Micro heat exchanger with small hole throttling function

A heat exchanger, miniature technology, applied in the direction of heat exchanger types, indirect heat exchangers, heat exchange equipment, etc., can solve problems such as mismatched heat transfer, excessive volume, difficult to weld throttling components, etc., and achieve layout The effect of flexibility, simple layout and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be described below in conjunction with the accompanying drawings and specific embodiments. In the following description, the refrigerant refers to the refrigerant used in the vapor compression refrigeration system, such as R22, R134a, R407c, R410a, etc.; and the fluid refers to another refrigerant that exchanges heat with the refrigerant, Such as water, ethylene glycol aqueous solution, air, refrigerant, etc.

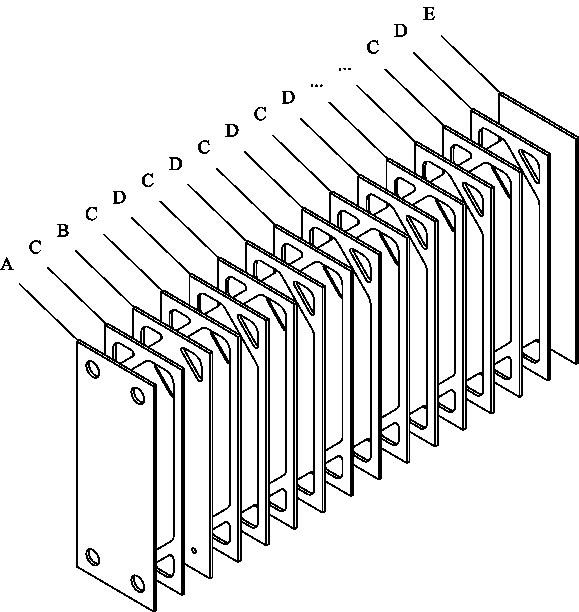

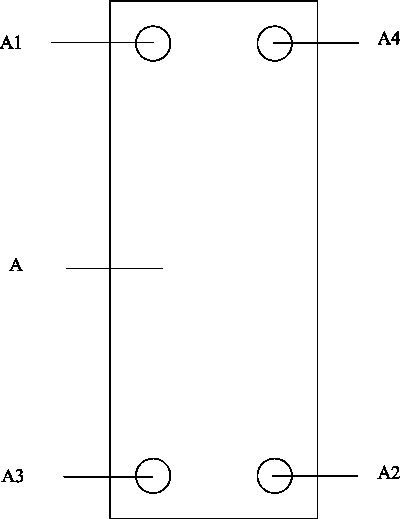

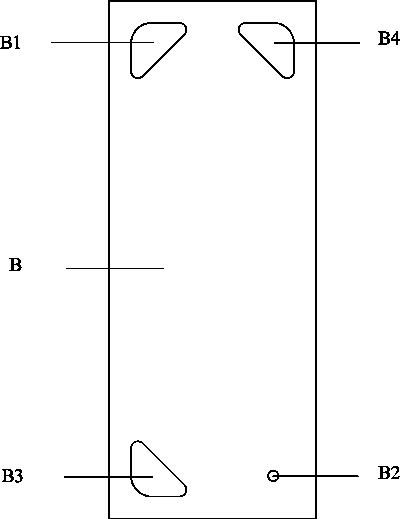

[0027] like figure 1 As shown, according to a specific embodiment of the present invention, the micro heat exchanger is made of five different types of metal sheets (typically stainless steel sheets with a thickness less than 1mm) stacked in a certain order, and then vacuum diffusion welded formed an entity. The five types of plates are: interface plate A, refrigerant throttling plate B, fluid heat exchange plate C, refrigerant heat exchange plate D, and blind plate E.

[0028] Channels for refrigerant and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com