Patents

Literature

31results about How to "Even distribution of water flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

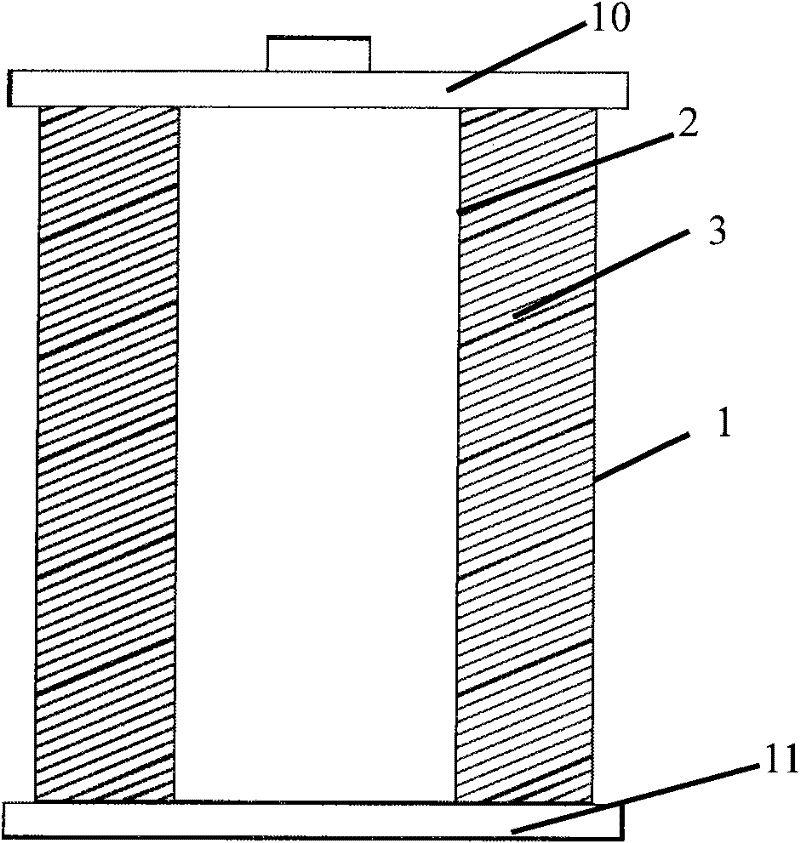

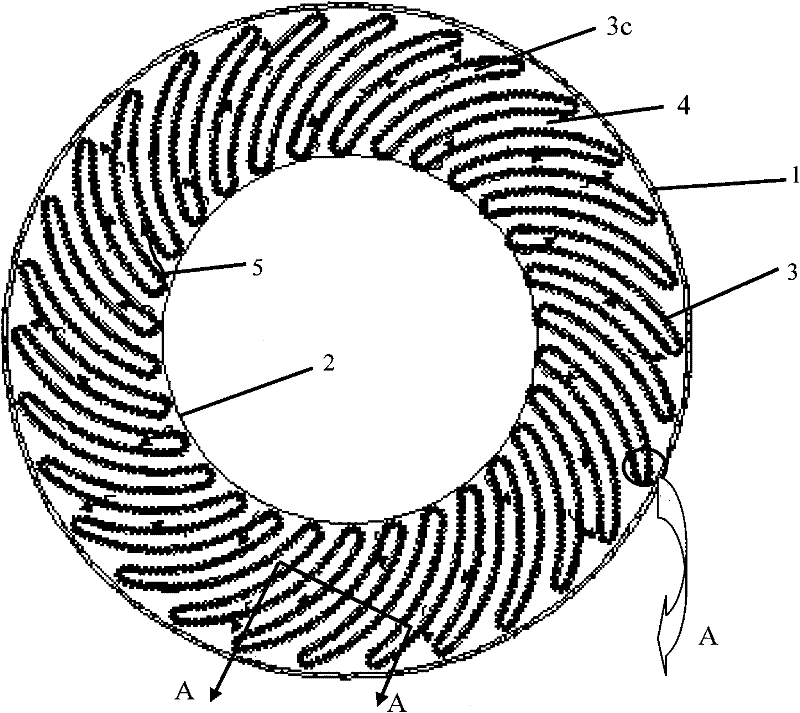

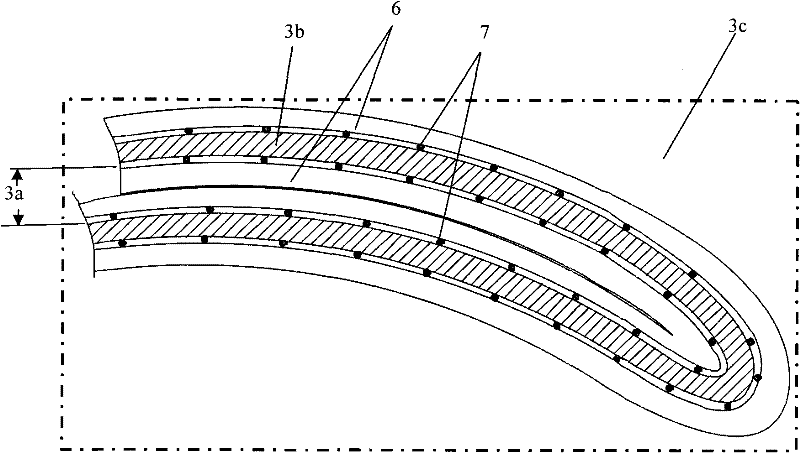

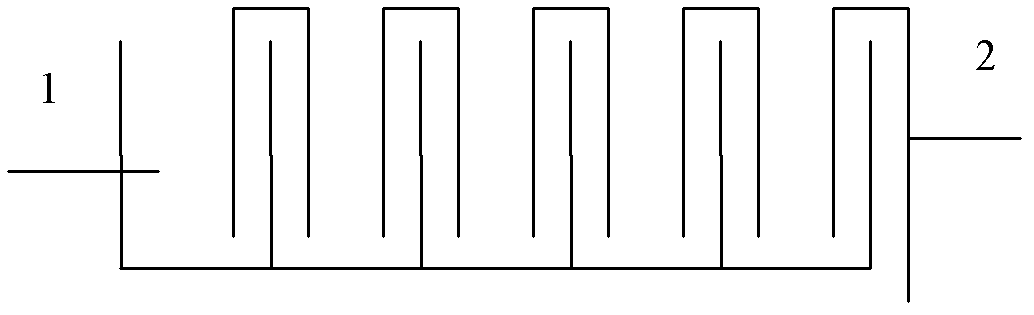

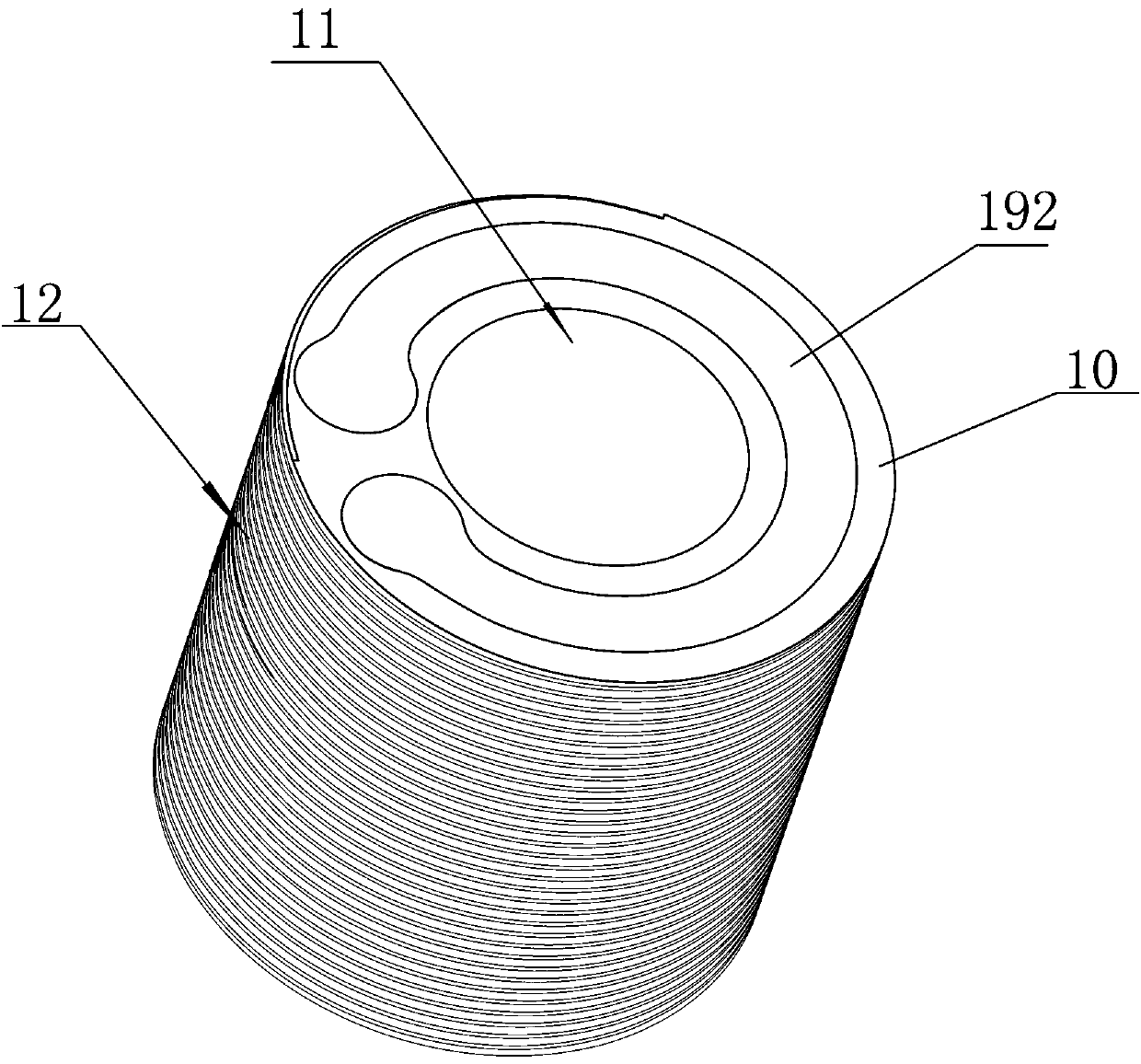

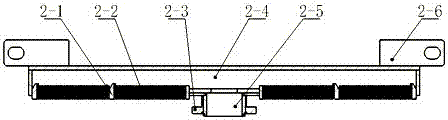

High-flux high-dirt-holding-capacity filtering element and preparation method thereof

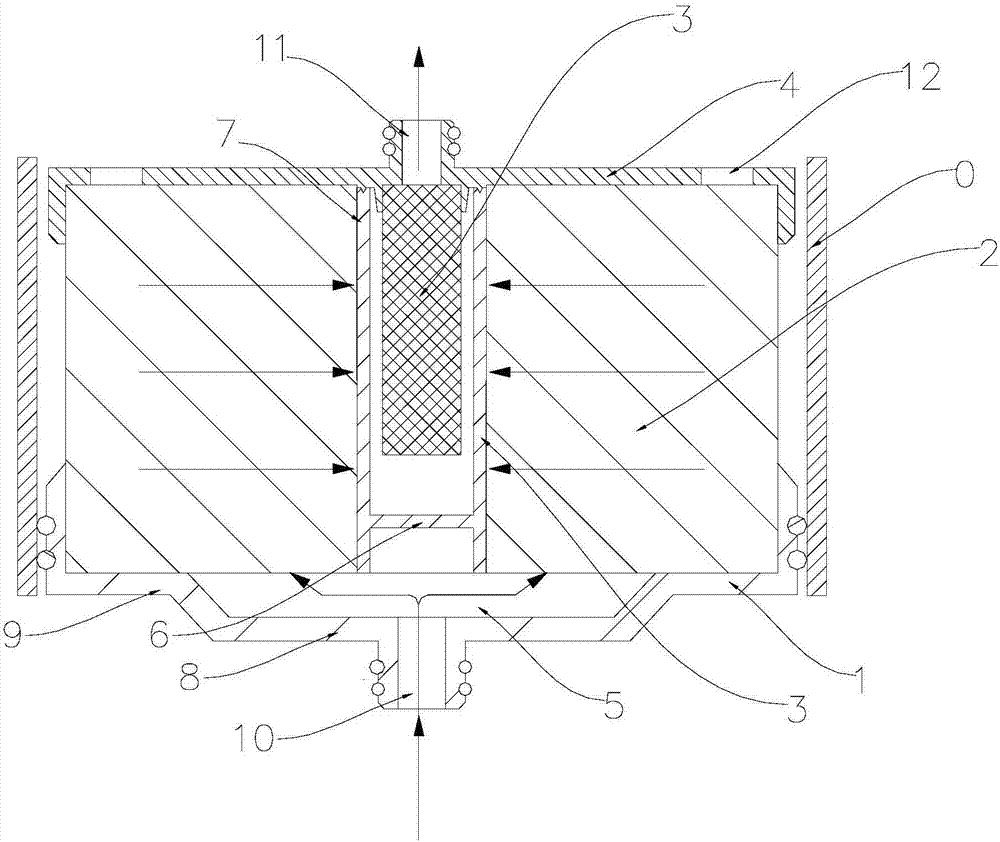

InactiveCN102188848AExtended service lifeEven distribution of water flowStationary filtering element filtersCENBOLFiltration membrane

The invention discloses a high-flux high-dirt-holding-capacity filtering element, which comprises a filtering medium layer (3), a central tube (2), a shell (1) and upper and lower end covers (10, 11), wherein the filtering medium layer (3) is folded into an arc-shaped fold and then encloses the central tube (2), and the whole is cylindrical; the shell (1) is sleeved outside a cylindrical filtering medium; the filtering medium layer comprises a filtering layer (3b) and plastic net layers (8) which are positioned on two sides of the filtering layer; the filtering layer consists of at least two layers of filtering materials (3d); and the upper and lower ends of the central tube (2) and the shell (1) are fixedly connected with the upper and lower end covers. A high-flux folding filtering element is wide in runner, relatively low in fluid resistance, and more uniform in flow distribution of water inlet and outlet ends of the filtering element. Compared with the conventional W-shaped linear fold designing filtration membrane, the high-flux folding filtering element is improved by over 30 percent in terms of filling density, large in filtering area, high in total dirt-holding capacity and long in service life of the filtering element.

