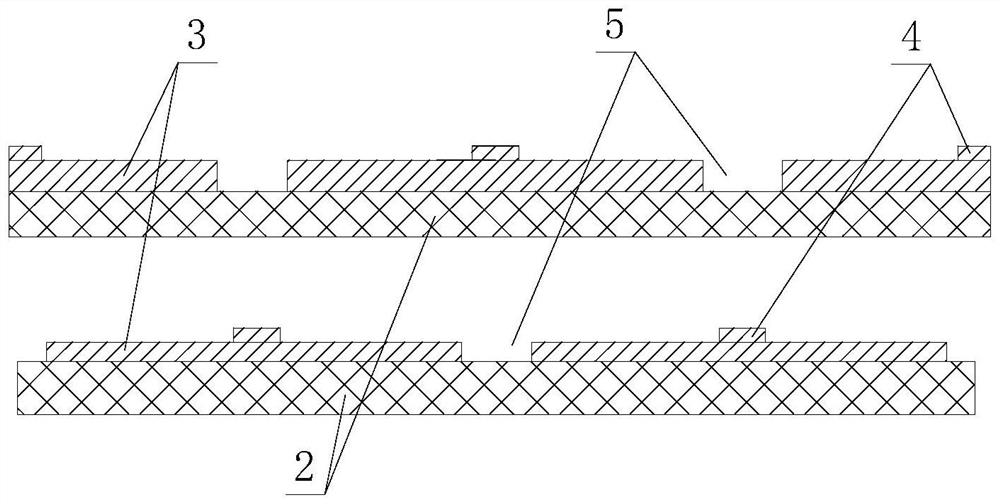

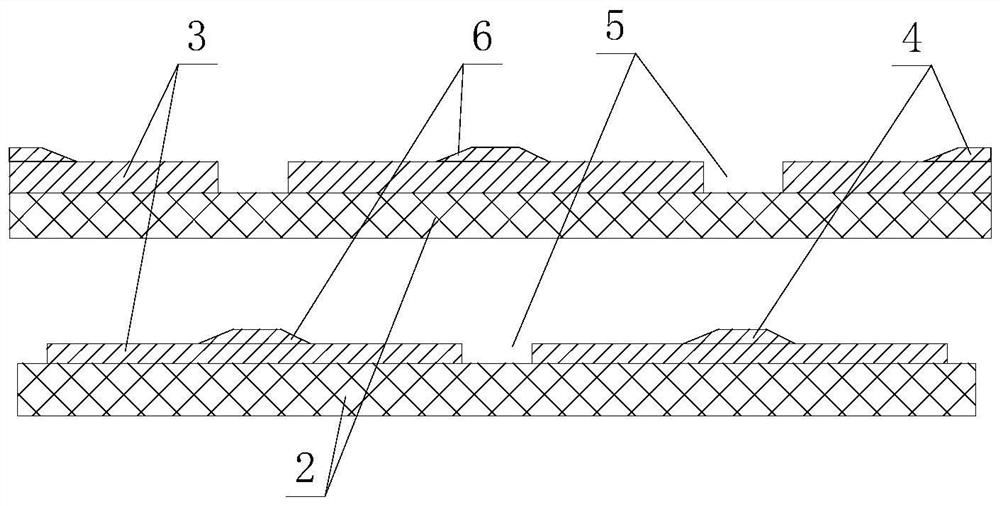

[0068] see Figure 1-Figure 22 , the metallized film capacitor includes a capacitor core 1, the capacitor core 1 is a round core type or a flat core type, and it is formed by winding at least one polypropylene film 2, and the upper and lower ends of the capacitor core 1 are wound Several metal layers are sprayed respectively; among them, the surface of the polypropylene film 2 is distributed with several vapor-deposited aluminum layers 3, and the vapor-deposited aluminum layer 3 is provided with a metal thickening layer 4, and the adjacent vapor-deposited aluminum layer 3 There is a margin 5 between them.

[0069] The setting of the margin 5 can ensure that when the capacitor core 1 is wound, there is a certain dielectric strength between the plurality of polypropylene films 2, and can increase the current-carrying cross-sectional area of the capacit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com