Dry-type high-frequency high-voltage transformer structure

A high-frequency high-voltage, transformer technology, applied in the direction of fixed transformer or mutual inductance, transformer/inductor cooling, transformer/inductor magnetic core, etc., can solve the problems of unreliable long-term operation, low boost voltage, small transfer capacity, etc. , to achieve the effect of ensuring high-frequency insulation level, high-voltage output, and excellent dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

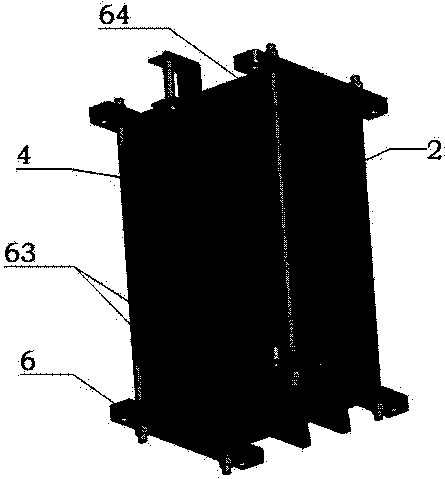

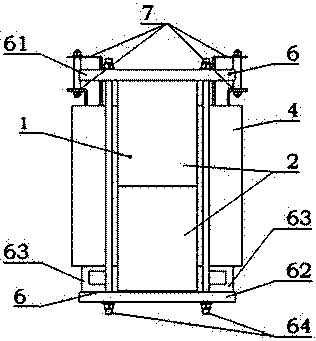

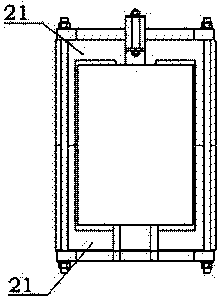

[0075] As attached Figure 1-13 As shown, the large-capacity dry-type high-frequency high-voltage transformer 1 of the present invention includes: an EE-type magnetic core 2, a square frame 3, a square coil 4, a fixed support device 6, and also includes a copper bar or copper wire 7 for the coil. Such as Figure 5 As shown, the EE-shaped magnetic core 2 is formed by two E-shaped magnetic cores 21 facing each other with openings and aligned up and down. Each E-shaped magnetic core 21 is composed of a bottom yoke 22, a center pillar 23 and two side pillars 24. A closed magnetic circuit is formed between the upper and lower bottom yokes 22, the center pillar 23 and the side pillar 24 of the EE-type magnetic core.

[0076] The square bobbin 3 is sleeved on the center column 24 of the EE-type magnetic core 2. The square coil 4 is a vertical structure, and is wound on the square bobbin 3 by a combination of a low voltage coil 41 and a high voltage coil 42. The square coil 4 An axial he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com