Owner:浙江瑞普环境技术有限公司

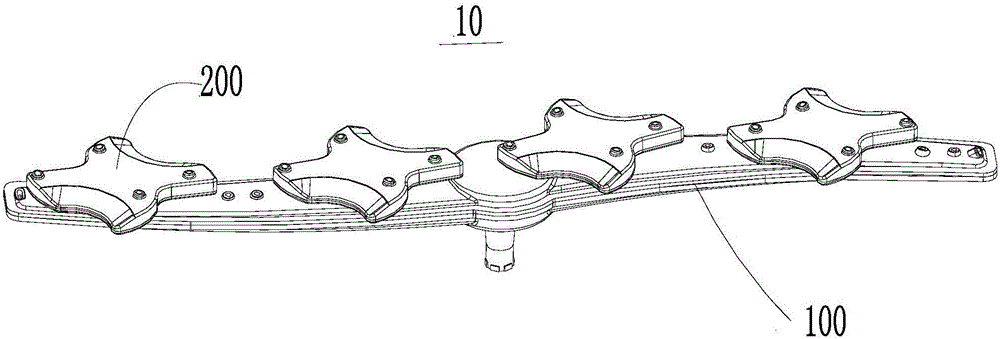

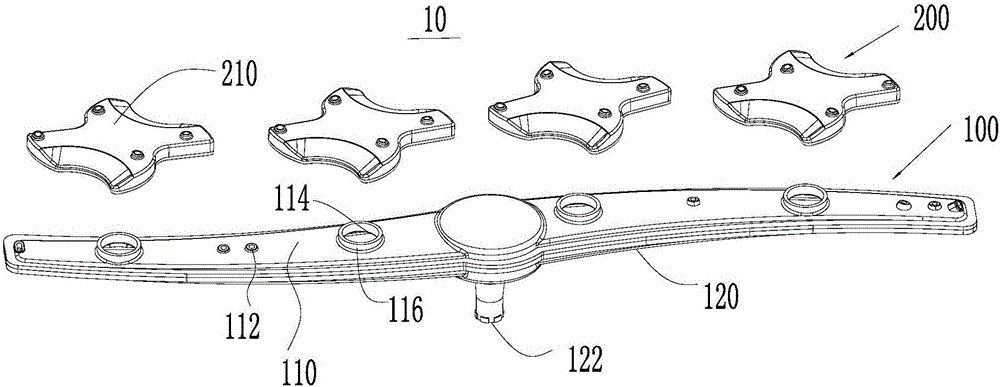

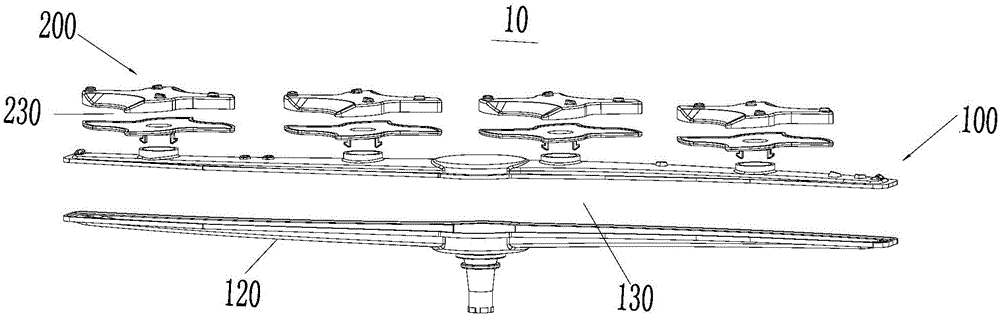

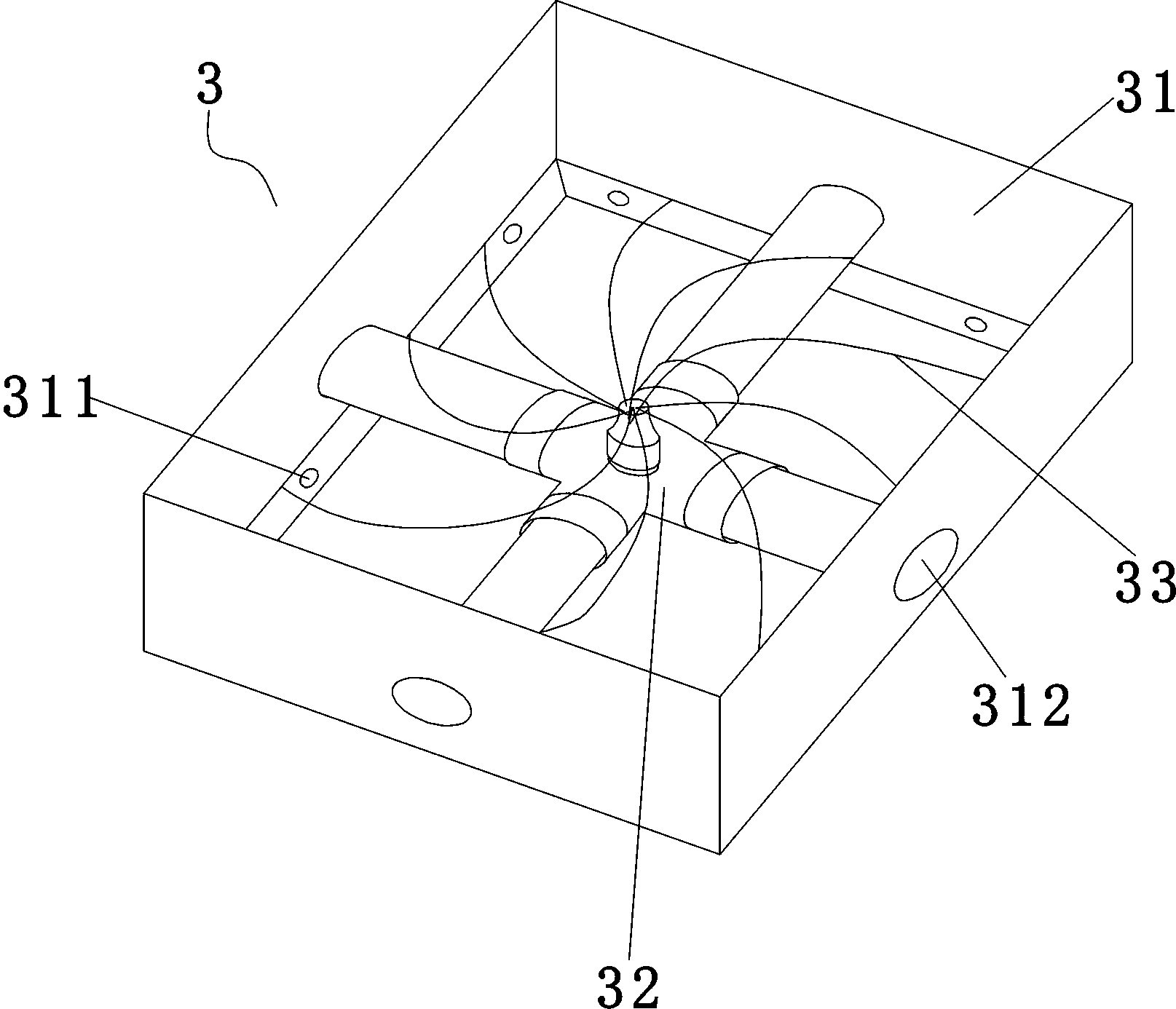

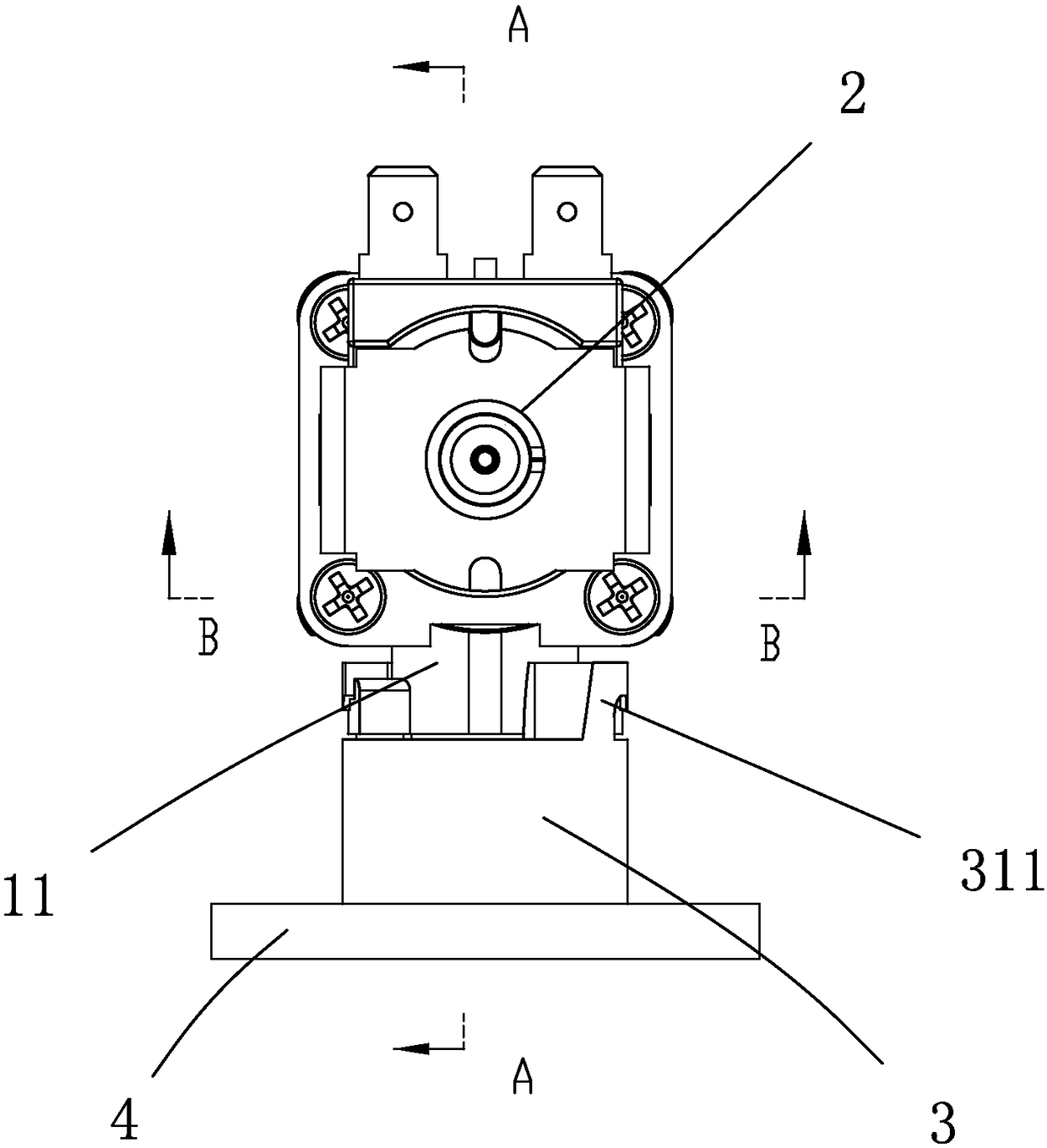

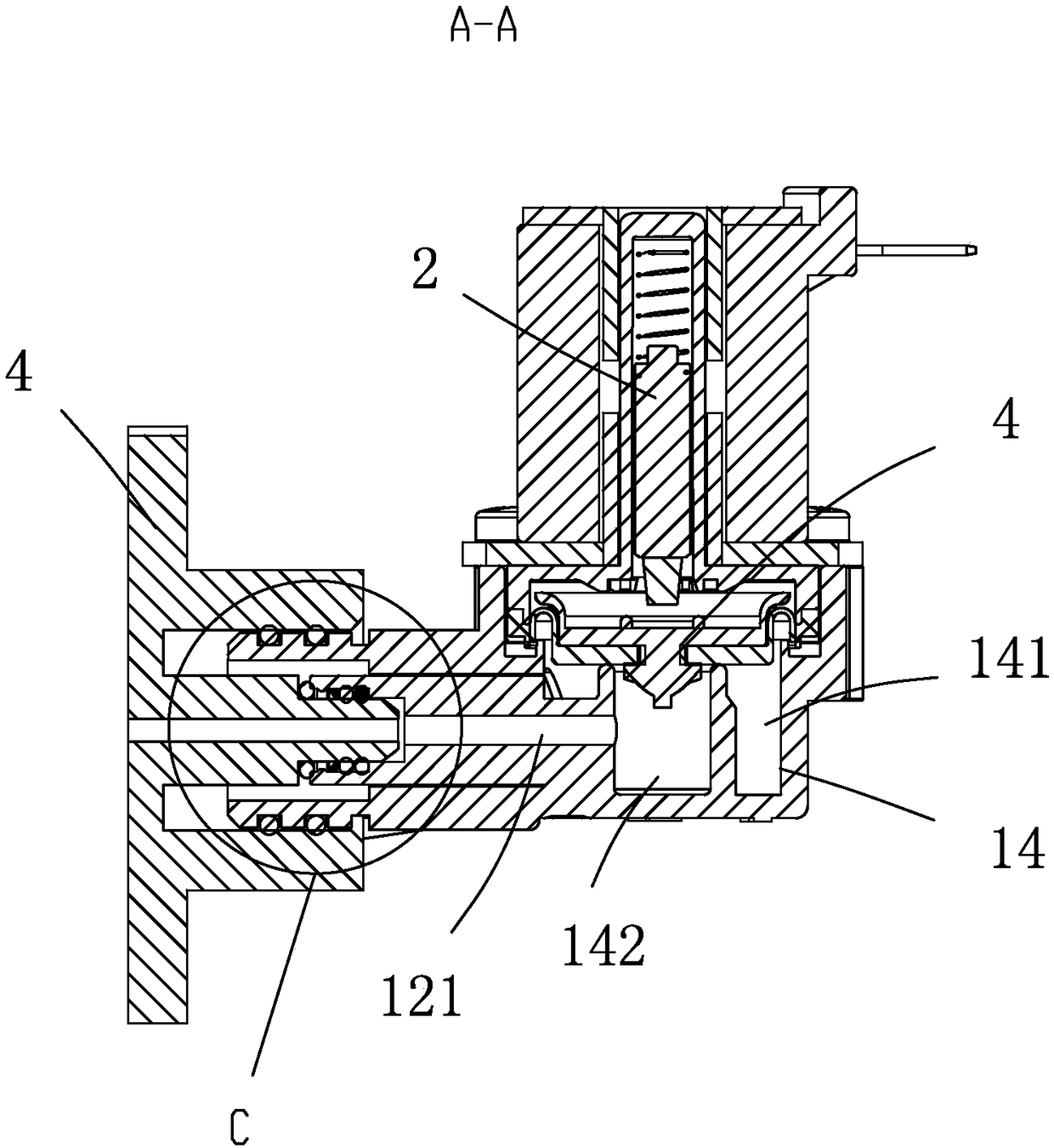

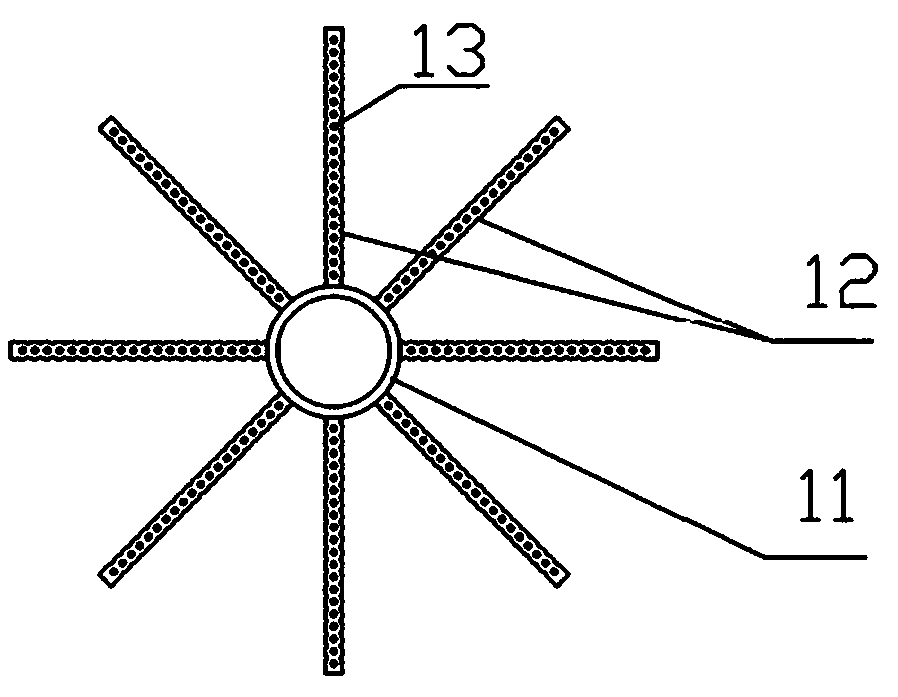

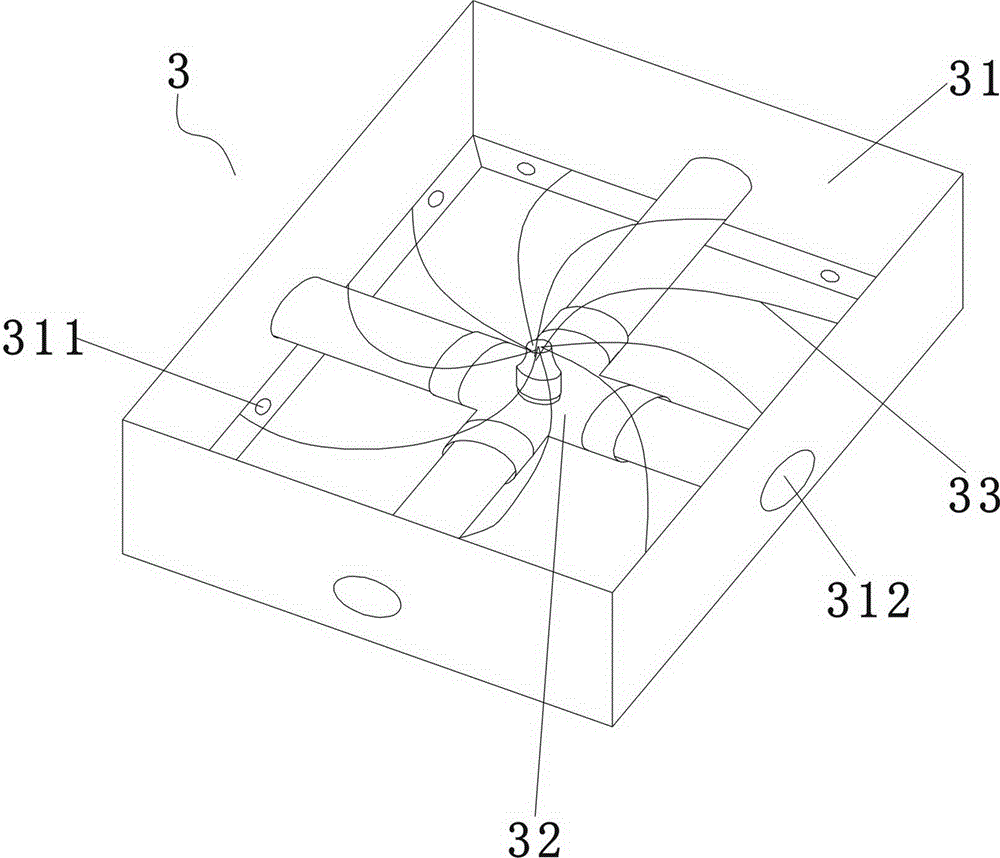

Spraying device of dish washing machine and dish washing machine

ActiveCN105919529AHigh efficiency washing effectEven distribution of water flowTableware washing/rinsing machine detailsEngineeringMechanical engineering

The invention provides a spraying device of a dish washing machine. The spraying device comprises a first sprayer and a second sprayer, wherein the first sprayer comprises a first water storage cavity and a first spraying surface; the second sprayer is rotationally arranged on the first spraying surface; the second sprayer is a quadrilateral sprayer, and comprises a second water storage cavity, a second spraying surface and a plurality of second spraying holes; the second spraying holes are formed in the second spraying surface, and are communicated with the second water storage cavity; the first water storage cavity is communicated with the second water storage cavity. The spraying device has the advantage that the second sprayer is the quadrilateral sprayer, so that the distribution of sprayed water flow is more uniform, the blind area of washing is reduced, the effective washing area is increased, and the washing efficiency of the spraying device of the dish washing machine is greatly improved.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

Efficient open type net pipe flowing channel reverse osmosis membrane element

ActiveCN109092064APrevent scalingReduce exposureWater/sewage treatment bu osmosis/dialysisReverse osmosisGlass fiberReverse osmosis

