Miniature circuit breaker with high breaking capacity

A small circuit breaker, high-breaking technology, applied in the direction of circuit breaker components, circuit breaker contacts, protection switch operation/release mechanism, etc., can solve the problem of poor position consistency, affecting multi-pole circuit breaker linkage performance, affecting Consistency of multi-pole circuit breakers and other issues, to achieve the effect of reducing material cost, light weight, and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

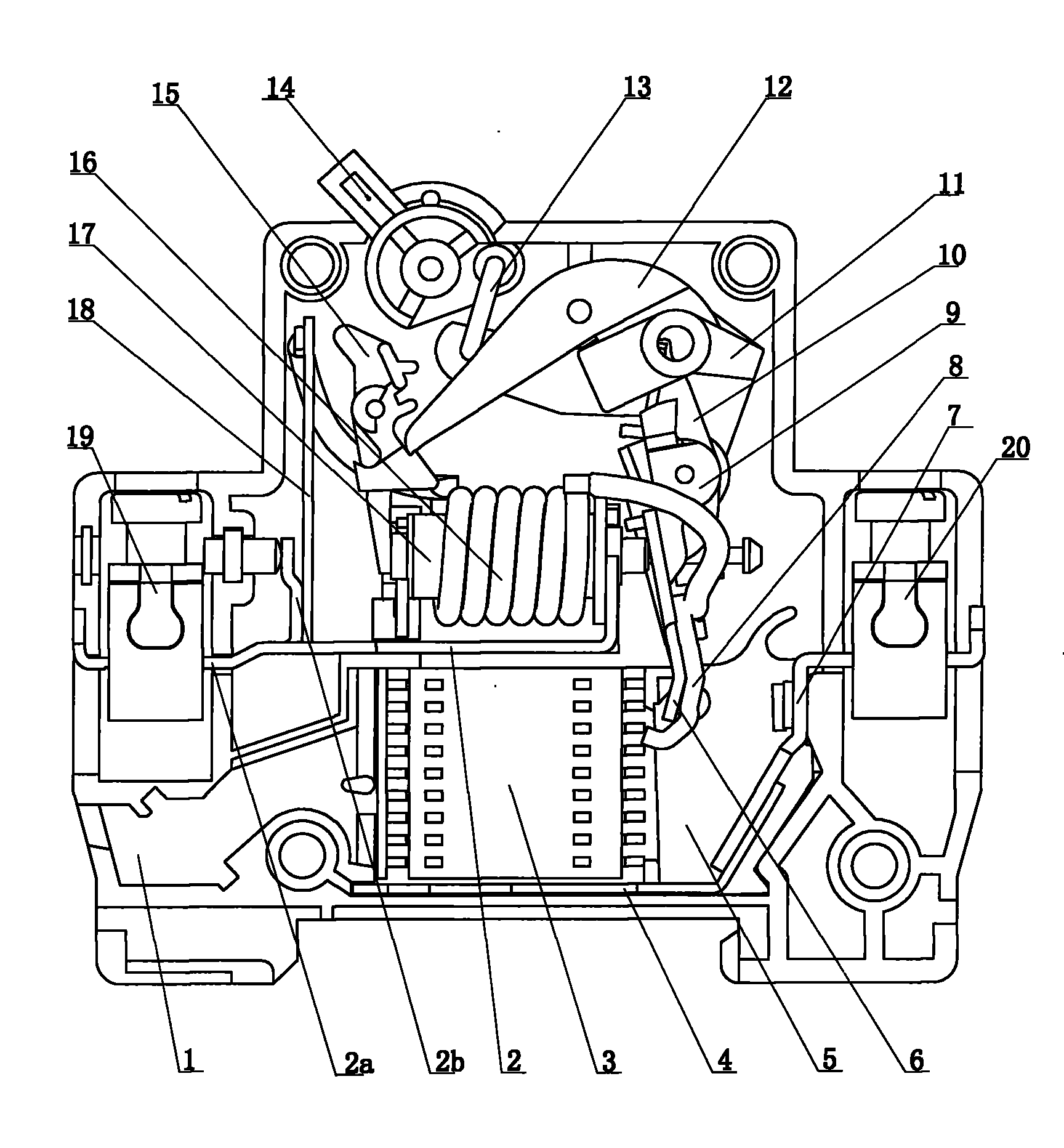

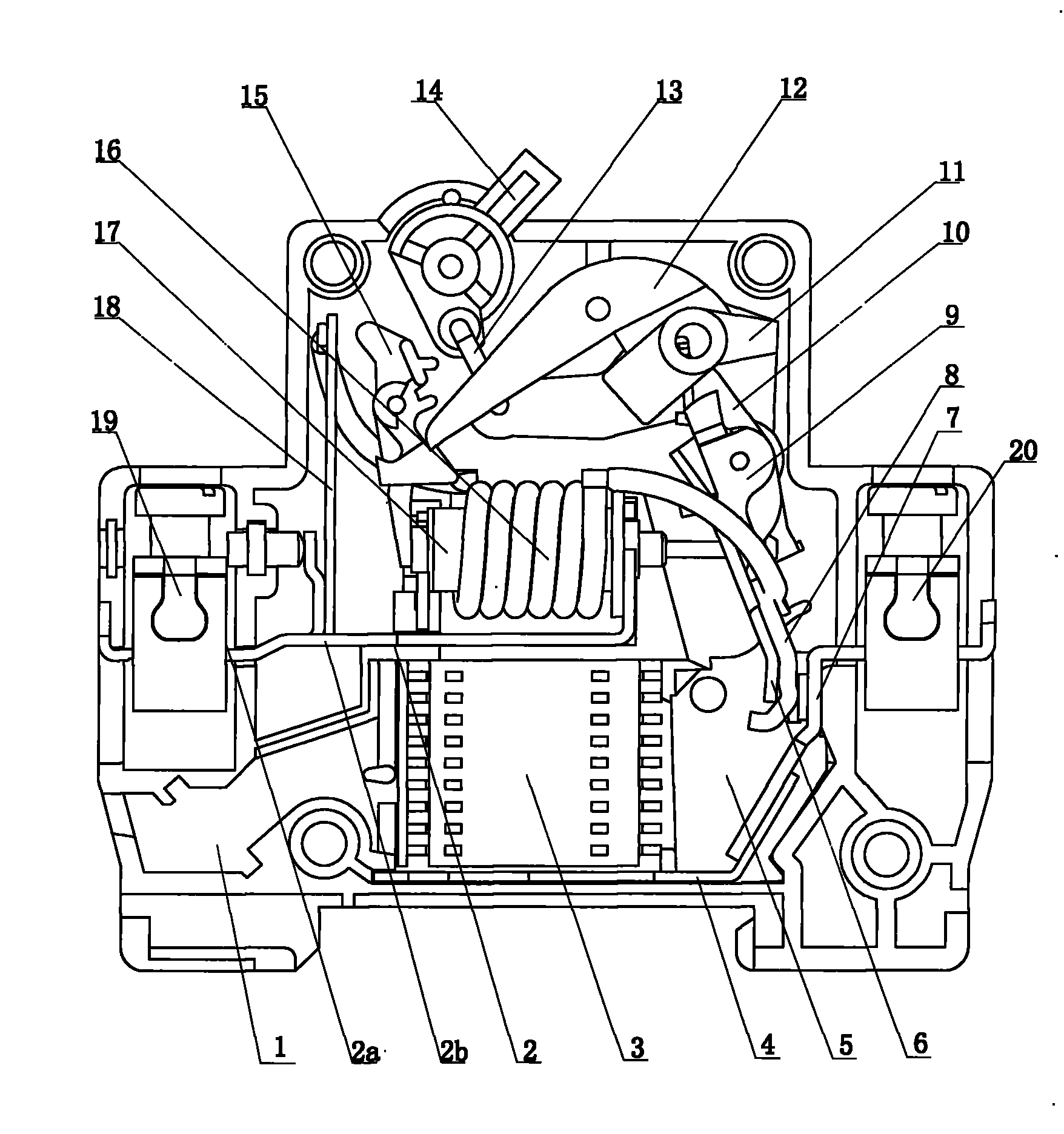

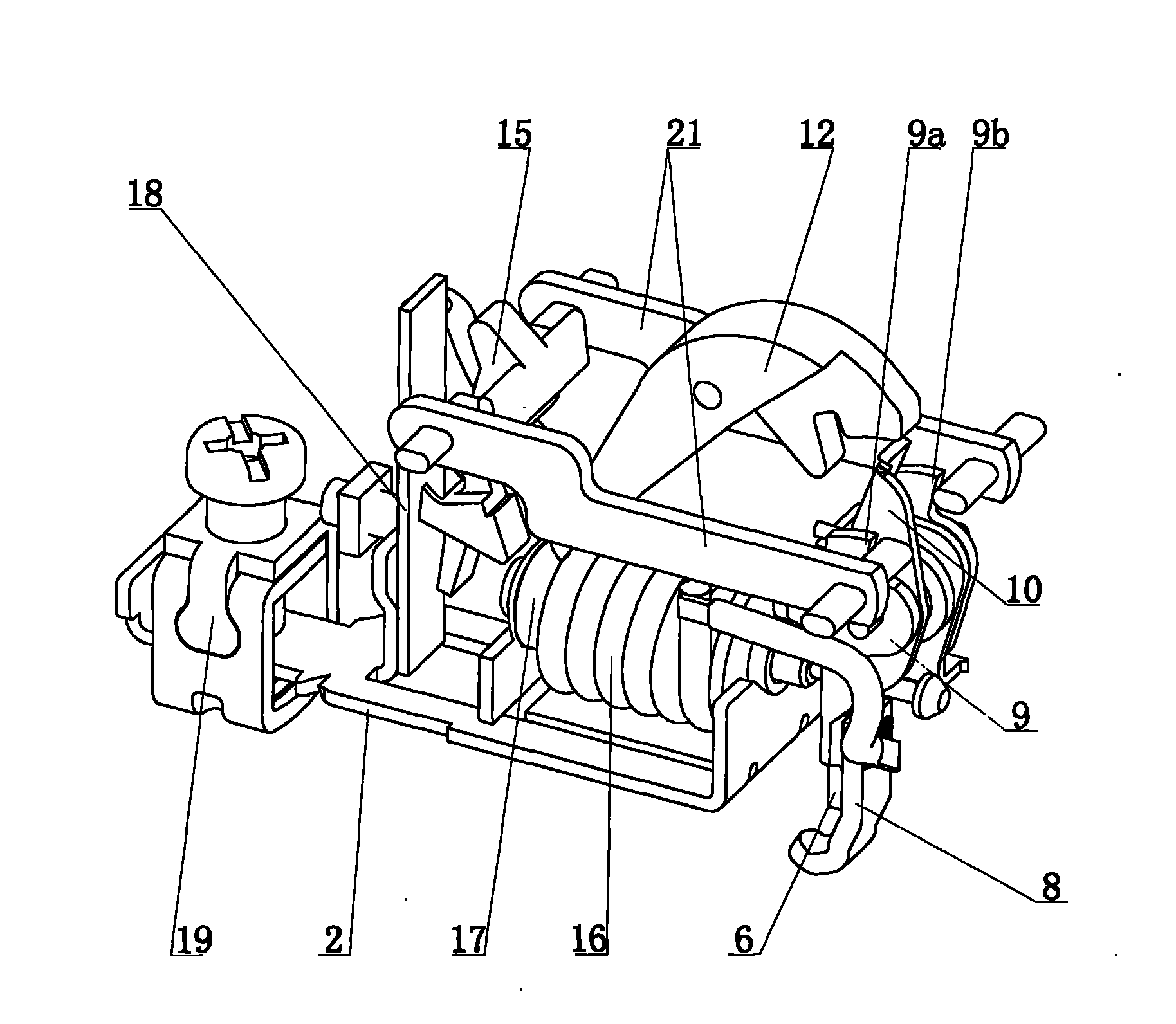

[0035] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings.

[0036] figure 1 , figure 2 The structure of the present invention after the upper cover is removed is shown, and only the lower cover of the housing 1 is retained in the figure. The upper and lower covers together constitute the insulating casing 1 of the present invention. In addition to providing the basic insulation of the miniature circuit breaker, the molded insulating casing is also a bracket for installing various internal components, and has sufficient electrical strength and mechanical strength to meet the needs of small circuit breakers. Performance requirements for circuit breakers.

[0037] The casing 1 in this embodiment is made of plastic, and the casing 1 is used as a bracket, and components such as a yoke assembly, an operating mechanism, an arc extinguishing system, and a moving contact assembly are installed in the casing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com