Patents

Literature

80results about How to "Reduce the number of solder joints" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solder paste detection threshold optimization method based on SMT big data

ActiveCN108960306AReduce weldingReduce the number of solder jointsCharacter and pattern recognitionGenetic algorithmsSolder pasteGenetic algorithm

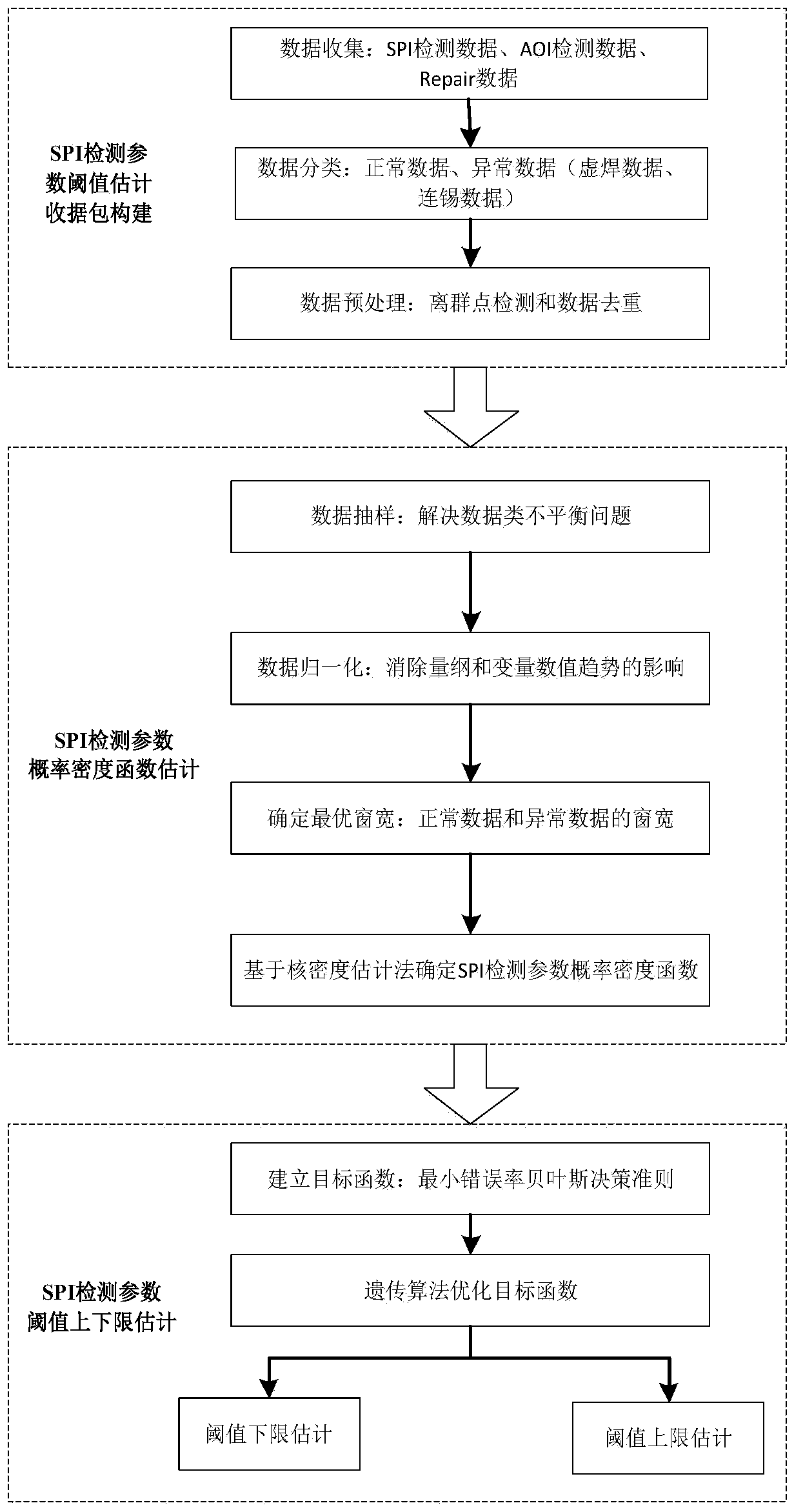

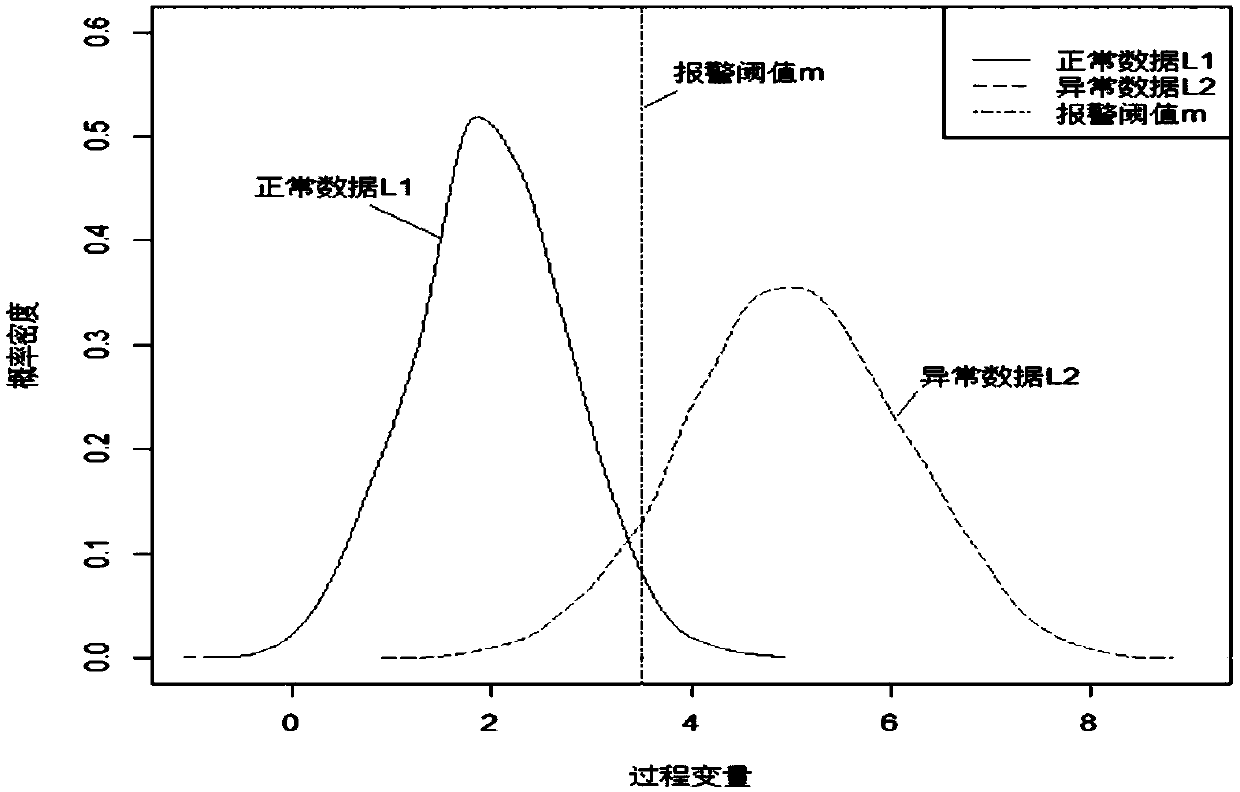

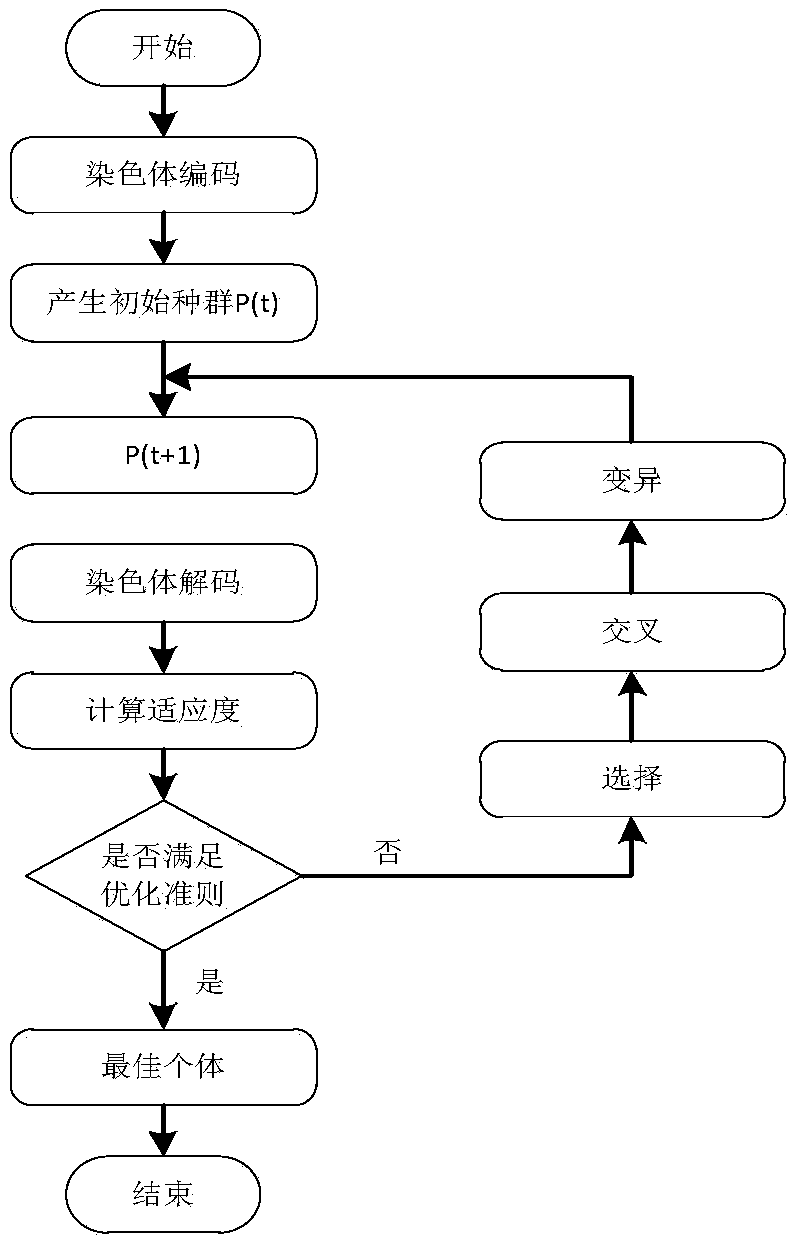

The present invention provides a solder paste detection threshold optimization method based on SMT big data. The problems are mainly solved that a traditional artificial experience SPI threshold setting method cannot effectively discover potential badness in the PCB printing process and cannot reduce the cold solder joint and continuous tin electrodeposit defects caused by the solder paste amount.The method comprises the steps of: constructing a threshold estimation data packet; estimating an SPI parameter state; optimizing an SPI threshold, taking an SPI detection value as an operation variable to allow a corresponding value to be a target function when the sum of a misjudgment rate and a misdetection rate reaches the lowest, employing a genetic algorithm to perform optimization of the target function to obtain an optimization threshold, and setting the obtained optimization threshold as the SPI threshold of the surface mounting technology. The design of the solder paste detection threshold optimization method is rigorous and complete, the threshold value setting method has theoretical property and feasibility to effectively control the defects such as cold solder joint and continuous tin electrodeposit caused by the solder paste amount to flow into the surface mounting technology (SMT) later process so as to improve the whole yield of a PCB.

Owner:XIDIAN UNIV

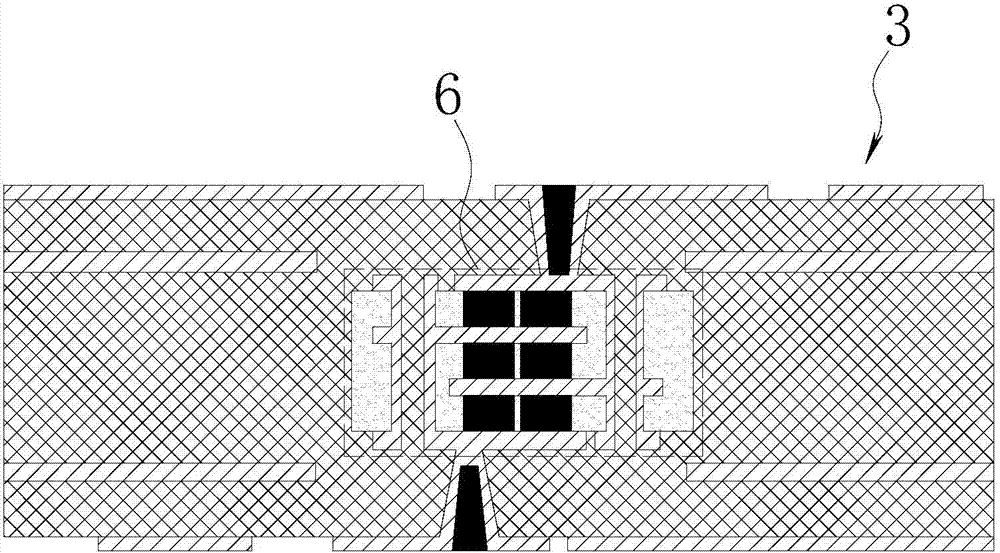

COB packaging structure of light-emitting diode

InactiveCN103594464AReduce design difficultyReduce wiring difficultySemiconductor/solid-state device detailsSolid-state devicesHigh densityChipset

The invention relates to a COB packaging structure of a light-emitting diode. The COB packaging structure comprises a substrate, n drive chips and n light-emitting diode chip sets, wherein each light-emitting diode chip set comprises N light-emitting diode chips, n and N are integers, n is larger than or equal to 1, N is larger than or equal to 1, the n drive chips and the n light-emitting diode chip sets are packaged on the front face of the substrate in a modular mode to form n sets of COB display modules, the n drive chips and the n light-emitting diode chip sets form lamp-driver co-plane devices in a one-to-one connection mode, a fixed number of bonding pads are arranged on the back face of the substrate, and all the drive chips and all the light-emitting diode chip sets are communicated with the bonding pads on the back face of the substrate in a routing and hole passing mode. The n lamp-driver co-plane devices are packaged to form a new COB device, the number of the bonding pads on the back face of the substrate is fixed and independent of the number of sets of the drive chips, and therefore a large number of pins are saved, external device cables are greatly reduced, and the higher density can be achieved compared with the density achieved through traditional packaging.

Owner:GUANGDONG VTRON TECH CO LTD

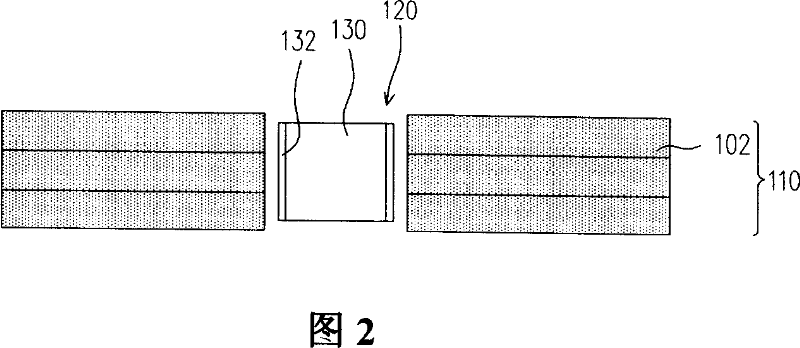

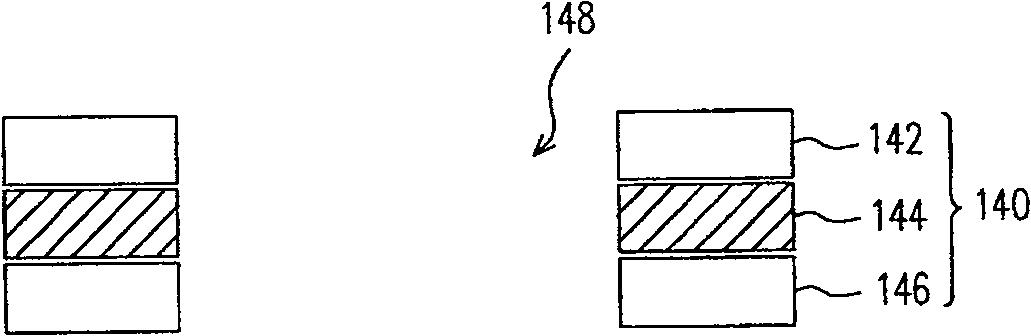

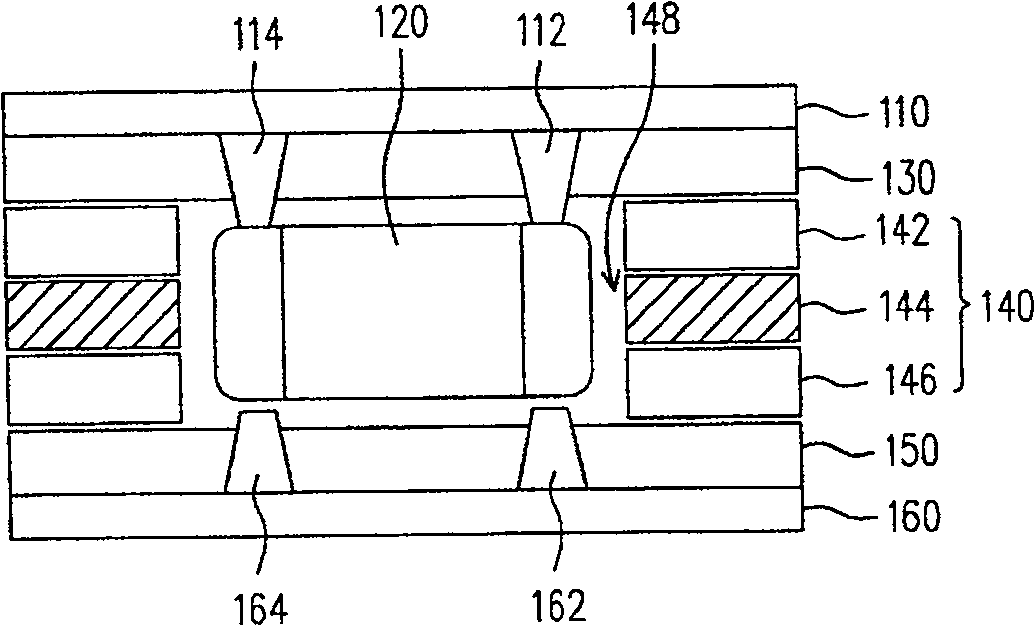

Method for manufacturing substrate of embedded element

InactiveCN101038885AImprove space utilizationReduce the number of solder jointsPrinted circuit assemblingSemiconductor/solid-state device detailsElectrical connectionOptoelectronics

The invention discloses a method for making substrate embedded with element. The method includes: firstly, providing a core layer comprised by stacking plural insulation layers in partially curing state; and then, forming embedding hole on the core layer and disposing an inner embedded element with at least one electrodes in the embedding hole; respectively forming metallic layers on upper and lower surfaces, and pressing the core layer and the two metallic layer together to fill the insulation layer into the embedding hole and coat the periphery surface of the embedded element; at last, respectively patterning the metallic layers of the upper and lower surface of the core layer to from a first signal layer and a second signal layer on both upper and lower surfaces of the core layer thereby electrically connecting the embedded element to realize electrical connection of the electrode of the embedded element and the first signal layer.

Owner:ADVANCED SEMICON ENG INC

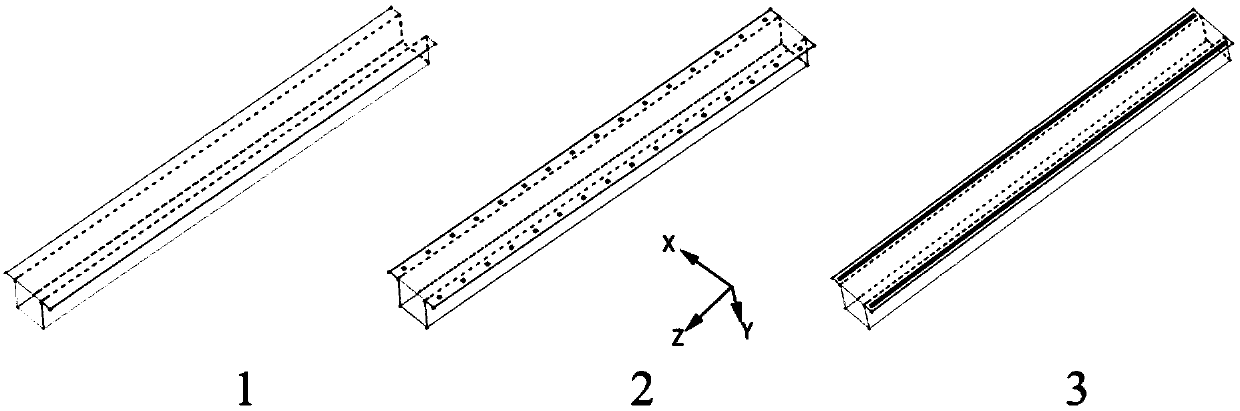

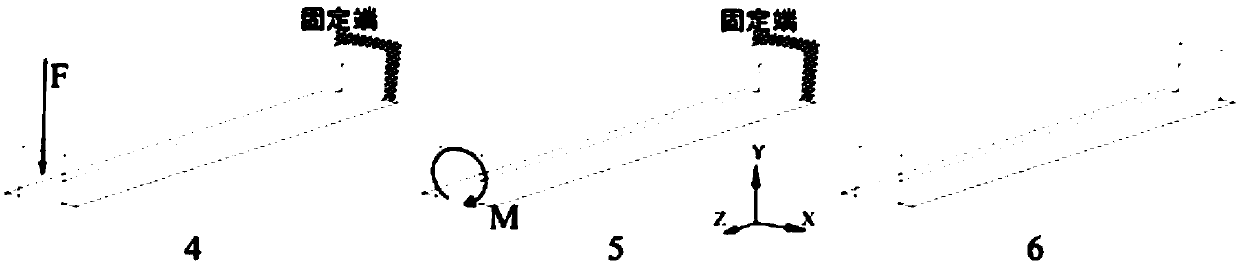

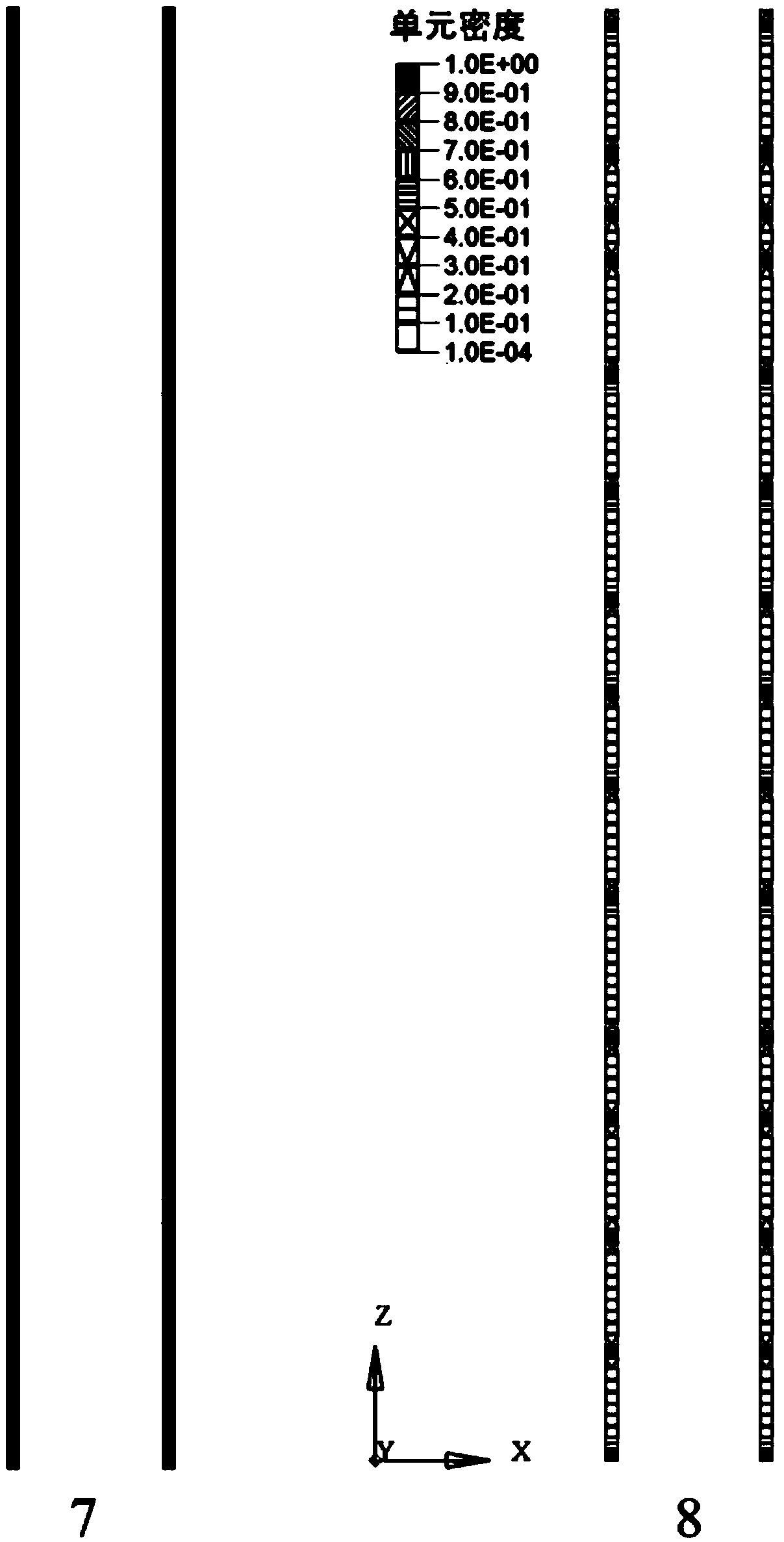

Nonlinear topological optimization method for car body welding spot arrangement

ActiveCN106126849AGuaranteed accuracyGuaranteed reasonablenessGeometric CADDesign optimisation/simulationManufacturing cost reductionElement model

The invention discloses a nonlinear topological optimization method for car body welding spot arrangement. The method comprises the steps that a vehicle crash simulation finite element model is established, LS-DYNA calculation is submitted, and displacement values of crash performance key attention nodes are output; a white car body linear rigidity simulation finite element model is established, and GENESIS optimizing calculation is submitted; entity units are adopted for modeling of relevant welding spots in a crash model and a white car body model; an equivalent static load method is adopted for transforming crash nonlinear conditions into linear static conditions for topological optimization design; the welding spots are set to be topological variables, obtained welding spot density values are updated into the crash finite element model, and a new round of crash simulation analysis is conducted; lastly, a convergence result is postprocessed. According to the method, the entity welding spots are subjected to topological optimization, car body welding spot arrangement is realized on the premise that crash properties at all important moments are met, reasonability of car body welding spot arrangement is ensued, redundant welding spot arrangement is avoided, the number of the welding spots is reduced, manufacturing cost is lowered, and production efficiency is improved.

Owner:迅仿科技(上海)有限公司 +2

Adaptive multi-step variable domain solder joint layout optimization method based on topology optimization for automotive components

InactiveCN109063357AGuaranteed reasonablenessReduce the number of solder jointsGeometric CADDesign optimisation/simulationElement modelEngineering

The invention provides an adaptive multi-step variable domain optimization method for automobile component solder joint layout based on topology optimization, Based on the finite element model of continuous solder joint element, the definition of multi-step variable domain solder joint topology optimization problem, the criteria of multi-step iteration progression and termination, and the verification of optimization scheme, the optimization design of structural solder joint number and layout form is completed. The technical proposal of the invention solves the problems that the existing solder joint topology optimization method in the prior art cannot simultaneously optimize the number of solder joints and the position of the solder joint arrangement, and the existing solder joint screening strategy will lead to the uncertainty of the design proposal. The technical proposal of the invention solves the problems that the existing solder joint topology optimization method cannot simultaneously optimize the number of solder joints and the position of the solder joint arrangement.