Owner:JIANGSU KUNYI ENVIRONMENTAL ENG CO LTD

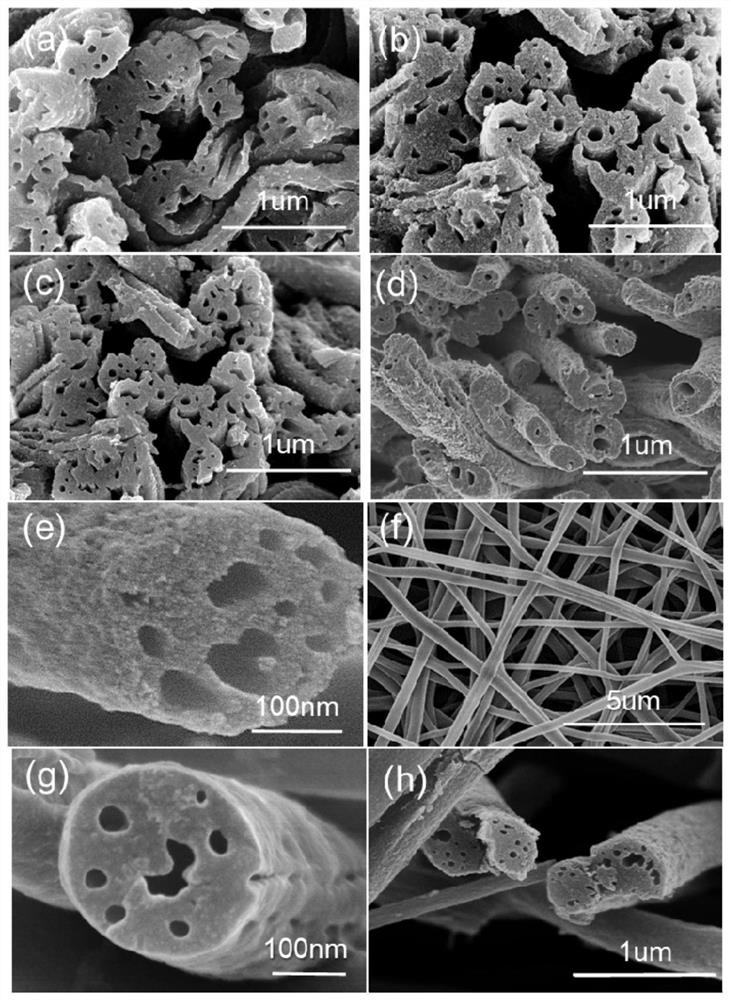

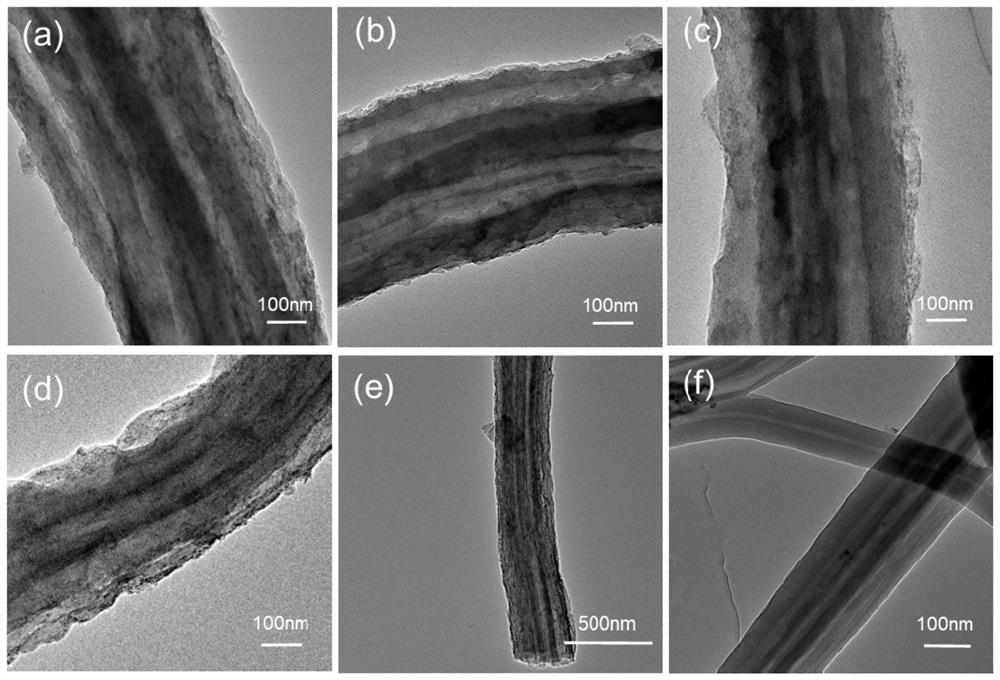

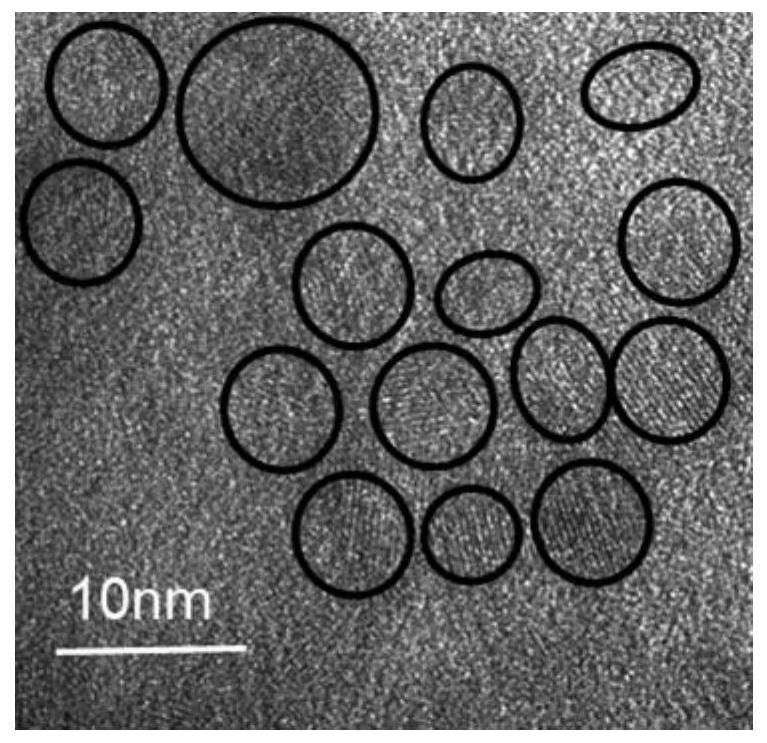

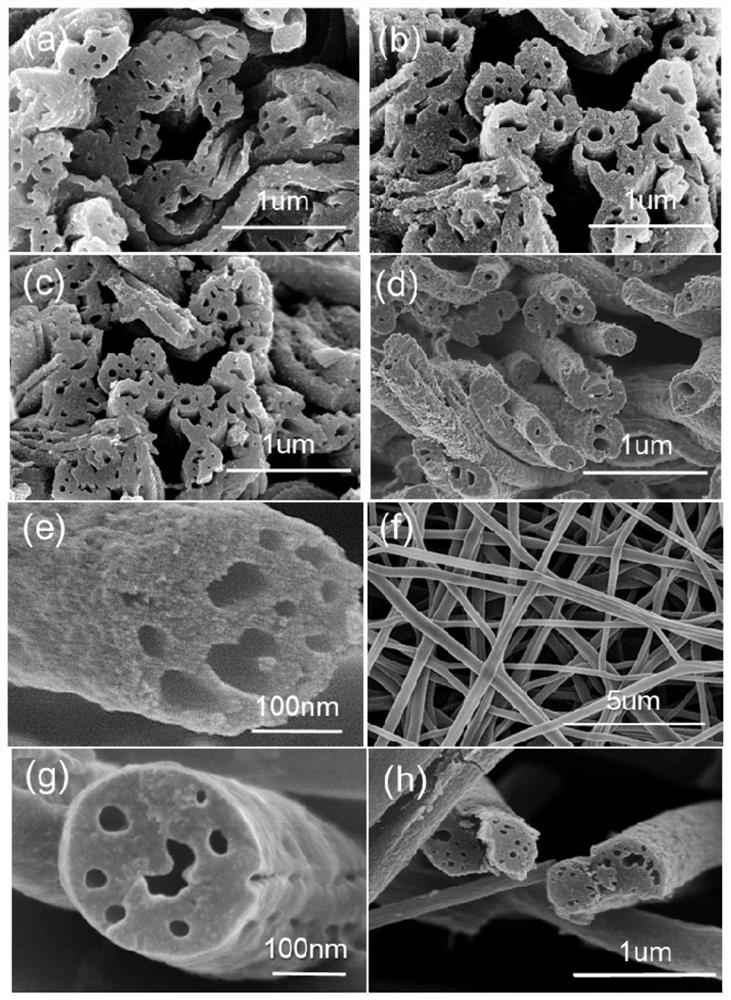

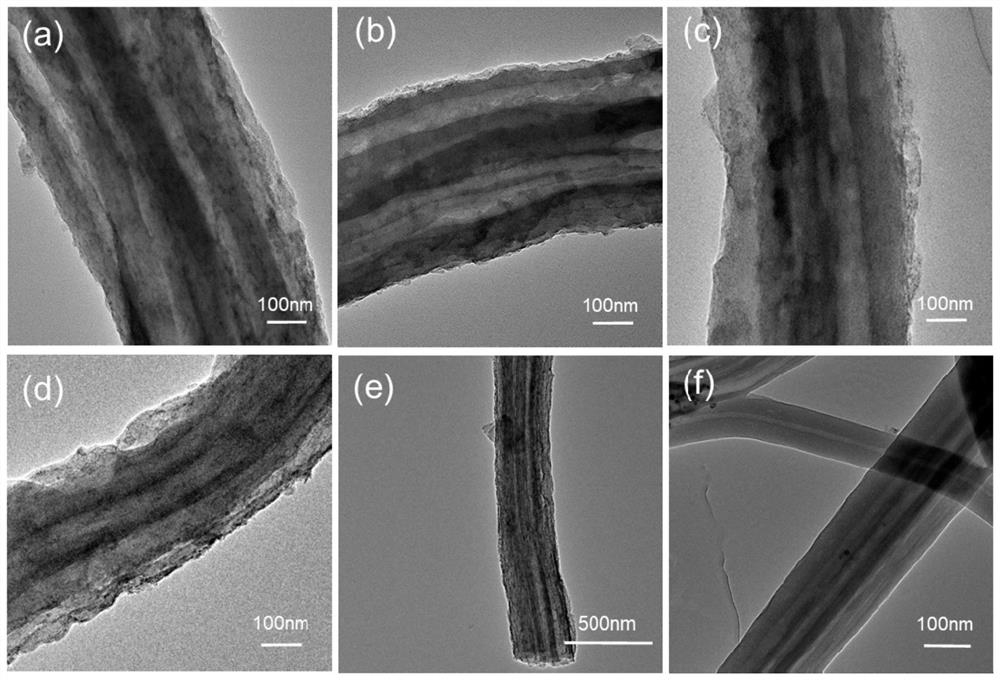

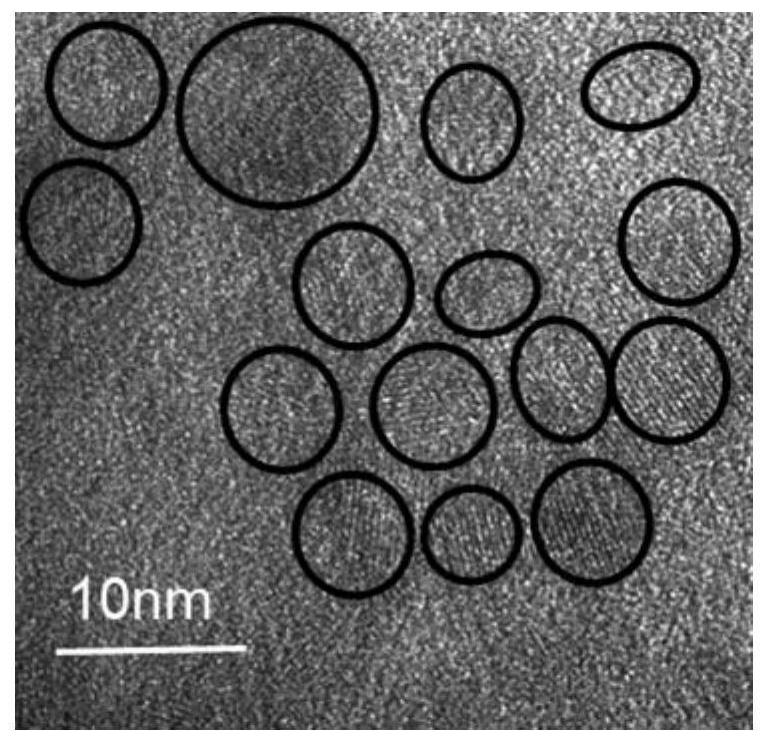

Porous multi-hollow flexible composite nanofiber membrane material and preparation method thereof

ActiveCN113073426AImprove flexibilityHigh mechanical strengthHollow filament manufactureNon-woven fabricsHollow fibreFiber

The invention relates to a porous multi-hollow flexible composite nanofiber membrane material and a preparation method thereof. According to the method, a porous multi-hollow flexible composite nanofiber membrane is prepared through coaxial electrostatic spinning, wherein an outer layer solution for coaxial electrostatic spinning consists of a sacrificial high-molecular polymer, a retained high-molecular polymer and a solvent A, and an inner layer solution for coaxial electrostatic spinning is composed of a sacrificial high-molecular polymer, a material capable of generating a substance with semiconductor characteristics and low surface energy in the spinning process, and a solvent B; and then the sacrificial high-molecular polymer in the porous multi-hollow flexible composite nanofiber membrane is removed to obtain the membrane material formed by stacking porous multi-hollow nanofibers, wherein the porous multi-hollow nanofibers are provided with a plurality of hollow pipelines and three-dimensional penetrating through hole micro-nano structures with the hollow surfaces. The membrane material disclosed by the invention has relatively high flexibility and mechanical strength, and the problems of fragility, low mechanical strength and the like of a porous composite fiber material and a single hollow fiber material are solved.

