Multilayer small-size mutually inverse type non-inductive resistor

A non-inductive resistance, reciprocal technology, applied in the direction of resistors, non-adjustable metal resistors, spiral coil/spiral disk resistance elements, etc., can solve the problem of large resistance size, and achieve the effect of reducing the overall length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

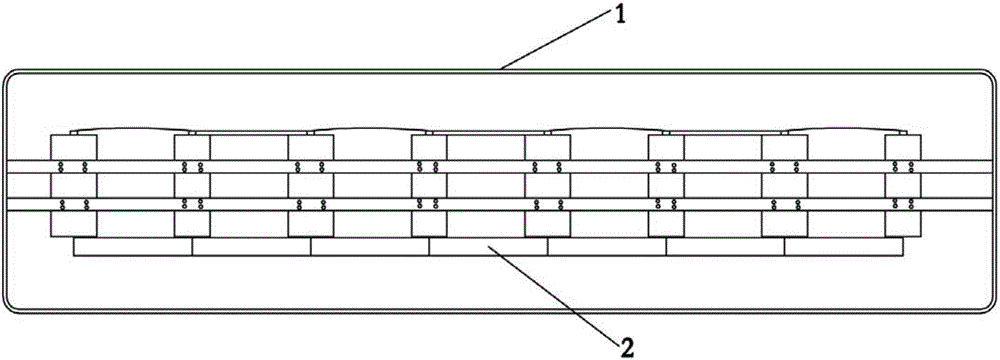

[0024] like figure 1 As shown, the non-inductive resistor 2 of the present invention is arranged in the compact impulse voltage generator 1, and the resistance value of the non-inductive resistor 2 is calculated according to the wavefront resistance and the half-peak resistance in the impulse voltage generator as follows:

[0025] T f ≈2.33(R d +R f )C 1 C 2 / (C 1 +C 2 );

[0026] T t ≈0.693(R d +R t )(C 1 +C 2 );

[0027] where T f is the front time, T t is the half-peak time, R d is the total damping resistance inside the shock generator, R f is the resistance value of segmented non-inductive wave front resistance, R t is the half-peak resistance value, C 1 is the capacitor of the impulse voltage generator, C 2 is the total capacitance of the sample.

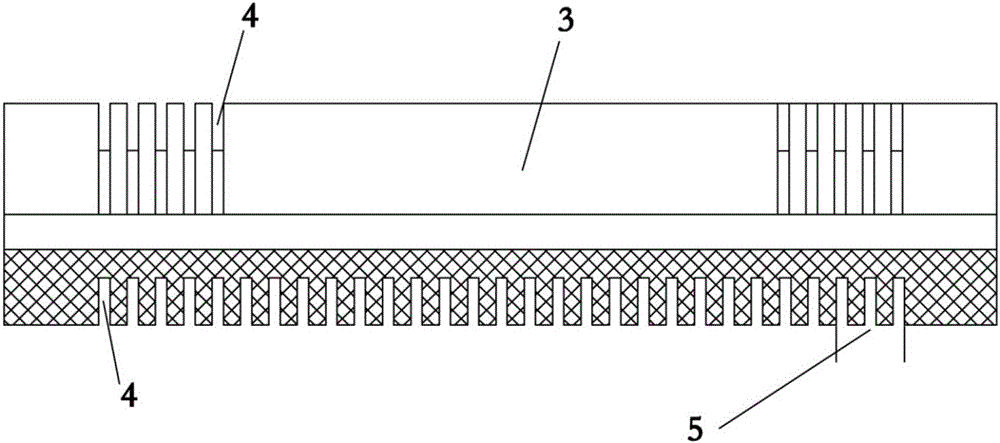

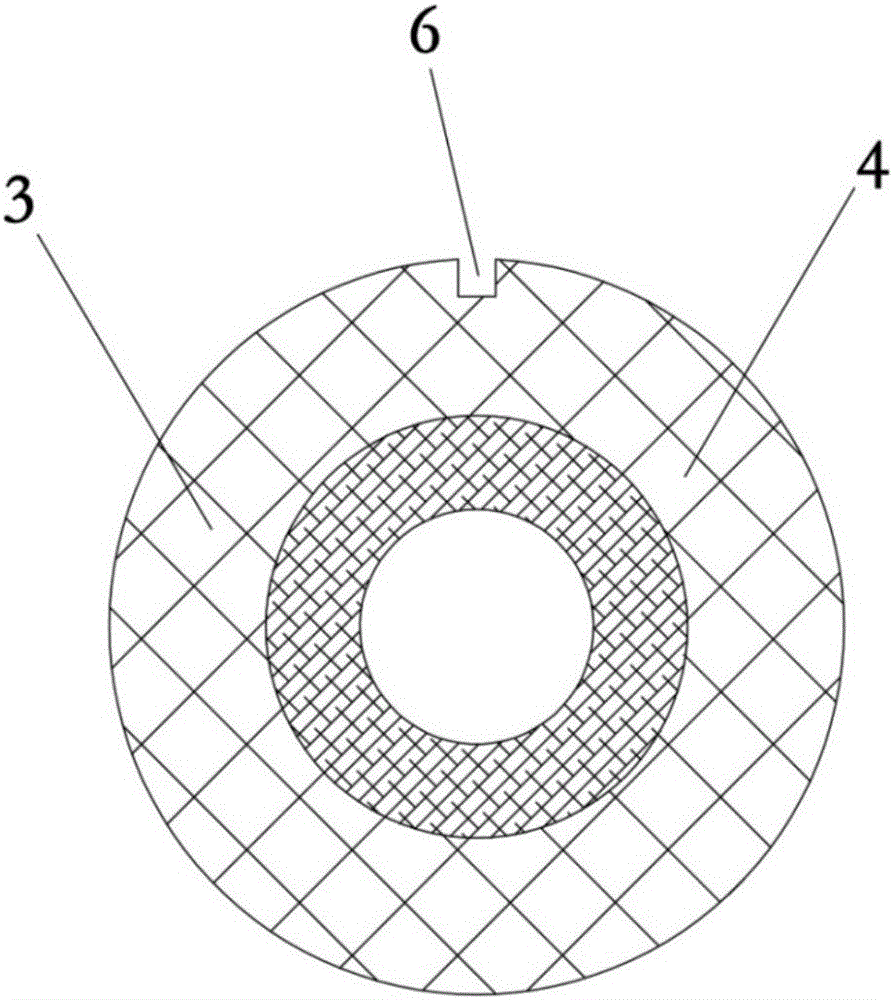

[0028] like Figures 2 to 4 As shown, a multi-layer small-v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com