Owner:DALIAN UNIV OF TECH

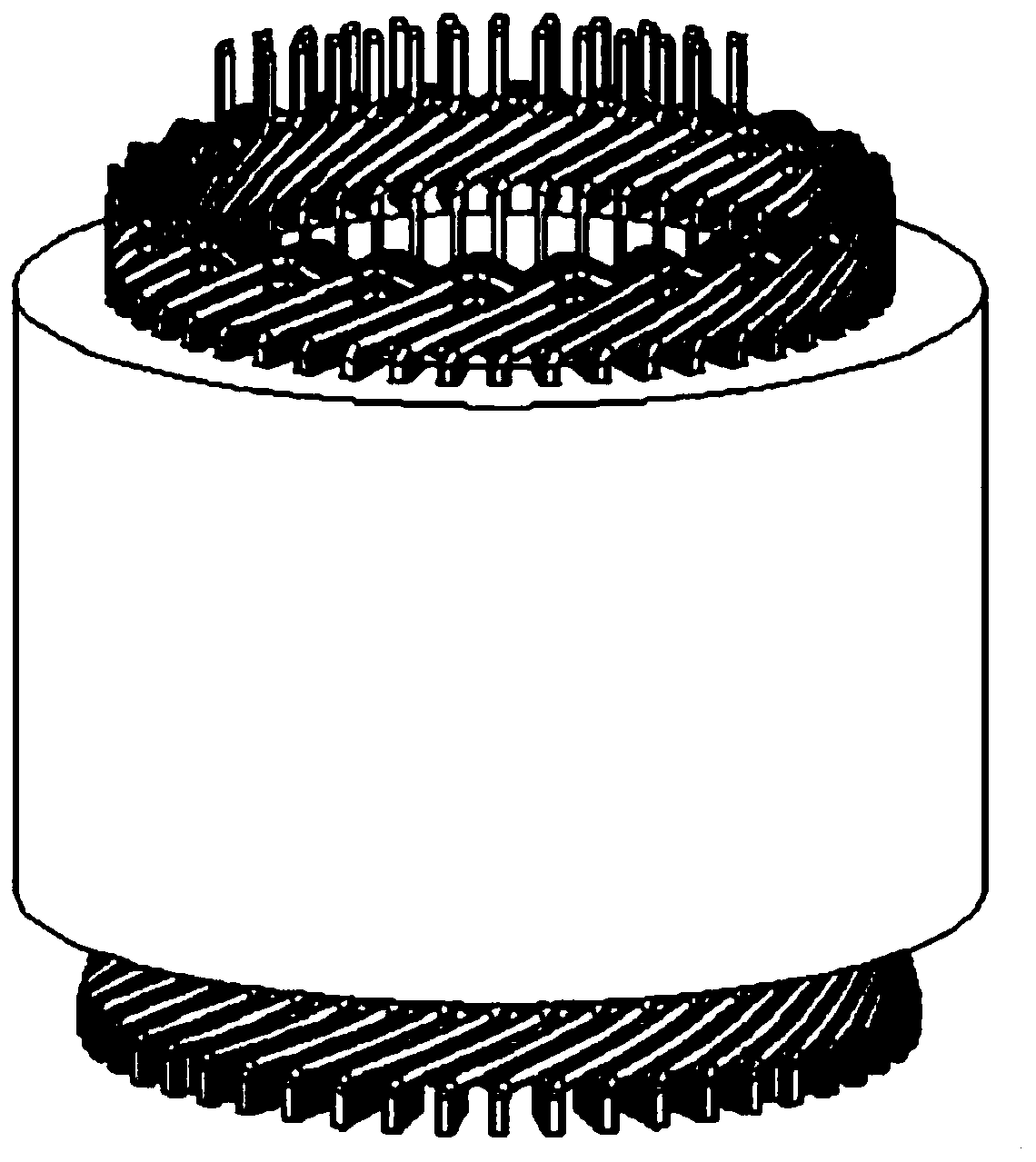

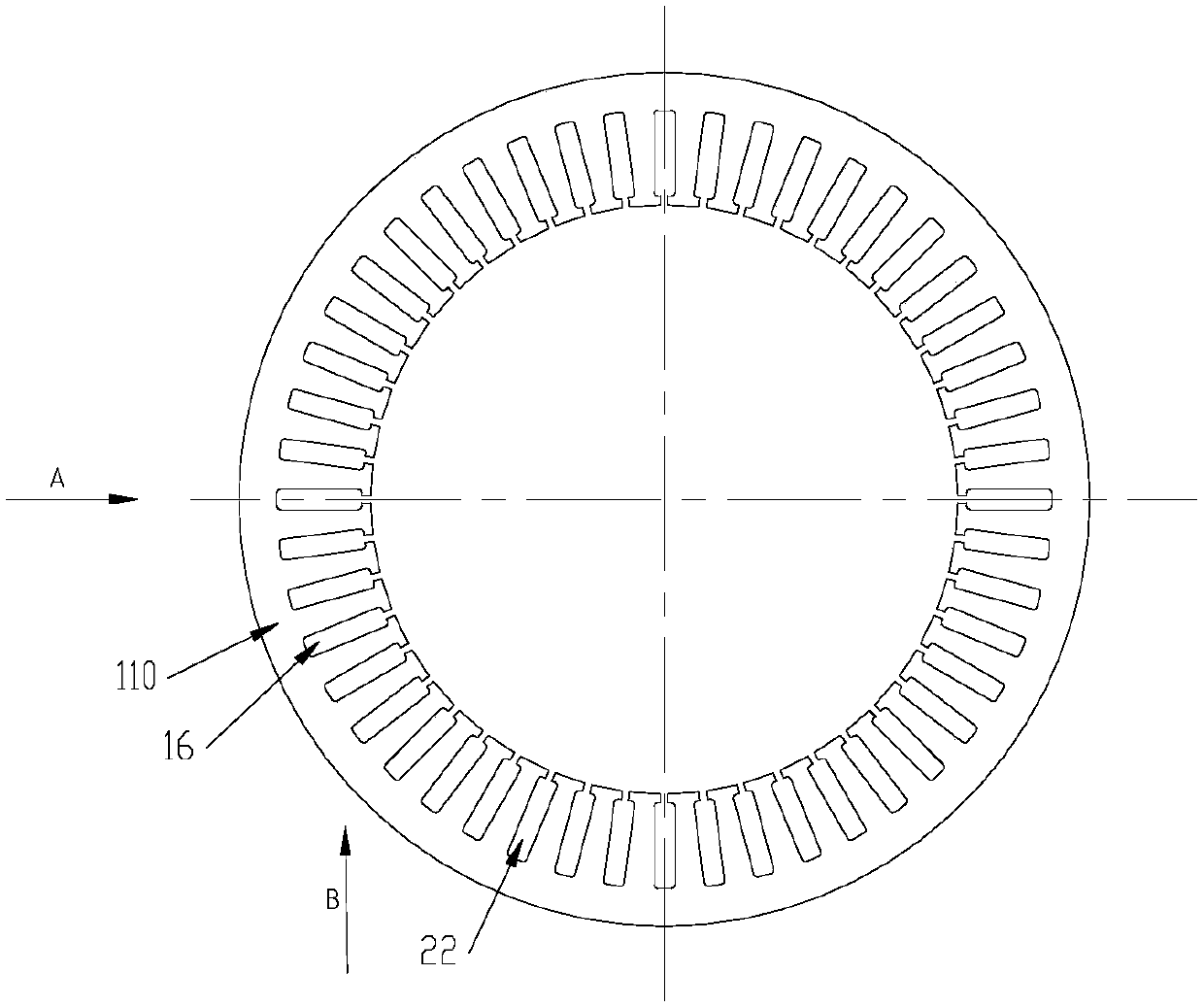

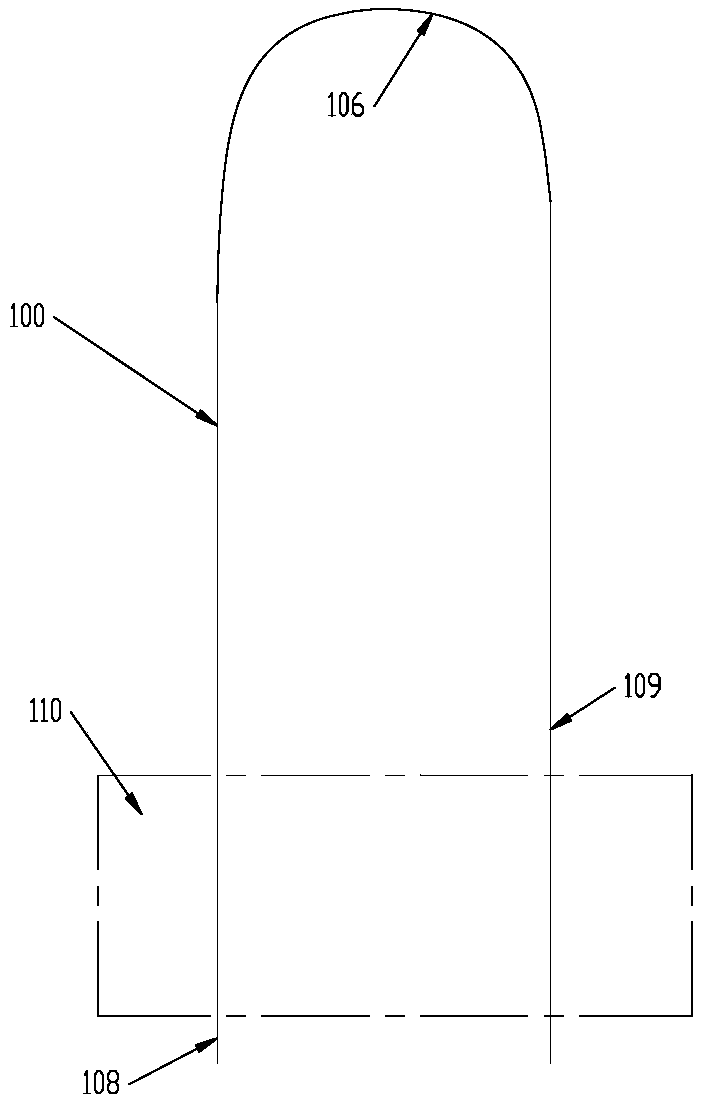

Flat wire continuous wave winding, stator and motor

PendingCN111446797AReduce noiseImprove noiseMagnetic circuit stationary partsWindings conductor shape/form/constructionElectric machineEngineering

The invention belongs to the technical field of test equipment, and particularly provides a flat wire continuous wave winding, a stator and a motor. The invention aims to solve the problems of difficult production and easy damage caused by many welding spots of a flat wire motor in the prior art. The flat wire continuous wave winding comprises a wire inlet end, a wire outlet end and an S-shaped wave winding located between the wire inlet end and the wire outlet end. The number of winding layers of the flat wire continuous wave winding is 2N, and the pitch is y. A jump winding part is arrangedat the joint of the Nth layer and the (N + 1) th layer of the flat wire continuous wave winding. The pitch of each phase of wire group at the jump winding part is y + 1, wherein N and y are both natural numbers greater than or equal to 1. According to the flat wire continuous wave winding, a scheme of continuously winding a flat wire is adopted, so that welding spots are reduced.

Owner:NIO CO LTD

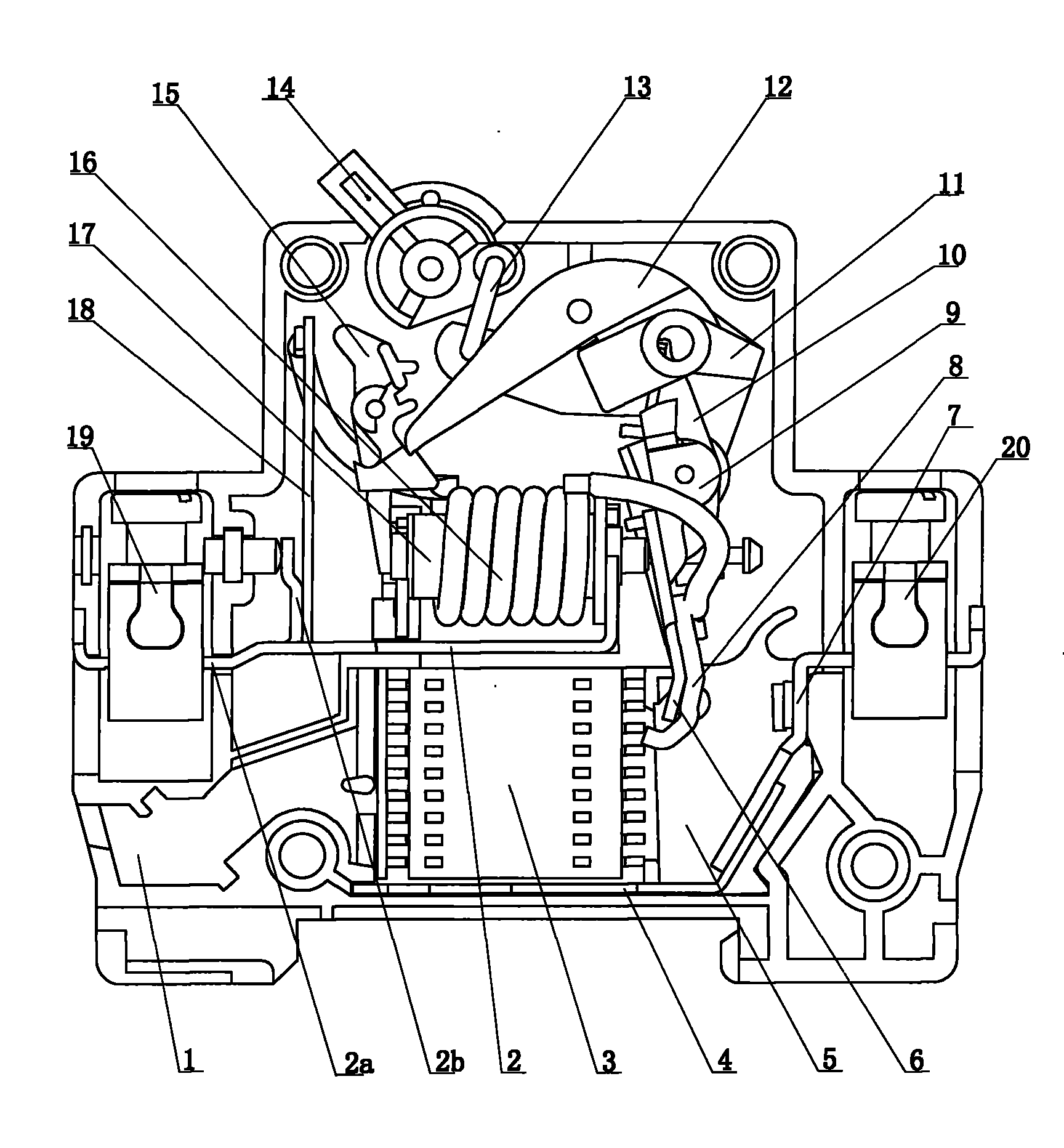

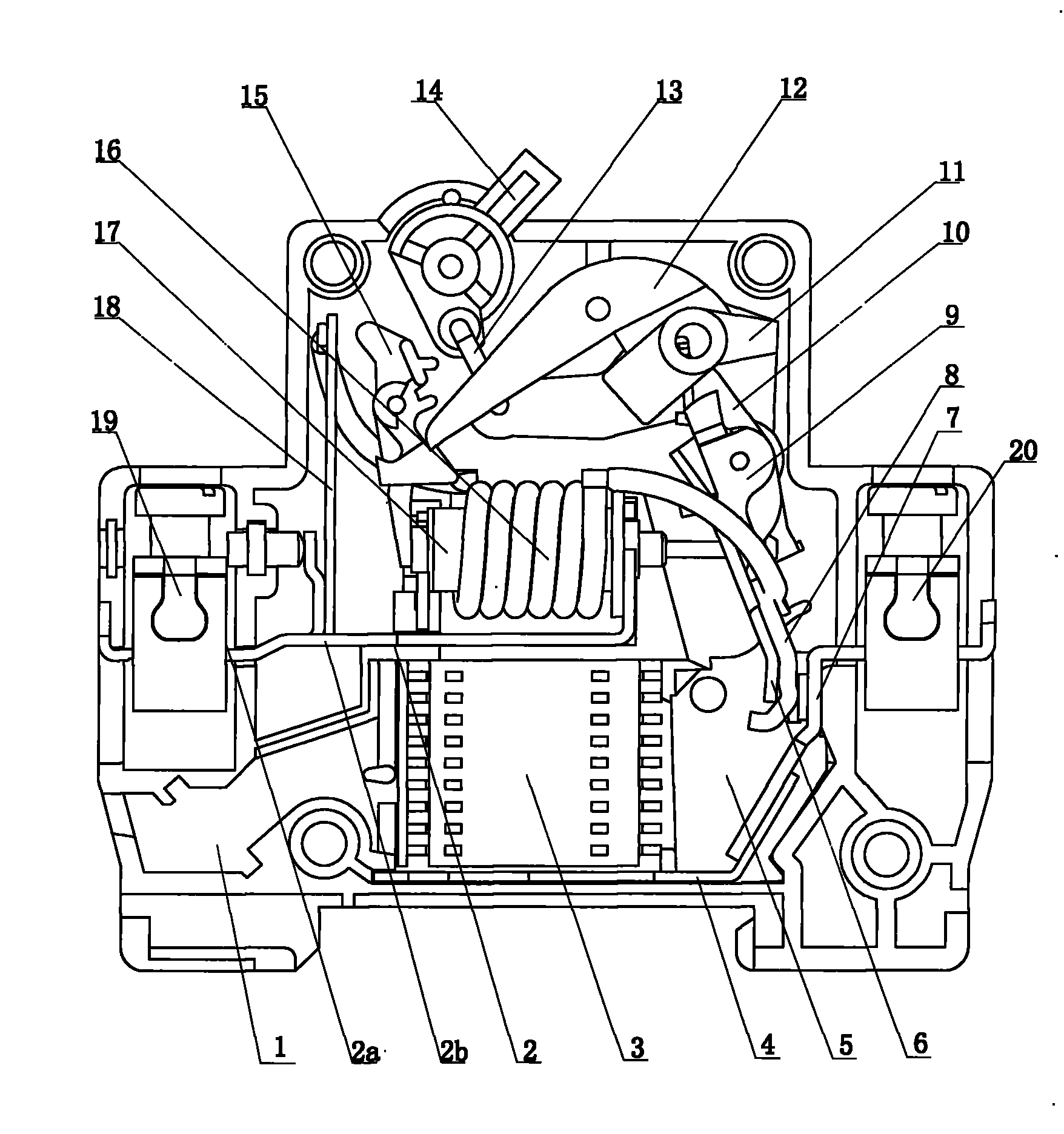

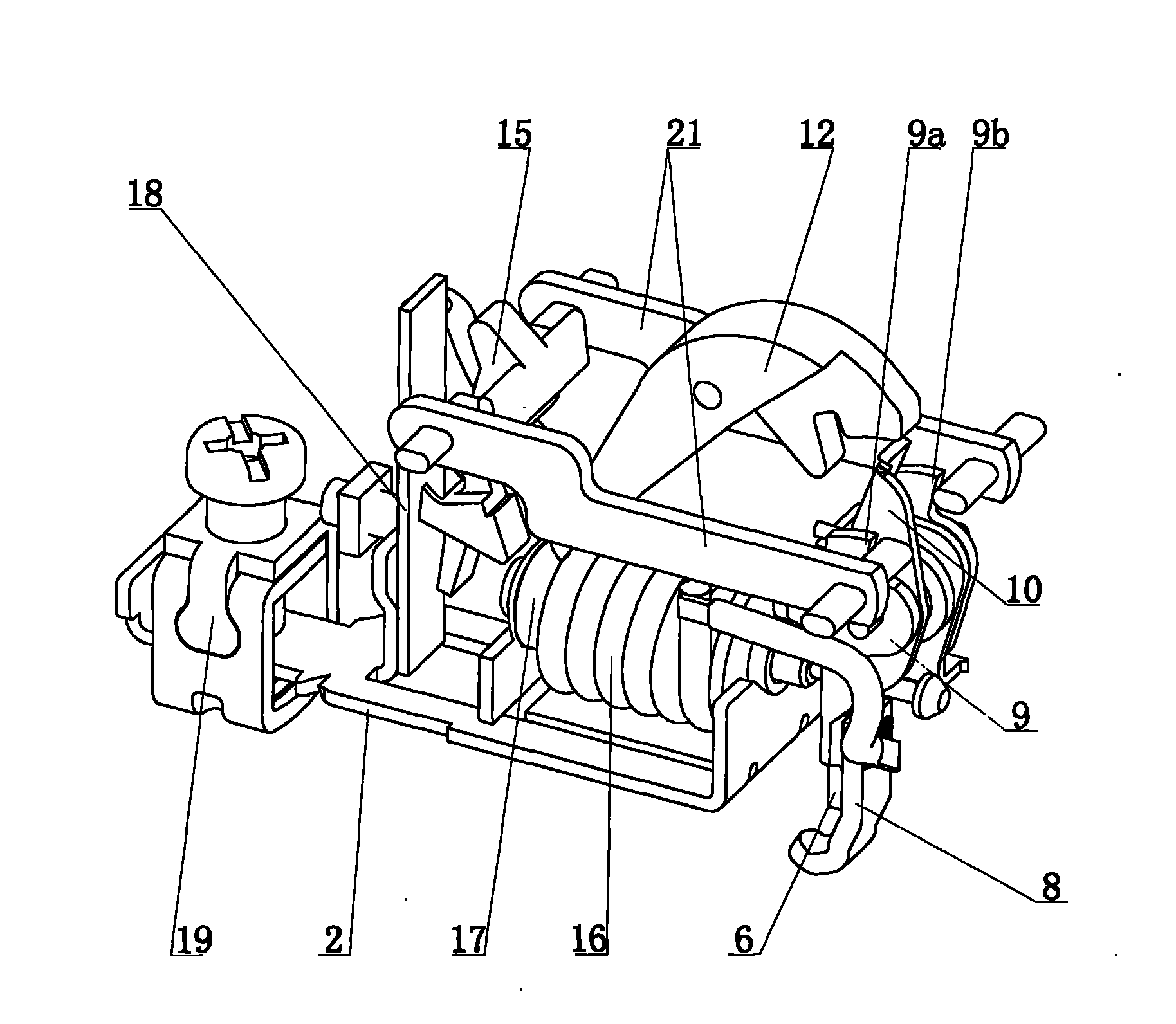

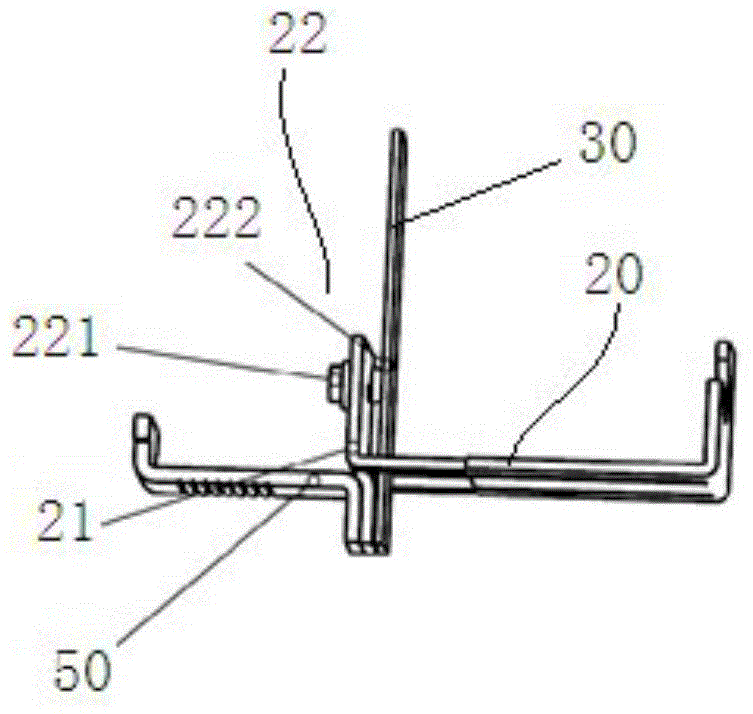

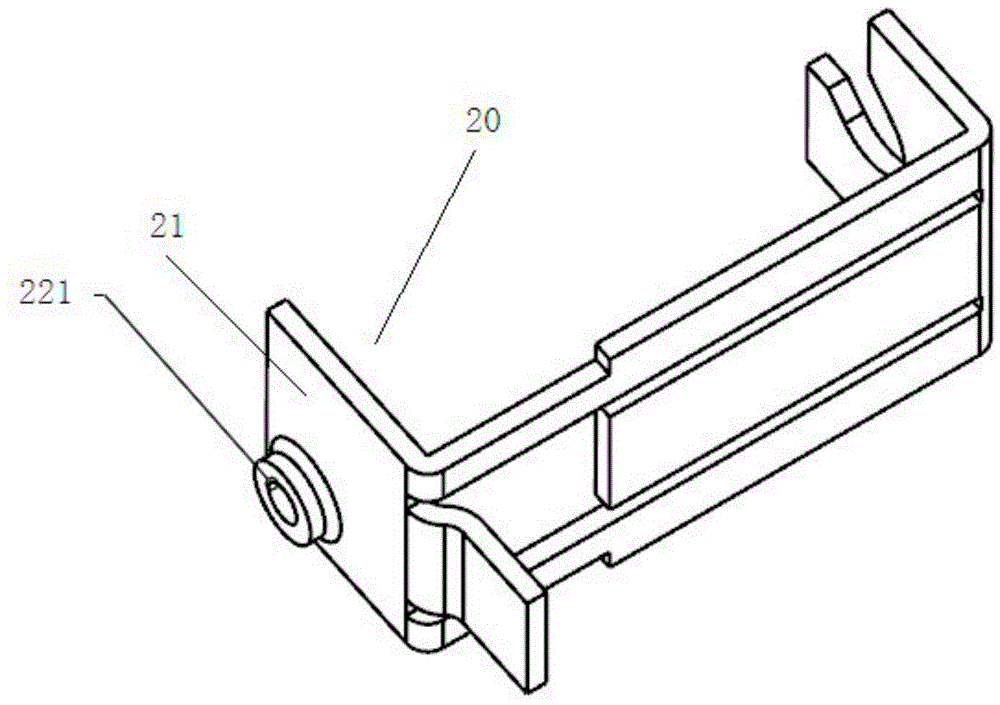

Miniature circuit breaker with high breaking capacity

InactiveCN102082048ASimple structureReduce the number of solder jointsProtective switch operating/release mechanismsCircuit-breaking switch contactsCopper wireInternal resistance

The invention discloses a miniature circuit breaker with a high breaking capacity, which comprises a shell, wherein the shell is internally provided with a magnet yoke assembly, a moving contact assembly, an arc extinction system and an actuating mechanism. A magnet yoke, a wiring board and a connecting sheet in the magnet yoke assembly are designed into a whole to ensure that the structure of the magnet yoke assembly is simplified, the quantity of soldered dots of the magnet yoke assembly is reduced and the internal resistance of a circuit breaker is lowered; a moving contact in the moving contact assembly comprises a contact support and a contact which are connected, the specific gravity of the contact support is smaller than that of the moving contact, and a magnet conductive plate is additionally arranged on the back of the moving contact and used for accelerating the transfer of an electric arc, therefore, the breaking capacity of the circuit breaker is improved; and a plurality of linkage lug bosses used for multipolar linkage are arranged on a contact support body, thus the linkage performance of the multipole circuit breaker is effectively ensured. A coil is connected with the moving contact through an annealed copper wire in a spot welding manner, and the soldered spots are moved from the linkage lug bosses to the moving contact without influencing the linkage property of the multipole circuit breaker. The invention has the advantages of high breaking capacity, high consistency of the interelectrode linkage and good reliability performance.

