Miniature heat exchanger integrating condensing, throttling and evaporation

A heat exchanger, micro technology, applied in evaporator/condenser, refrigeration and liquefaction, fluid circulation arrangement, etc., can solve the problems of difficult welding, difficult piping layout, difficult to guarantee welding quality, etc., to reduce the system volume , System beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be described below in conjunction with the accompanying drawings and specific embodiments.

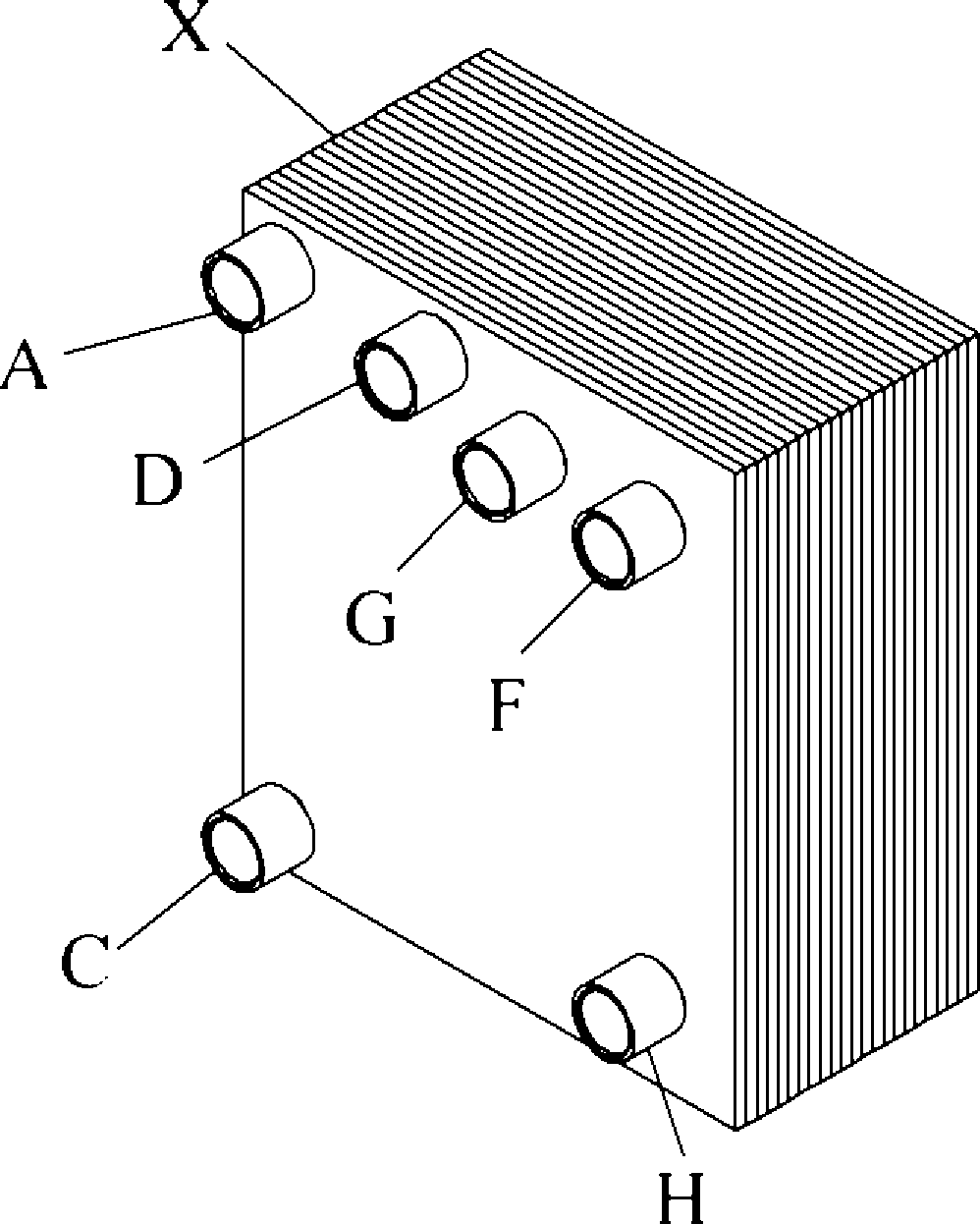

[0029] like figure 1 As shown, according to a specific embodiment of the present invention, the condensation-throttling-evaporation integrated micro heat exchanger includes: a micro heat exchanger body X, and a refrigerant inlet joint A, a refrigerant outlet joint F, a second The second fluid inlet connector C, the second fluid outlet connector D, the third fluid inlet connector G and the third fluid outlet connector H.

