Heat tripping adjusting assembly

A technology for adjusting components and thermal tripping, applied in the direction of operation/release mechanism of protection switches, etc., can solve the problems of affecting the temperature rise performance of circuit breakers, high production costs, inability to accurately adjust tripping accuracy, etc., achieving a simple structure and reducing production. Difficulty and cost, the effect of stable temperature rise performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

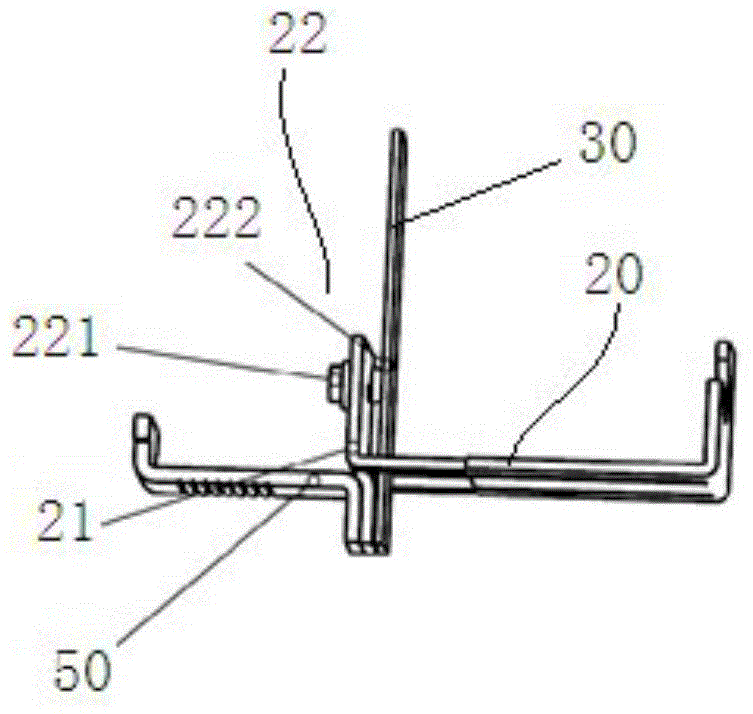

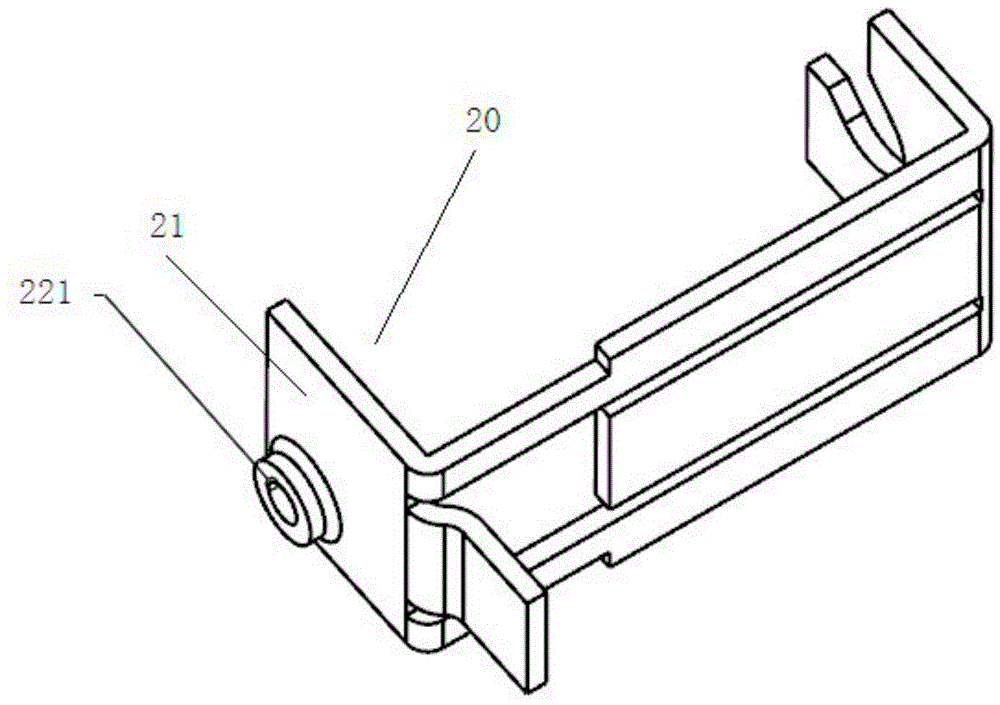

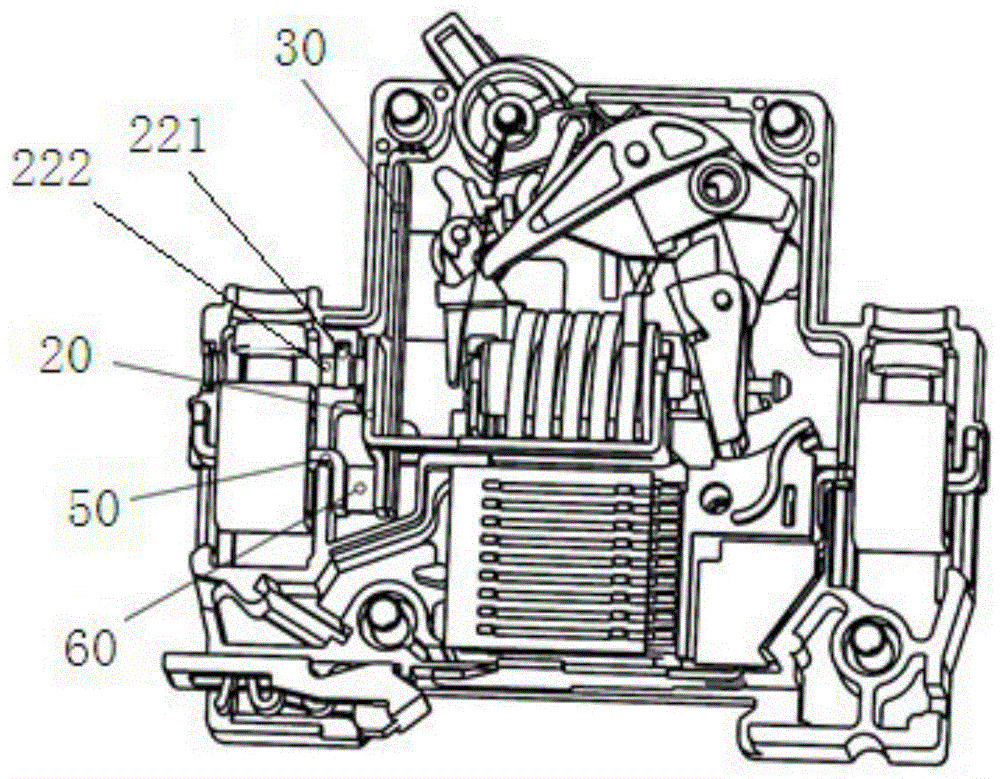

[0022] A thermal trip adjustment assembly of the present invention will be described in detail below with reference to the accompanying drawings.

[0023] refer to Figure 1-3 , this embodiment provides a thermal trip adjustment assembly, including a yoke 20 and a bimetal 30 arranged on the yoke 20, such as figure 1 , figure 2 As shown, the lower end of the yoke 20 has a punched opening, and the part complementary to the opening extends downwards, the bimetal 30 is arranged in the opening, and the end of the bimetal 30 It is connected with the end of the magnetic yoke 20 by welding. A side of the yoke 20 close to the bimetal 30 is provided with a baffle 21 , and the baffle 21 is formed by bending one end of the yoke 20 . The adjusting member 22 is arranged on the baffle plate 21, and the adjusting member 22 is stretched to resist the bimetallic strip 30, so that the bimetallic strip 30 is bent toward the side close to the tripping mechanism; or the adjusting member 22 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com