Steel bar positioning structure for building construction

A positioning structure and building construction technology, applied in the direction of building structure, construction, building materials processing, etc., can solve the problems of easy displacement and deflection of steel bars, inconvenient disassembly, inconvenient handling and transportation, etc., to achieve improvement Overall stability, ease of handling, and strength-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

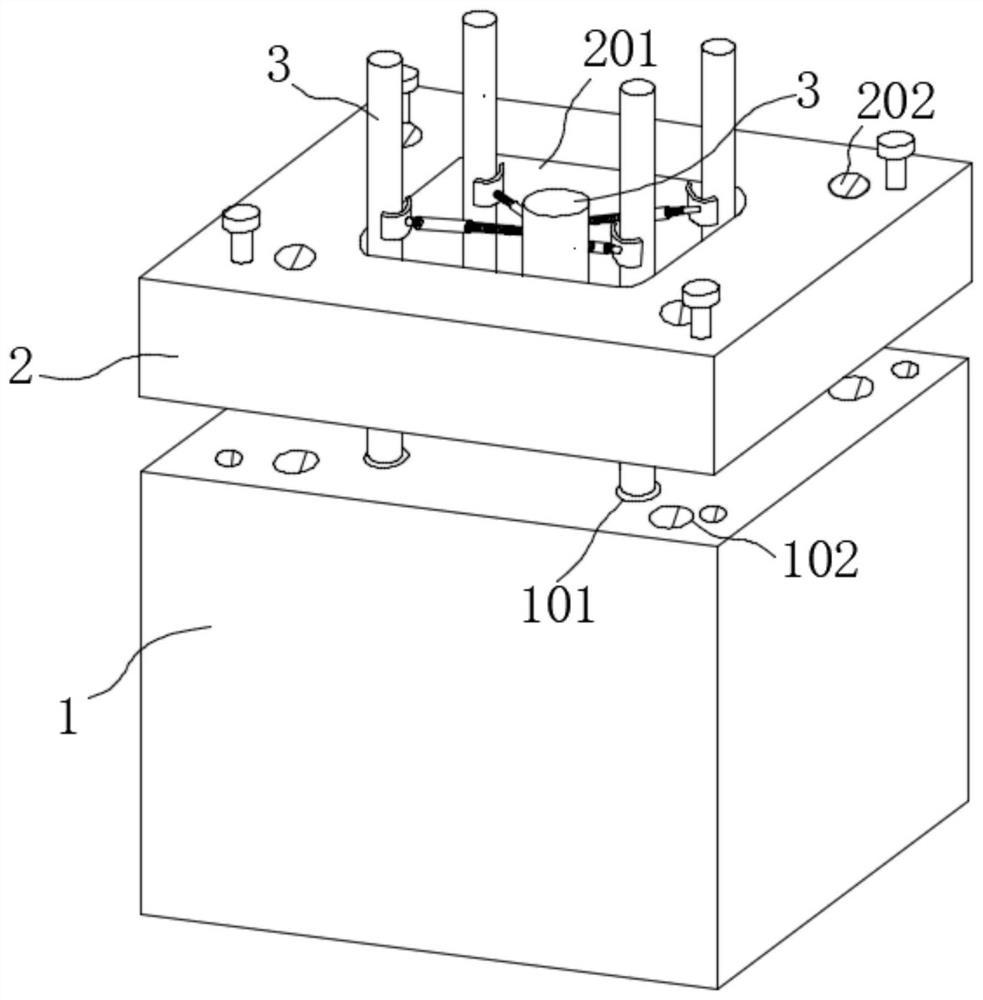

[0026] Example 1: See Figure 1-2 , the present invention provides a technical solution: a steel bar positioning structure for building construction, including a positioning seat 1, a positioning template 2 and a first positioning mechanism, the positioning seat 1 is in the shape of a rectangular column and its end is provided with a through-type multiple A first through hole 101 and a second through hole 102, the four corners of the end of the positioning seat 1 are provided with first screw holes; a plurality of the first through holes 101 and the second through holes 102 are distributed in the positioning seat in a rectangular array 1 end face, the first through hole 101 is located inside the second through hole 102, and the inside of the first through hole 101 and the second through hole 102 are both pierced with steel bars; the positioning template 2 is placed directly above the positioning seat 1, and the positioning template 2 The four corners are connected and matched ...

