JCD integrated device integrated with VDMOS and preparation method thereof

A technology for integrating devices and device areas, which is applied in semiconductor/solid-state device manufacturing, electrical solid-state devices, semiconductor devices, etc., and can solve the problems of complex JFET device manufacturing process, rising manufacturing cost, and poor performance of compatible JFET devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

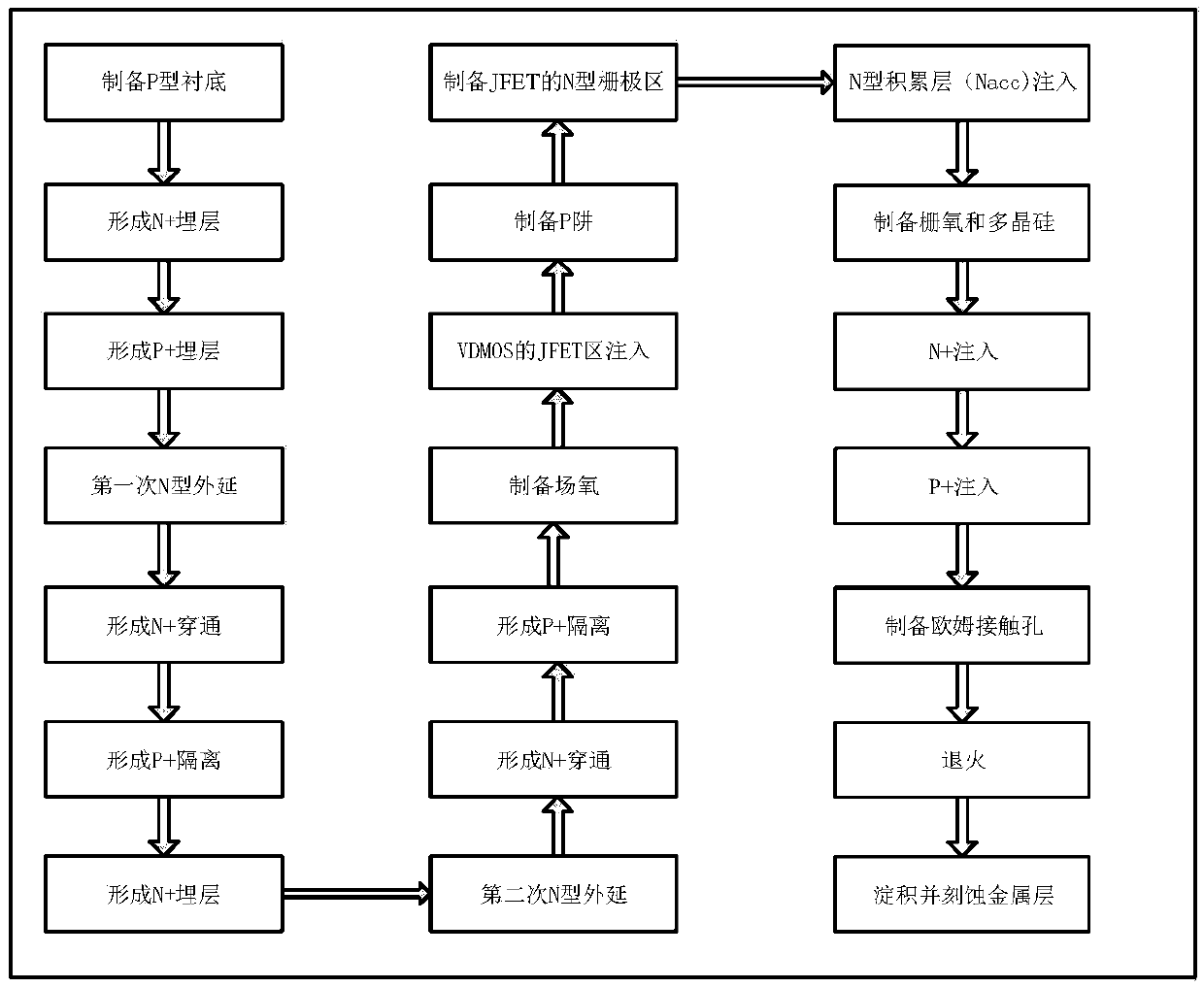

[0080] This embodiment provides a method for manufacturing a JCD integrated device based on N-type epitaxy, such as figure 1 Shown is a schematic diagram of the manufacturing process flow of the integrated device of the present invention, which specifically includes the following main process steps:

[0081] Step 1: Prepare the substrate;

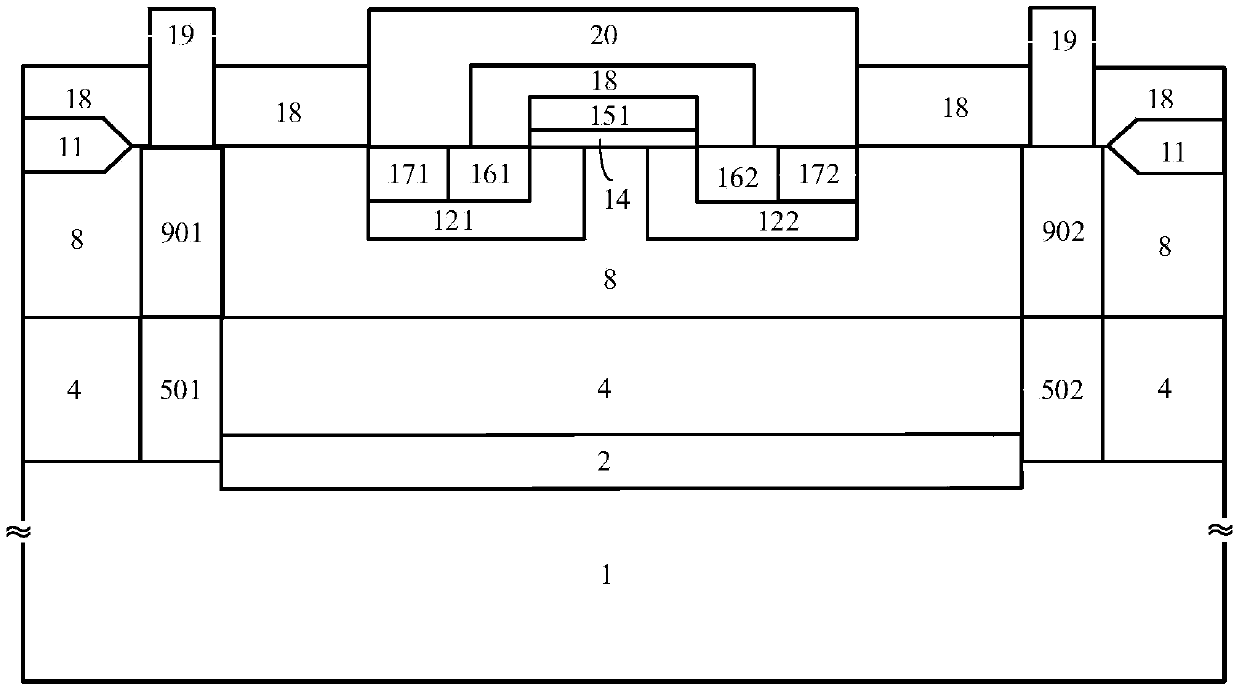

[0082] preparation A boron-doped silicon substrate with crystal orientation is used as the P-type substrate 1; in this embodiment, the P-type substrate 1 has a resistivity of 30-50Ω·cm and a substrate thickness of 550-750um;

[0083] Step 2: Form N+ buried layer;

[0084] On the surface of the high-voltage VDMOS device area of the P-type silicon substrate 1 prepared in step 1, the NBL1N Buried Layer plate is used for etching, and phosphorus is ion-implanted without high-temperature push to form an N+ buried layer 201; in this embodiment, the ion implantation energy 60KeV, ion implantation dose is 1e15~5e15cm -2 ;

[0085] Step 3: Form P+ buried ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com