Solder paste detection threshold optimization method based on SMT big data

An optimization method and detection threshold technology, applied in the direction of gene models, genetic rules, instruments, etc., can solve the problems of SPI equipment misjudgment and missed judgment, reduce the final yield of products, manual maintenance, etc. The number of connected tins, the improvement of production efficiency and product yield, the effect of good global optimization and parallelism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

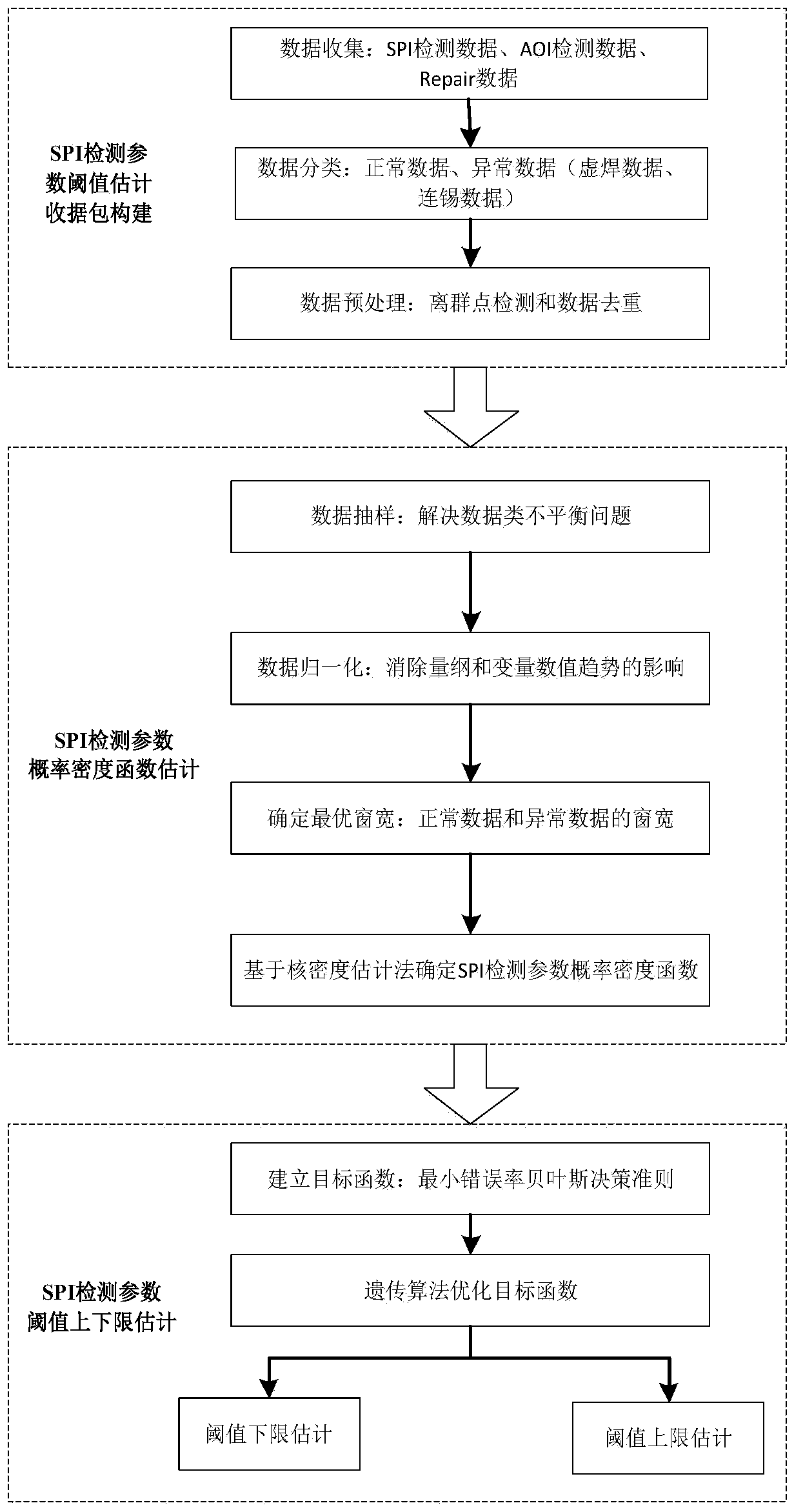

[0032] The traditional SPI threshold setting mainly relies on the professional knowledge and experience of the operator. Only by printing a PCB board first can the empirical threshold be obtained. The obtained threshold lacks theoretical guidance and greatly reduces production efficiency. This method is also contrary to the intelligence and high efficiency of the modern manufacturing industry. For this problem, the present invention proposes a SPI threshold optimization method based on SMT big data after research. See figure 1 , including the following steps:

[0033] (1) Build a threshold estimation data package:

[0034] (1a) Data collection: For pads printed by surface mount technology of the same package type, collect historical data generated during the SMT production process. The collected data includes historical data of three main stations, which are SPI detection data, AOI automatic optical inspection data and Repair maintenance data. SPI inspection data mainly incl...