Owner:DONGHUA UNIV

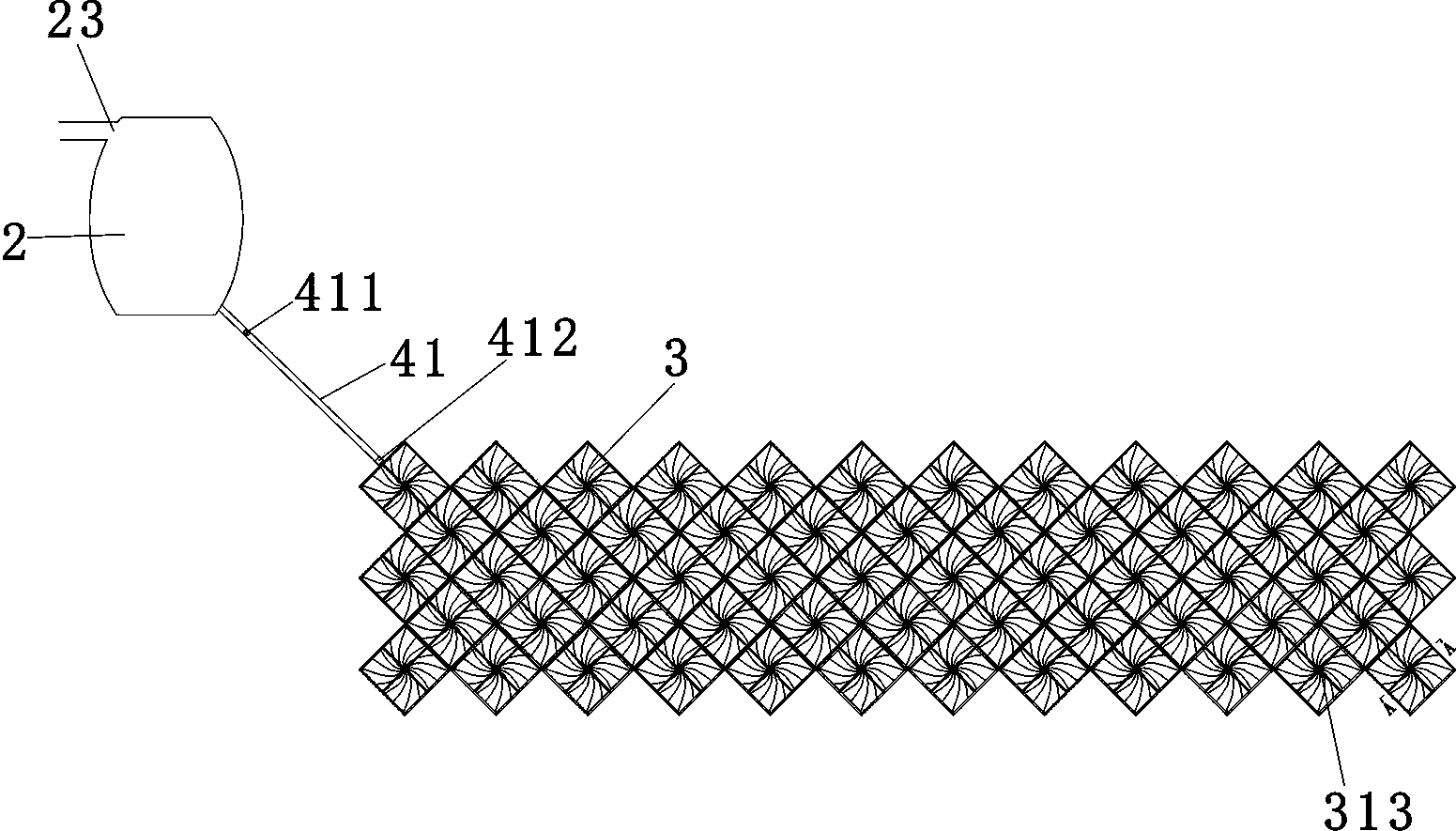

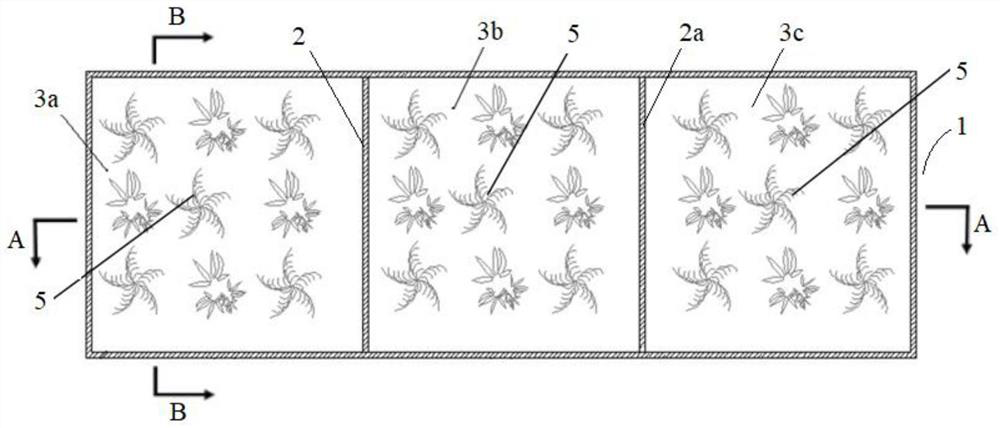

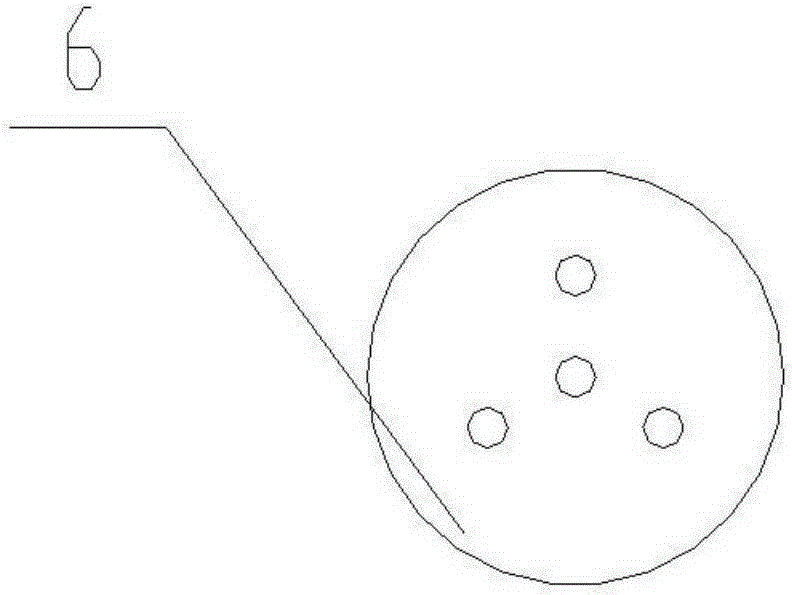

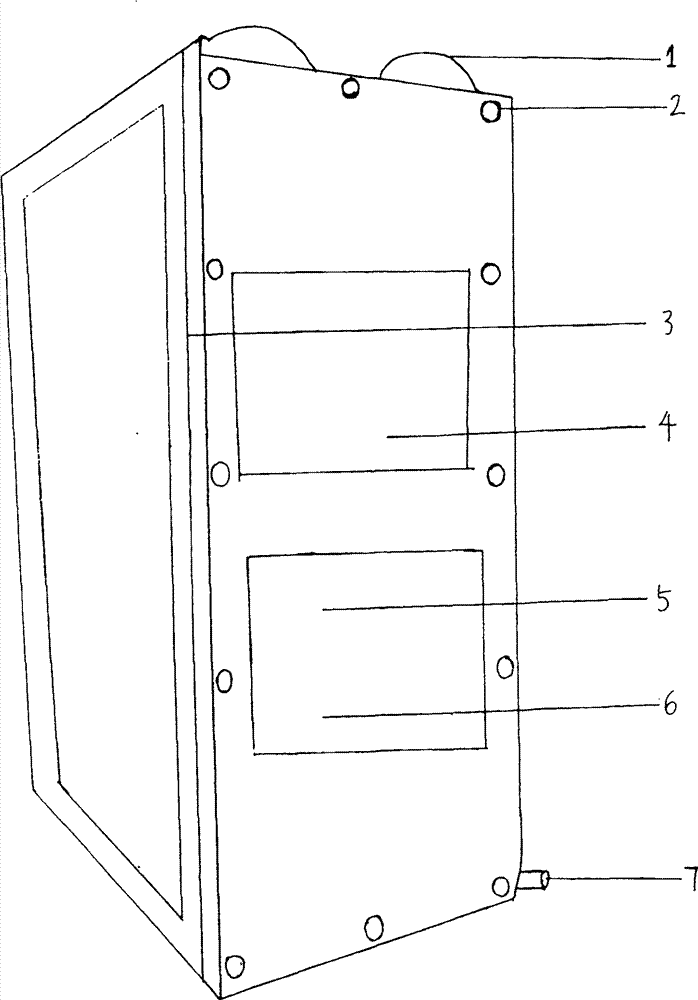

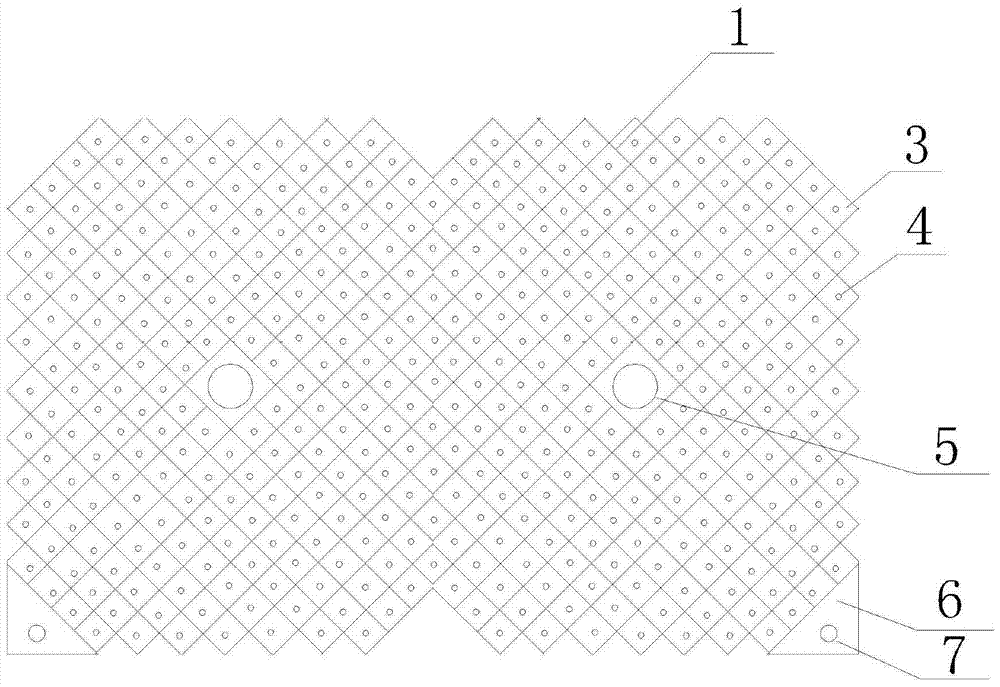

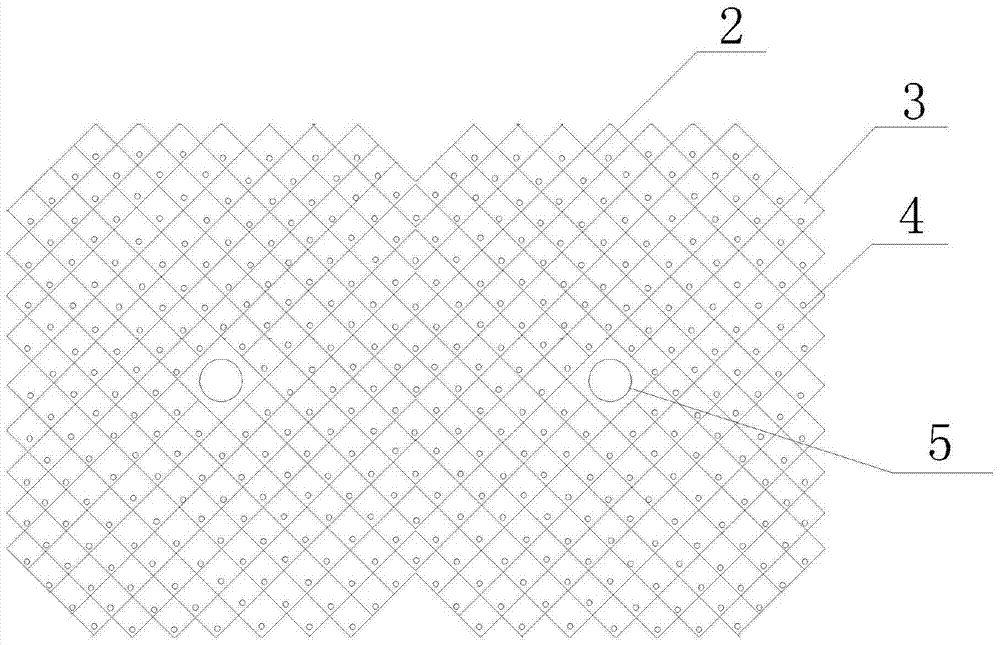

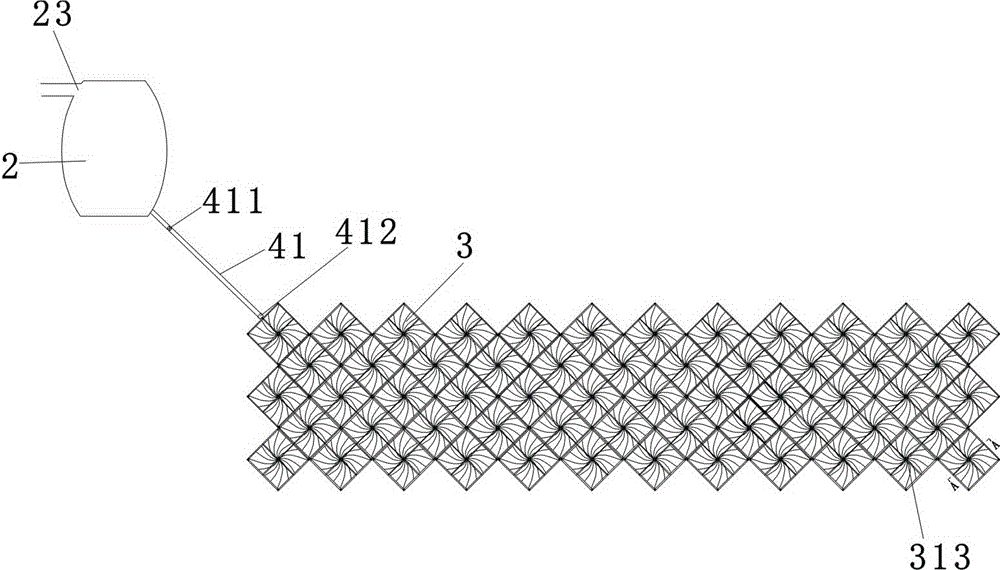

Field bionic hatching method of fertilized salmon eggs

ActiveCN104304121ALow costUnique designClimate change adaptationPisciculture and aquariaWater flowEngineering