Owner:无锡唯特电气技术有限公司

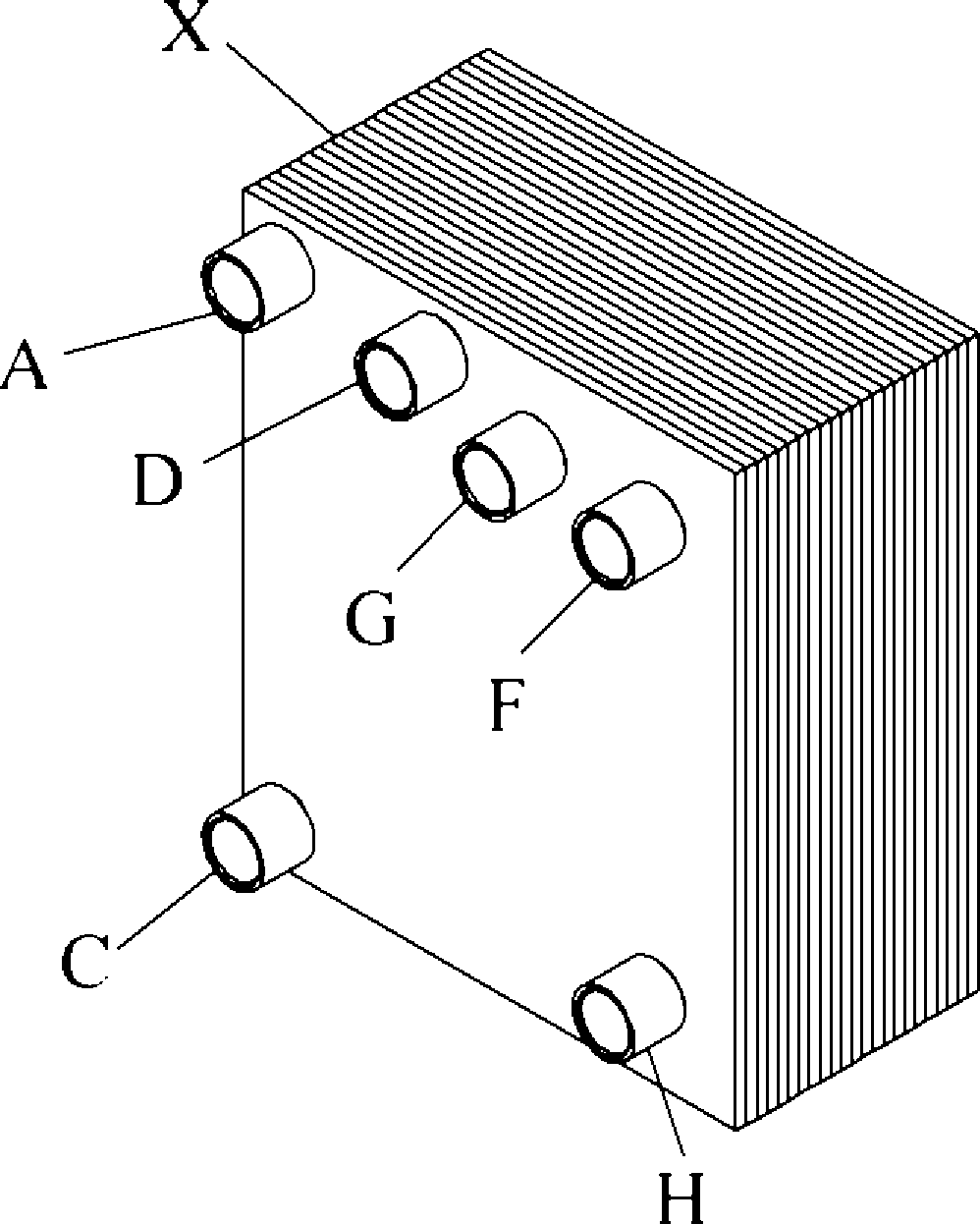

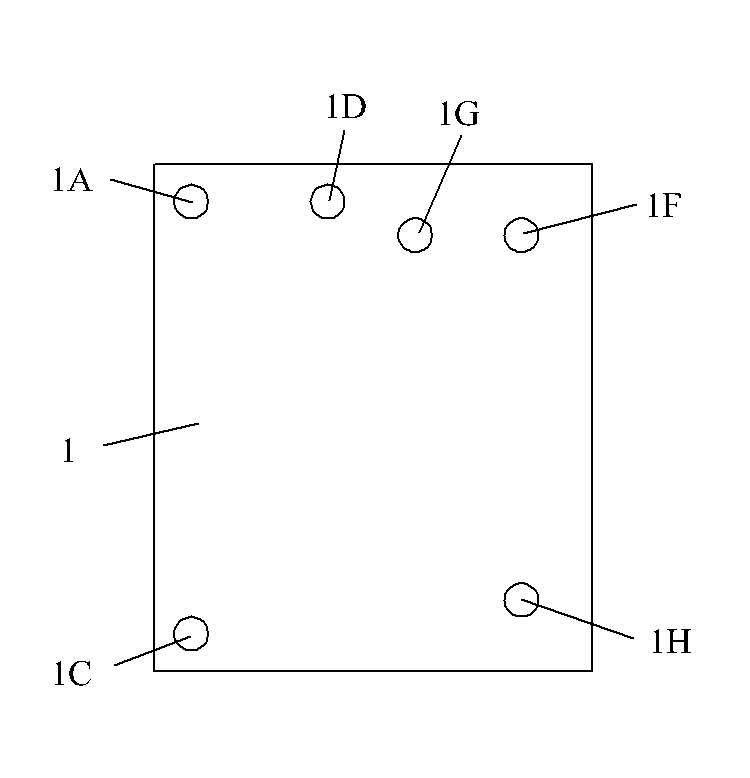

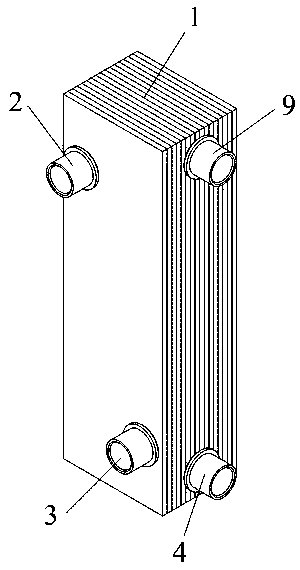

Miniature heat exchanger integrating condensing, throttling and evaporation

ActiveCN104315757AReduce volumeReduce the number of solder jointsMechanical apparatusEvaporators/condensersEvaporationEngineering

The invention provides a miniature heat exchanger integrating condensing, throttling and evaporation. The miniature heat exchanger comprises a miniature heat exchanger body X which is formed by multiple layers of sheet metal through vacuum hot pressing diffusion welding, a refrigerant inlet connector A, a refrigerant outlet connector F, a second-kind fluid inlet connector C, a second-kind fluid outlet connector D, a third-kind fluid inlet connector G and a third-kind fluid outlet connector H. The miniature heat exchanger body X is an entity which is formed in a way that a plurality pieces of sheet metal, with different runners etched in the surfaces, are stacked according to a certain sequence and then are heated and compressed under a vacuum environment. The miniature heat exchanger has the advantages that condensing, throttling and evaporation of refrigerant can be completed in one device, cooling of a second kind of fluid and heating of a third kind of fluid can be achieved at the same time, a condenser, a throttling element and an evaporator are highly integrated, pipeline connection among the three parts is omitted, compact structure and self heat insulation are achieved, and system size can be effectively reduced when the miniature heat exchanger is applied to a miniature refrigerating system.

Owner:武汉麦丘科技有限公司

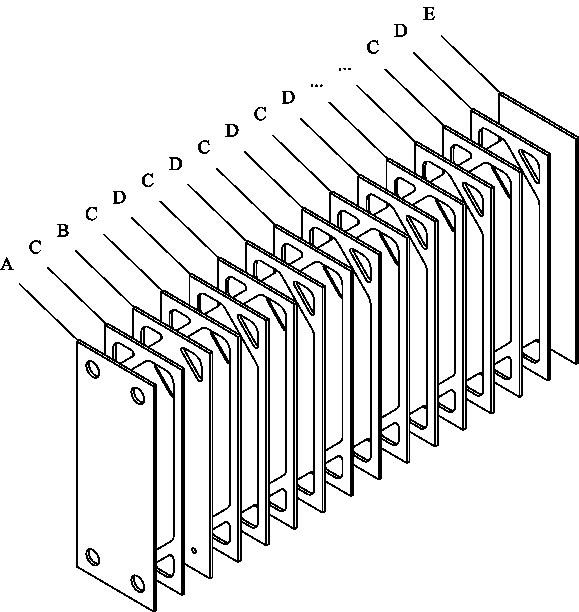

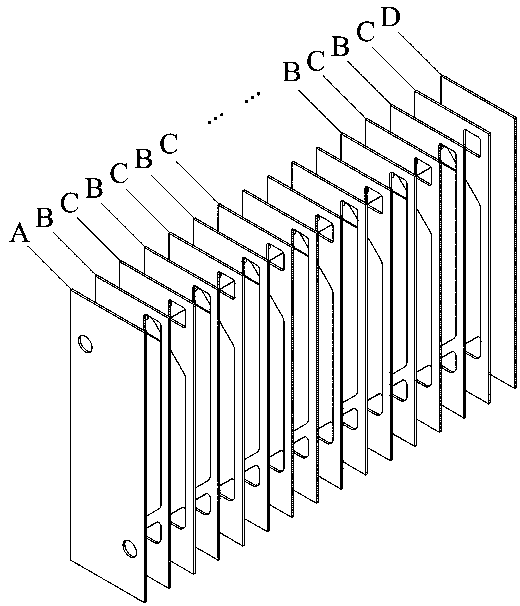

Micro heat exchanger with small hole throttling function

InactiveCN103759560ACompact structureReduce volumeLaminated elementsStationary plate conduit assembliesEngineeringPhase change

The invention provides a micro heat exchanger with a small hole throttling function. The micro heat exchanger can serve as an evaporator or a condenser and is a solid formed by laminating five different kinds of etching plates in a certain sequence and welding the etching plates through vacuum diffusion welding. The micro heat exchanger comprises an interface plate A, a refrigerating fluid throttling plate B, one or more fluid heat exchange plates C, one or more refrigerating fluid heat exchanger plates D and a blind plate E. A small throttling hole is formed in the refrigerating fluid throttling plate B, throttling depressurization can be performed on refrigerating fluid when the refrigerating fluid flows through the small hole, throttling and phase-change heat exchanging of the refrigerating fluid can be achieved through one device, throttling elements such as capillary tubes, throttling short tubes and the like are eliminated, and quantity of external connection tubes and welding points is reduced. The micro heat exchanger with the small hole throttling function is compact in structure, small in size and capable of reducing volume and mass of the system when applied to a micro vapor compression refrigerating system.

Owner:MICROCOOL TECH

Buried resistor and manufacture process thereof

ActiveCN103338592AImprove reliabilitySave spacePrinted circuit assemblingPrinted circuit non-printed electric components associationElectrical resistance and conductanceCopper foil

The invention relates to the buried resistor technical field, in particular to a buried resistor and a manufacture process thereof. The buried resistor includes a first copper foil layer, a second copper foil layer, a third copper foil layer, a first insulating PP layer, a second insulating PP layer, an insulating base layer and a resistance layer, wherein the third copper foil layer, the second insulating PP layer, the second copper foil layer, the first insulating PP layer, the resistance layer and the first copper foil layer are sequentially arranged on the insulating base layer from bottom to up, the resistance layer is arranged between the first copper foil layer and the first insulating PP layer, the second copper foil layer is arranged between the first insulating PP layer and the second insulating PP layer, and the third copper foil layer is arranged between the second copper foil layer and the insulating base layer. An ultrathin core board is machined through using a double-sided etching one-step lamination method so as to form a buried resistor structure, and therefore, production efficiency is greatly improved, and product quality can be ensured; and with the buried resistor applied to a PCB, the space of the PCB can be saved, and at the same time, the reliability of the PCB can be improved.

Owner:苏州市三生电子有限公司

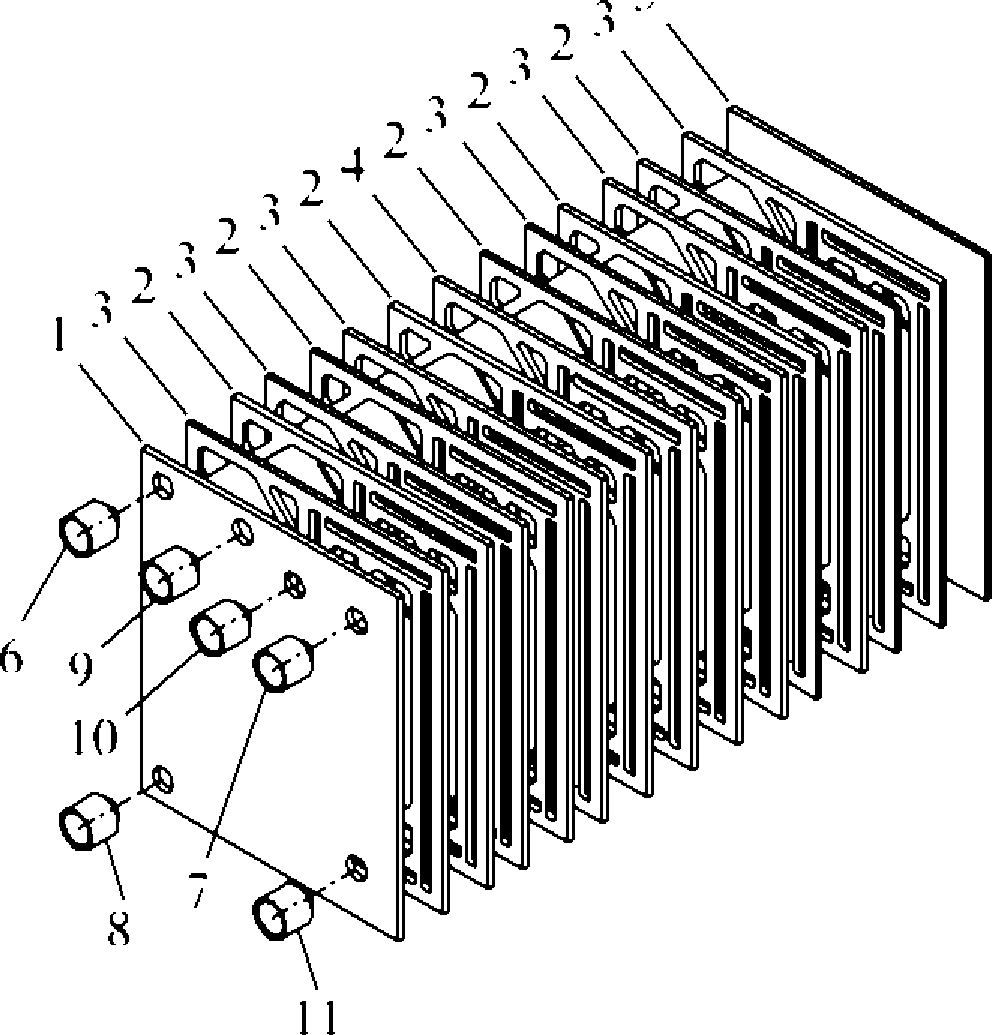

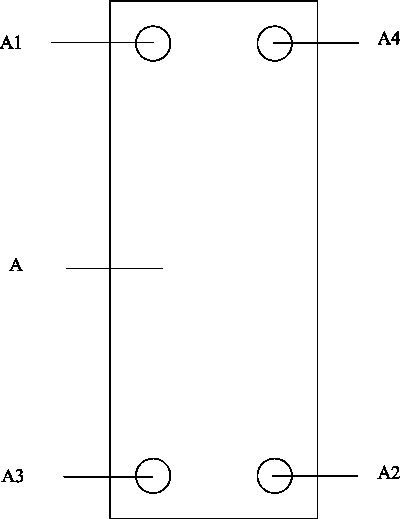

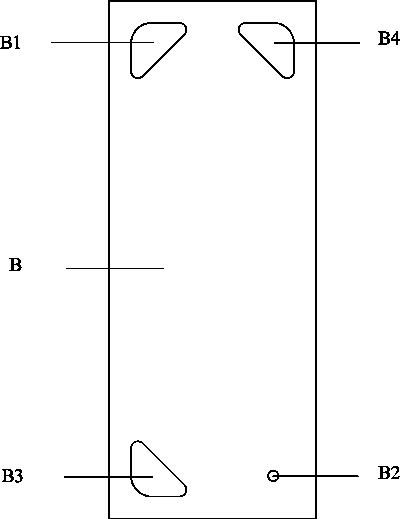

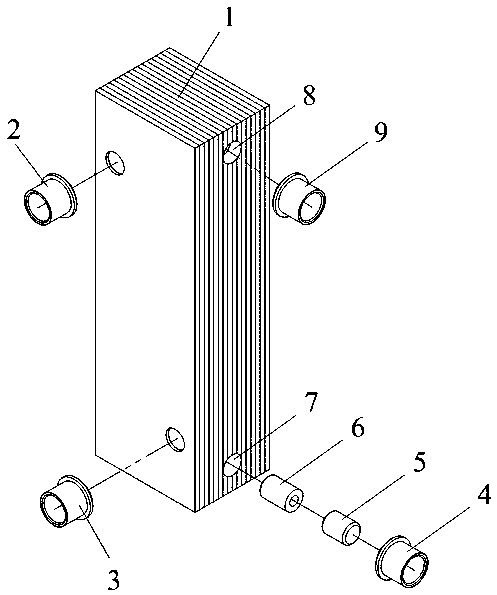

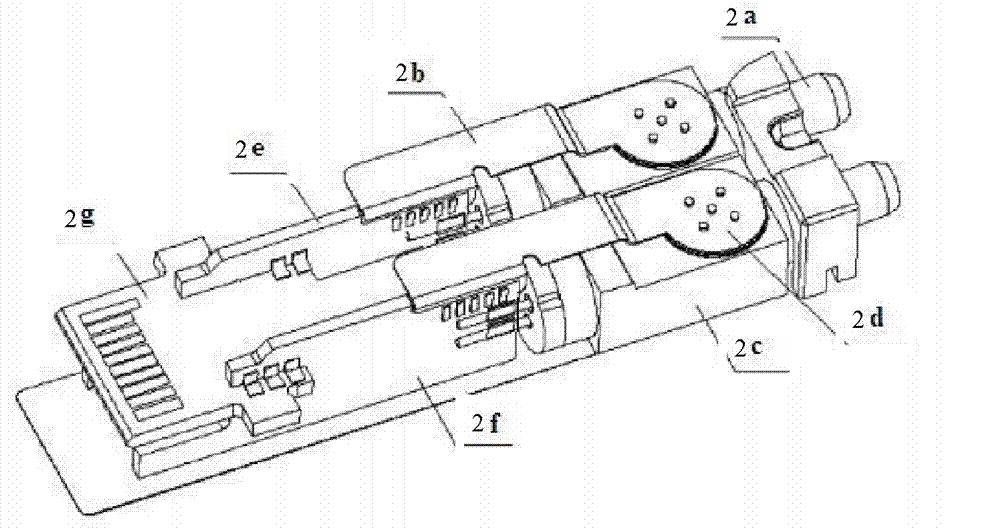

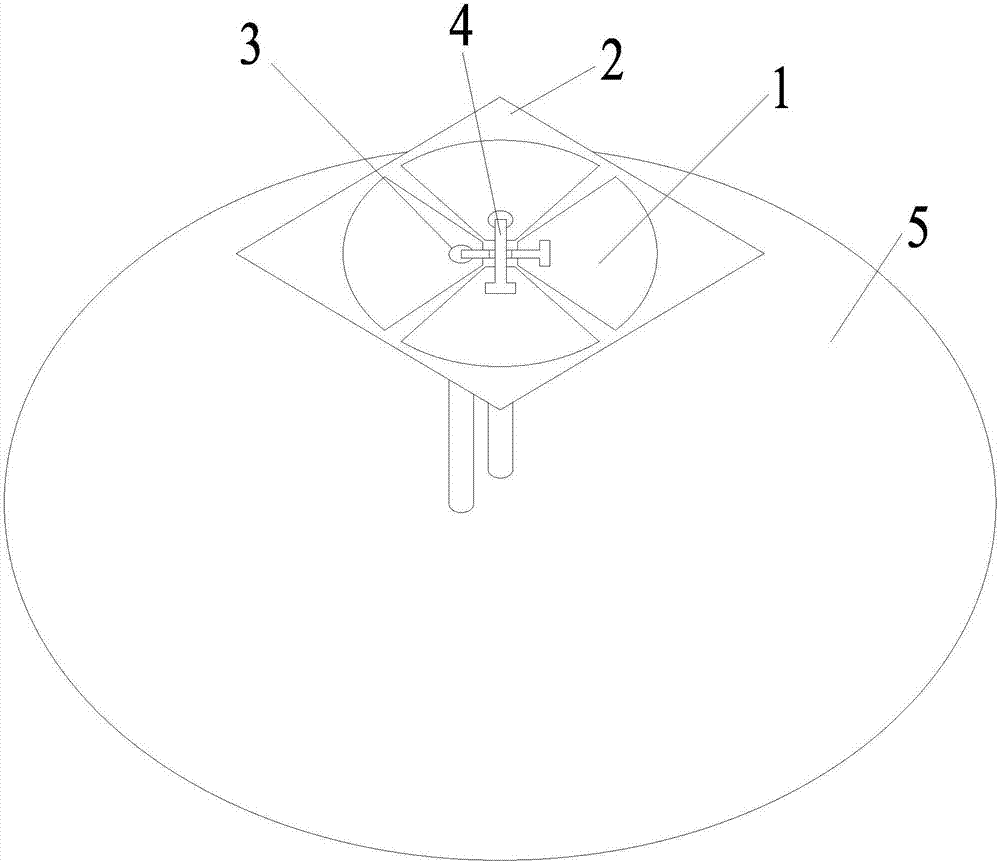

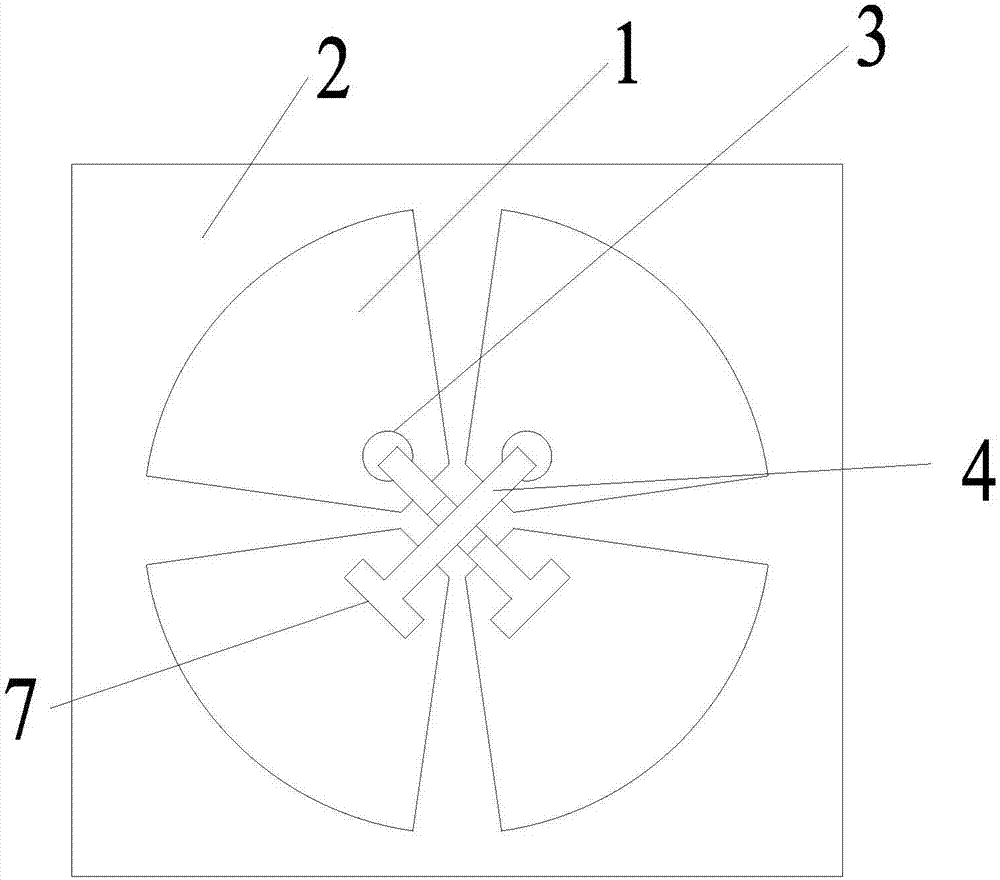

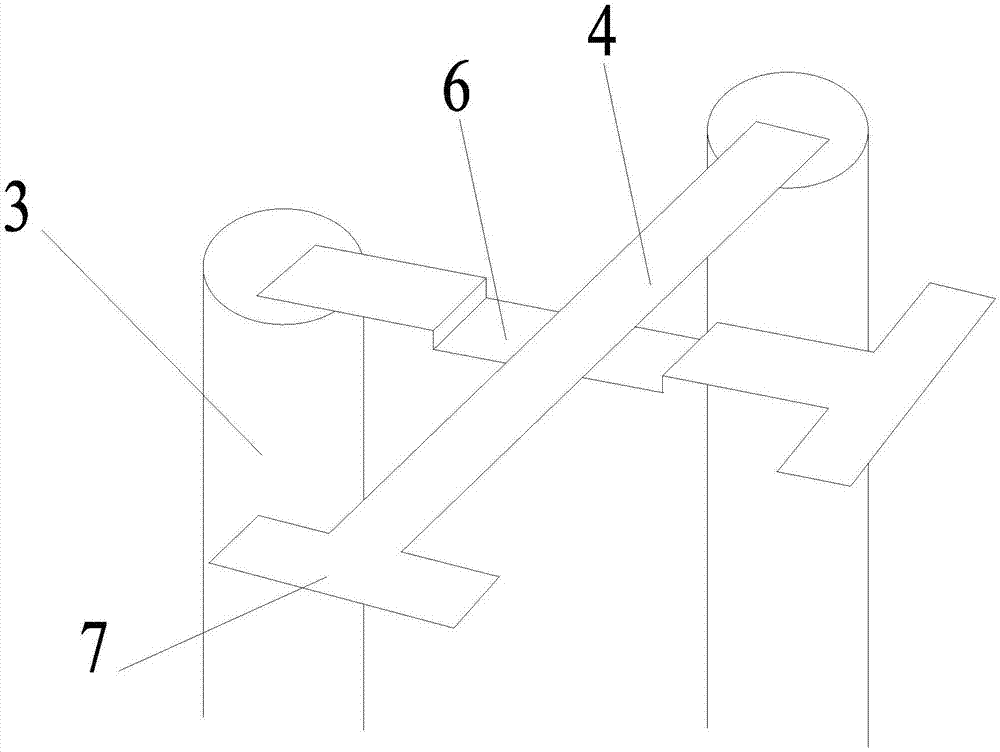

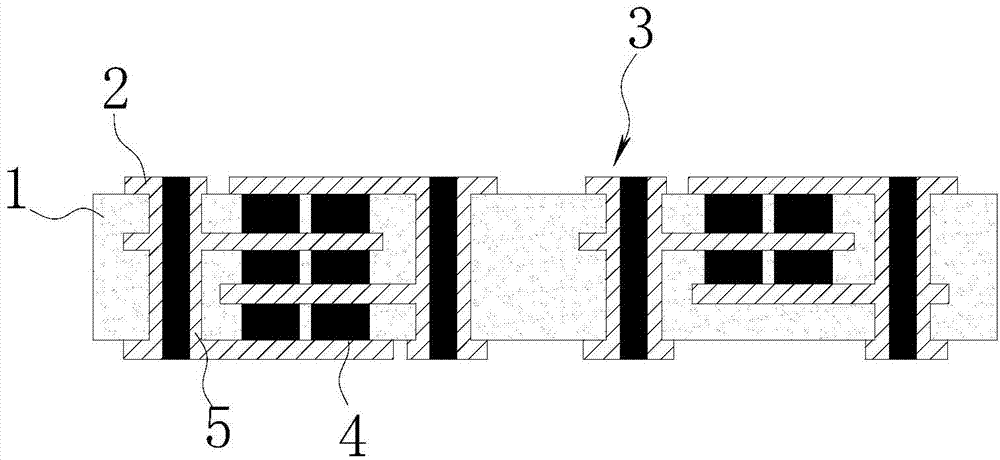

Integrated micro heat exchanger assembly with dry filter and throttling

ActiveCN103727706BCompact structureReduce volumeEvaporators/condensersStationary plate conduit assembliesMolecular sieveFiltration

The invention provides an integrated micro heat exchanger which can complete drying filtering, throttling and phase-change heat transferring of a refrigerant in a single component and can be used as an evaporator and a condenser as well, and relates to an integrated micro heat exchanger component with drying filtering and throttling functions. The integrated micro heat exchanger component comprises a micro plate heat exchanger 1, a fluid connector 2, another fluid connector 3, a refrigerant connector 4, a drying filtering element 5, a micro throttling element 6, a refrigerant circulation hole 7, another refrigerant circulation hole 8 and a refrigerant connector 9. The micro plate heat exchanger 1 is an entity formed by arranging four plates, etched into flow passages of different shapes, according to a certain sequence prior to vacuum diffusion welding. The refrigerant circulation hole 7 and the refrigerant circulation hole 8 are formed by means of post processing in the side face direction after the micro plate heat exchanger 1 is welded together into the entity. The drying filtering element 5 and the micro throttling element 6 are mounted in the refrigerant circulation hole 7. The drying filtering element 5 is a molecular sieve filter formed by sintering, and the micro throttling element 6 is a short throttling pipe or a throttling orifice with micropores drilled in the middle.