Embodiment 2

[0048] The SPI threshold optimization method based on SMT big data is the same as embodiment 1, and the establishment objective function described in step (3a) includes the following steps:

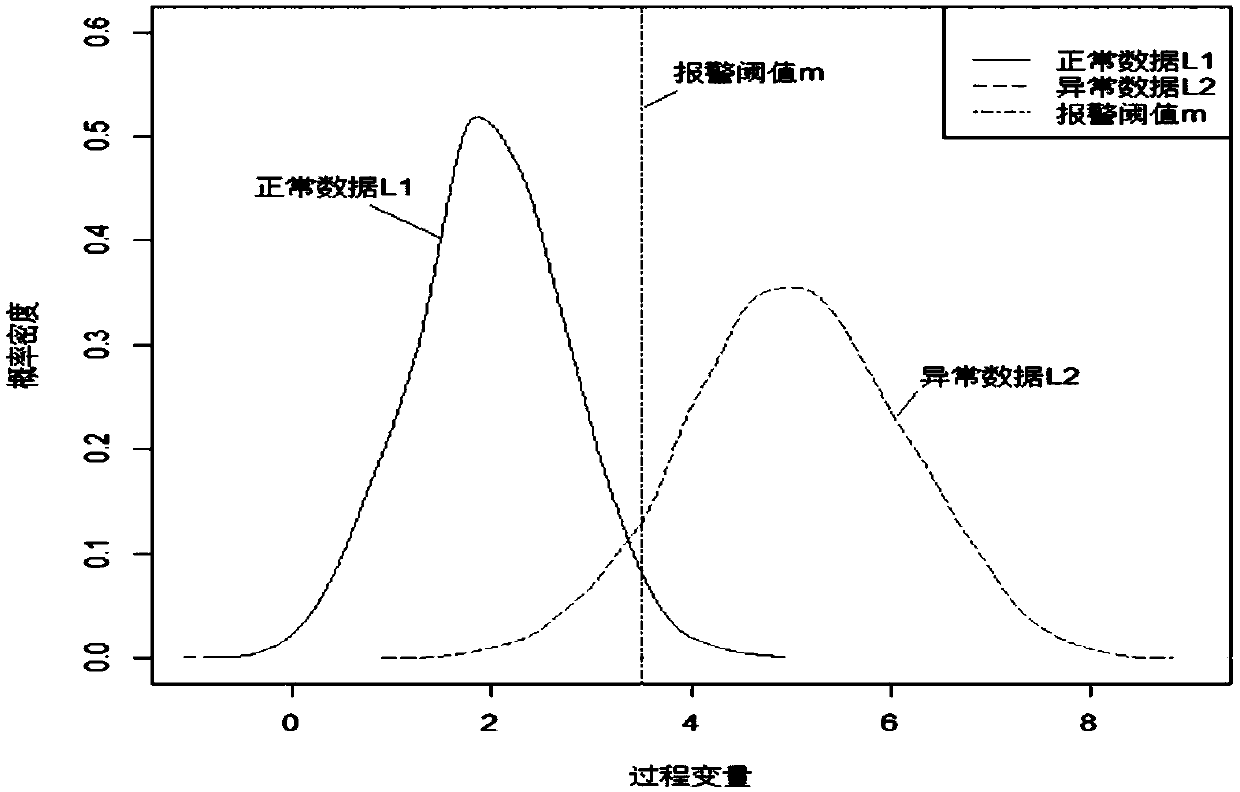

[0049] (3a1) Establishing the objective function: According to the minimum error Bayesian decision theory, calculate the SPI misjudgment rate and missed judgment rate, and the expressions of the SPI misjudgment rate and missed judgment rate are shown in the following formula.