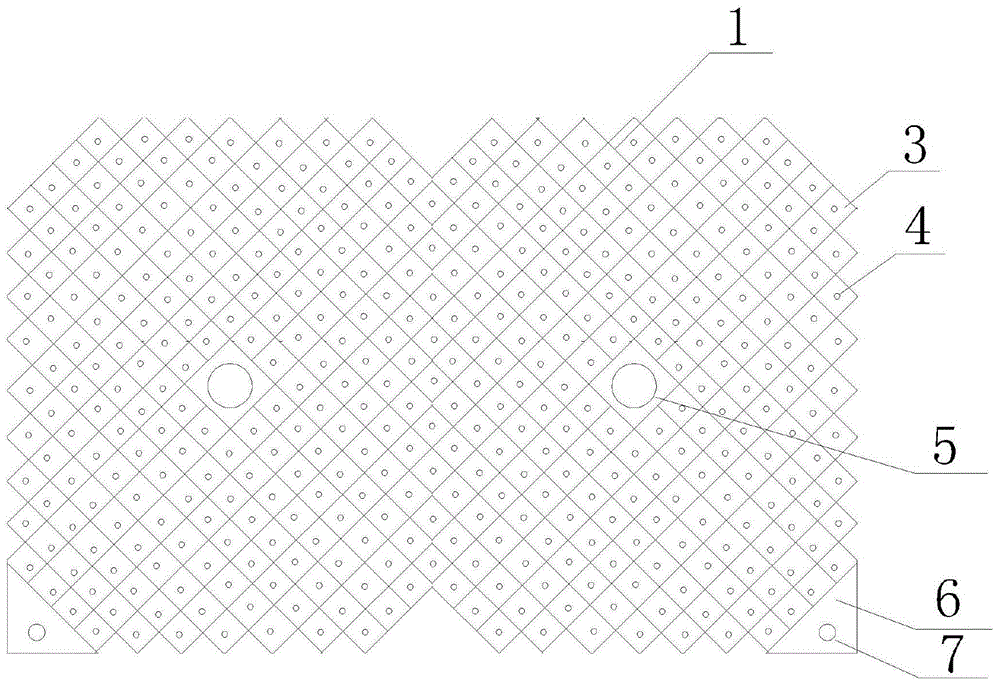

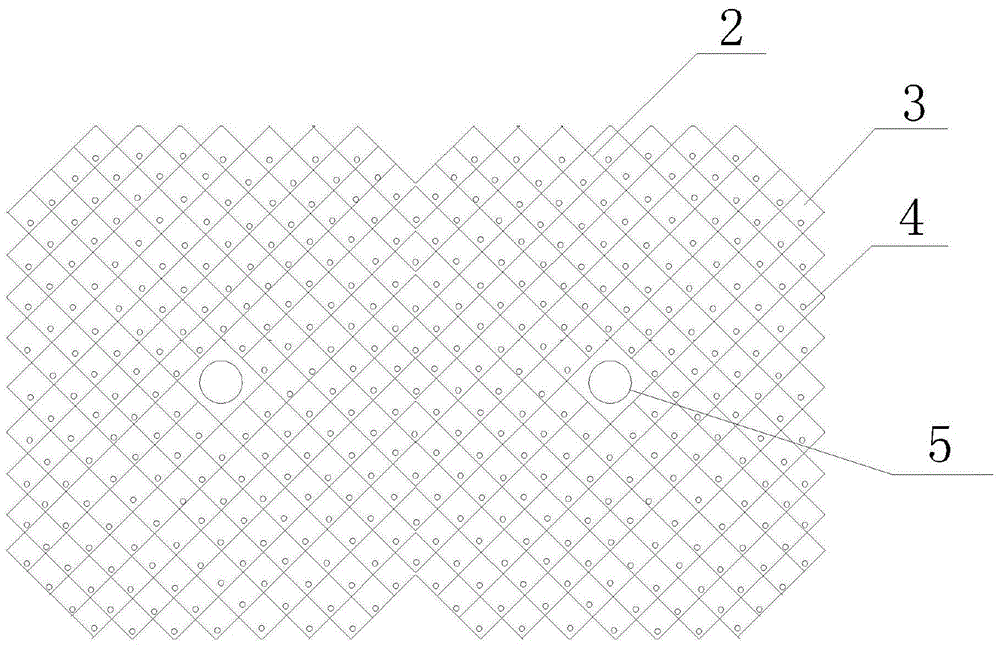

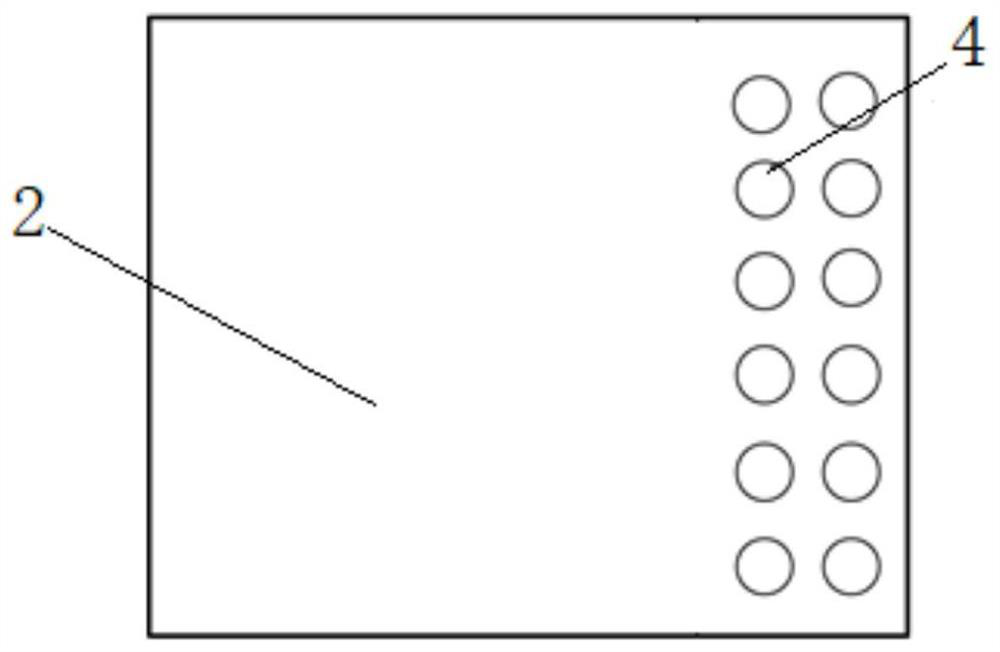

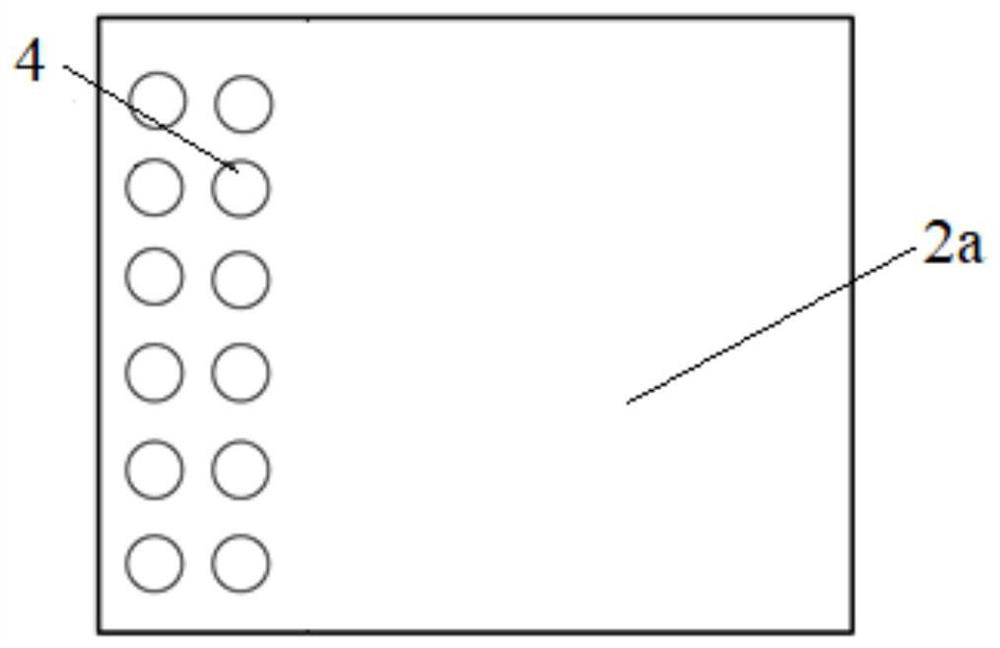

The invention discloses a field bionic hatching method of fertilized salmon eggs and belongs to the technical field of salmon breeding. A hatcher comprises a first side plate, a second side plate and nylon bolts. The first side plate and the second side plate can be symmetrically fastened to each other and are provided with nylon bolt plug holes which are symmetric; after symmetric fastening, the first side plate and the second side plate are fixed through nylon bolt plugs; the first side plate and the second side plate are both evenly provided with egg carrier cells in diamond shapes; the egg carrier cells of the first and second side plates are symmetrically fastened; the center of each egg carrier cell of the first side plate is provided with an escape hole; one corner of each egg carrier cell, on the same side, of the second side plate is provided with another escape hole. The hatcher can sink well in water, has stable shape and structure, allows smooth passage of water and allows water flow to be evenly distributed; the hatcher has the advantages that the size is small, materials are easy to obtain and assembly is simple; egg survival rate is up to greater than 70%.

Owner:HEILONGJIANG RIVER FISHERY RES INST CHINESE ACADEMY OF FISHERIES SCI

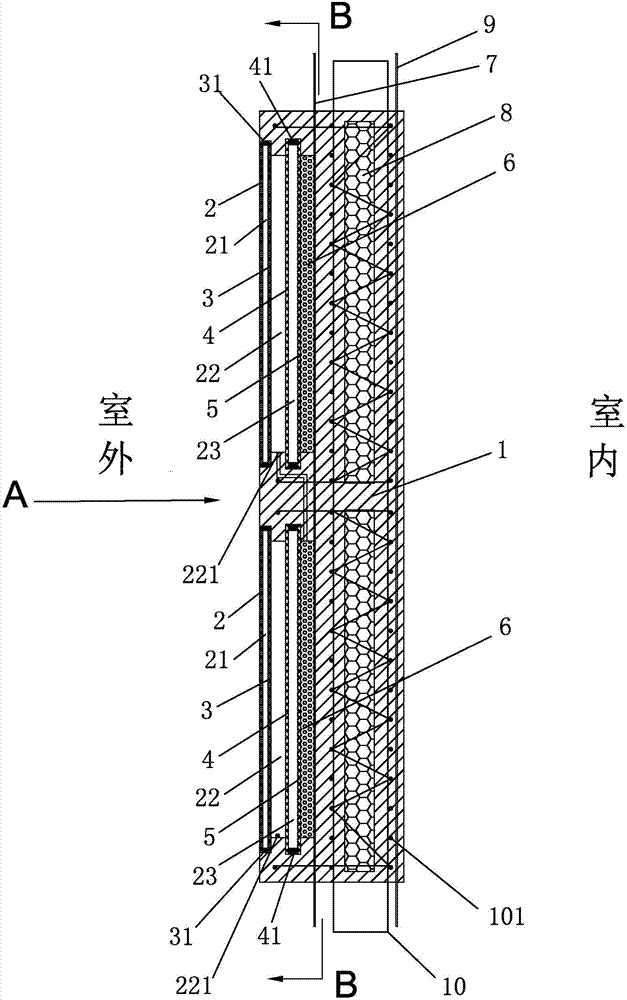

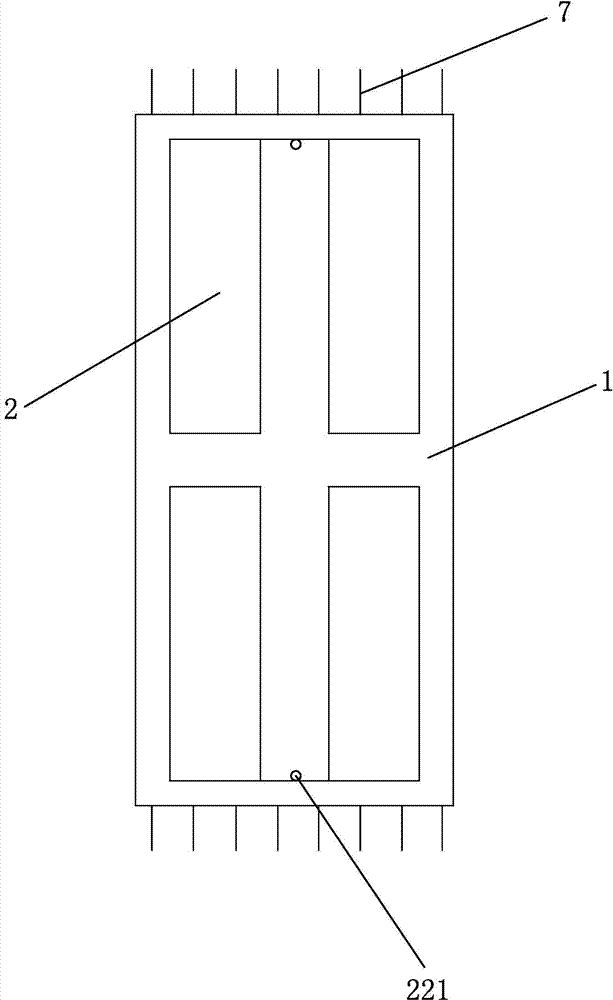

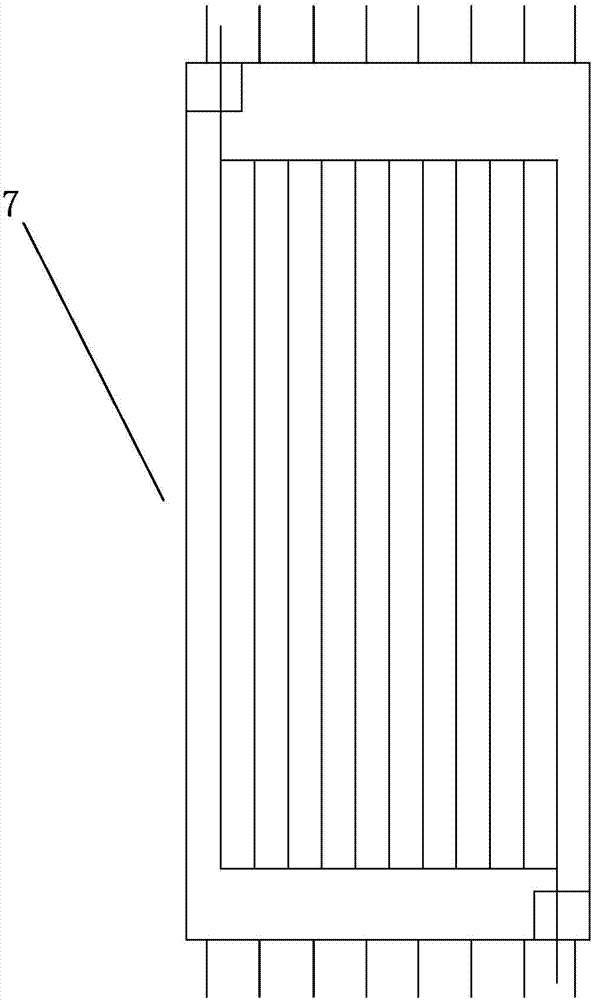

Prefabricated capillary energy-storage heat-dissipation wall

ActiveCN104294958ARenovation investment is smallEven distribution of water flowDispersed particle filtrationWallsElectricityThermal insulation

The invention relates to a prefabricated capillary energy-storage heat-dissipation wall. The prefabricated capillary energy-storage heat-dissipation wall comprises a concrete wall, the concrete wall is sequentially provided with a first tempered glass layer, a second tempered glass layer, a first-stage dedusting filter screen, a second-stage dedusting filter screen, an air adsorption layer, a passive heat source ground heating capillary pipe net, thermal insulation materials and a wall body capillary pipe net from outside to inside. The periphery of the first tempered glass layer and the periphery of the second tempered glass layer are sealed through first sealing glue to form a closed first air layer, a closed second air layer is formed between the first-stage dedusting filter screen and the second tempered glass layer, the periphery of the first-stage dedusting filter screen and the periphery of the second-stage dedusting filter screen are sealed through second sealing glue to form a closed third air layer, the second-stage dedusting filter screen is in close contact with the air adsorption layer, and the capillary pipe nets are in close contact with the air adsorption layer. The prefabricated capillary energy-storage heat-dissipation wall is convenient to install and use and low in cost, strong air and noise pollution can be avoided, the electricity consumption is small, and energy is saved.