Owner:武汉麦丘科技有限公司

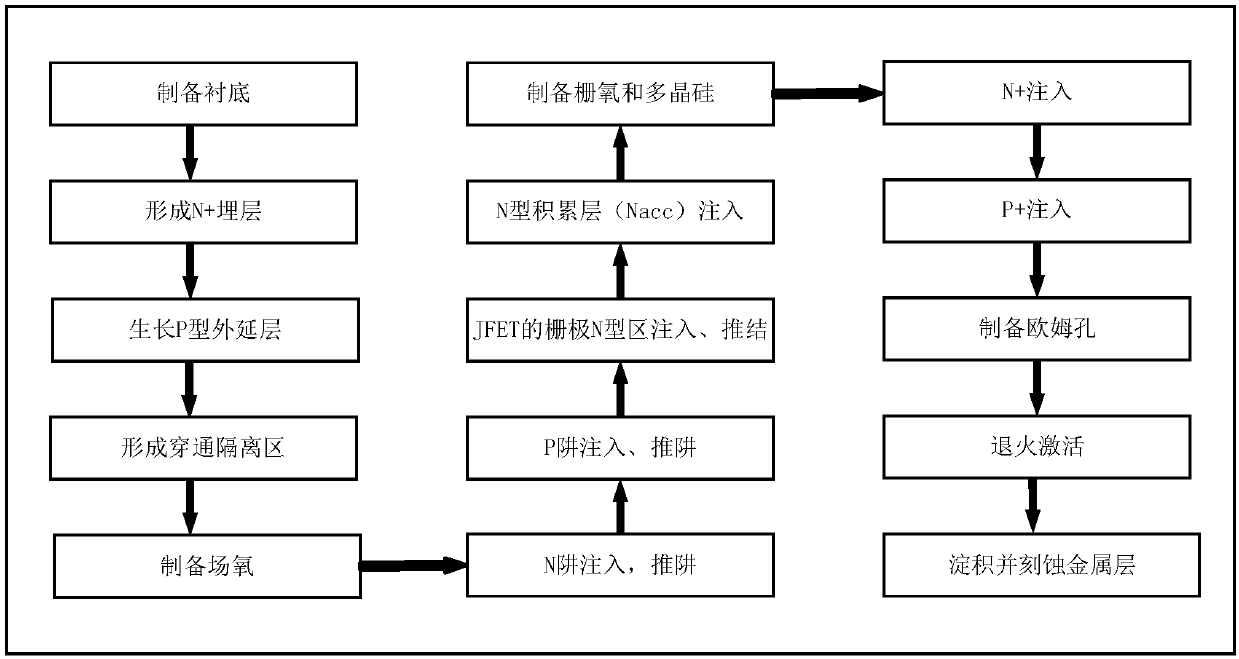

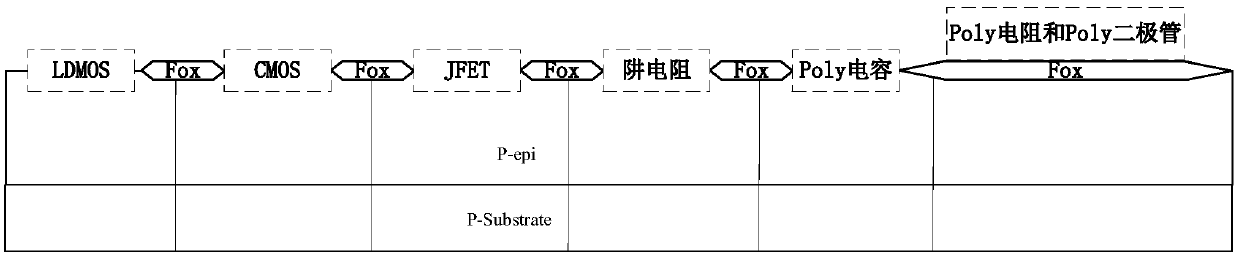

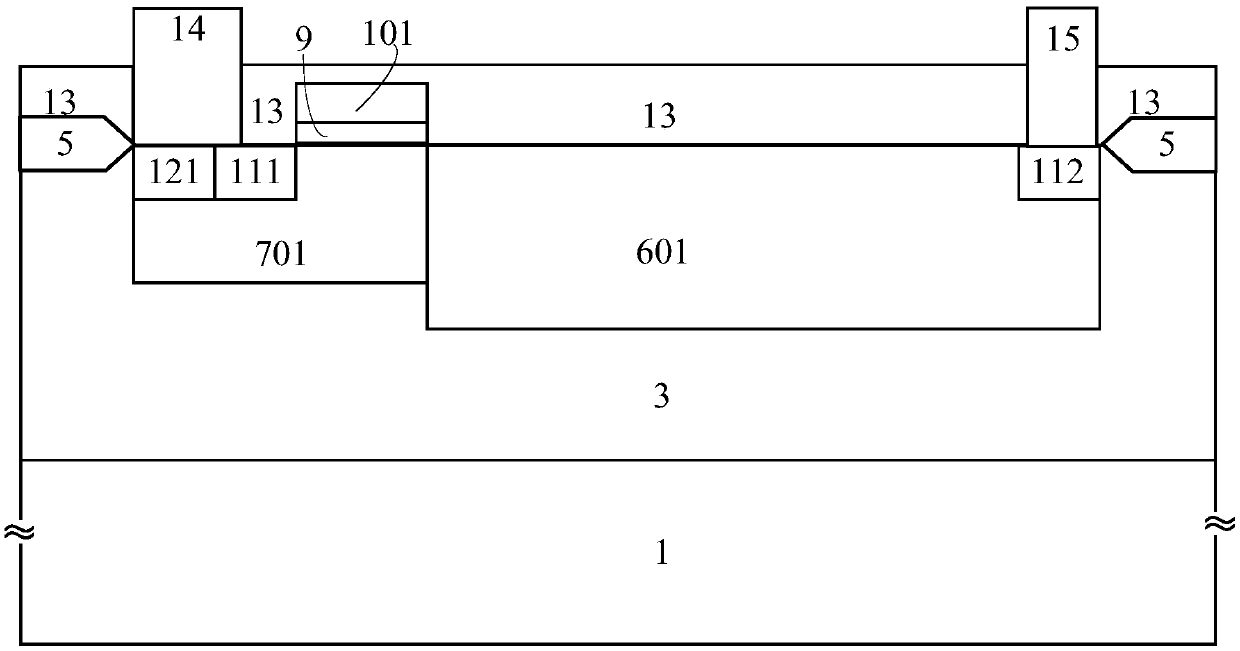

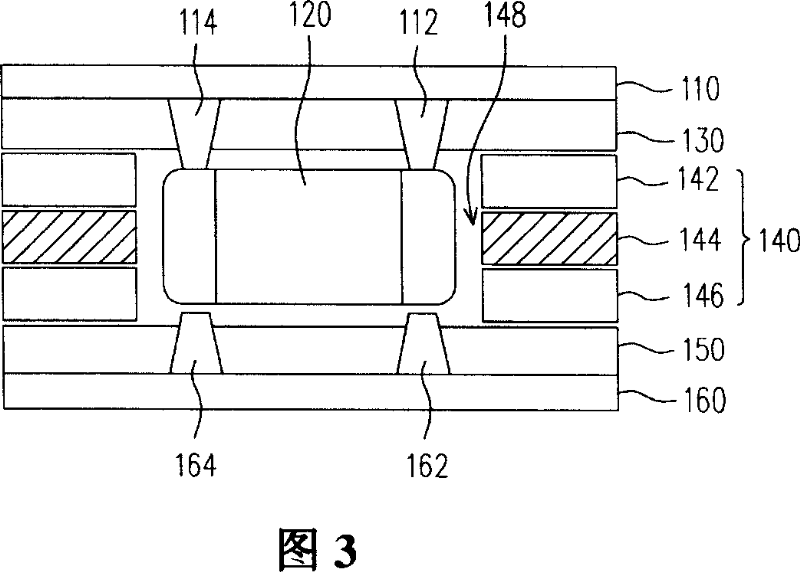

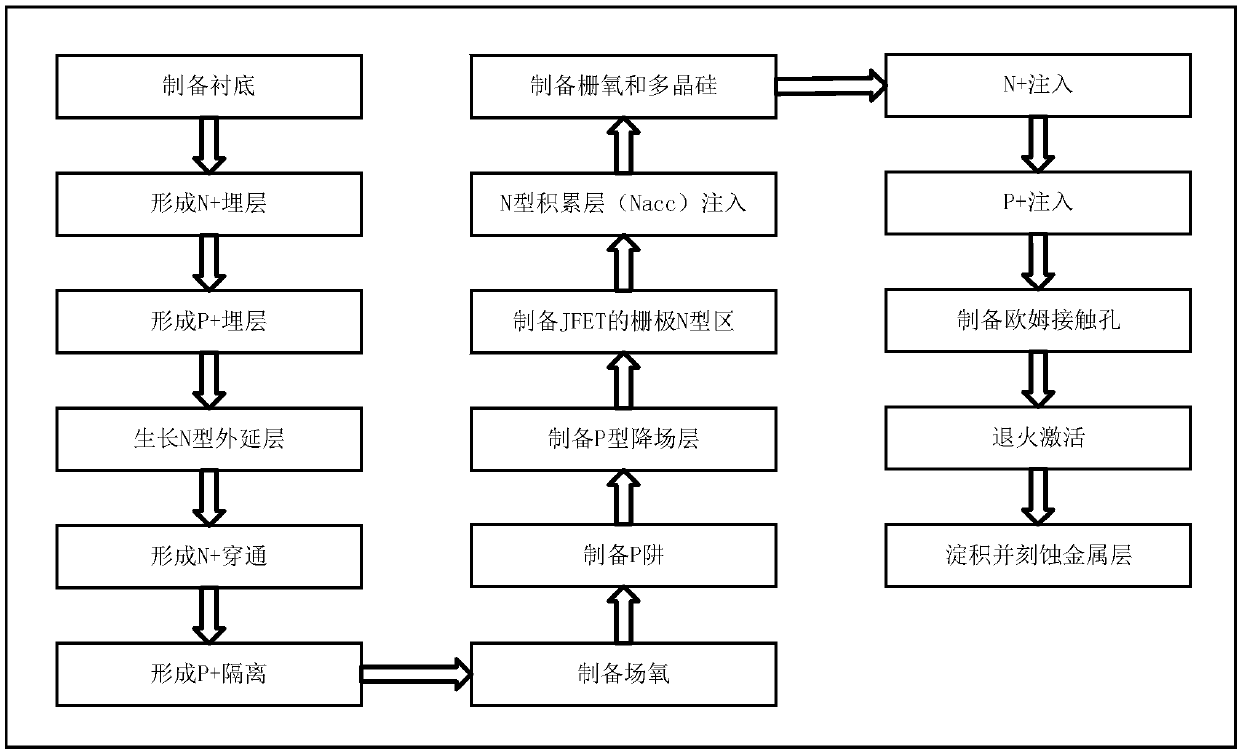

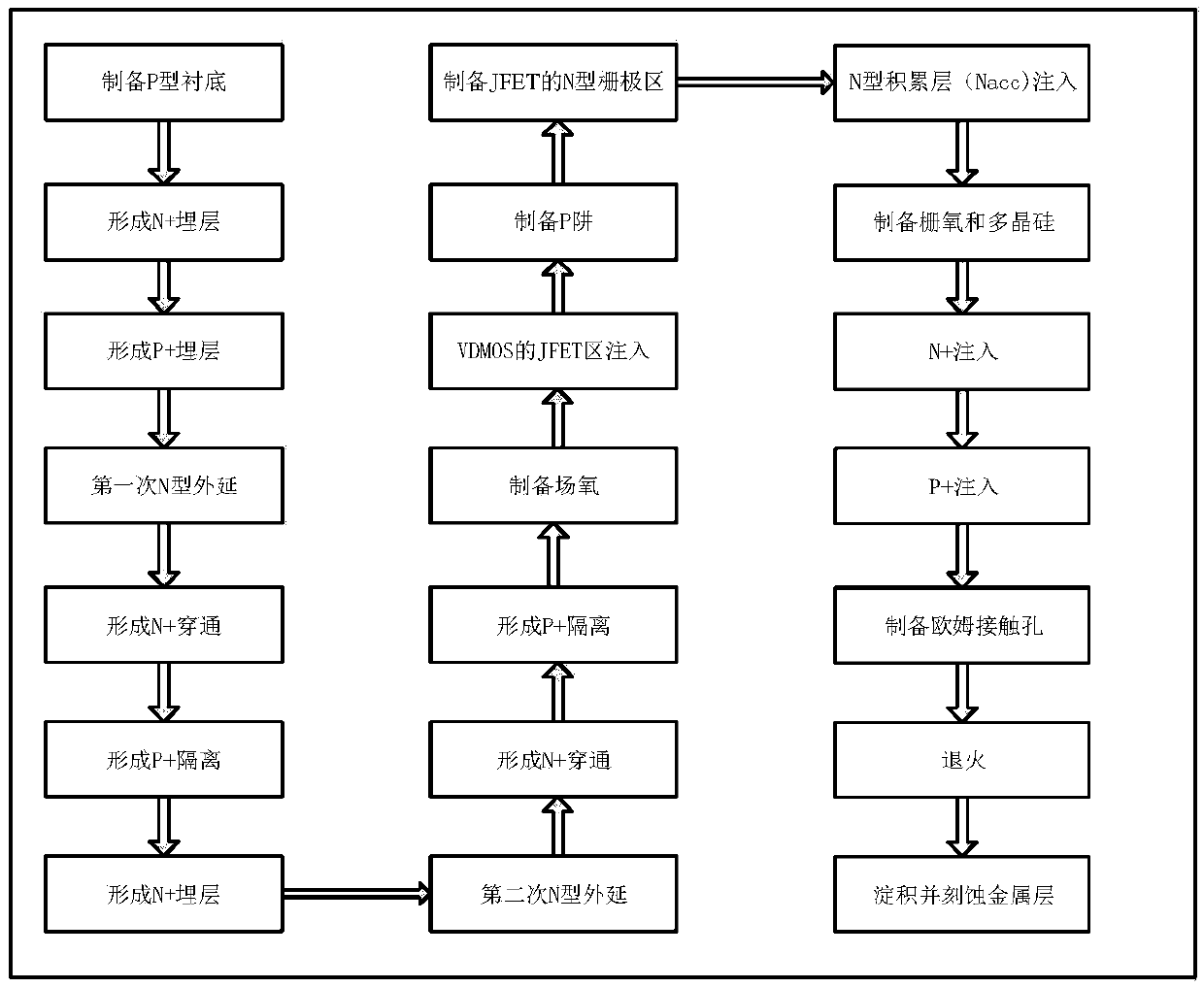

JCD integrated device based on P type epitaxy and preparation method thereof

ActiveCN109671706AReduce power consumptionImprove simulation accuracySolid-state devicesSemiconductor/solid-state device manufacturingIsolation effectLow voltage

The invention relates to a JCD integrated device based on a P type epitaxy and a preparation method thereof, and belongs to the technical field of power semiconductor integration. The preparation method mainly comprises the following process steps of preparing a substrate; forming an N+ buried layer; growing a P type epitaxial layer; forming a penetration isolation region; preparing field oxygen;performing N trap injection and trap pushing; performing P trap injection and trap pushing; performing JFET grid electrode N type region injection and junction pushing; preparing gate oxygen and polycrystalline silicon; performing N+ injection; performing P+ injection; preparing ohm holes; performing annealing activation; performing deposition and etching a metal layer; integrating PJFET, CMOS, nLDMOS (and / or without) Poly resistors, Poly diodes, Poly capacitors and trap resistors into the same chip. The JCD integrated device provided by the invention has the advantages that the high-low voltage device compatibility is good; the isolation effect is good; the mask templates are few; the JFET has the advantages of high precision simulation features, great input impedance, high-speed, good anti-radiation features and the like; the integration of the low-voltage JEFT devices with high-voltage control DMOS parts and low-voltage logic CMOS parts is realized; the JCD integrated device can beapplied to the process design of the power source management IC, protection circuits and integrated operation amplifiers.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

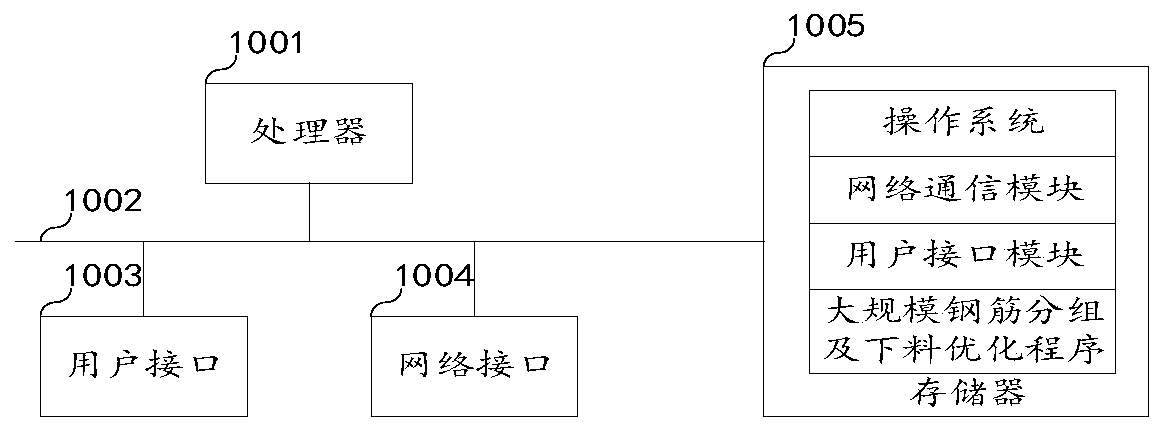

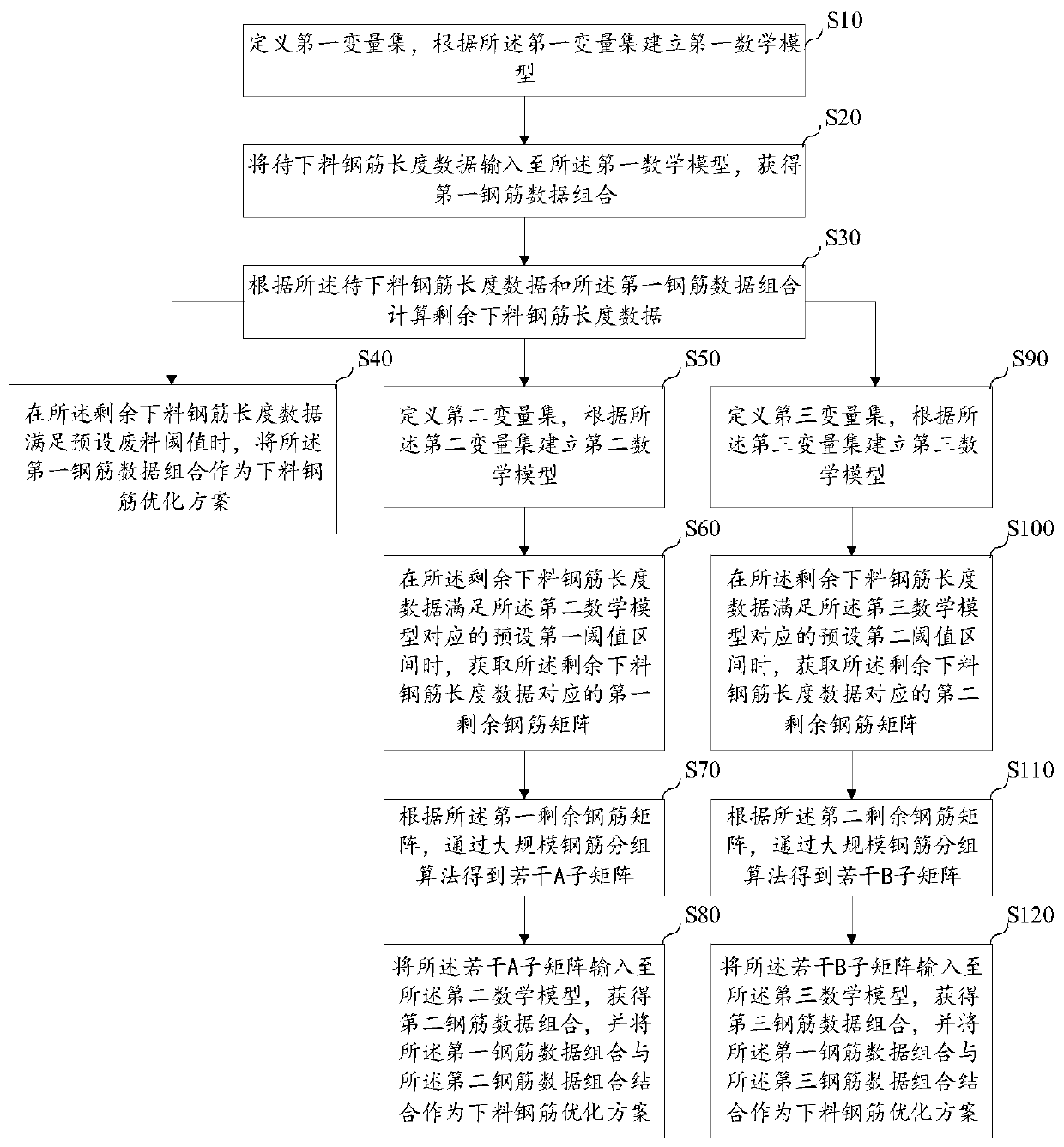

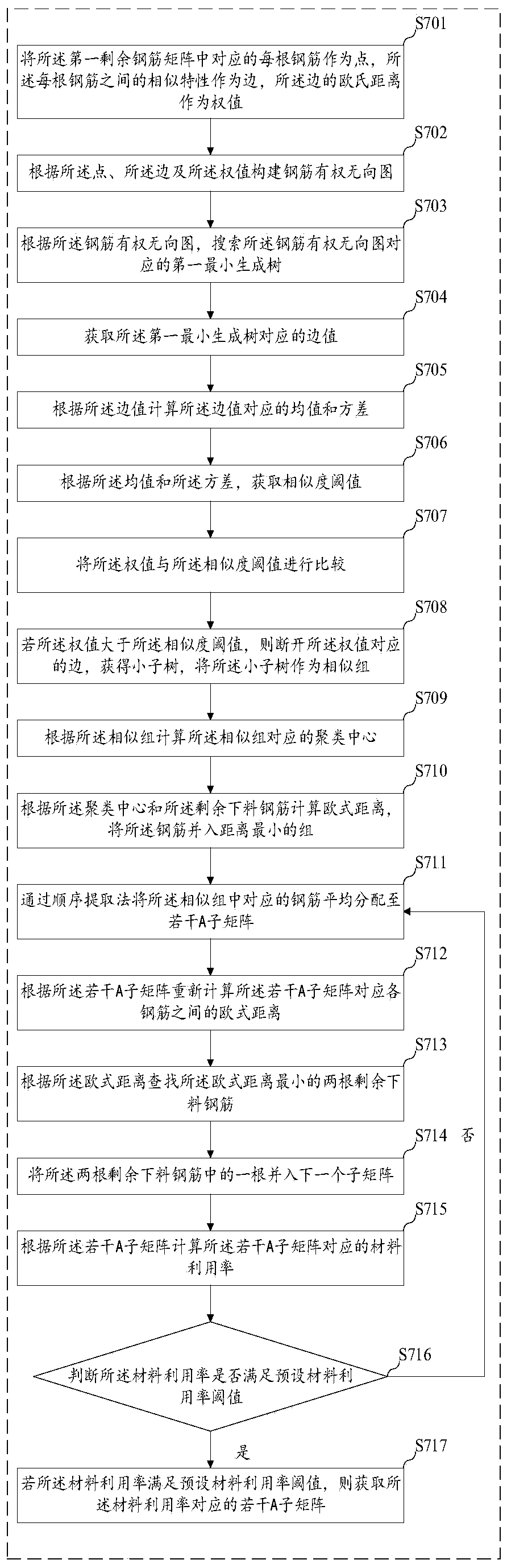

Large-scale steel bar grouping and blanking optimization method and device

The invention belongs to the technical field of civil engineering, and discloses a large-scale steel bar grouping and discharging optimization method and device. The method comprises the steps of defining a first variable set, creating a first mathematical model, inputting to-be-blanked steel bars, and acquiring a first steel bar data combination and remaining blanked steel bars; defining a secondvariable set and a third variable set; establishing a second mathematical model and a third mathematical model, dividing the residual steel bar matrix into a first residual steel bar matrix and a second residual steel bar matrix according to a threshold; obtaining a plurality of sub-matrixes A or a plurality of sub-matrixes B through large-scale steel bar grouping, inputting the plurality of sub-matrixes A and the raw materials into the second mathematical model to obtain a second steel bar data combination, and inputting the plurality of sub-matrixes B and the raw materials into the third mathematical model to obtain a third steel bar data combination; combinding the first steel bar data combination with the second steel bar data combination and the third steel bar data combination to serve as a large-scale steel bar grouping and discharging optimization scheme, the steel bar waste rate and the welding point number are greatly reduced, and therefore the total cost of a steel bar project is reduced.

Owner:HUBEI UNIV OF ARTS & SCI

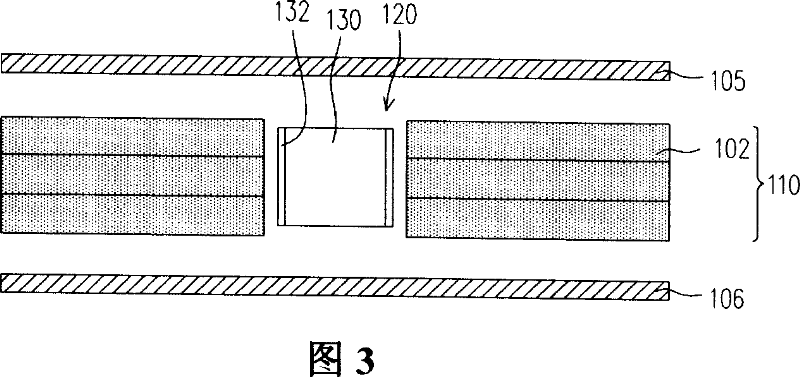

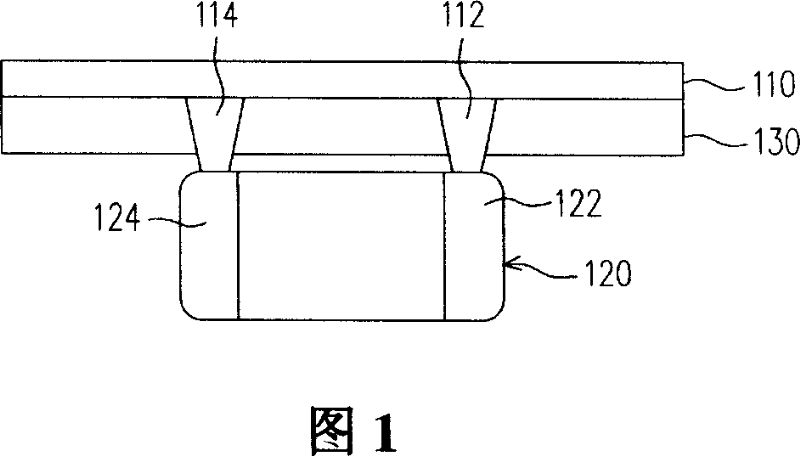

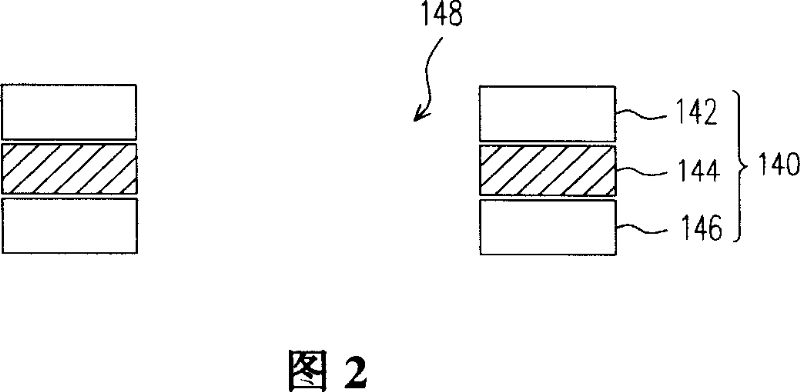

Substrate with embedded element and manufacturing method thereof

InactiveCN101039552AImprove space utilizationReduce the number of solder jointsPrinted circuit assemblingSemiconductor/solid-state device detailsElectrical and Electronics engineeringMetal

The present invention discloses a substrate with embedded components and its manufacturing methods. The manufacturing method includes providing a first metal layer and an embedded component, wherein the first metal layer has at least two first salient points, which respectively linked to the embedded components; then, placing embedded components in buried holes of a core layer; providing a second metal layer, which has at least two second salient points, corresponding to the embedded components; then, pressing in order the first metal layer, the core layer and the second metal layer, so that the two first salient points and two second salient points are electrically connected to the embedded components; finally, forming the first metal layer into patterns, in order to form a first circuit layer; and forming the second metal layer into patterns, in order to form a second circuit layer, and making the embedded components electrically connected between the first circuit layer and the second circuit layer.

