Motor winding and winding method

A winding method and technology for motor windings, which are used in electric components, manufacturing of motor generators, shape/style/structure of winding conductors, etc., can solve the problem of unfavorable uniform magnetic field distribution and magnetic field conduction of multi-lobe stators, and product quality is difficult to control. The problem of high production cost, to reduce the quality weak point, eliminate the coil solder joint, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

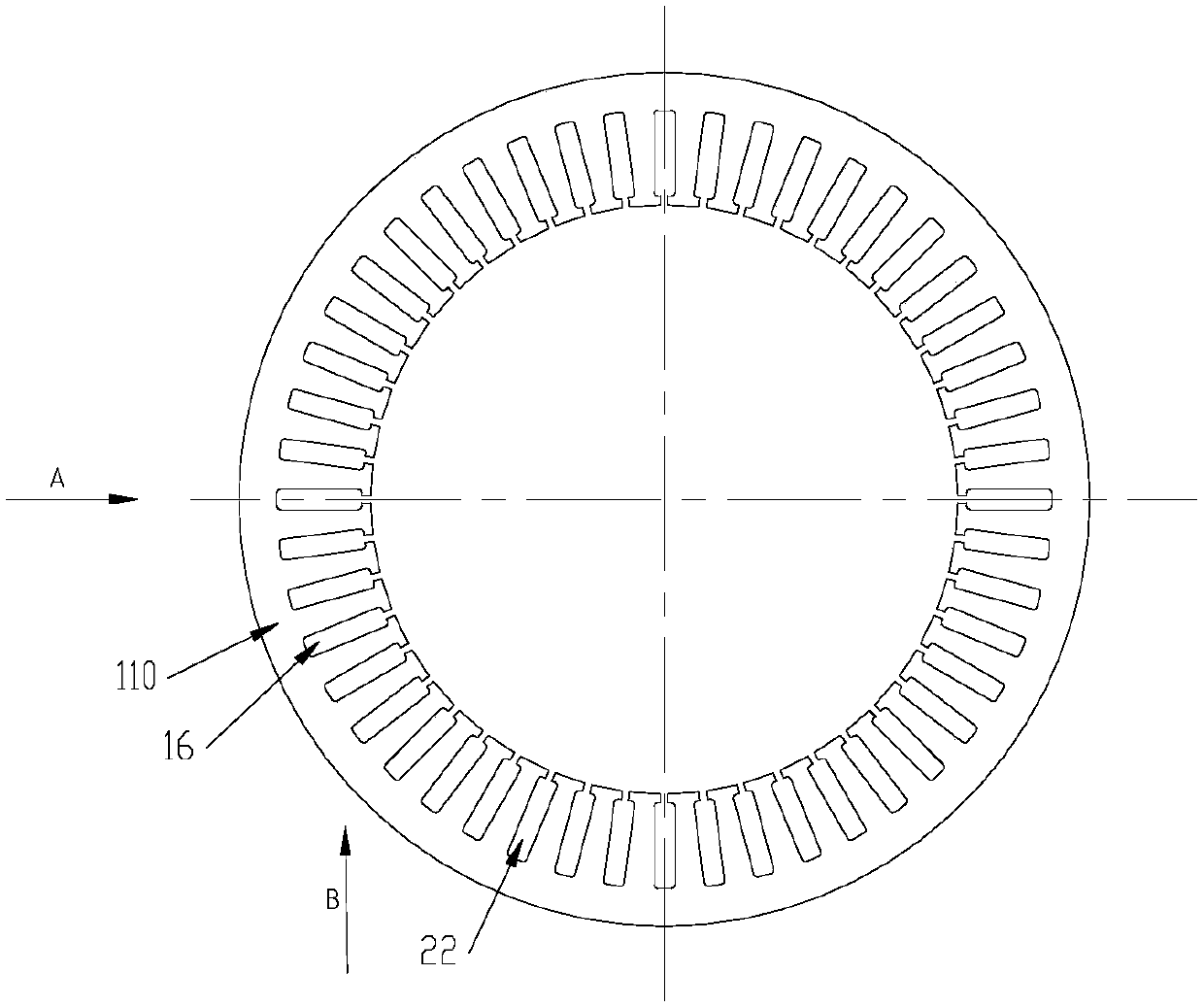

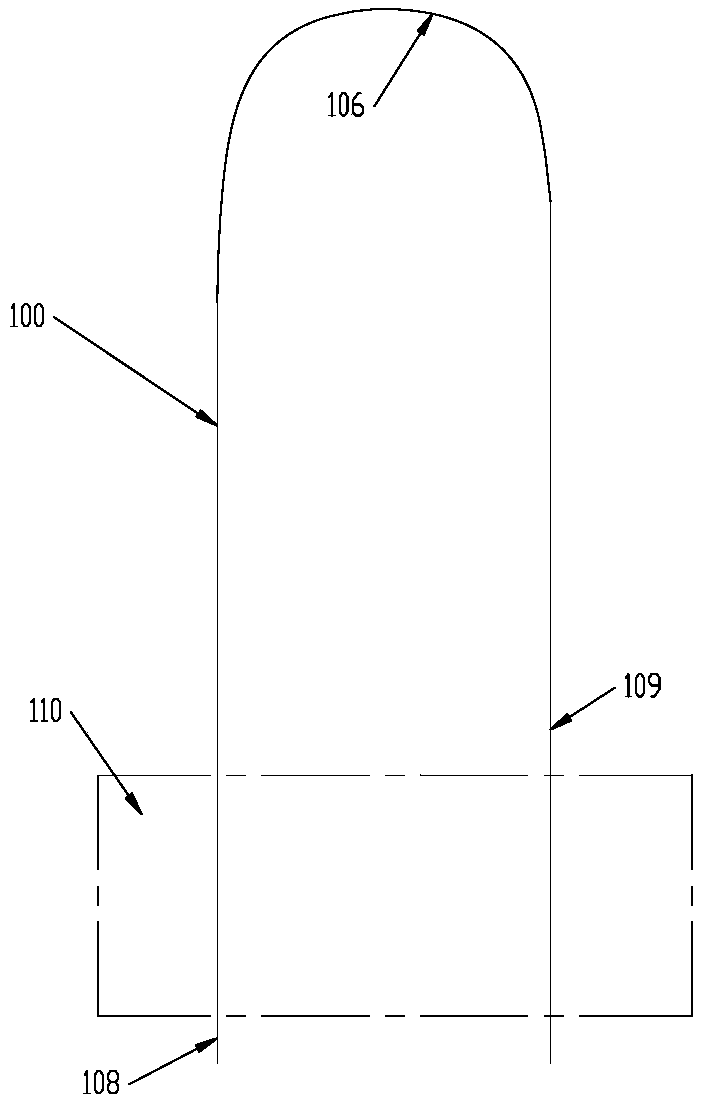

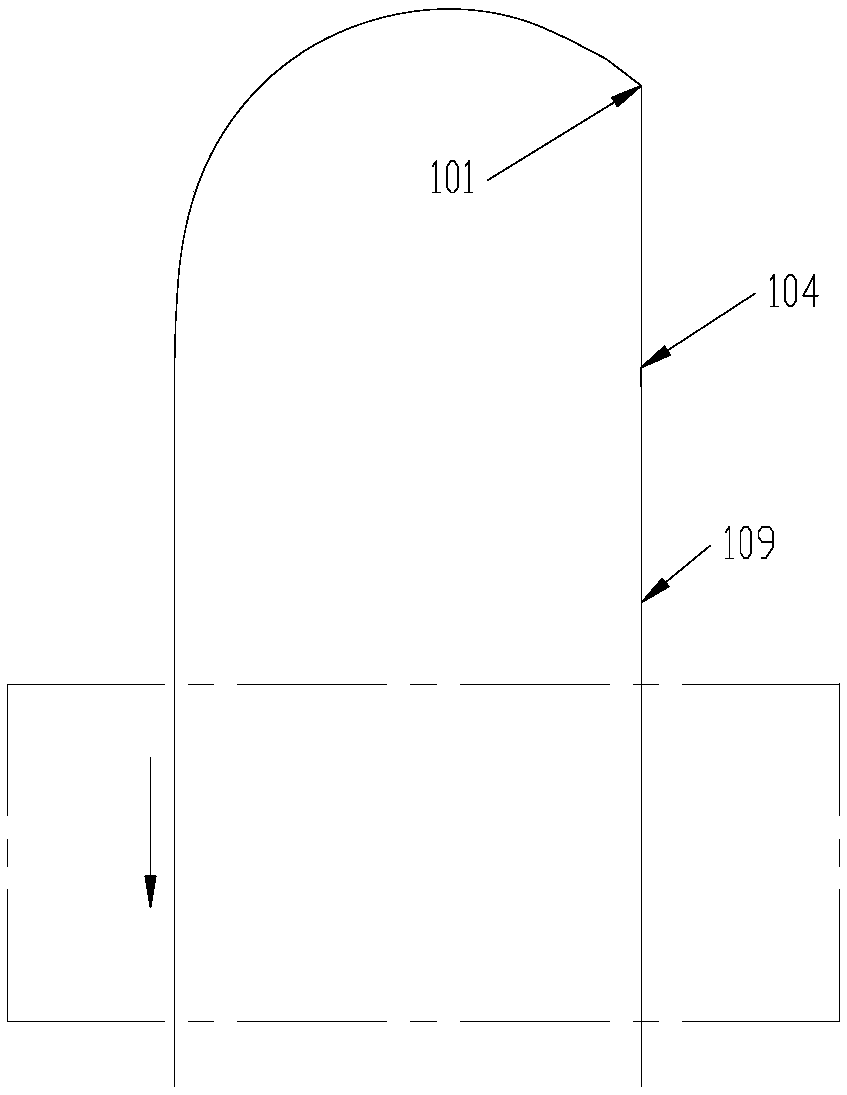

[0023] See Figure 2-7 The winding process of the one-turn coil shown in the winding method uses a long conductor 100 to pass through the slot 22 on the stator 110, and then the end of the conductor is turned back to form a U-shape 106, and the free end 108 of the conductor is removed from Insert the end of slot 16 into another slot 16 (see figure 2 ), the conductor is pulled through the wire slot 16, when the U-shaped part of the conductor is close to the iron core wire slot, while the conductor is being pulled, it is carried out at the first bending point 101 on the conductor leading end 109 drawn from the wire slot 22 First bend (see image 3 ), and then pull the conductor into the slot 16 gradually, and make a second bend at the second bending point 102 on the lead-out end of the conductor (see Figure 4 ), then insert the conductor into the wire slot 16, and perform a third bend at the third bending point 103 on the lead-out end of the conductor (see Figure 5 ), the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com