Embodiment 2

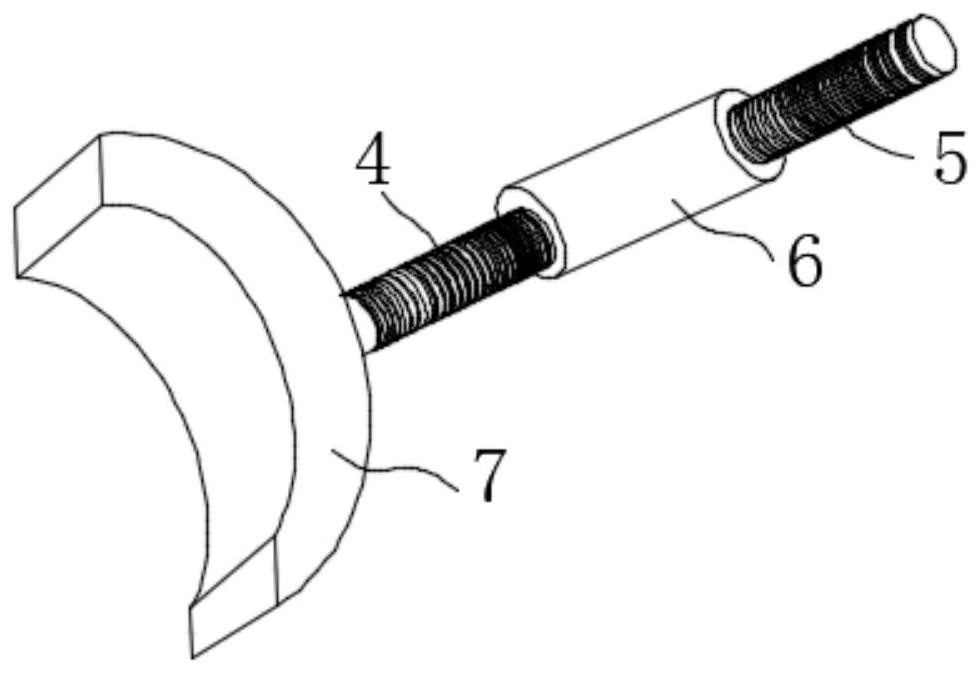

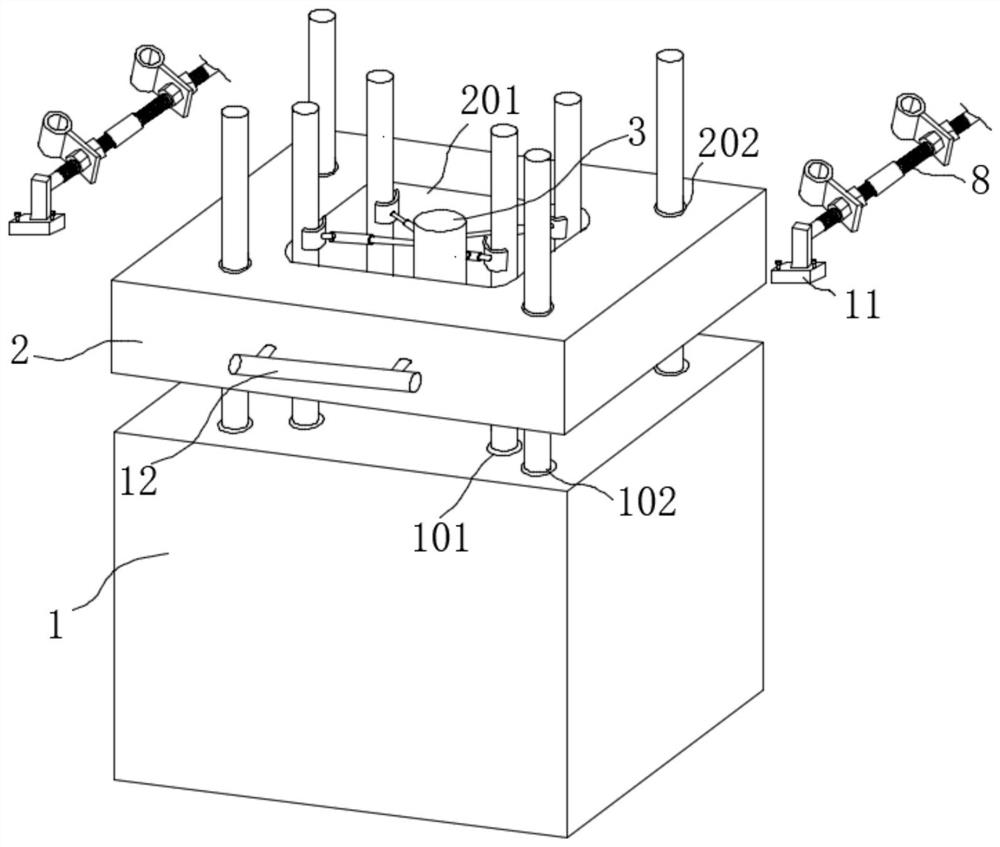

[0030] Example 2: see Figure 3-5, the present invention provides a technical solution: a steel bar positioning structure for building construction, including a positioning seat 1, a positioning template 2, a first positioning mechanism and a second positioning mechanism, the positioning seat 1 is in the shape of a rectangular column and its end is set There are a plurality of through-type first through holes 101 and second through holes 102 , and first screw holes are provided at the four corners of the end of the positioning seat 1 . The second positioning mechanism includes a mounting seat 11, a third screw rod 8, a nut 10 and a steel bar positioning cylinder 9. The mounting seat 11 is in a T shape and is fixed to the four corners of the end of the positioning template 2 by screws. A third screw rod 8 is connected between the seats 11; the third screw rod 8 includes two threaded sections 801 and a limiting section 802, and the two threaded sections 801 are connected to both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com