Owner:ADVANCED SEMICON ENG INC

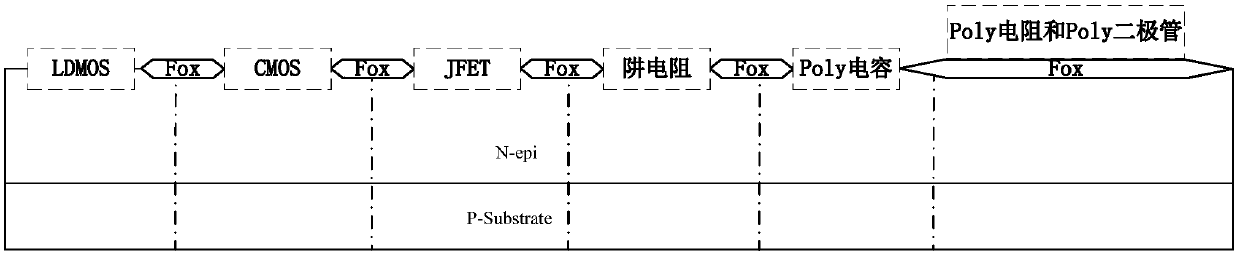

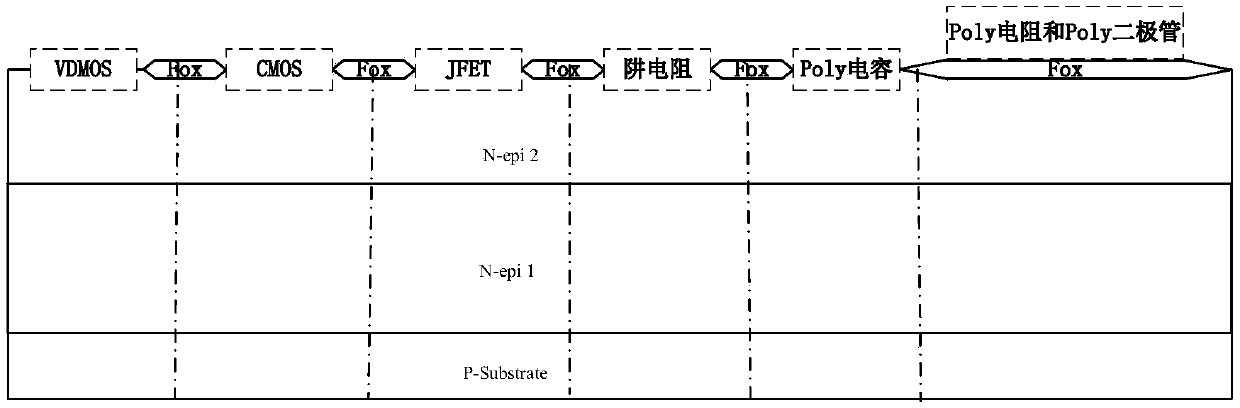

JCD integrated device based on N-type epitaxy and preparation method thereof

ActiveCN109686736AReduce power consumptionImprove simulation accuracyTransistorLow voltageEngineering

The invention provides a JCD integrated device based on N-type epitaxy and a preparation method thereof, and belongs to the technical field of power semiconductor integration. The high-simulation precision JFET part, the CMOS part with high integration degree, convenient logic control and low power consumption and the high-voltage control DMOS part with the high switching speed are integrated on the same chip for the first time, so that the chip has the system function. At the same time, passive components such as poly capacitors, poly resistors and poly diodes can be integrated with the chipto form a circuit. Such a rich device type can bring great flexibility to the power circuit design. The overall process uses fewer masks, the process level reusability is strong, and the manufacturingcost control can be facilitated. High and low voltage compatibility, high performance, high efficiency and high reliability are achieved on the limited chip area. The chip made by using the JCD integration technology has better comprehensive performance and is favorable for development of the one-chip power system integration.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

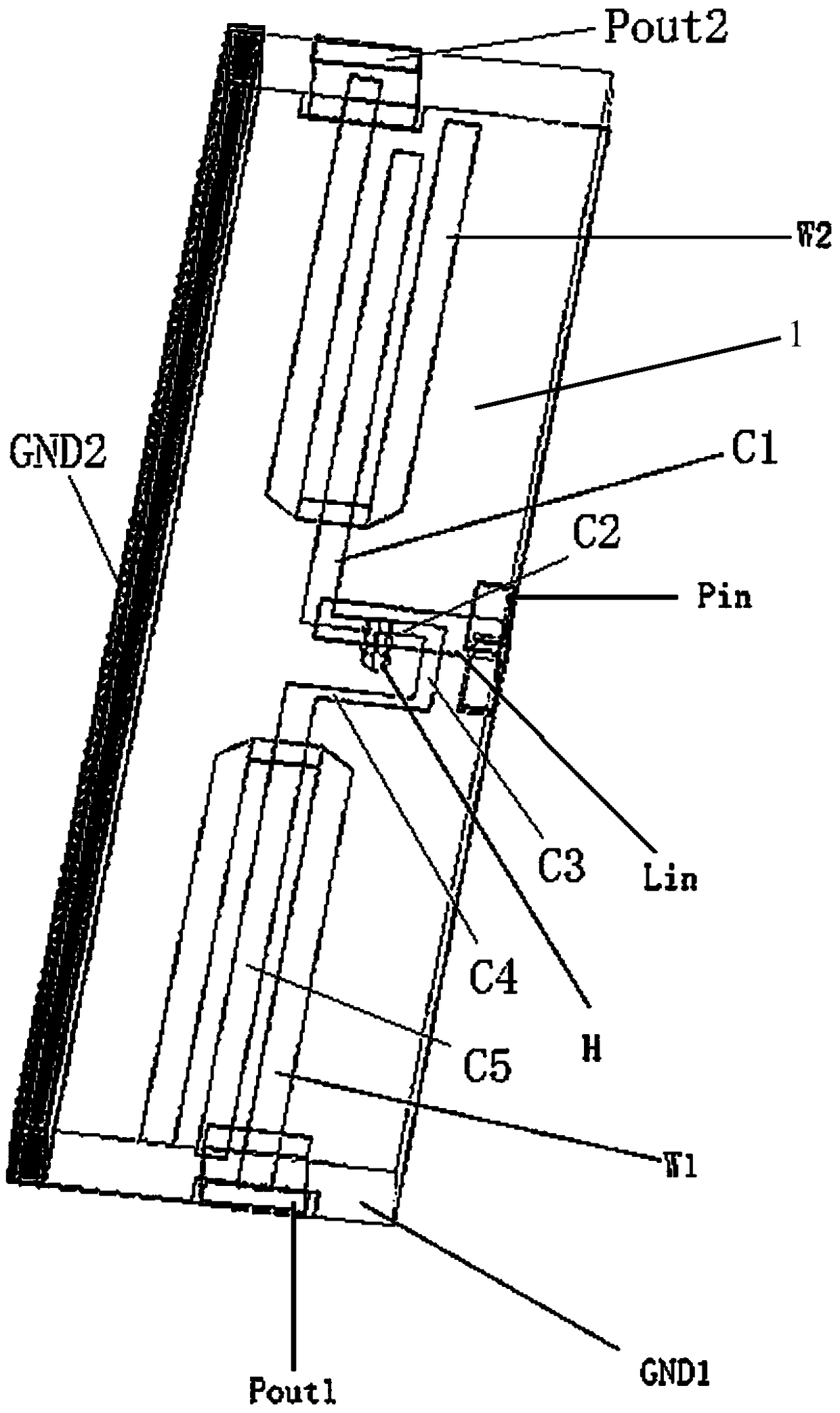

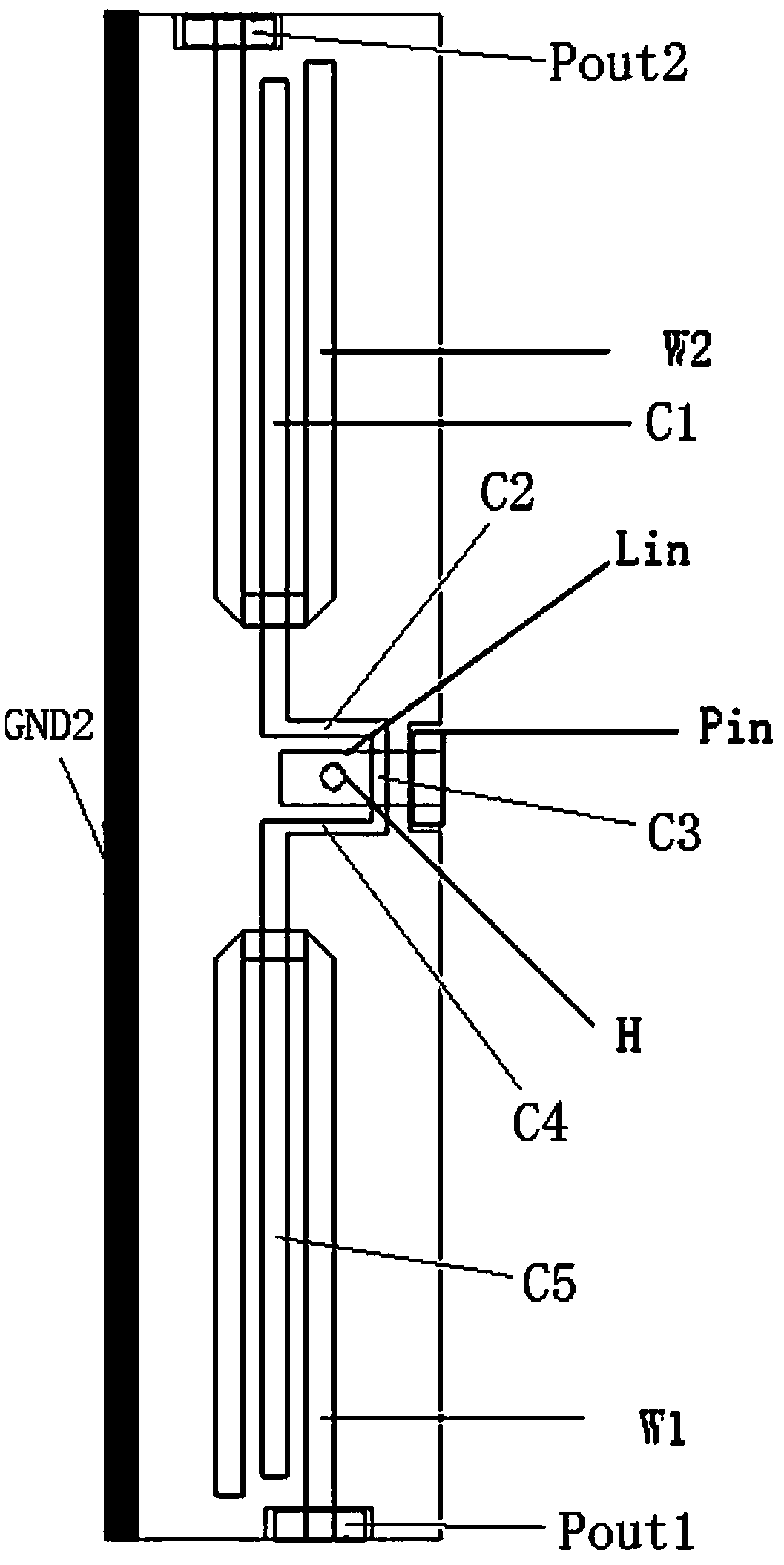

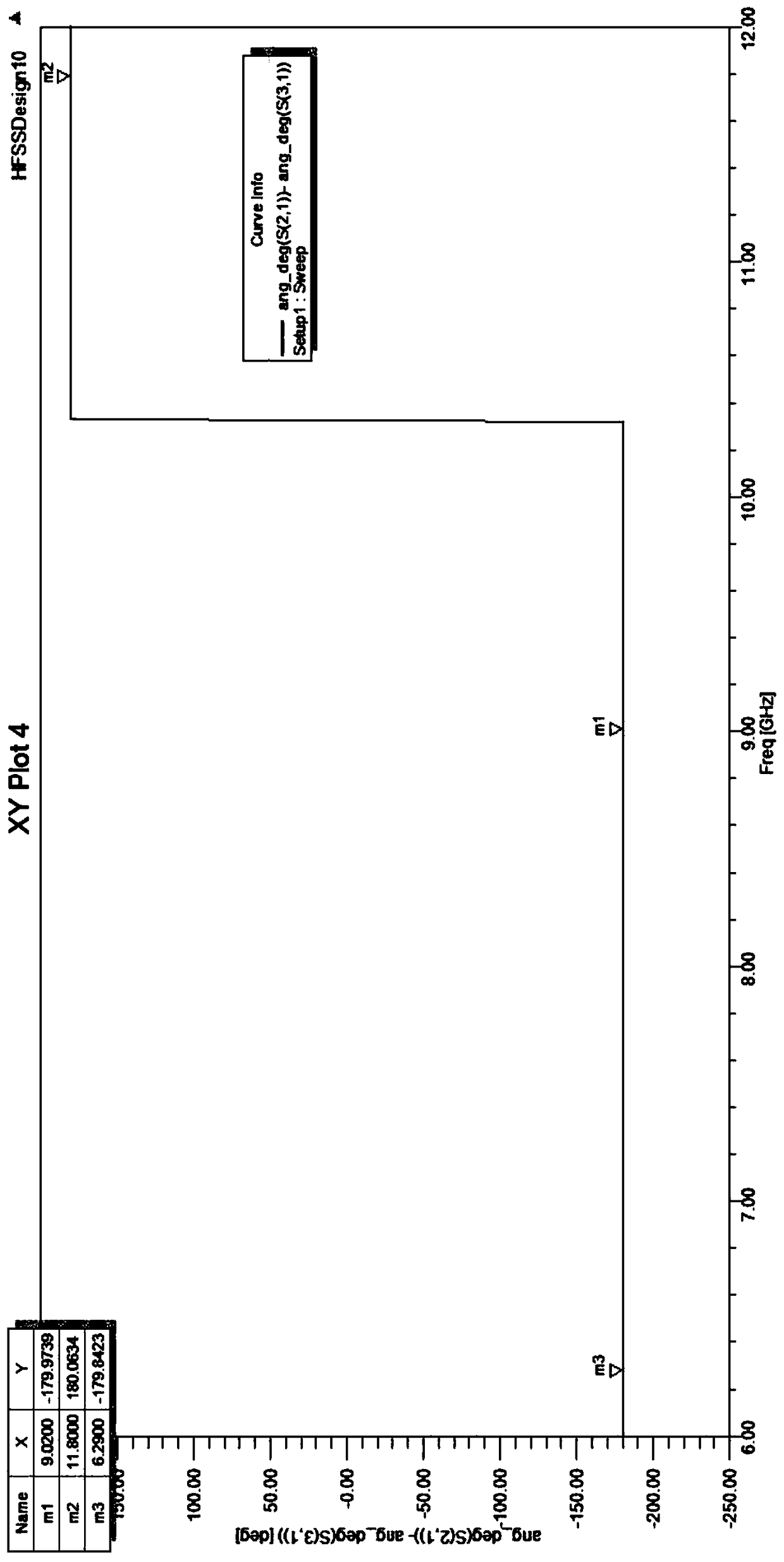

Novel LTCC structure based ultra wide band balun

Owner:深圳市永盛微波技术有限公司

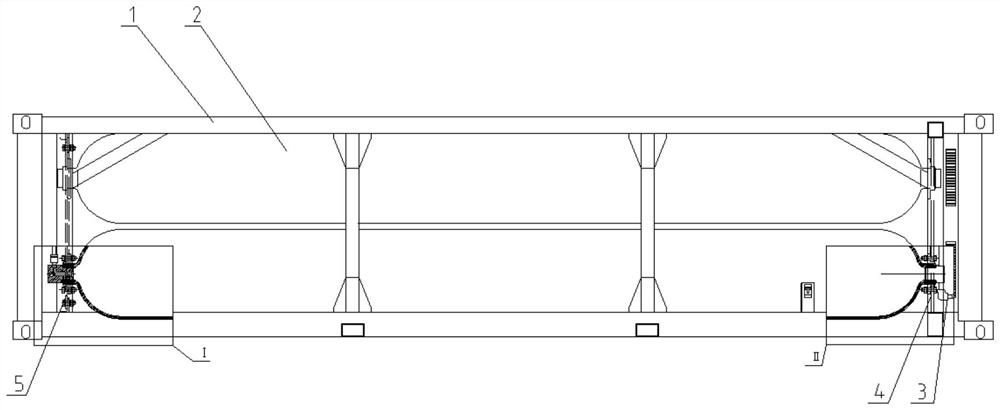

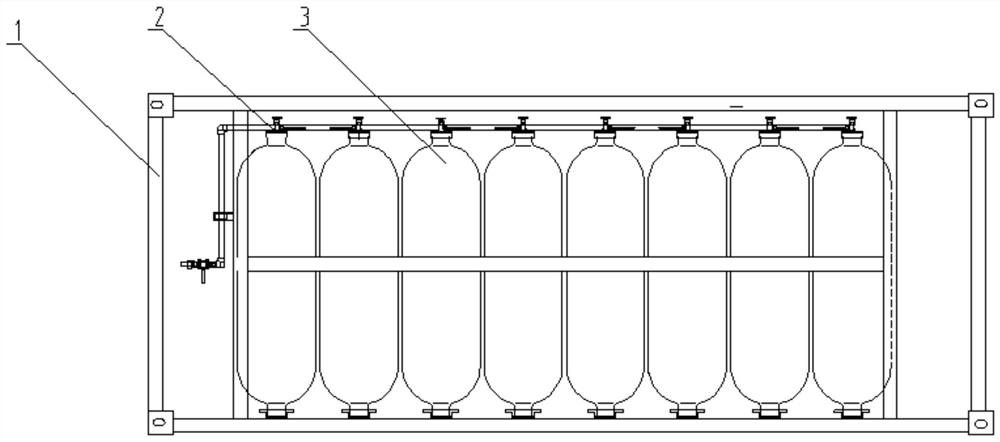

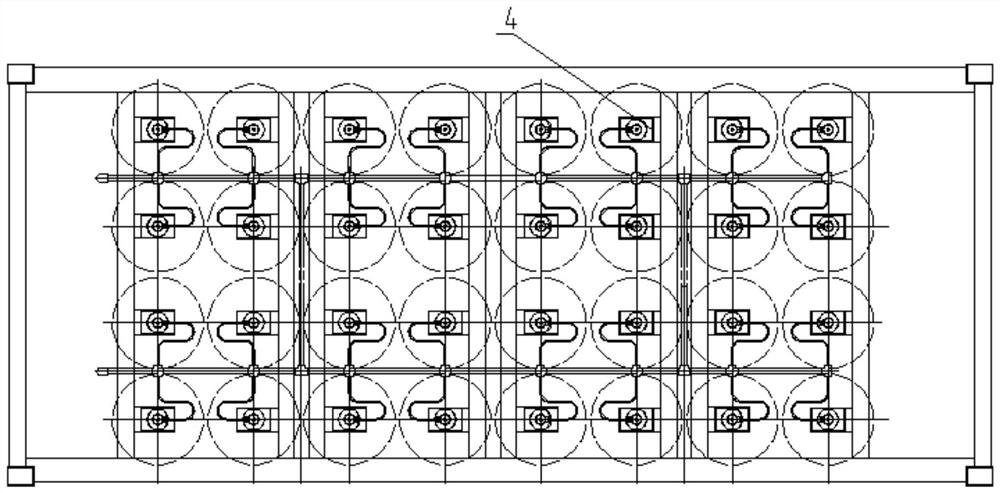

Winding gas cylinder tube bundle type container

PendingCN112483893AIncrease volumeSmall volumeVessel mounting detailsVessel manufacturingFiberCarbon fibers

The invention discloses a winding gas cylinder tube bundle type container. The winding gas cylinder tube bundle type container is characterized by comprising a front end plate, a rear end plate and nine large-volume steel inner container circumferential carbon fiber winding gas cylinders, and the two ends of each winding gas cylinder are connected with a front end connecting flange and a novel anti-rotation combined flange correspondingly; and each anti-rotation combined flange is composed of a flange plate, a pressing block I and a pressing block II, the pressing block II and the flange plateare fastened through hexagon socket screws, after fastening, the anti-rotation combined flange is connected with the corresponding winding gas cylinder, after screwing, the pressing block I and the pressing block II are fastened through hexagon socket screws, and the flange plate is fixed on the rear end plate through bolts. The winding gas cylinder tube bundle type container has the advantages of being small in weight-volume ratio, large in volume, light in weight, small in number of pipeline connecting points and welding points, small in number of leakage points, good in structural stability of a pipeline system and the like.

Owner:ZHEJIANG REIN GAS EQUIP

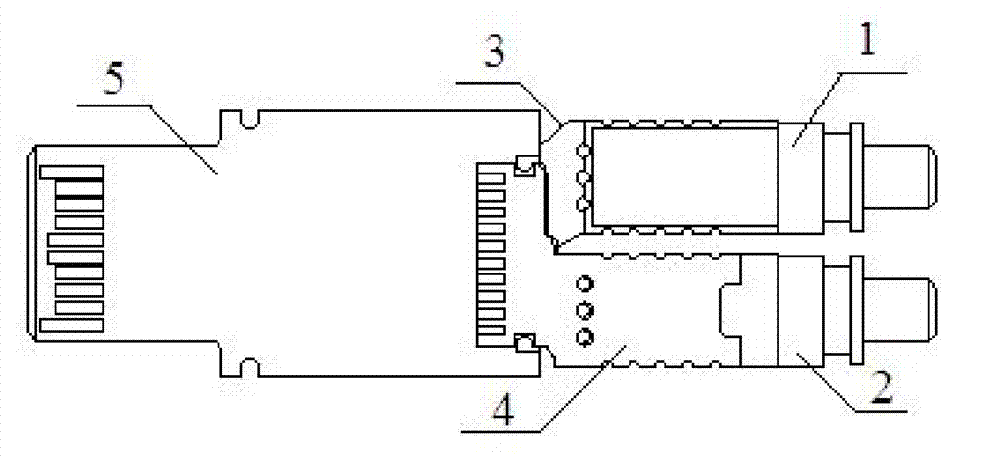

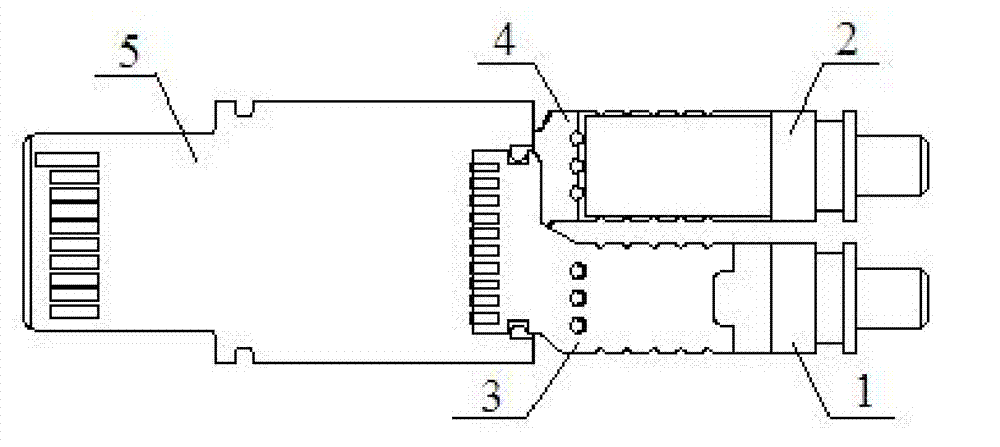

CSFP optical transceiver module

InactiveCN102759780ASimplify the manufacturing processIncrease productivityCoupling light guidesTransceiverFlexible circuits

The invention discloses a CSFP optical transceiver module, which includes a main board, a first bidirectional transceiver, a second bidirectional transceiver, a first flexible circuit board and a second flexible circuit board, wherein the main board is provided with a main board top layer and a main board bottom layer; one end part of the main board top layer is provided with a first bonding pad, the main board is connected with one end of the second flexible circuit board through the first bonding pad, and the other end of the second flexible circuit board is connected with the second bidirectional transceiver; and one end part of the main board bottom layer is provided with a second bonding pad, the main board is connected with one end of the first flexible circuit board through the second bonding pad, and the other end of the first flexible circuit board is connected with the first bidirectional transceiver. According to the CSFP optical transceiver module, the main board is connected with the two bidirectional transceiver directly through the flexible circuit boards, thereby simplifying the manufacturing process, improving the production efficiency, and reducing the design and manufacturing costs; welding points are reduced in the manufacturing process, so that failure caused by insufficient welding is avoided, and the stability and reliability of products are greatly improved.