Owner:安徽中宝建材科技有限公司

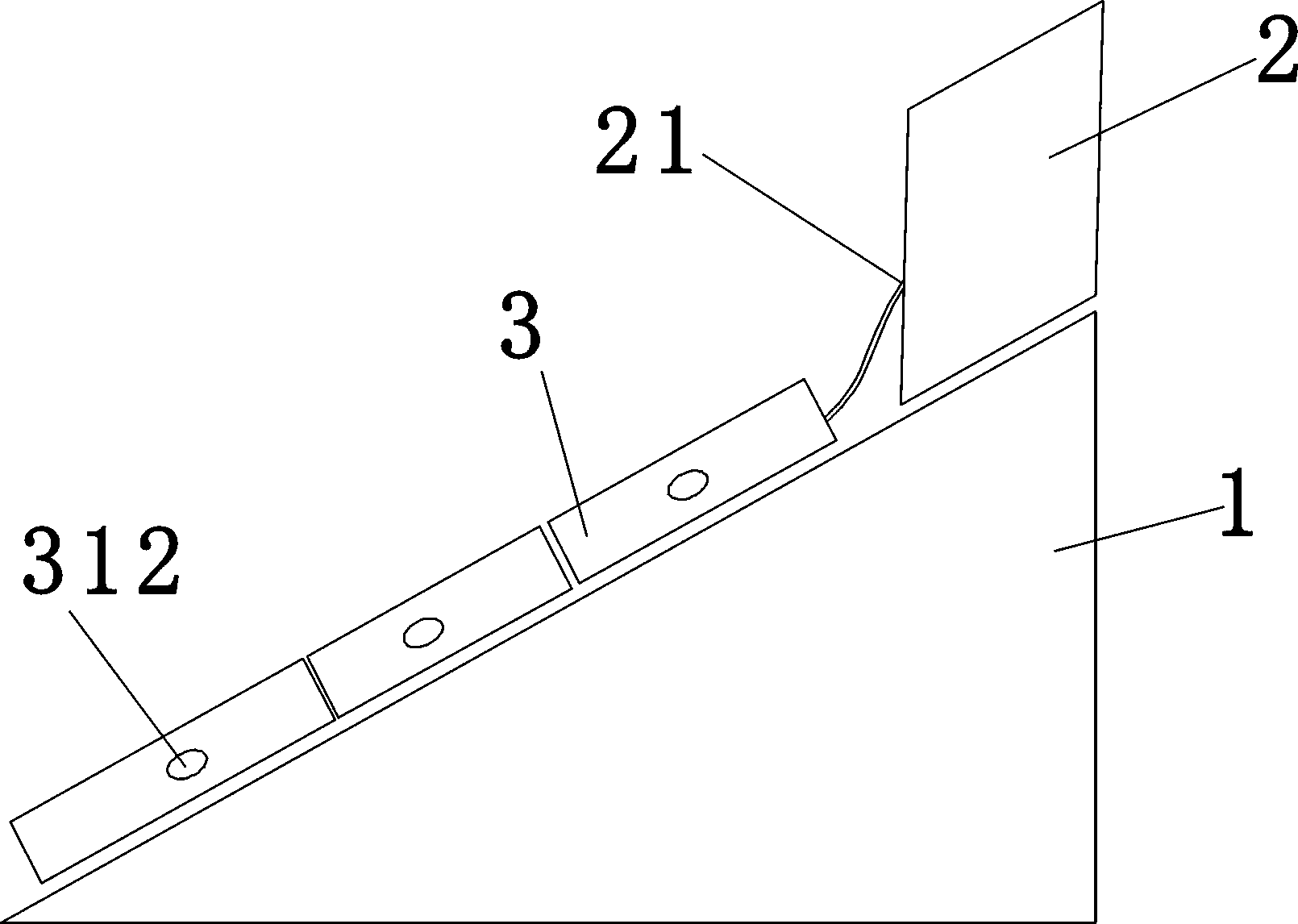

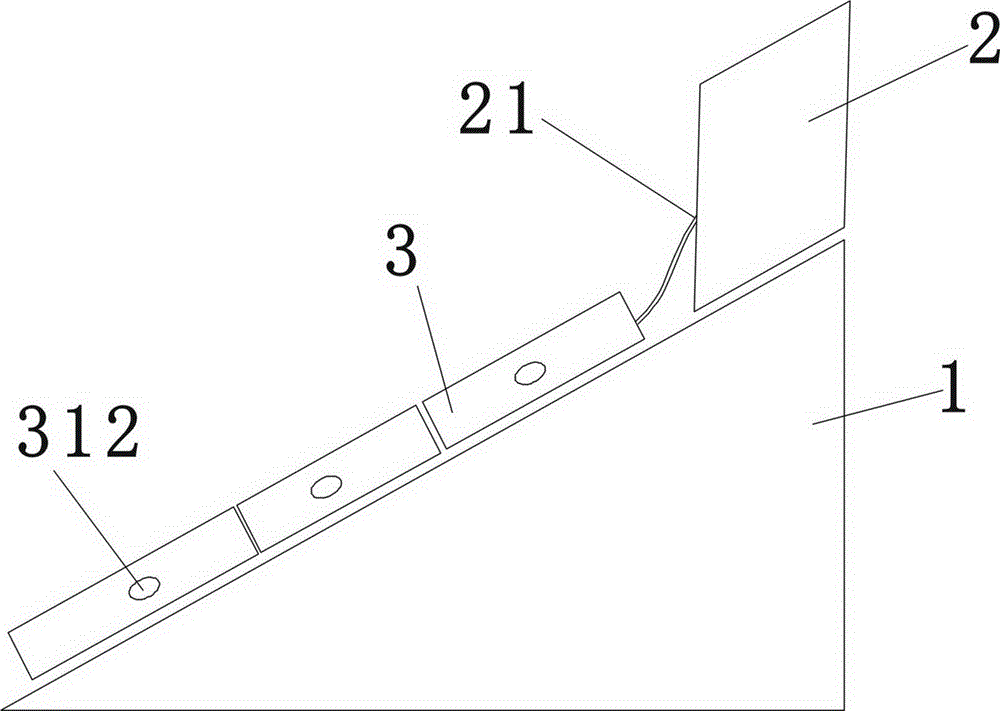

Vegetation recovery system and method for vegetation recovery with system

The invention provides a vegetation recovery system which comprises an exposed hillside with a certain slope or level sandy land, a water cellar arranged in a high position of the hillside or a level position higher than the sandy land, vegetation planting units laid along a sloping surface of the hillside or the sandy land lower than the water cellar, a main flow pipe and branch pipes; the vegetation planting units comprise square plastic frames, crossed four-way pipes located in the centers of the plastic frames and provided with openings on the top surfaces, and cotton yarns located at the openings of the top surfaces of the four-way pipes and extending to the side edges of the plastic frames; the four-way pipes in the centers of the adjacent vegetation planting units are mutually connected via the branch pipes; one end of the main flow pipe is connected with a water outlet at the bottom of the water cellar; and the other end of the main flow pipe is connected with the branch pipe in any vegetation planting unit.The vegetation recovery system employs the vegetation planting units in special structures, is convenient to construct and low in maintenance cost, and does not require manual sprinkling and watering, a plant survival rate is high, and after plants grow, roots of the plants can penetrate into rock or the earth surface and can exert a good water holding and soil fixation effect.The invention further provides a method for vegetation recovery of the hillside or the sandy land exposing the rock with the vegetation recovery system.

Owner:王承辉

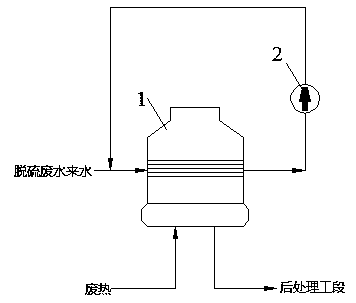

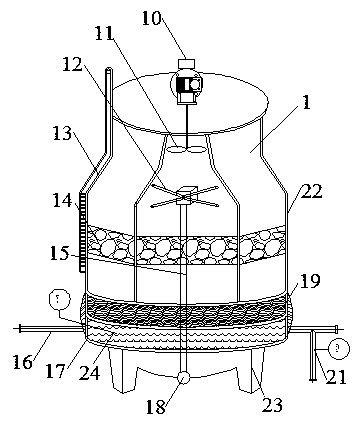

Efficient energy-saving concentration treatment device for desulfurization wastewater

PendingCN110316778AEven distribution of water flowImprove heat exchange performanceWaste water treatment from gaseous effluentsWater/sewage treatment by heatingEfficient energy useHigh concentration

Owner:国能浙江北仑第一发电有限公司 +1

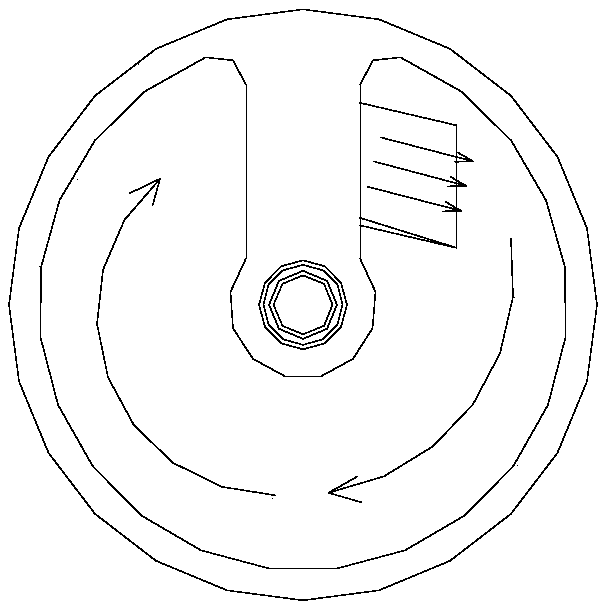

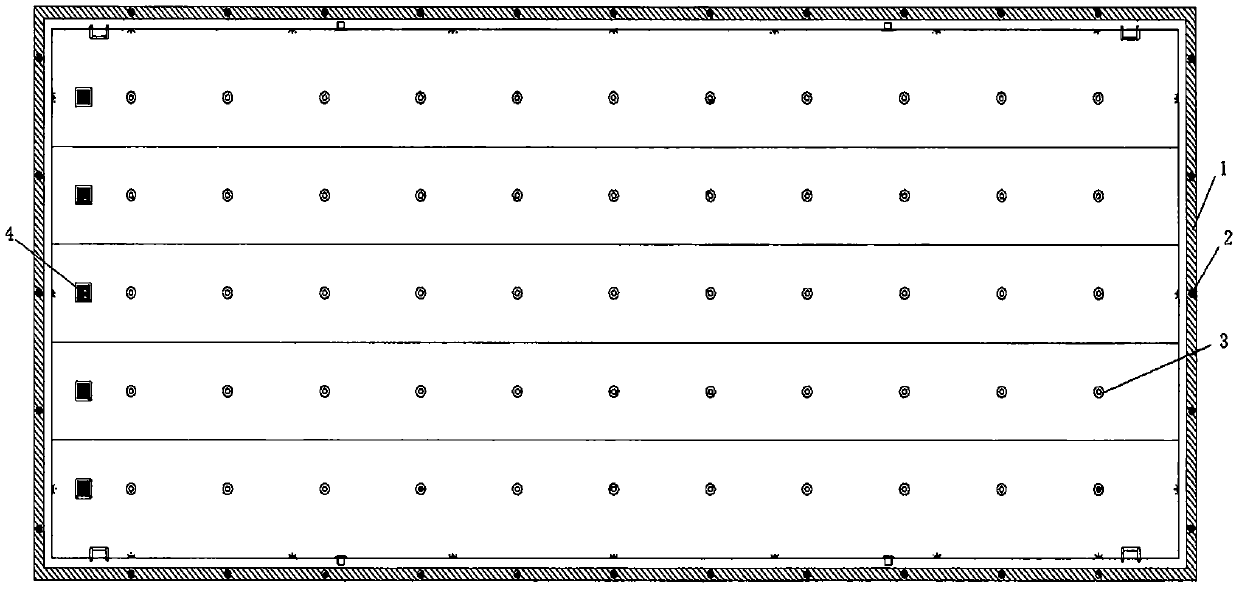

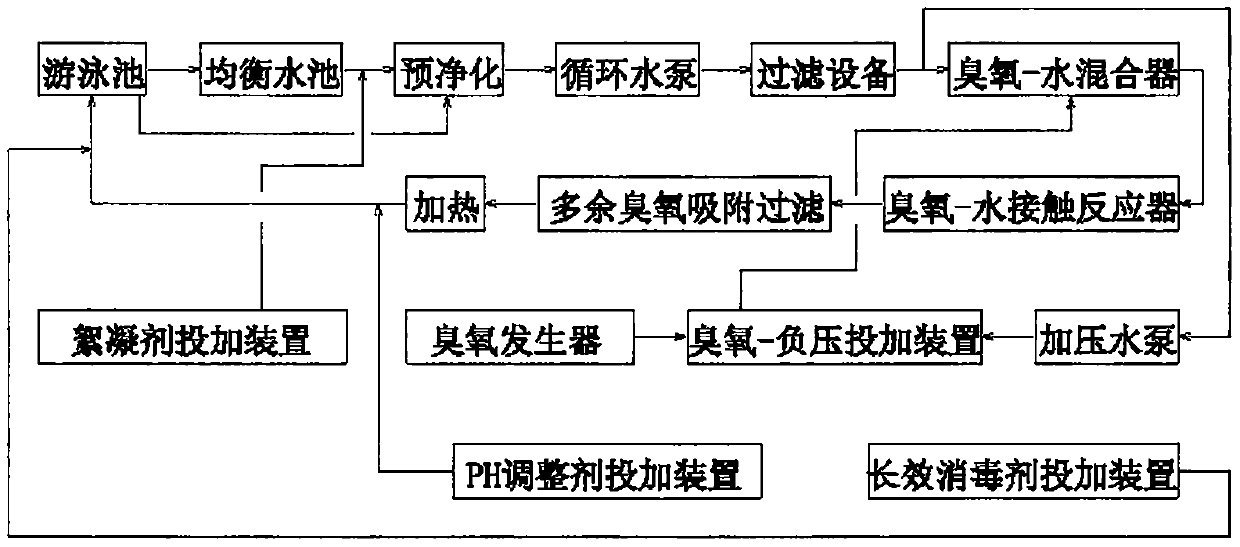

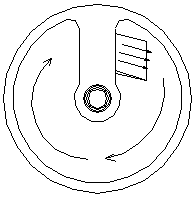

Construction technology for mixed-flow and countercurrent swimming pool

InactiveCN107795157AUniform free residual chlorineUniform and consistent pH valueGymnasiumSwimming poolsMixed flowMarine engineering