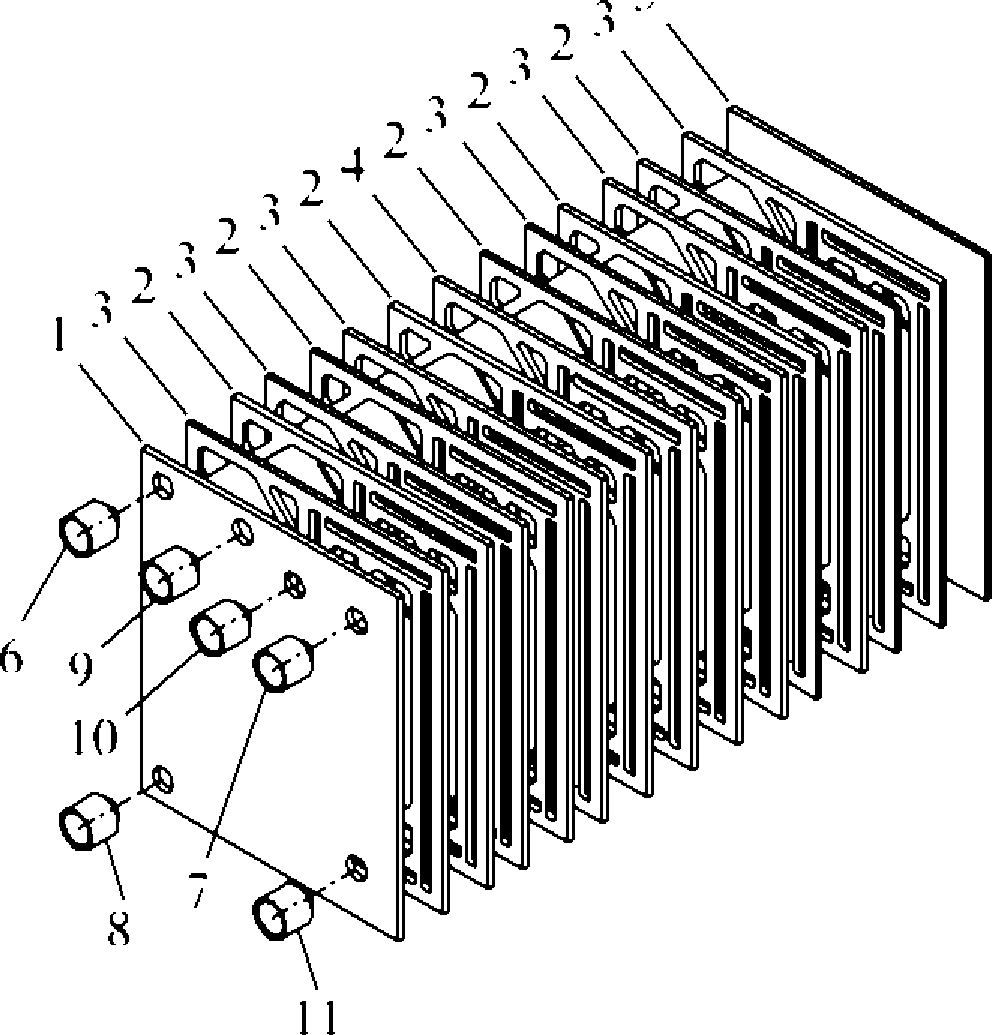

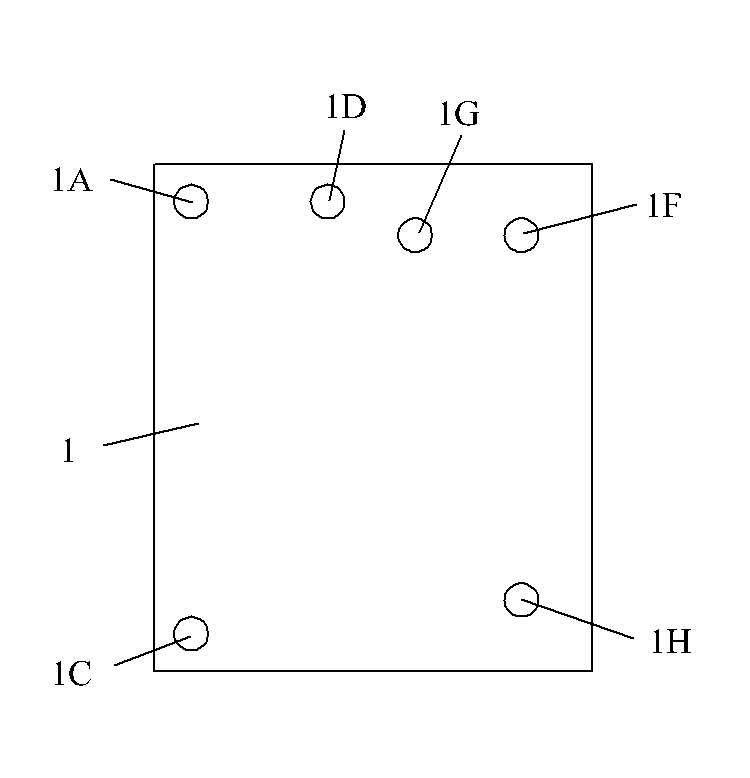

[0030] The micro-heat exchanger body X is formed by multi-layer metal sheets through vacuum hot-pressing diffusion welding, and forms interlaced refrigerant flow channels and fluid flow channels inside it. After vacuum hot-pressing diffusion welding between the plates of the micro heat exchanger body X, the plates are tightly combined due to the mutual diffusion of metal atoms and become an entity, thus achi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com