GAP SEAL device

A technology for sealing devices and gaps, which is applied in the direction of sealing devices, windows/doors, building components, etc., and can solve the problems of sealing device wear, failure to meet sealing requirements for a long time, and large size of sealing strips, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

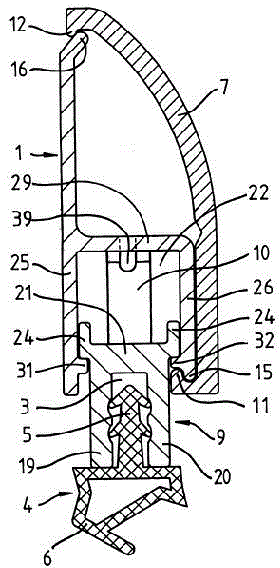

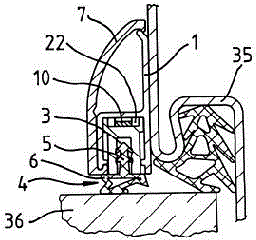

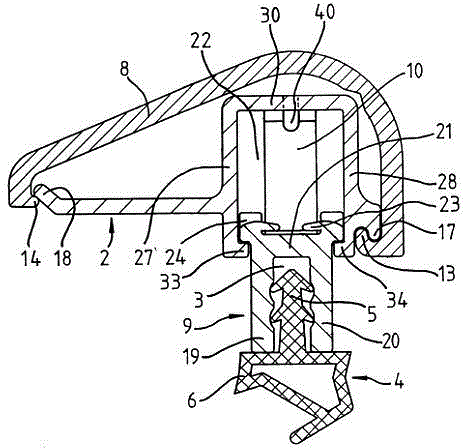

[0019] The gap sealing device of the present invention will be further described below through two embodiments with reference to the accompanying drawings.

[0020] The gap sealing device of the present invention, if used to seal the gap between the door leaf and the door frame, then consists of the fixing strip 1, and if used to seal the gap between the two door leaves, then consists of the fixing strip 2. Both fixing strips 1 and 2 are approximately U-shaped in cross-section, while the narrower built-in strip 9 , which also has a U-shaped cross-section, extends into the fixing strip. An installation groove 3 is provided in the built-in strip 9 for installing the sealing strip 4, and the sealing strip 4 is composed of a fixed part 5 and a shorter sealing part 6, and the fixed part 5 is installed in the installation groove 3 of the built-in strip 9. The possible elastic movement distance of the built-in strip 9 in the fixed strips 1 and 2 is greater than the deformation of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com