Novel LTCC structure based ultra wide band balun

An ultra-broadband, new type of technology, applied in the direction of waveguide devices, electrical components, connecting devices, etc., can solve the problems of narrow temperature adaptation range, weak impact resistance, high dielectric loss, etc., achieve wide temperature adaptation range, convenient installation process, The effect of increasing packing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

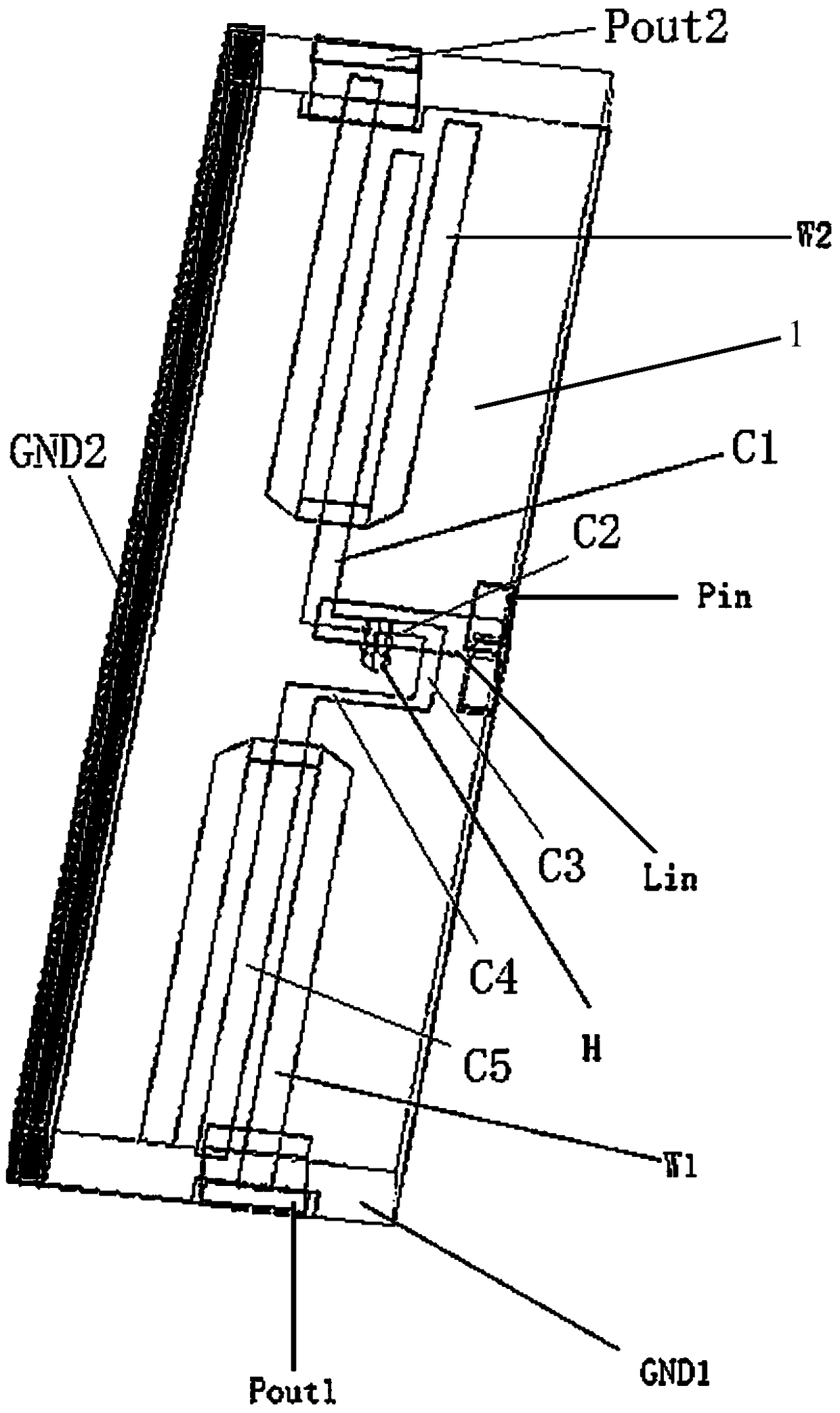

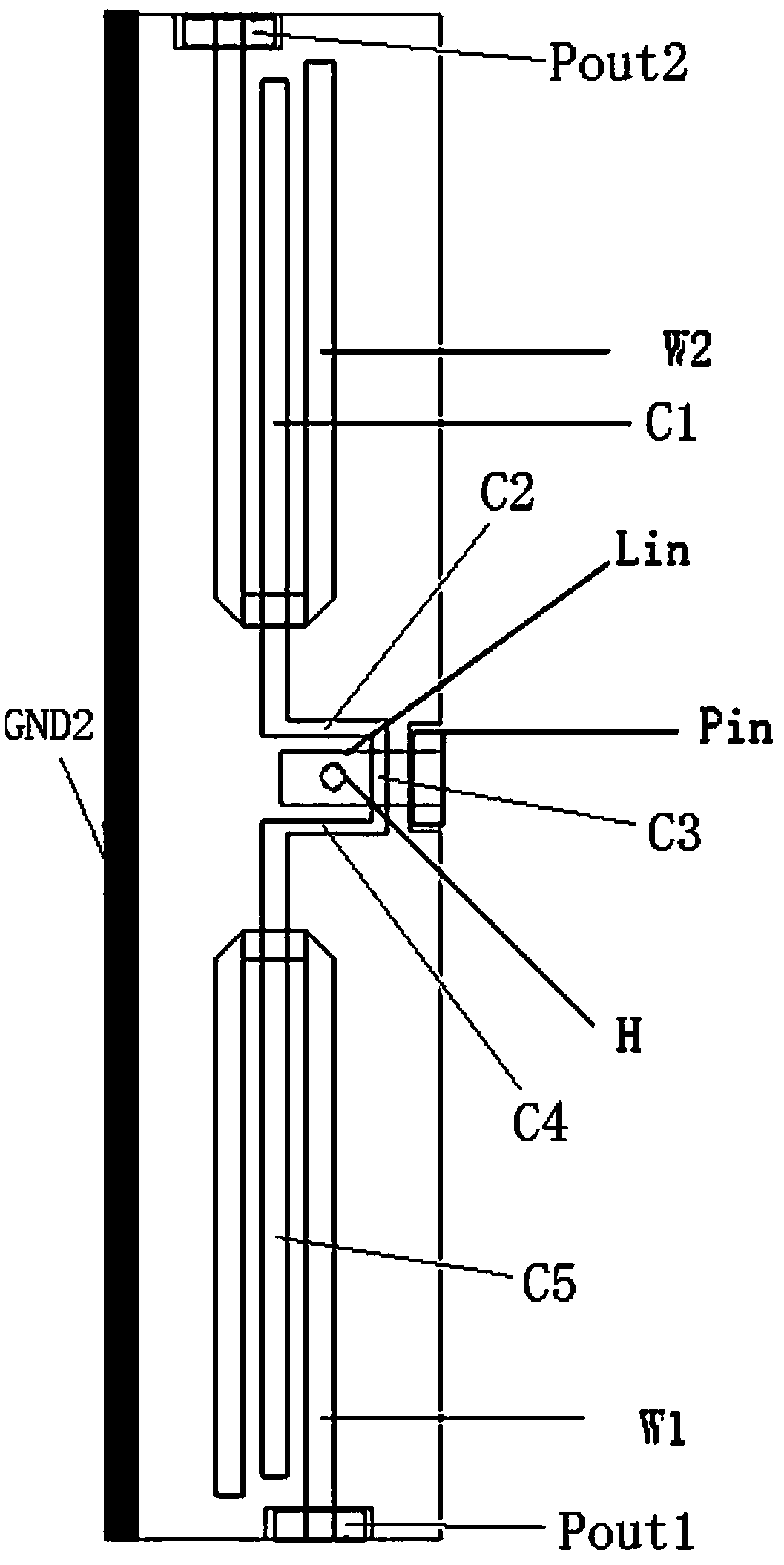

[0016] The invention discloses an ultra-wideband balun based on a novel LTCC structure, combining figure 1 and figure 2 As shown, it includes a ceramic glass substrate 1, and the ceramic glass substrate 1 is provided with an input port Pin, an input connection lead Lin, a connecting column H, an output port Pout1, an output port Pout2, a ground layer GND1, a ground layer GND2, and a transmission line W1 , transmission line W2, first slot C1, second slot C2, third slot C3, fourth slot C4, and fifth slot C5, the left side of the ground layer GND1 is provided with a ground layer GND2, and the right side of the ground layer GND1 An input port Pin is provided, an output port Pout1 is provided on the front side of the ground layer GND1, an output port Pout2 is provided on the rear side of the ground layer GND1, and a transmission line W1 and a transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com