Owner:WUHAN TELECOMM DEVICES

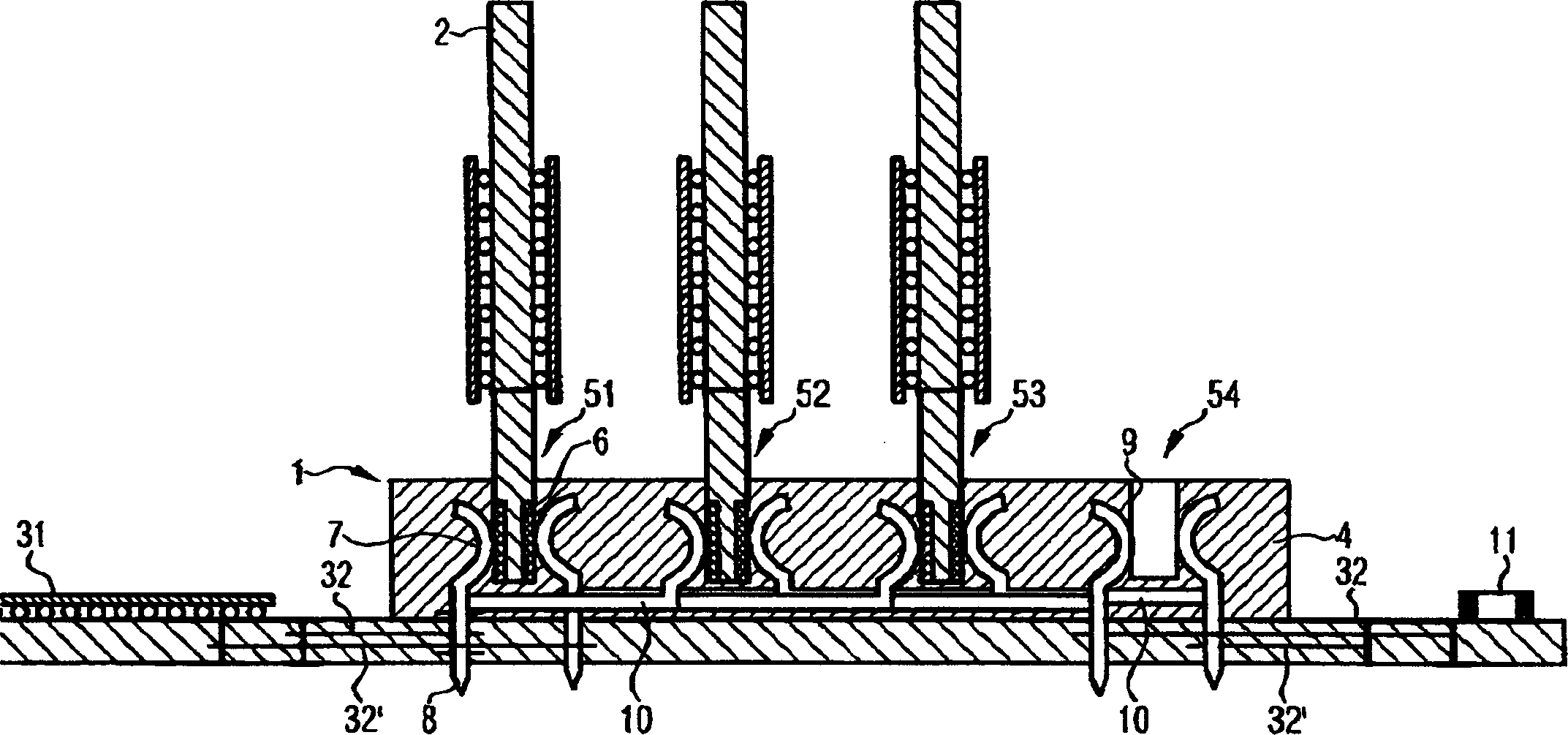

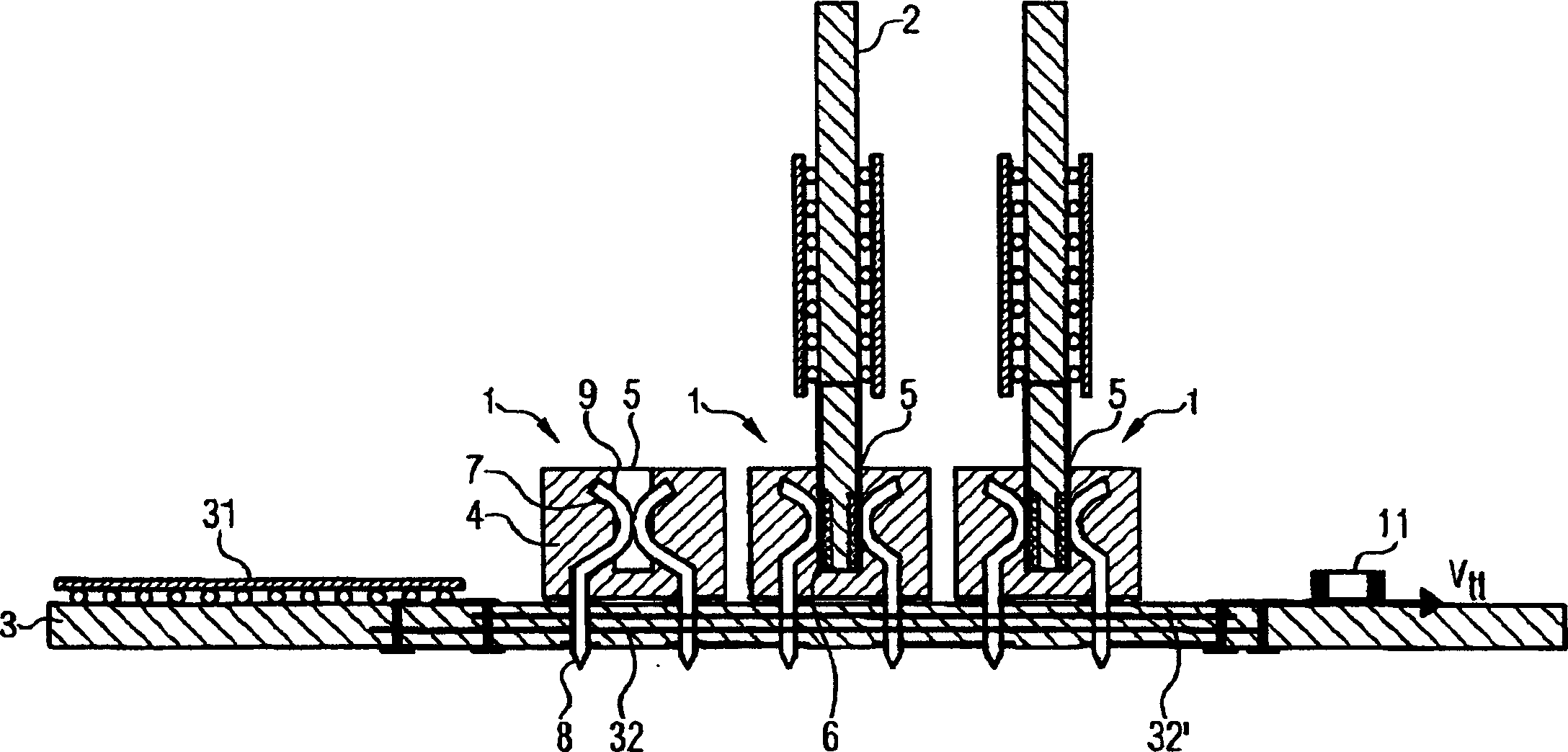

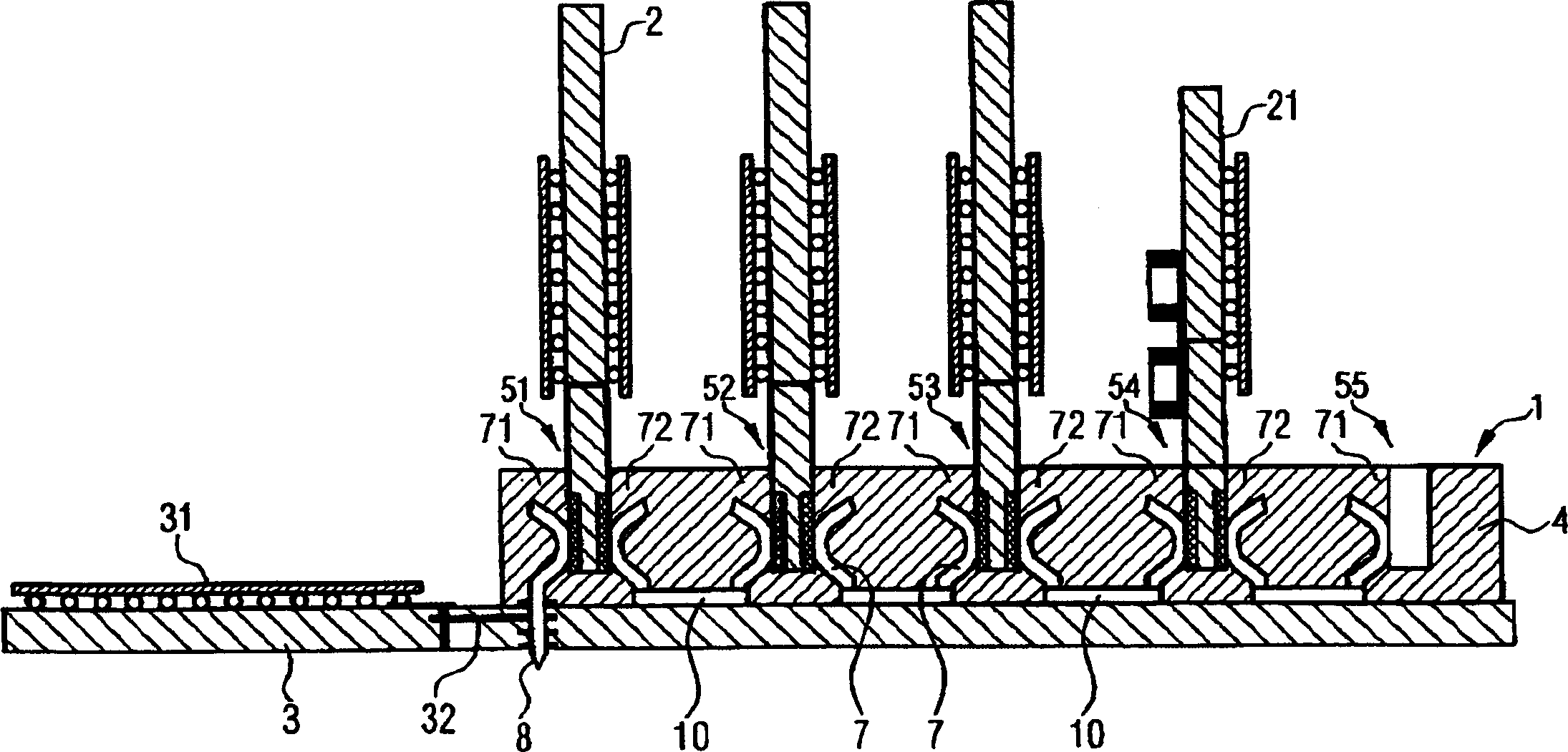

Connector with plural switching assemblies of compatible interface

InactiveCN1472845AConvenient ArrangementReduce the number of solder jointsCoupling device detailsTwo-part coupling devicesClock ratePropagation time

A connector is described for fixing a plurality of switching assemblies on a substrate. The connector is also for making contact with the plurality of switching assemblies, which have compatible interfaces. The connector has a plurality of receptacle devices with contact elements and internal contact connections between corresponding contact elements, as a result of which, the length of the connections between the switching assemblies is reduced, signal propagation times are shortened and a higher clock rate for operating the switching assemblies is made possible.

Owner:INFINEON TECH AG

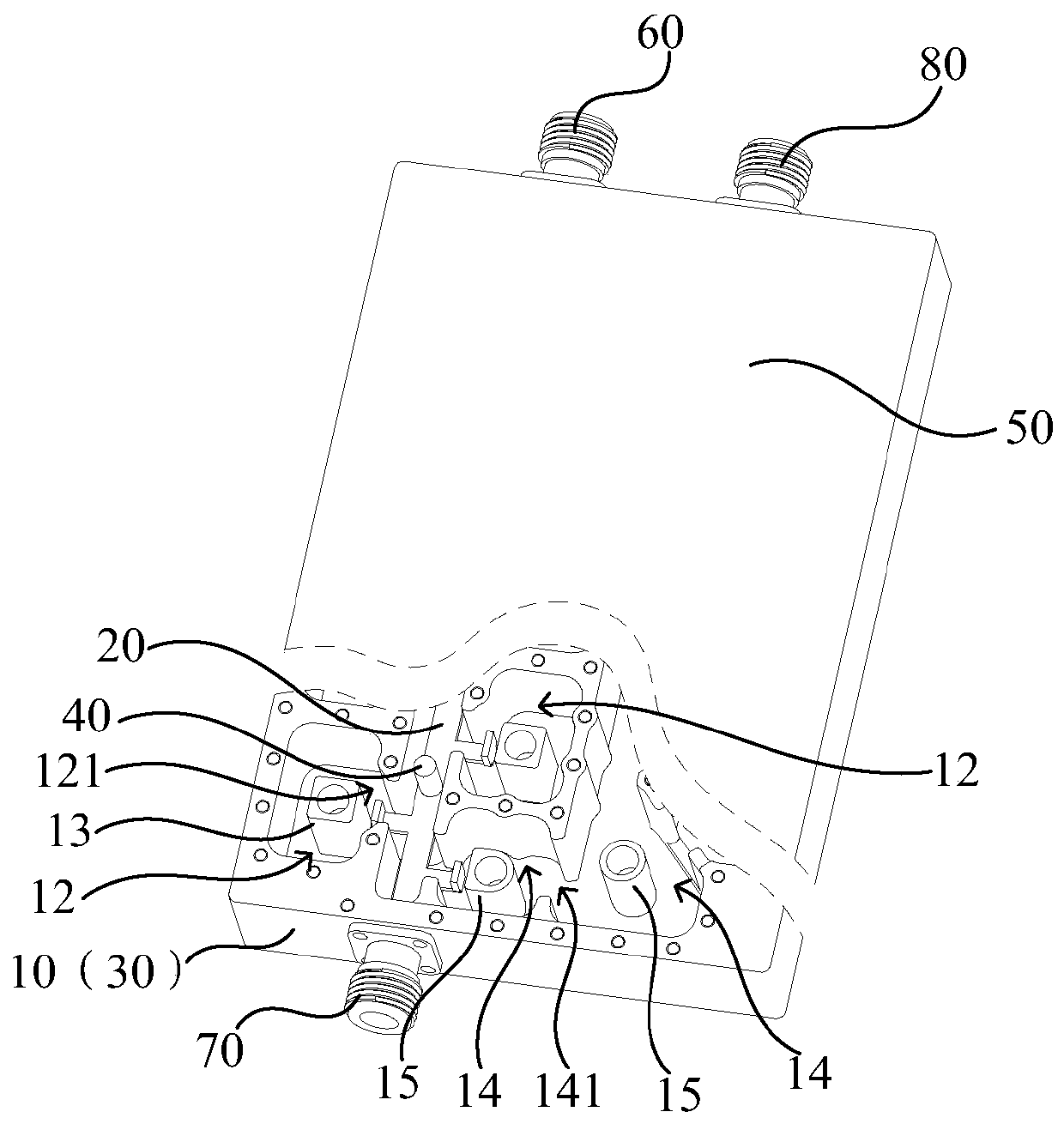

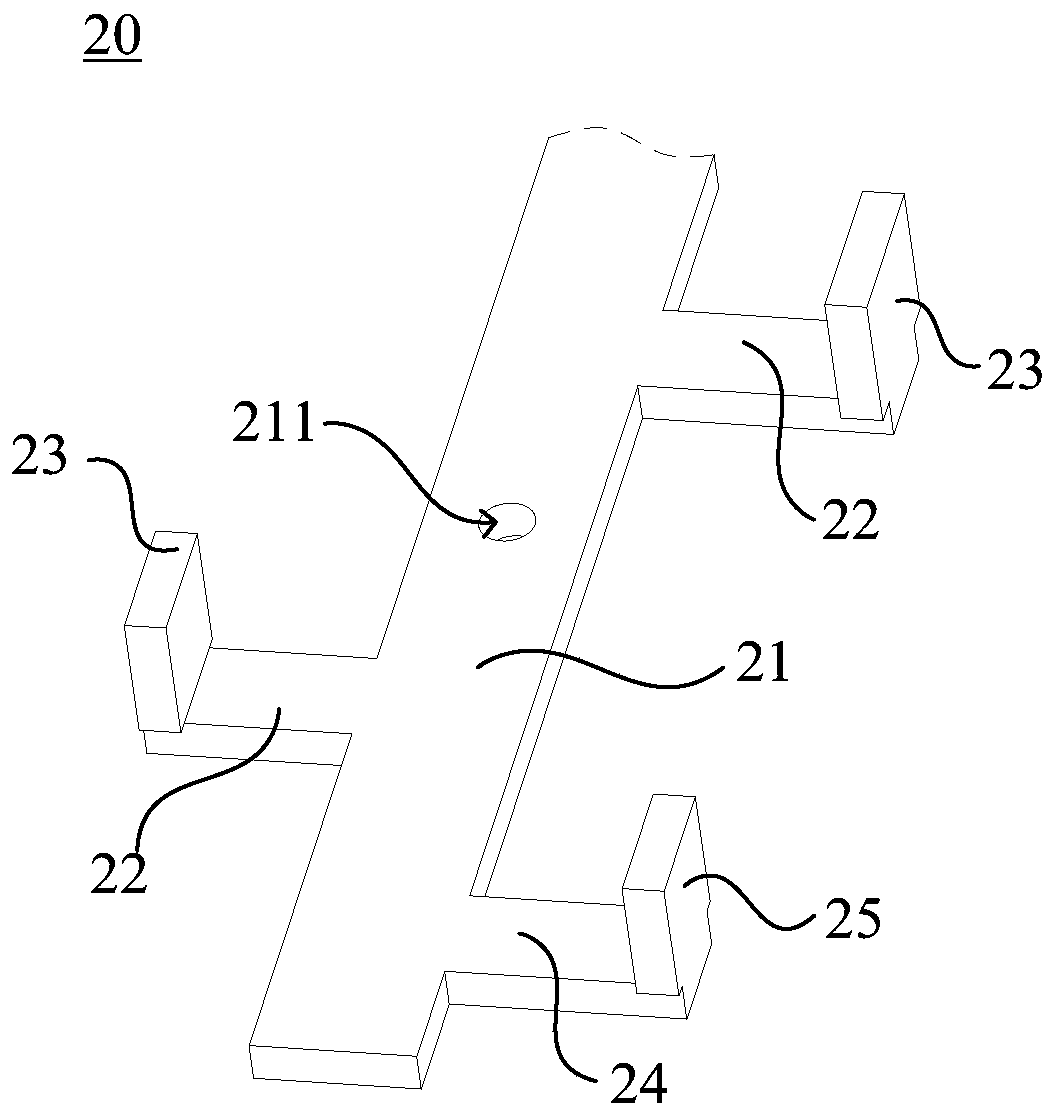

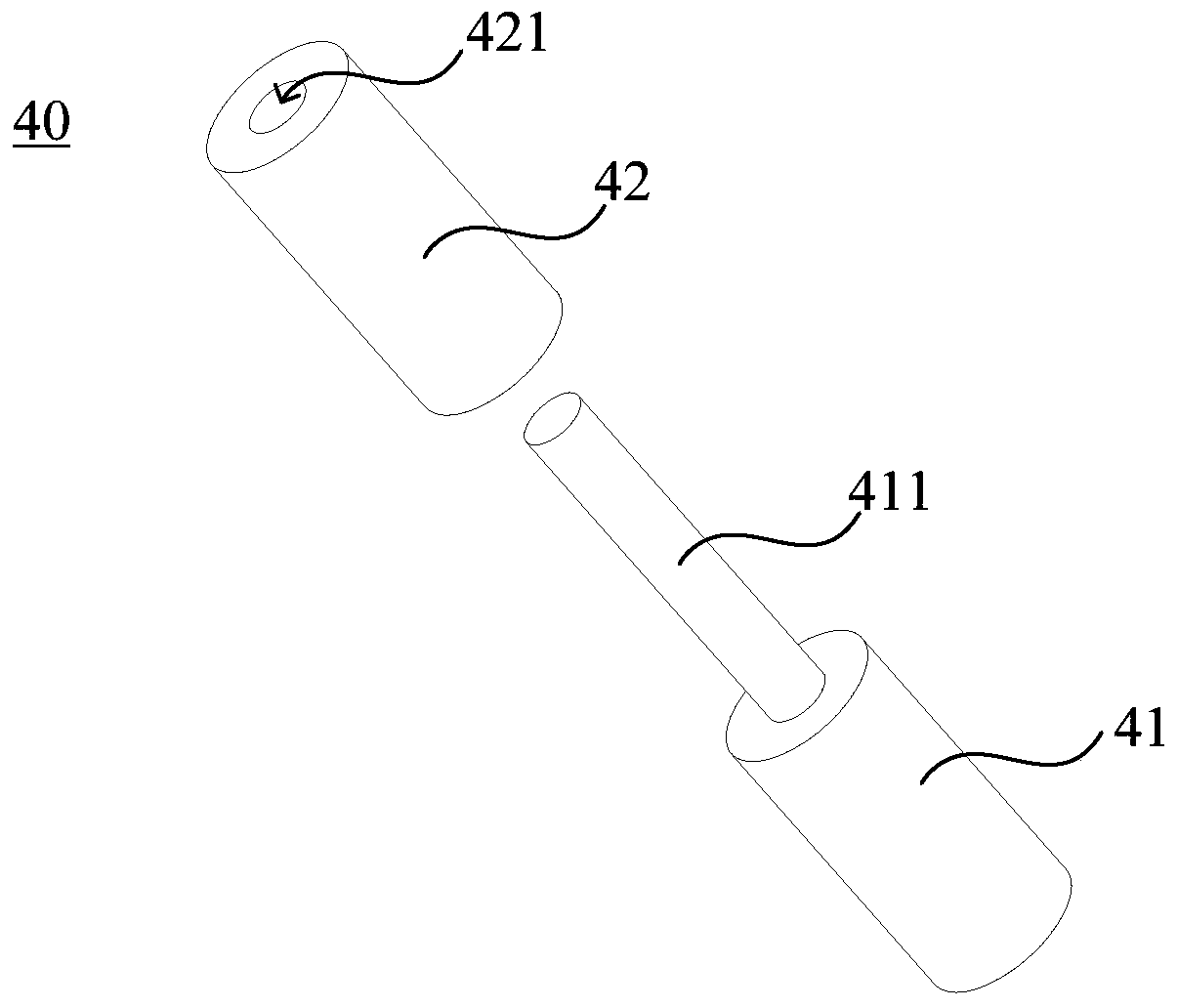

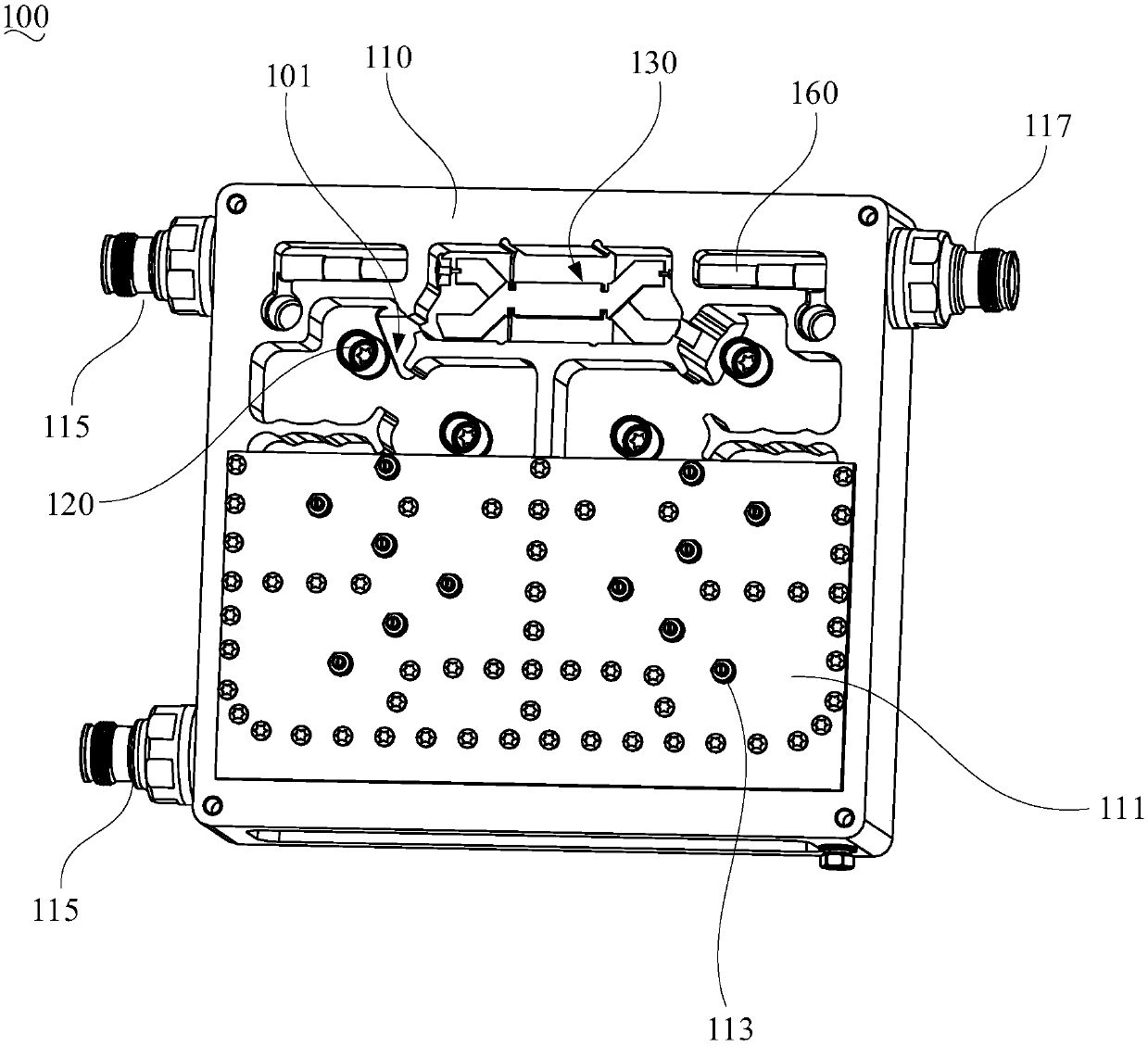

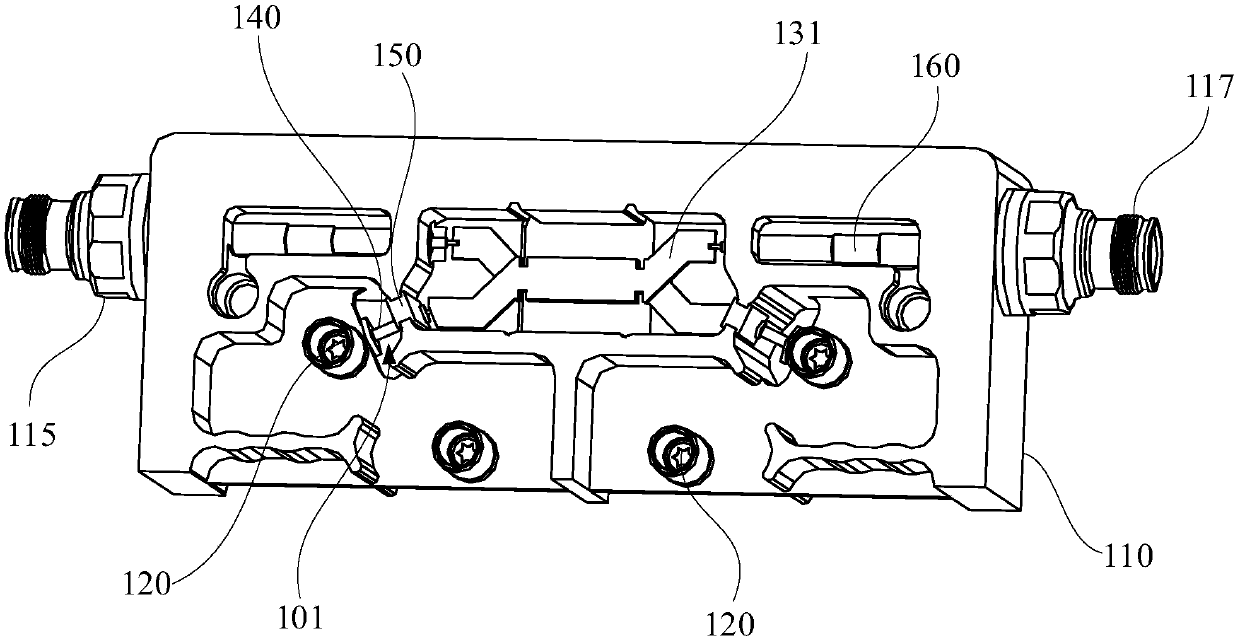

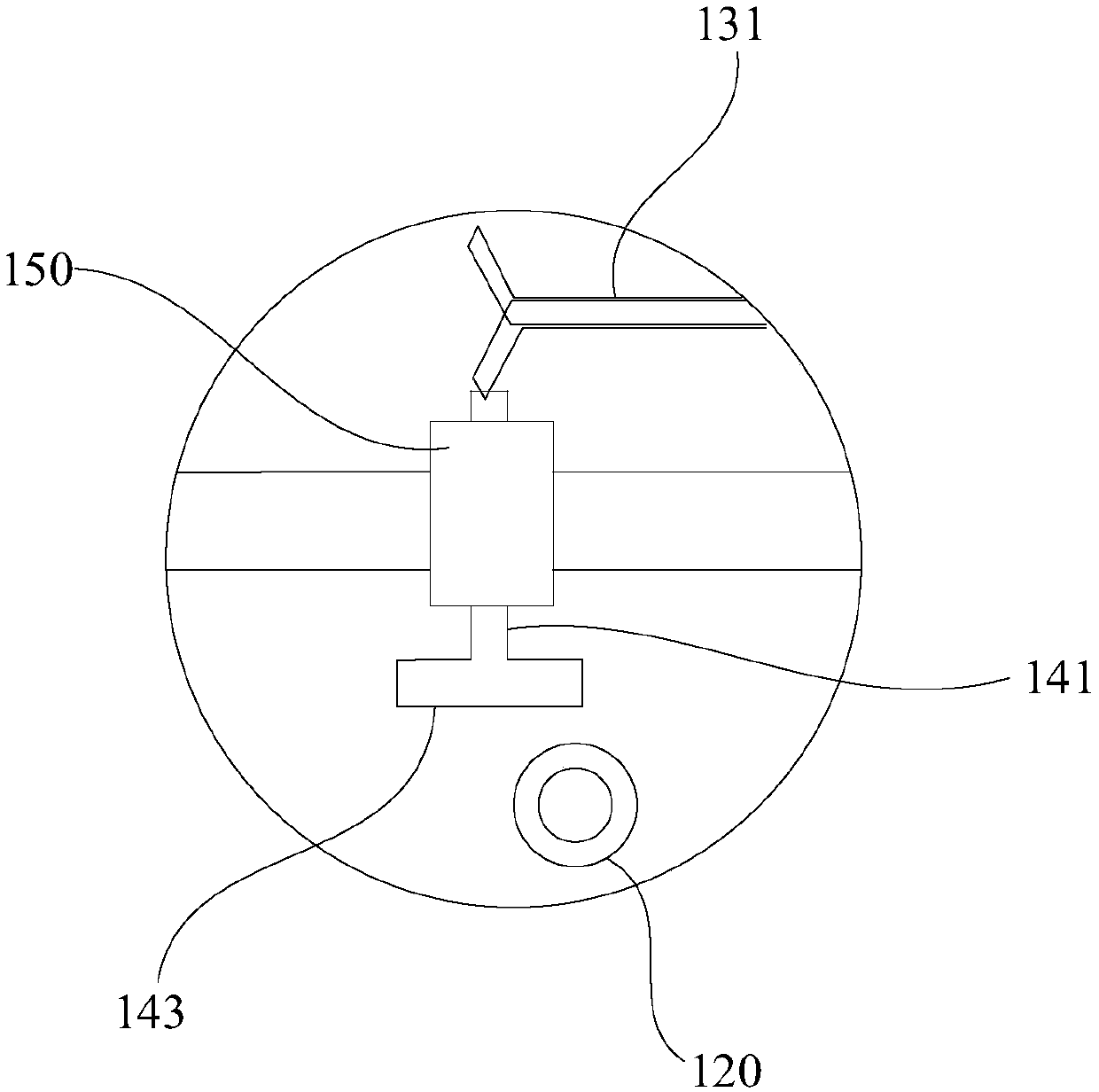

Band elimination filter and combiner

PendingCN111009709AReduce the number of solder jointsSimple structureWaveguide type devicesResonant cavityStructural coupling

The invention relates to a band elimination filter and a combiner. The band elimination filter comprises a metal cavity, a coupling feed piece, a metal layer, an insulating support piece and a cover plate. The coupling feed piece comprises a main feed piece, a plurality of first connecting pieces and a plurality of first coupling feed plates. The other end of each first connecting piece is correspondingly connected with each first coupling feed plate, and the other end of each first connecting piece extends into a first resonant cavity through a notch. The first coupling feed plates and firstresonance columns are arranged at an interval. The main feed piece, the first connecting pieces and the first coupling feed plates are an integrated structure. The coupling feed piece is isolated fromthe metal layer through the insulating support piece, and the cover plate covers the metal cavity. As the main feed piece, the first connecting pieces and the first coupling feed plates are the integrated structure, a traditional mode of welding and connecting the main feed piece, the first connecting pieces and the first coupling feed plates is not needed, the number of welding spots can be reduced, the structure is simplified, cost is low, assembling is simple, and production efficiency is higher.

