Method for manufacturing substrate of embedded element

A technology of embedded components and manufacturing methods, which is applied in the direction of semiconductor/solid-state device manufacturing, electrical components, and printed circuits connected with non-printed electrical components. Components are embedded in the substrate, affecting the alignment of embedded components and contacts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

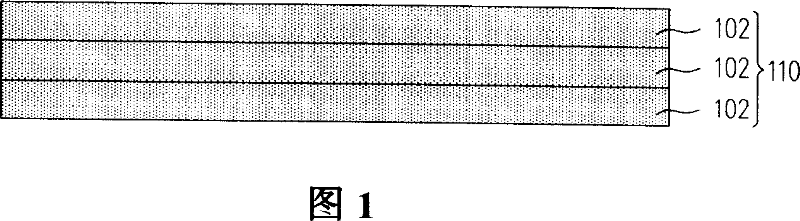

[0031] FIG. 1 to FIG. 10 are schematic diagrams sequentially illustrating a method for manufacturing a substrate with embedded components according to a first embodiment of the present invention. First, as shown in FIG. 1 , a core layer 110 is provided, and the core layer 110 is composed of a multi-layer first insulating layer 102 . Wherein, the form of the first insulating layer 102 can be a semi-cured state between liquid and solid, and its material is, for example, glass-oxygen resin (FR-4, FR-5), bismaleic acid imide Impregnation (preprag) insulating materials such as amine (Bismaleimide-Triazine, BT) or epoxy resin (epoxy resin). Since the first insulating layer 102 is in a semi-cured state, the first insulating layer 102 has both a fluid deformation property and a solid particle aggregation property, and the first insulating layer 102 is easily thermoset by being heated.

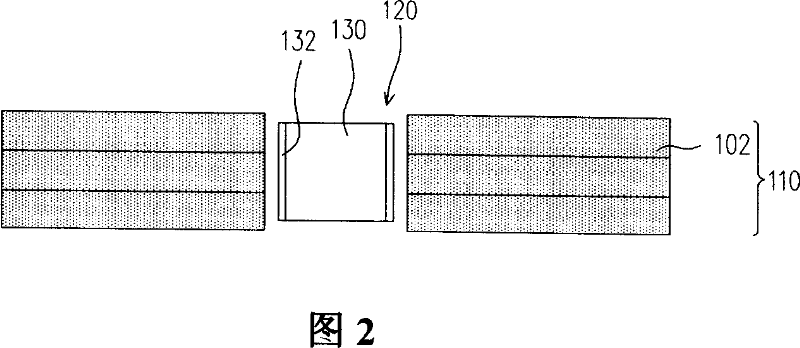

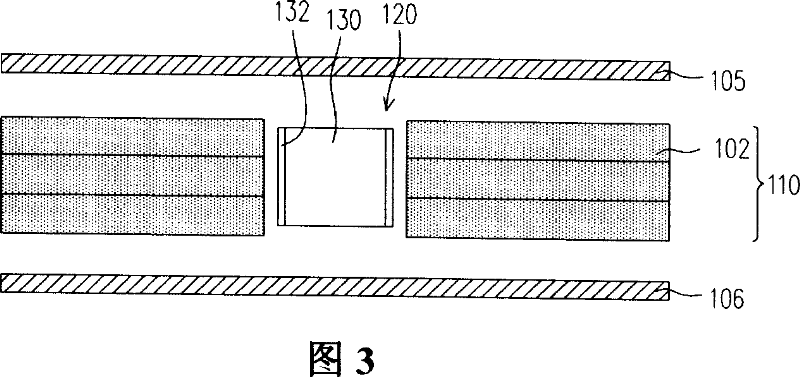

[0032] Next, as shown in FIG. 2, a buried hole is formed in the core layer 110, such as a through ...

no. 2 example

[0043] FIG. 11 to FIG. 20 are schematic diagrams sequentially illustrating a method for manufacturing a substrate with embedded components according to the second embodiment of the present invention. Wherein, the substrate manufacturing process of the embedded components in FIGS. 11 to 14 is the same as the substrate manufacturing process of the embedded components in FIGS. 1 to 4 in the first embodiment, and will not be repeated here.

[0044] Please refer to FIG. 15 and FIG. 16 at the same time, so that the embedded element 130 is electrically connected to the metal layer 105 . Wherein, the step of electrically conducting the embedded element 130 and the metal layer 105 may be to use laser drilling first, and then form a drill hole 140 in the core layer 110, and expose the electrode 132 of the embedded element 130, as shown in FIG. 15 shown. Then, electroplating is used to fill the drilled hole 140 with a conductive material, so that the conductive column 142 is formed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com