Manufacturing device of artificial turf hollow particles

A technology for manufacturing devices and artificial turf, which is applied in the field of rubber product equipment manufacturing, can solve problems such as impact, and achieve the effects of increasing comfort, reducing force, and increasing cushioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

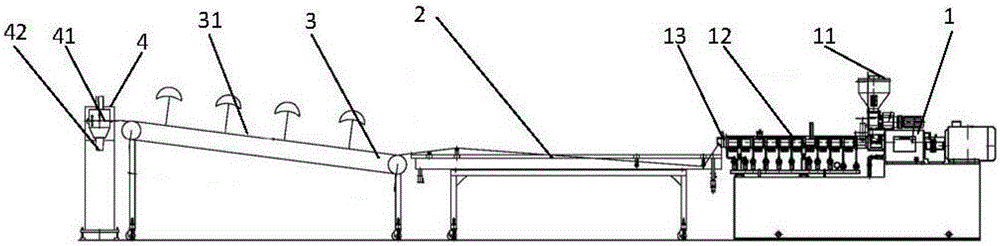

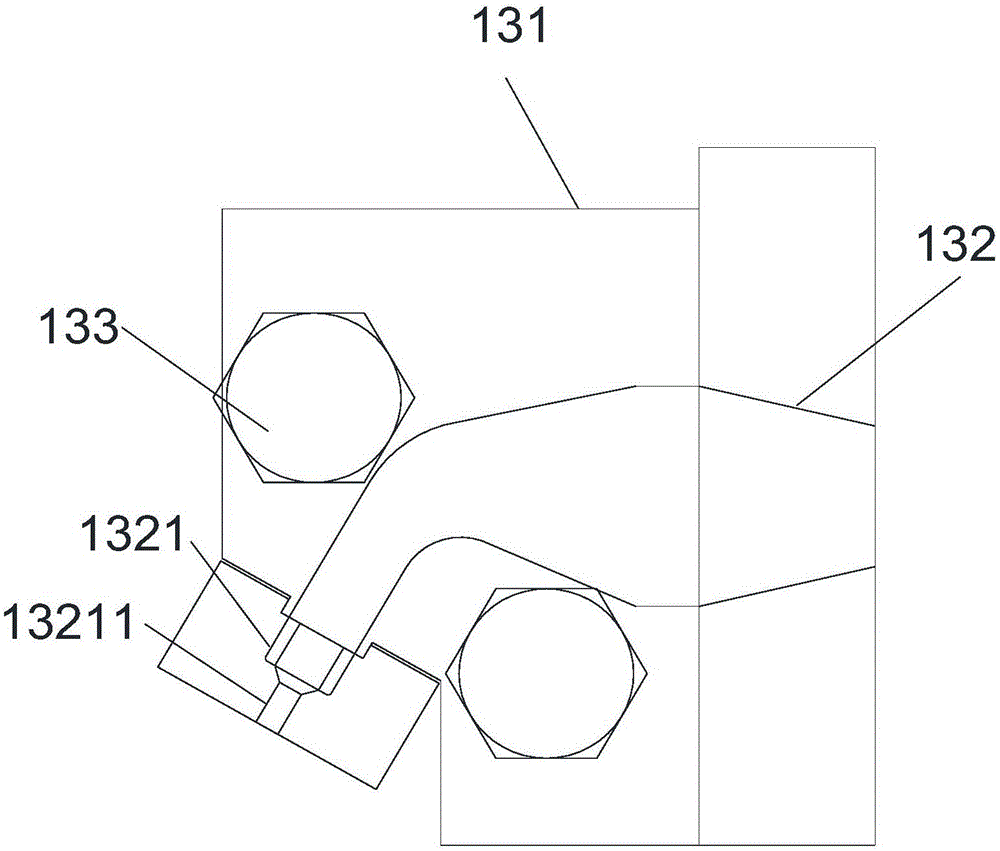

[0029] refer to figure 1 and combine figure 2 , the invention discloses a manufacturing device for artificial turf hollow particles, comprising an extruder 1, a cooling device 2, a delivery device 3 and a pelletizer 4; the extruder 1, the cooling device 2, the delivery device 3 and the cutter Granulator 4 is connected successively; Described extruder 1 comprises feeder 11, vacuum exhaust device 12 and die head 13; Described vacuum exhaust device 12 is connected with feeder 11 by intubation; Described die head 13 is installed on the vacuum exhaust device 12; the die head 13 includes a housing 131, a flow channel 132 and a heating element 133; the flow channel 132 and the heating element 133 are installed inside the housing 131; the heating element 133 is installed on the side wall of the flow channel 132; the heating element 133 is two, respectively arranged on both sides of the flow channel 132; the feed end of the flow channel 132 communicates with the discharge port of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com