[0050] The SPI misjudgment rate is:

[0051]

[0052] The SPI missed rate is:

[0053]

[0054] In the formula, f(x|w 1 ) is the probability density function expression of normal data obtained in step (2d); f(x|w 2 ) is the probability density function expression of the abnormal data obtained in step (2d); t is the solder paste SPI detection value, and the solder paste SPI detection value includes solder paste volume, solder paste area, solder paste height in the present invention, they all They have their...

Embodiment 3

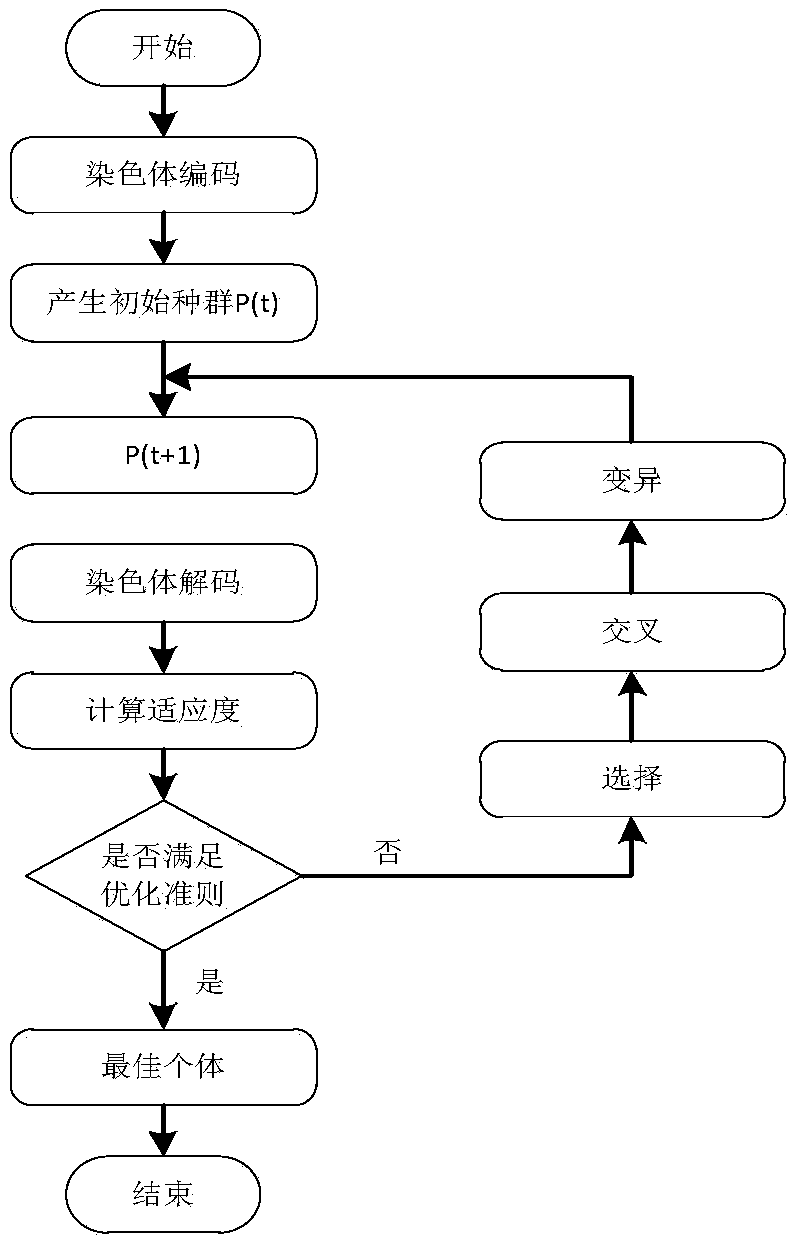

[0060] The SPI threshold optimization method based on SMT big data is the same as that in Embodiment 1-2. In step (3b), the objective function is optimized using a genetic algorithm to obtain the optimal threshold for SPI detection.

[0061] In the present invention, the optimization process involved in the genetic algorithm process optimized for detection threshold is described as follows:

[0062] (3b1) Customize the population size, crossover probability, and mutation probability. The population size is the number of initial generation thresholds; the crossover probability is the probability of individual crossover within each population; the mutation probability is the probability of gene mutation from the current generation population to the next generation.

[0063] (3b2) Initial population: Randomly generate the initial population according to the user-defined population size, and each individual represents the genotype of the chromosome. For example, if the custom pop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com