Owner:COMBA TELECOM TECH (GUANGZHOU) CO LTD

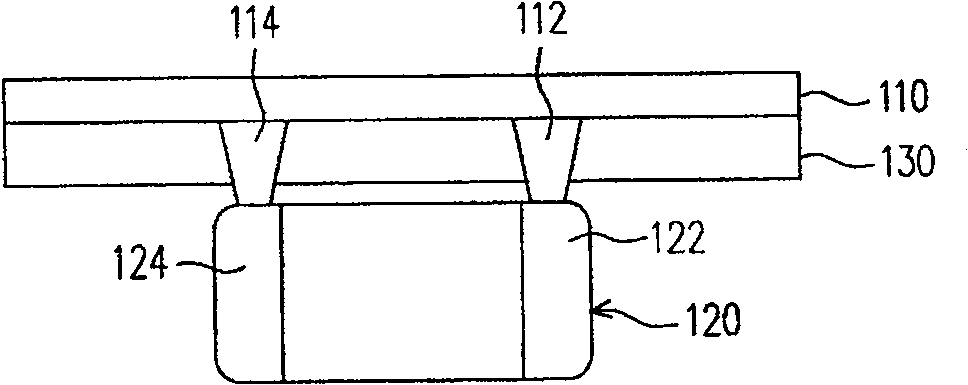

Substrate with embedded element and manufacturing method thereof

InactiveCN100542379CImprove space utilizationReduce the number of solder jointsPrinted circuit assemblingSemiconductor/solid-state device detailsEngineeringMetal

The invention discloses a substrate with embedded components and a manufacturing method thereof. The manufacturing method includes providing a first metal layer and an embedded component, the first metal layer has at least two first bumps, which are correspondingly connected to the embedded component; then, placing the embedded component in a buried hole in a core layer; providing A second metal layer, and the second metal layer has at least two second bumps, corresponding to the embedded element; after that, sequentially press the first metal layer, the core layer and the second metal layer, so that the two first The bump and the two second bumps are respectively electrically connected to the embedded components; finally, the first metal layer is patterned to form a first circuit layer; and the second metal layer is patterned to form a second circuit layer , and the embedded element is electrically connected between the first circuit layer and the second circuit layer.

Owner:ADVANCED SEMICON ENG INC

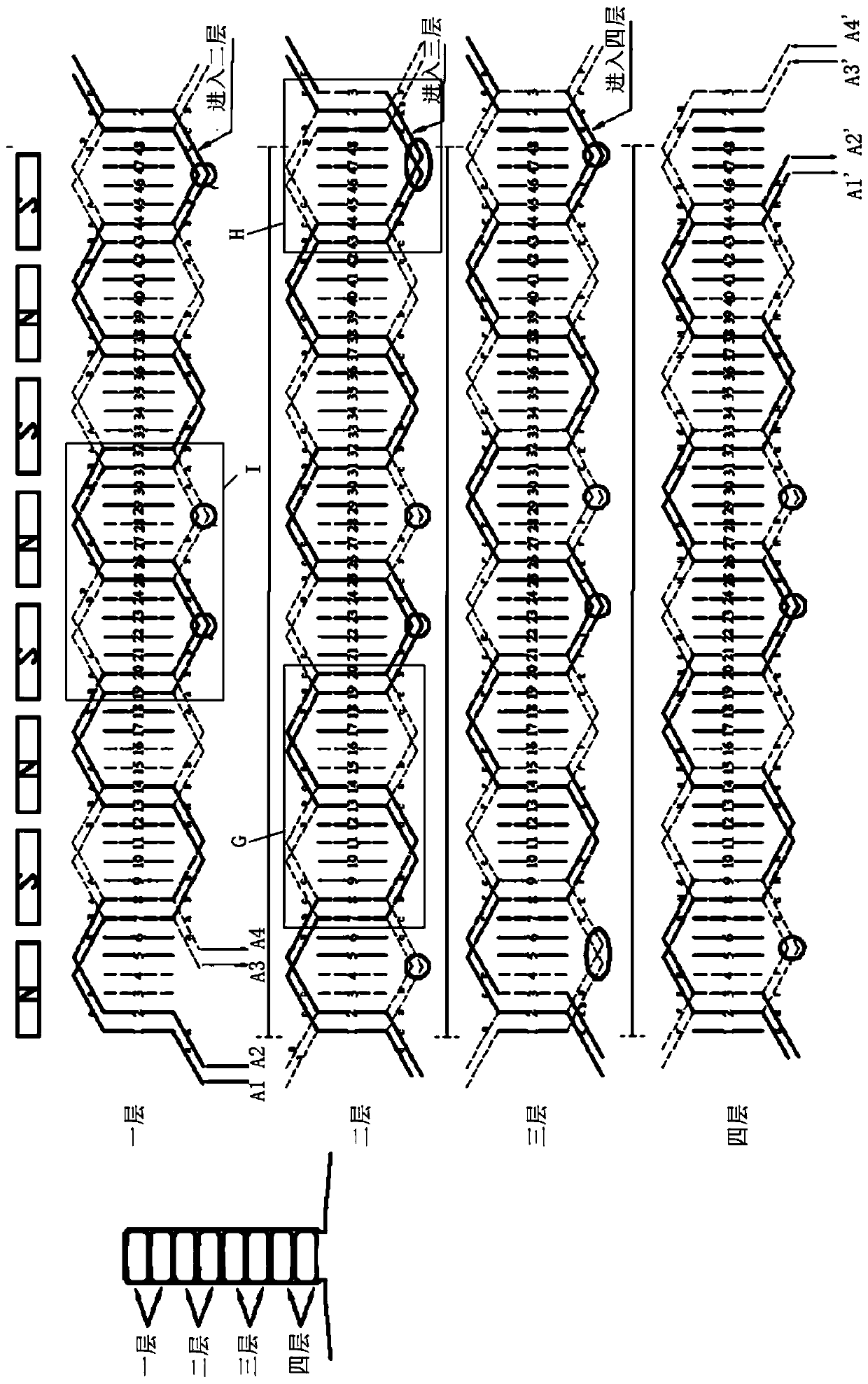

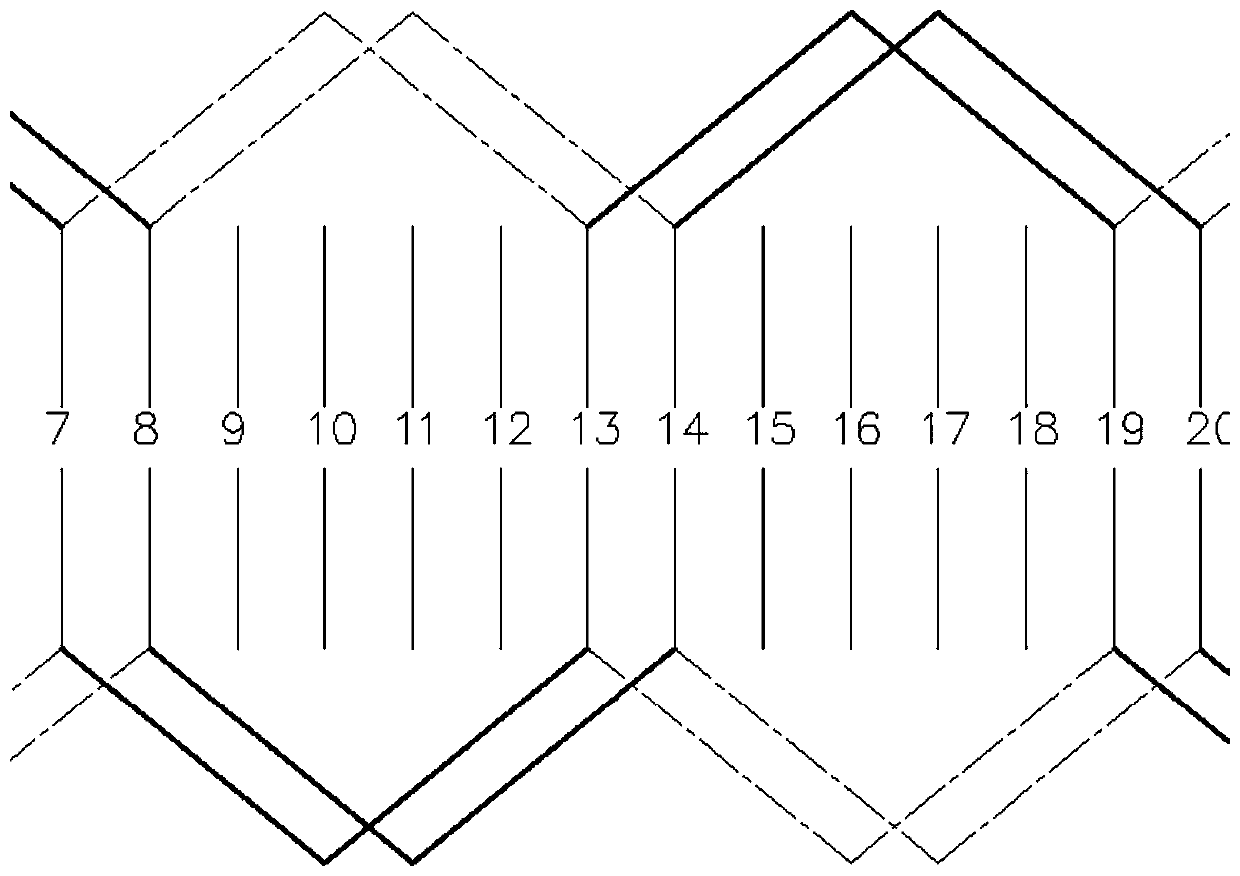

Motor winding and winding method

PendingCN107659088AReduce the number of solder jointsSolder joint removalManufacturing dynamo-electric machinesWindings conductor shape/form/constructionElectrical conductorElectric machine

The invention provides a winding method of a motor winding and the motor winding. By using the winding method and the motor winding, a technology is simple, production efficiency is high, cost is lowand the method and the winding can adapt to automation production. According to the motor winding made through using the method, a number of welding spots is less, weight weak points are reduced and reliability is high; and because a lot of welding is not needed, production efficiency is high and cost is low. In the winding method, one conductor is adopted and the following processes are repeatedtill that one conductor completes all or partial winding of one phase of winding. When one conductor completes the partial winding of the winding, leading-out terminals of partial windings are mutually connected so as to form one phase of winding. The repeated processes comprises that a free end of the conductor is inserted into a wire groove from a head end of one wire groove and is pulled out ofa tail end of the wire groove, and then the conductor carries out back bending; and the free end of the conductor is inserted into a tail end of the other wire groove and is pulled out of a head endof the other wire groove, and then the conductor carries out back bending. The motor winding comprises three phases of windings, and each phase of winding passes through one conductor of the wire groove or several connected conductors.

Owner:SUZHOU AMTF ROBOTS CO LTD

T-shaped coupling dual-polarization base station antenna

PendingCN107394376AImproving Impedance BandwidthReduce the number of solder jointsRadiating elements structural formsAntennas earthing switches associationDielectric substrateEngineering

The invention relates to a T-shaped coupling dual-polarization base station antenna. The T-shaped coupling dual-polarization base station antenna comprises a dielectric substrate, a reflection plate and two coaxial cables, wherein four radiation units are arranged on a lower surface of the dielectric substrate in a circumferential direction at an interval of 90 degrees, two feeding units are arranged on an upper surface of the dielectric substrate in the circumferential direction at an interval of 90 degrees, each feeding unit is correspondingly arranged above the two radiation units at an interval of 180 degrees in the circumferential direction, the two feeding units are crossed at a central position of the four radiation units, the reflection plate is arranged below the dielectric substrate, lower ends of the two coaxial cables are respectively connected with the reflection plate, and upper ends of the two coaxial cables are connected with the two feeding units. The T-shaped coupling dual-polarization base station antenna employs a T-shaped feeding structure, the impedance matching of the antenna can be effectively adjusted, and the impedance bandwidth of the antenna is improved and reaches 42%.

Owner:CHINA TOWER CO LTD

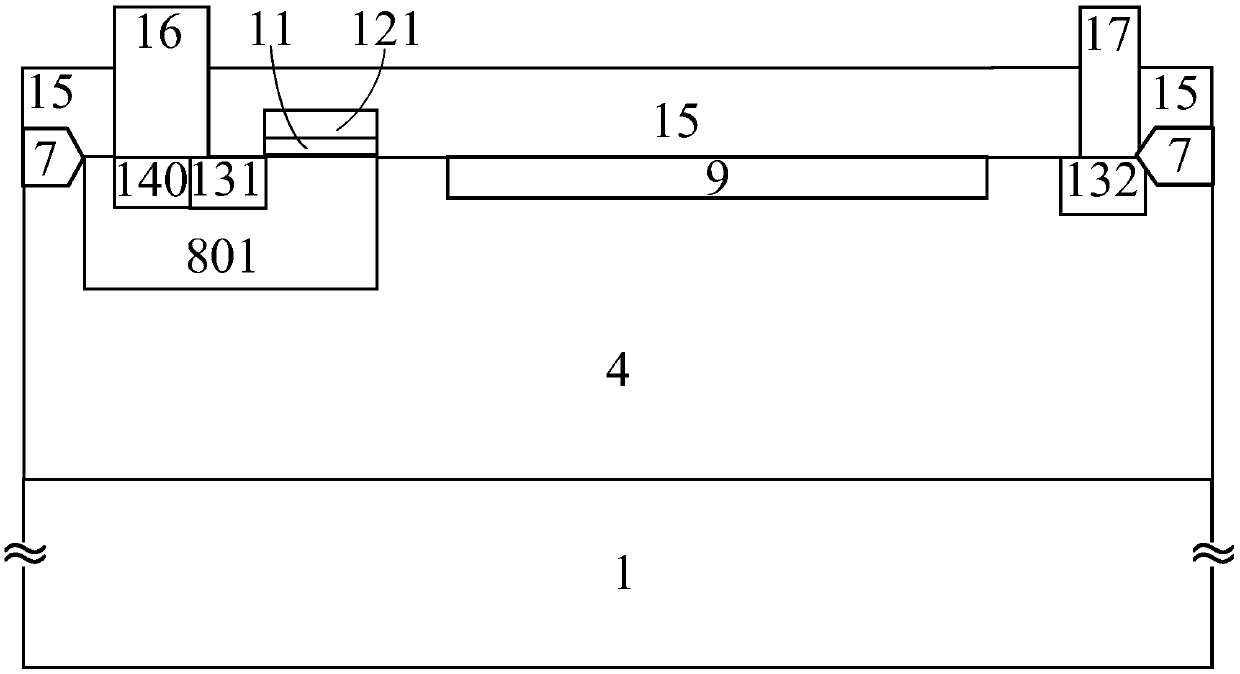

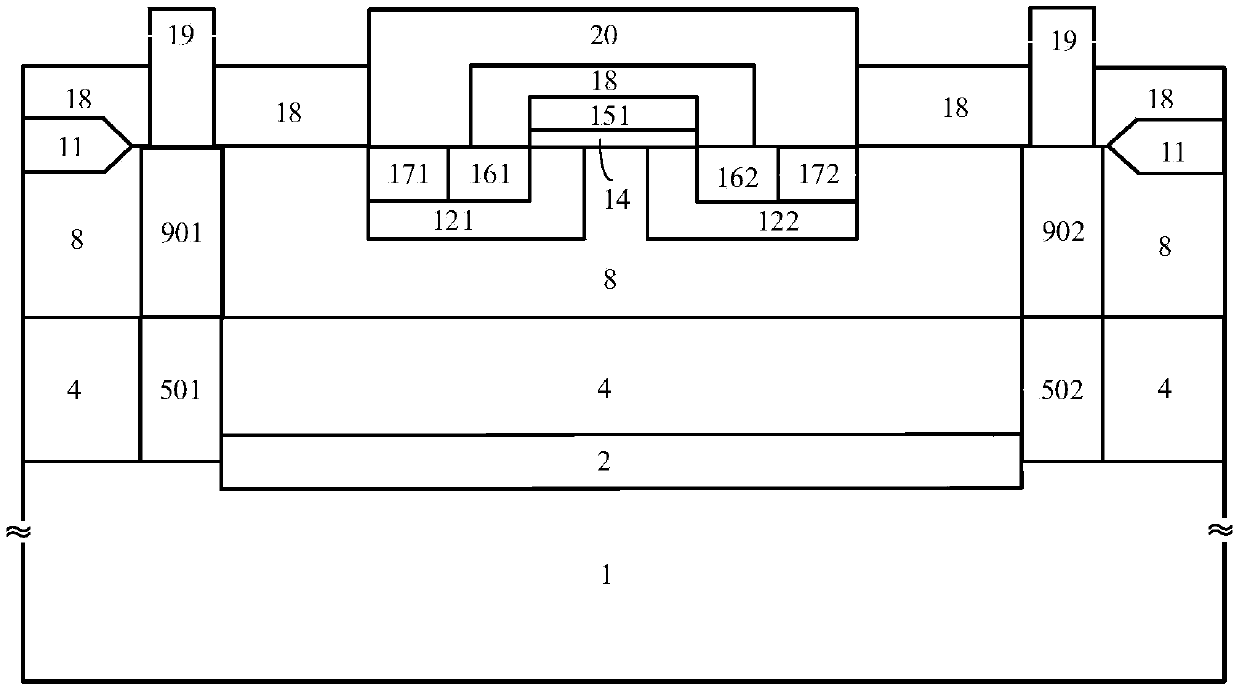

JCD integrated device integrated with VDMOS and preparation method thereof

ActiveCN109671707AReduce power consumptionIncrease power consumptionTransistorSolid-state devicesLow noiseLow voltage

The invention provides a JCD integrated device integrated with VDMOS and a preparation method thereof, and belongs to the technical field of power semiconductor integration. The manufacturing of JFET,CMOS and VDMOS on the same chip is realized by the invention for the first time; meanwhile, passive elements such as a poly capacitor, a poly resistor and a poly diode can be integrated with the JFET, CMOS and VDMOS to form a circuit. The advantages of high-switch speed and high voltage resistance of the VDMOS, excellent simulation characteristics, low-noise characteristics, temperature stabilityand anti-radiation capability of the JFET devices, high integrality of the CMOS part and the like are integrated by the invention; meanwhile, high flexibility is brought to the power circuit design.The whole process provided by the invention uses relatively few mask templates; the process level reusability is high; the manufacturing cost control is facilitated; the high-low-voltage compatibility, high performance, high efficiency and high reliability are realized on a limited chip area; the chip manufactured by using the JCD integration technology has good comprehensive performance and is favorable for the development of the single chip power system integration.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

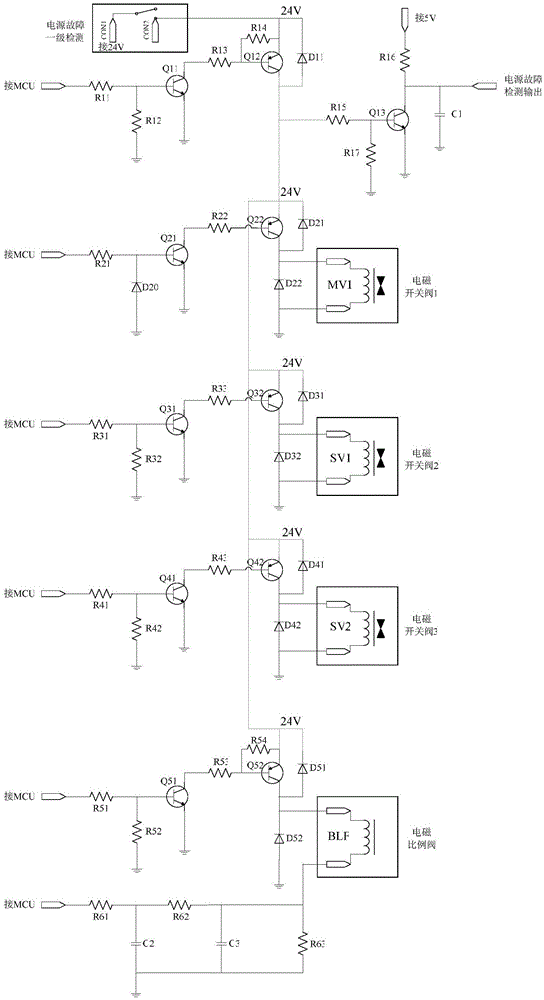

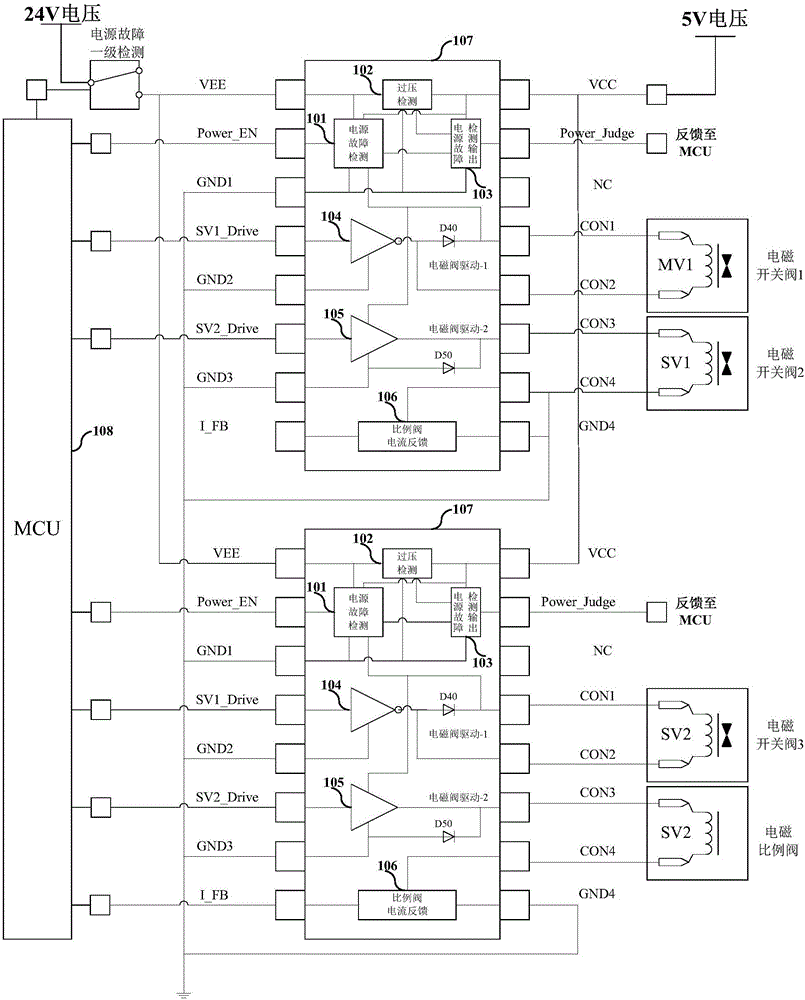

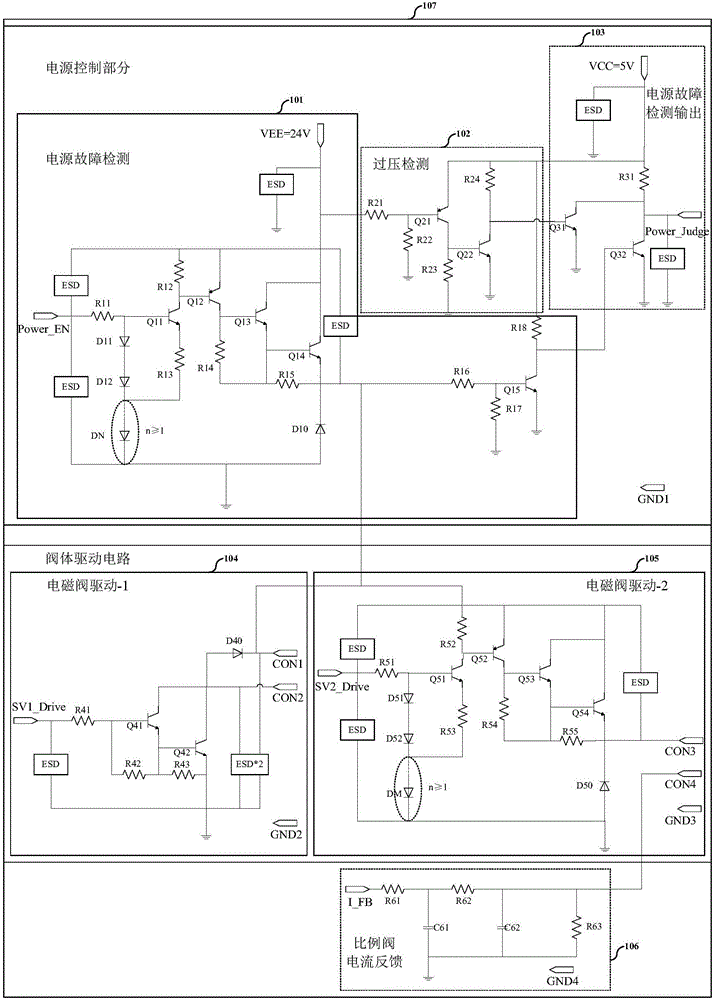

Electromagnetic valve drive circuit for fuel gas system

ActiveCN106369212AImprove consistencyHighly integratedOperating means/releasing devices for valvesExtensibilityControl signal

The invention discloses an electromagnetic valve drive circuit for a fuel gas system. The electromagnetic valve drive circuit for the fuel gas system is characterized by comprising a control unit and a plurality of drive chips, wherein a plurality of electromagnetic valve drive circuit units are integrated in the drive chips, the control unit is used for receiving control signals and sends the control signals to the drive chips selectively, the drive chips receiving the control signals control the corresponding electromagnetic valve drive circuit units to work and output drive signals to drive corresponding electromagnetic switching valves. By means of integration of the electromagnetic valve drive circuit units, the whole circuit design is simplified, PCB (printed circuit board) wiring is simplified, welding spots exposed outside are reduced, the overall reliability and safety of the system are improved, besides, the circuit extensibility is better, and the circuit can better meet the requirement of actual application.

Owner:CRM ICBG (WUXI) CO LTD

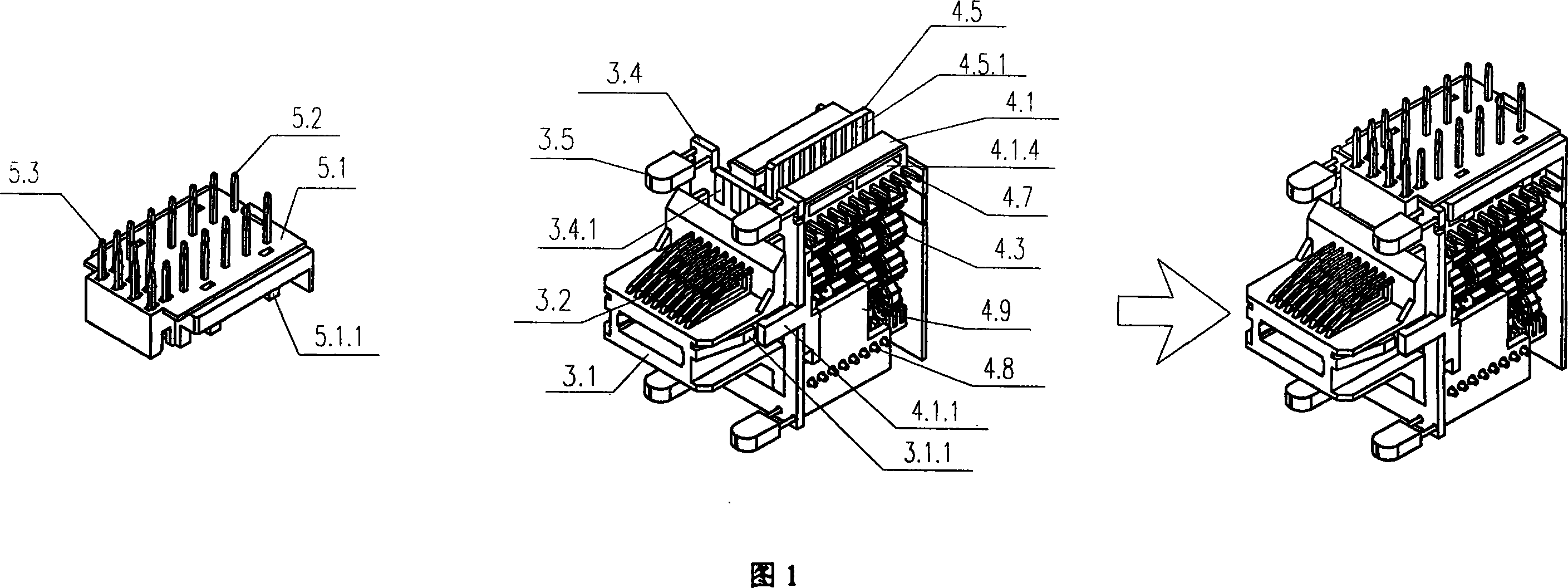

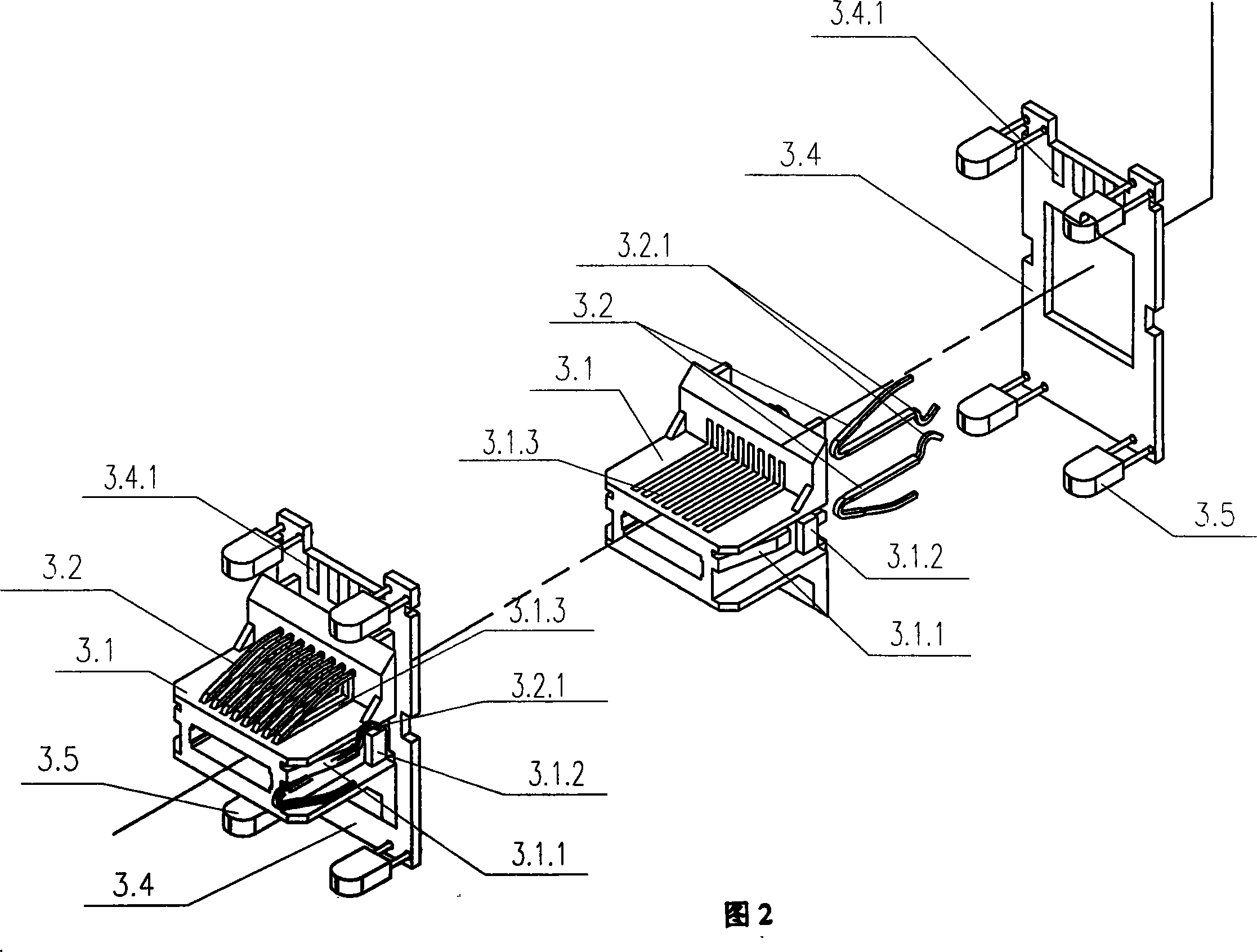

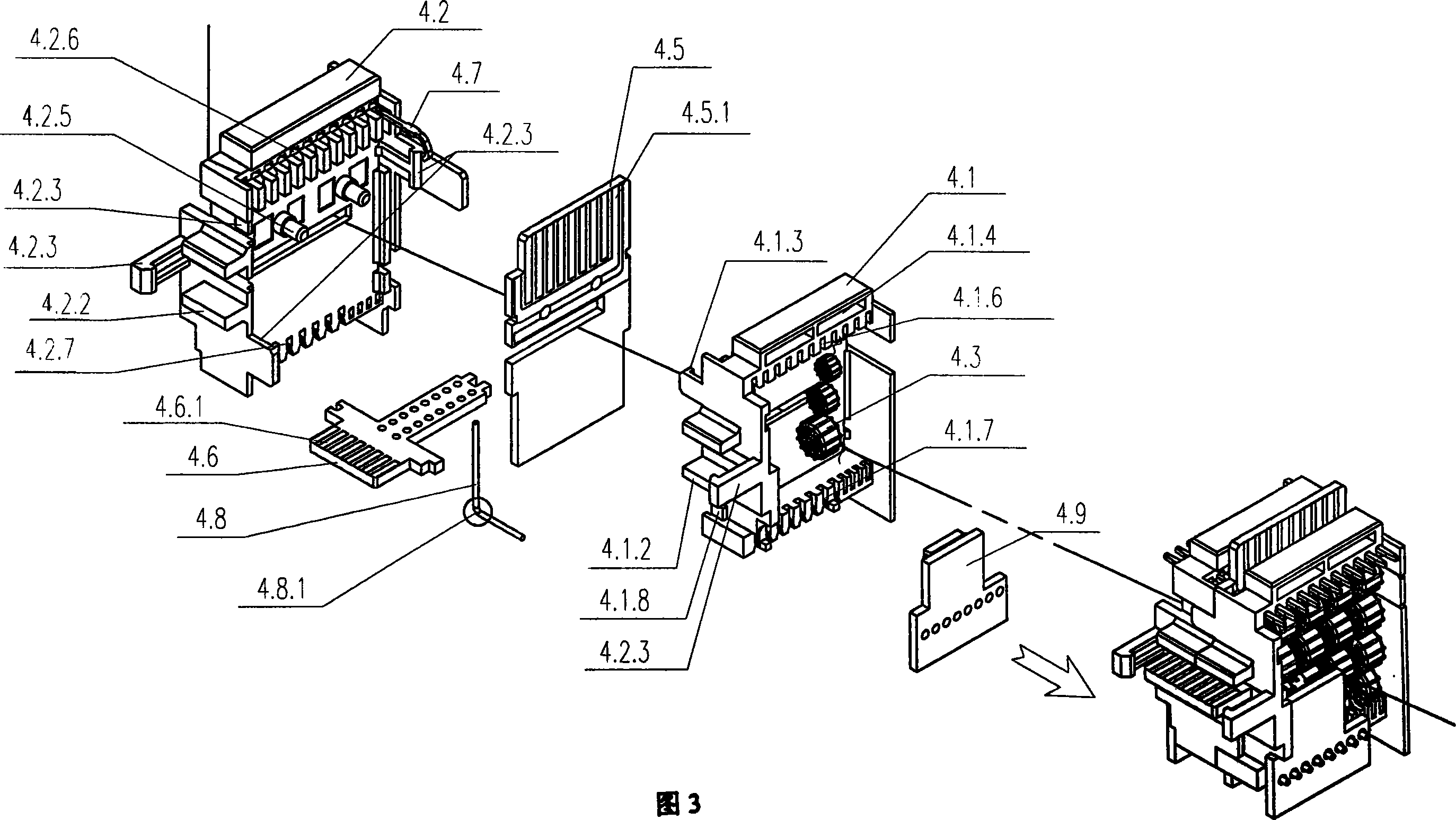

Novel multi-function RJ45 connector structure

InactiveCN101055960AEasy to installFor convenience, do not installCoupling device detailsTwo-part coupling devicesElectricityTransformer

The invention relates to a new multi-function RJ45 kind connector structure, comprising a module (A), a module (B) and a module (C). The module (A) comprises a golden needle I(3.2) and an electrical signal lamp submodular, which contains a signal lamp board (3.4); the module B comprises a plug I(4.5) and a plug II(4.6); the module(C) comprises a pin I(5.2) and a pin II(5.3). The gold needle I(3.2) and the plug II(4.6) adopt a pin board electrical connection; the signal lamp board (3.4) and the pin II(5.3) adopt a pin board electrical connection; and the plug I(4.5) and the pin I(5.2) adopt a pin board electrical connection. The said module B also includes an anti-thunder submodular (4.9). What the invention provides could be the two-in-one function of a RJ45 socket and a transformer, may also be three-in-one function of a RJ45 socket, a signal lamp and a transformer, and may also be four-in-one function of a RJ45 socket, a signal lamp, a transformer and an anti-thunder; the invention adopts a design for optimizing the internal elements division, reduces the element quantity, and reduces the circuit board quantity; and the invention leads into a pin board structure, accordingly significantly reducing solder joints, and simplifying the installation process.

Owner:HUALI COMP NETWORK ENG JIANGYIN CITY

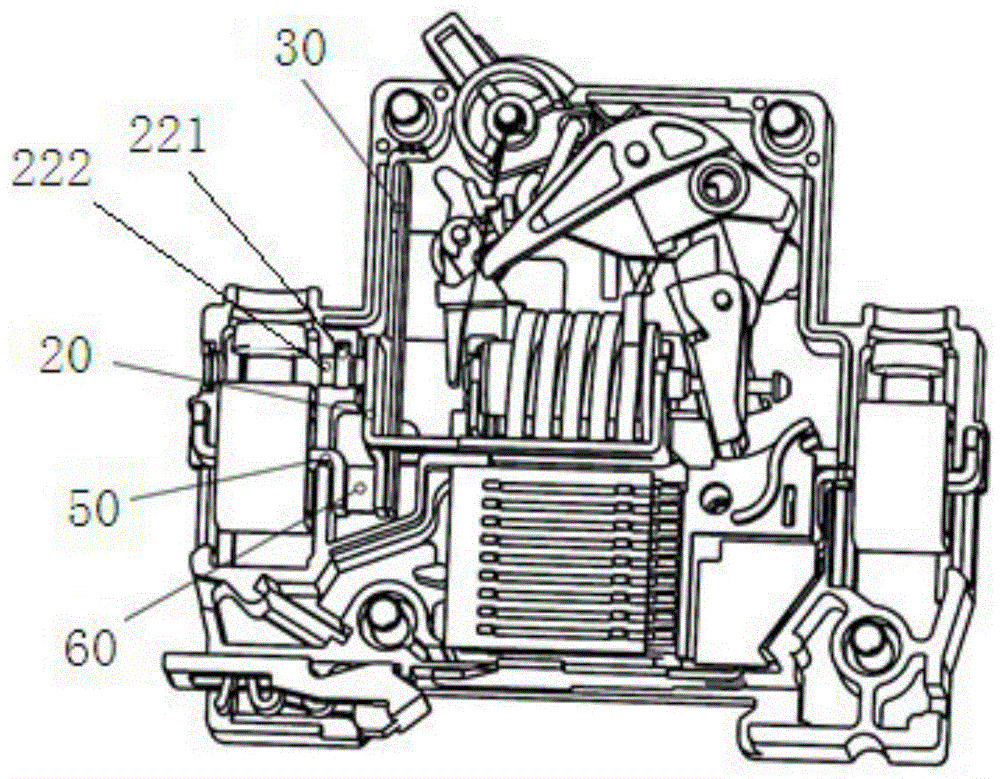

Heat tripping adjusting assembly

ActiveCN104465248ATrip controlReduce the degree of deformationProtective switch operating/release mechanismsCircuit breakerBimetallic strip

The invention discloses a heat tripping adjusting assembly. An adjusting piece is arranged on a baffle, and an adjusting key stretches to abut against a bimetallic strip, so that the bimetallic strip is close to a tripping mechanism. After the adjusting piece retracts, the bimetallic strip resets in an elastic mode and is away from the tripping mechanism. Therefore, the distance between the bimetallic strip and the tripping mechanism is adjusted through stretching and retracting of the adjusting piece on the baffle, so that the purpose of adjusting the tripping precision is realized. Compared with the arrangement mode that an adjusting piece is arranged on a breaker shell in the prior art, a magnet yoke in the heat tripping adjusting assembly is made of metal, the deformation degree of the magnetic yoke is small after temperature rises, the adjusting piece is arranged on the magnetic yoke with small deformation degree and directly abuts against the bimetallic strip, so that the heat tripping adjusting assembly can more precisely control tripping of a breaker.

Owner:DELIXI ELECTRIC

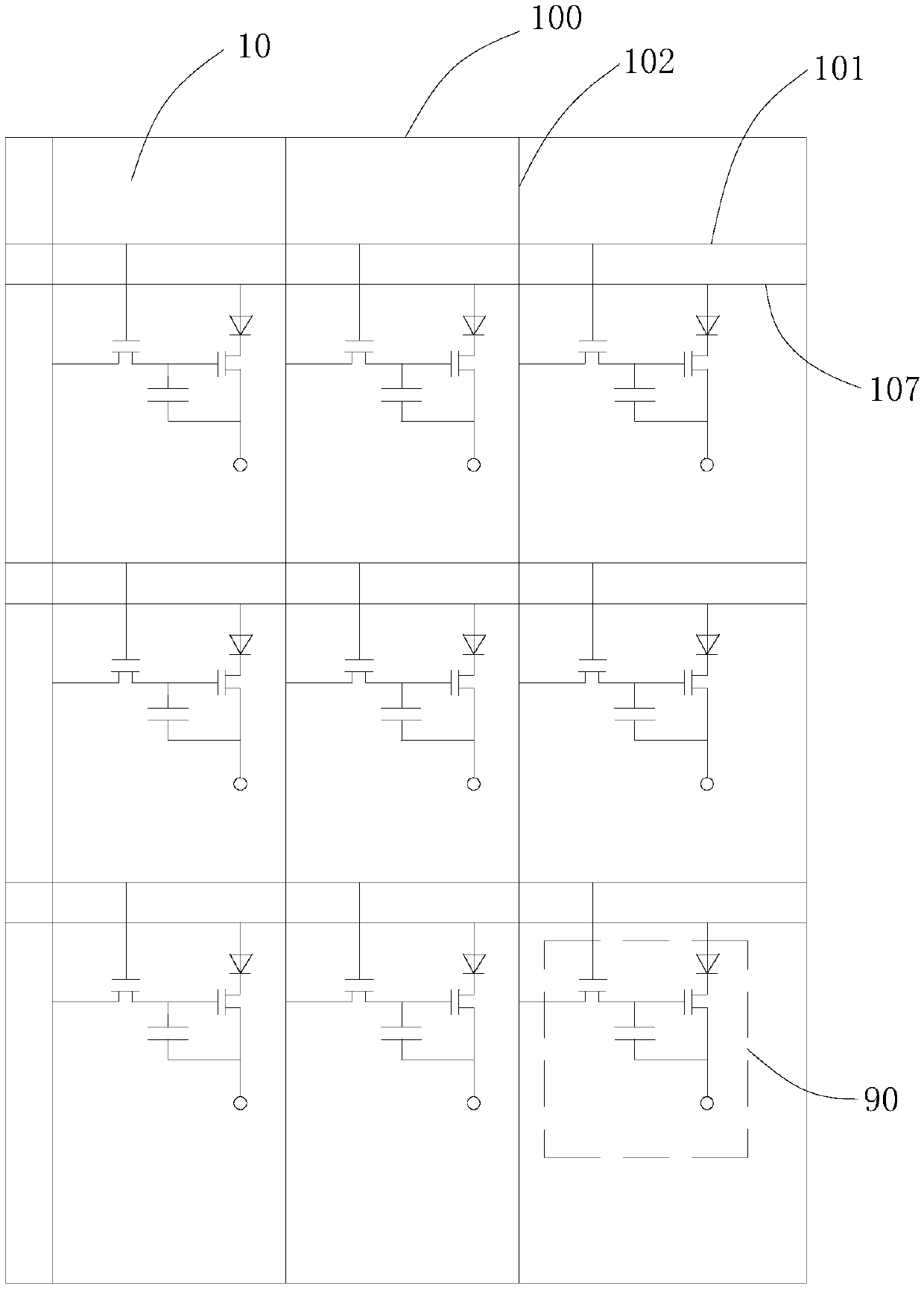

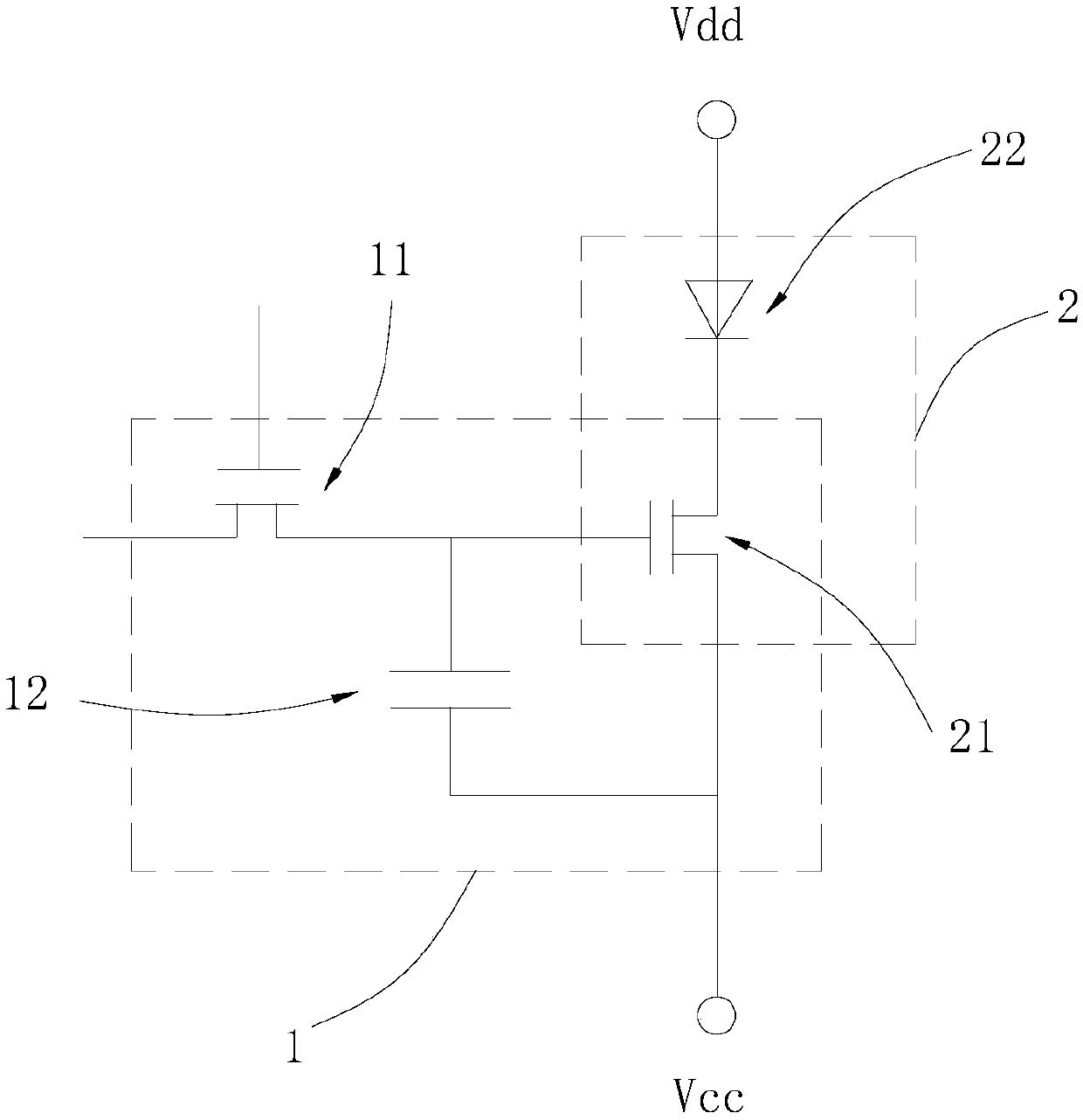

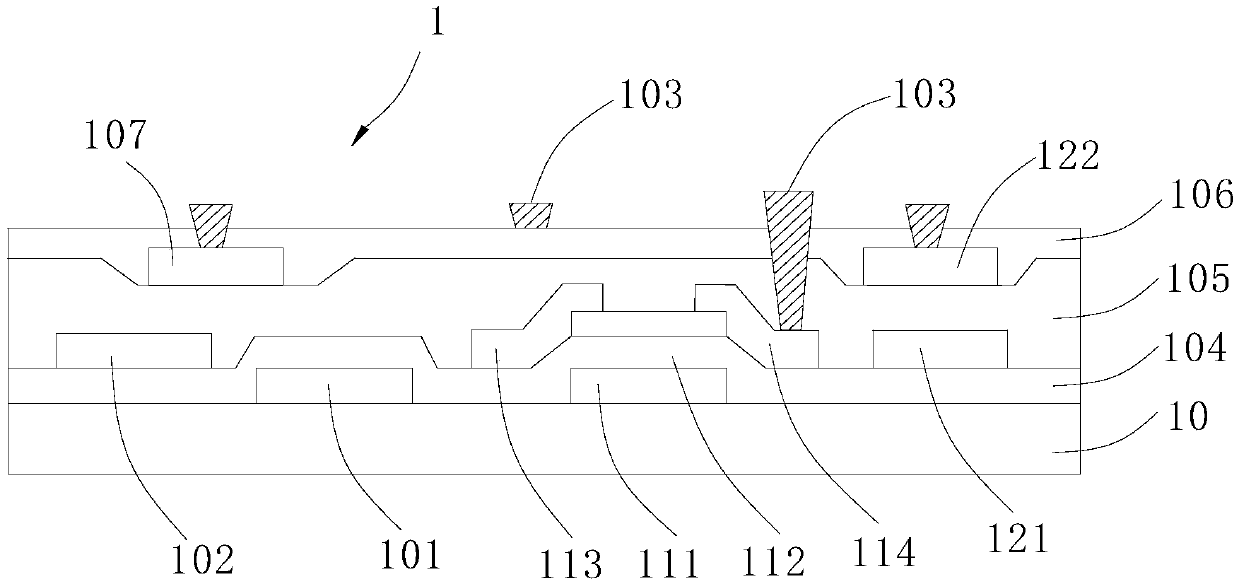

Light source plate, backlight module and display device

ActiveCN111290165ASimplify the manufacturing processMeet drive current requirementsStatic indicating devicesNon-linear opticsCapacitanceDriving current

The invention applicable to the technical field of display provides a light source plate, a backlight module and a display device. The light source plate comprises a driving substrate and a light-emitting packaging assembly. The driving substrate comprises a first substrate body, a switch element and a capacitor element, wherein the switch element and the capacitor element are arranged on the first substrate body. The light-emitting packaging assembly arranged on the driving substrate comprises a second substrate, a driving element and a light-emitting element, wherein the driving element andthe light-emitting element are packaged on the second substrate in a discrete element mode. According to the invention, the driving element and the light-emitting element are packaged on the second substrate in the form of discrete elements to form the light-emitting packaging assembly; the driving element can directly adopt an MOS tube discrete element capable of bearing a large driving current at present; the requirement for driving current of a light-emitting element used as backlight is met, the backlight technology that driving is conducted in an active driving mode is achieved, the driving substrate is easier to manufacture and larger in size, welding between the driving substrate and the light-emitting packaging assembly is simpler and more convenient, and operability of welding andassembling of the light source plate is simplified.

Owner:TCL CORPORATION

Method for embedding capacitors in printed-circuit board and printed-circuit board adopted by method

ActiveCN104780718AReduce the number of solder jointsSmall sizePrinted circuit assemblingMultilayer circuit manufactureCapacitanceEngineering

The invention discloses a method for embedding capacitors in a printed-circuit board and the printed-circuit board adopted by the method and belongs to the technical field of printed-circuit board manufacturing processes. According to the technical key point, the method comprises the following steps that (1) basic bodies are manufactured; (2) the basic body 1, the basic body 2, the basic body 3 and a metal layer are pressed by means of a multiple-layer board manufacturing process, one or more of the basic body 1, the basic body 2, the basic body 3 and the metal layer are combined and pressed to form a multiple-layer printed-circuit board, and the basic body 1 is arranged among the contact portions of the basic body 2, the basic body 3 and the metal layer; (3) drilling and metallization are performed; (4) outer-layer graph making is performed to form the multiple-layer printed-circuit board provided with multiple layers of embedded single capacitors and / or a multiple-layer single capacitor paralleled-connection structure. The method for embedding the capacitors in the printed-circuit board achieves accurate control of values of the embedded capacitors on the premise that additional cost is not needed to be increased, is simple in process and is used for manufacturing the printed-circuit board.

Owner:BOMIN ELECTRONICS CO LTD

Bridge combiner

The invention relates to a bridge combiner. The bridge combiner comprises a cavity, a bridge structure, filter structures composed of a plurality of resonators, and coupling structures. The bridge structure and the filter structures are integrated in the cavity, so that the structure is compact and the volume is reduced. The resonator of the first-cavity filter structure is electrically coupled with a bridge port of a bridge conduction band sheet through the corresponding coupling structures, coupling discs are not in direct contact with the resonators, and the conduction of signals between the bridge structure and the filter structures is realized in an electric coupling manner. Compared with a traditional structure, according to the bridge combiner, the bridge structure is connected withthe filter structures without using cables or connectors, and the welding operation can be reduced obviously, so that the quantity of welding spots is reduced. Moreover, one coupling structure can realize electric coupling with the filter structures simultaneously. Therefore, the structure of the bridge combiner can be simplified effectively.

Owner:COMBA TELECOM TECH (GUANGZHOU) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com