A mixed-flow and countercurrent swimming pool includes a swimming pool body, a water circulating purifying and supplying system, a disinfecting system, a heating and constant temperature system and awater quality regulation system. The swimming pool body is connected with each system through pipelines and internally provided with a bottom emptying opening, water inlets, an overflow backwater opening, pollution sucking openings, an escalator, a swimming lane line and an underwater lamp. The bottom emptying opening is arranged on one side of a deep water area of the bottom of the swimming poolbody. The water inlets are distributed at the bottom of the swimming pool body in a net shape. The overflow backwater opening is arranged in an overflow backwater tank at the periphery of the swimmingpool body. The pollution sucking openings are formed in the position of 200 mm below the water surface of the swimming pool body and evenly formed. The water circulating purifying and supplying system adopts a countercurrent or mixed-flow circulating mode. By means of a construction technology for the mixed-flow and countercurrent swimming pool, water flow distribution uniform can be achieved, short flow, eddy current and a stagnant zone do not exist, it is ensured that the PH value of free residual chlorine of different water layers is uniform and consistent, and the situation of pollutant deposition at the bottom of the swimming pool is reduced effectively.

Owner:朱旭东

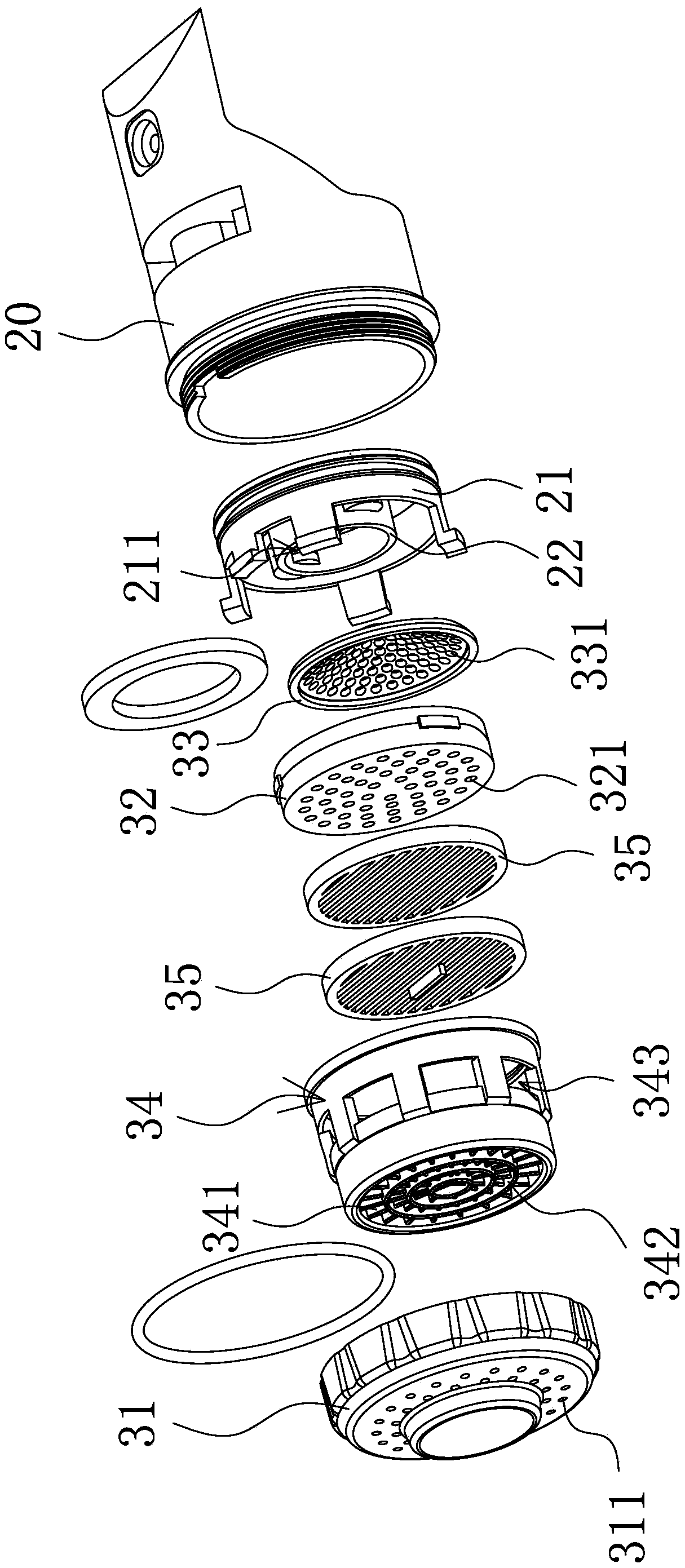

Integrated reverse osmosis filter element

InactiveCN107399837AReduce the numberImprove the level of integrationTreatment involving filtrationMultistage water/sewage treatmentWater filterReverse osmosis

The invention relates to an integrated reverse osmosis filter element. A water collecting pipe is arranged at the center of the reverse osmosis filter element, a water collecting hole is formed in the water collecting pipe, and purified water filtered by the reverse osmosis filter element is collected by the water collecting hole and flows into the water collecting pipe; and a rear filter element is arranged in the water collecting pipe, and the rear filter element further filters the purified water flowing into the water collecting pipe. By virtue of the arrangement, the rear filter element is arranged in the water collecting pipe of the reverse osmosis filter element in an integrated way, so that the reverse osmosis filter element integrates the rear filter element which has the functions of improving taste of the purified water filtered by a reverse osmosis membrane and adding minerals; meanwhile, overall size of the integrated reverse osmosis filter element after integration is not changed, and the aims of optimizing design, reducing the number of the filter elements and improving filter element integration level are achieved; and besides, the integrated reverse osmosis filter element provided by the invention is simple in structure, obvious in effect and applicable to popularization and application.

Owner:QINGDAO ECONOMIC & TECHN DEV ZONE HAIER WATER HEATER

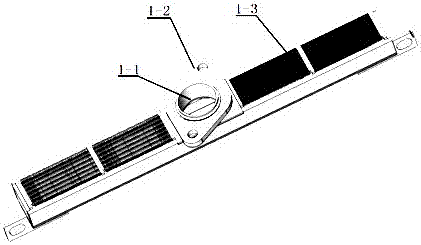

Improved water outlet device of ozone water generator

InactiveCN105508725AReduce impactImprove work efficiencyValve members for absorbing fluid energyOzoneEnvironmental engineering

The invention provides an improved water outlet device of an ozone water generator, belongs to the technical field of machinery and solves the problem that existing water outlet devices of ozone water generators are inconvenient to use. The improved water outlet device of the ozone water generator comprises a casing and a water outlet pipe, wherein the casing has an accommodating cavity for generating ozone water; the water outlet pipe is arranged on one side of the casing and used for outputting the ozone water, and a sprinkler unit for dispersing the ozone water and spraying the ozone water to the outside is mounted at an outlet of the water outlet pipe. The improved water outlet device has the advantages of high working efficiency and convenience in use.

Owner:ZHEJIANG ECO ELECTROMECHANICAL MFG CO LTD

Water supplying filtering device

InactiveCN102580393AThe principle is clearSimple structureWatering devicesFiltration separationPolyesterYarn

The invention discloses a water supplying filtering device, wherein a material with a capillary water sucking function is covered on the wall of a water utensil for supplying water, and the material can be cotton cloth, cotton yarn, non-woven fabrics, polyester yarns and the like. One end of the device is arranged in the water utensil for supplying water, the other end of the device is arranged outside the water utensil for supplying water, the middle portion of the device upwards passes through the wall of the water utensil for supplying water, and the device is reversely covered on the wall of the water utensil for supplying water in a reversed-U shape. The material with the capillary water sucking function sucks water upwards in the water utensil for supplying water and prevents particles in a water body from flowing upwards by using a capillary structure material, and the material with the capillary water sucking function generates siphon principle under effect of weight and pressure and leads water to flow downwards outside the water utensil for supplying water.

Owner:陈国柱

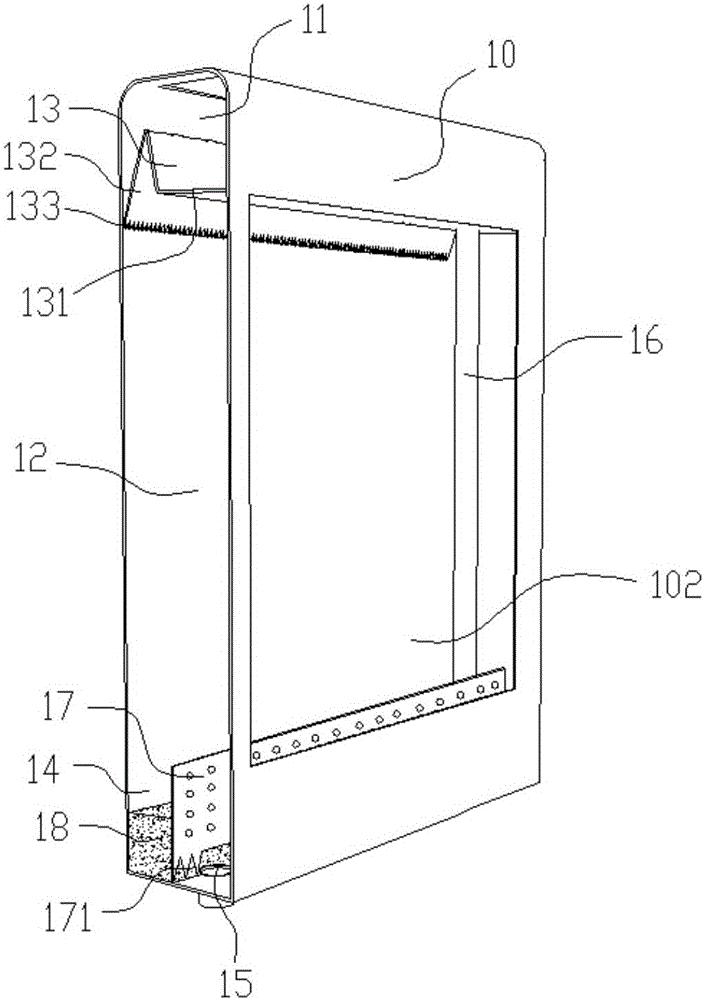

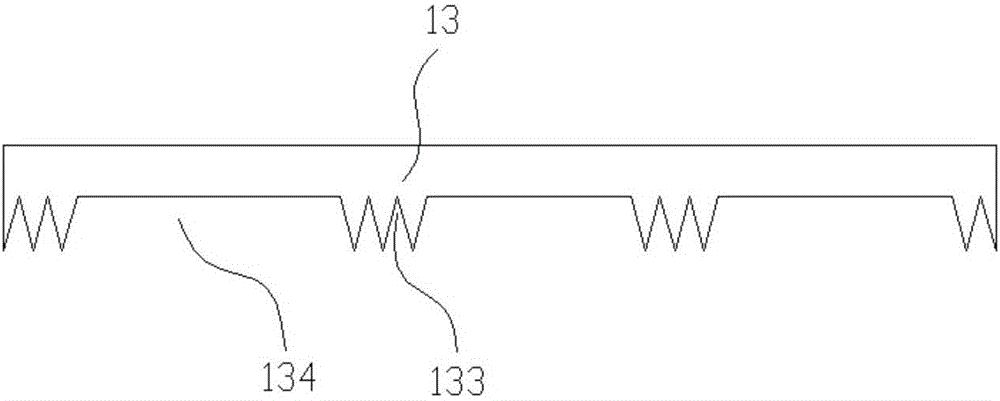

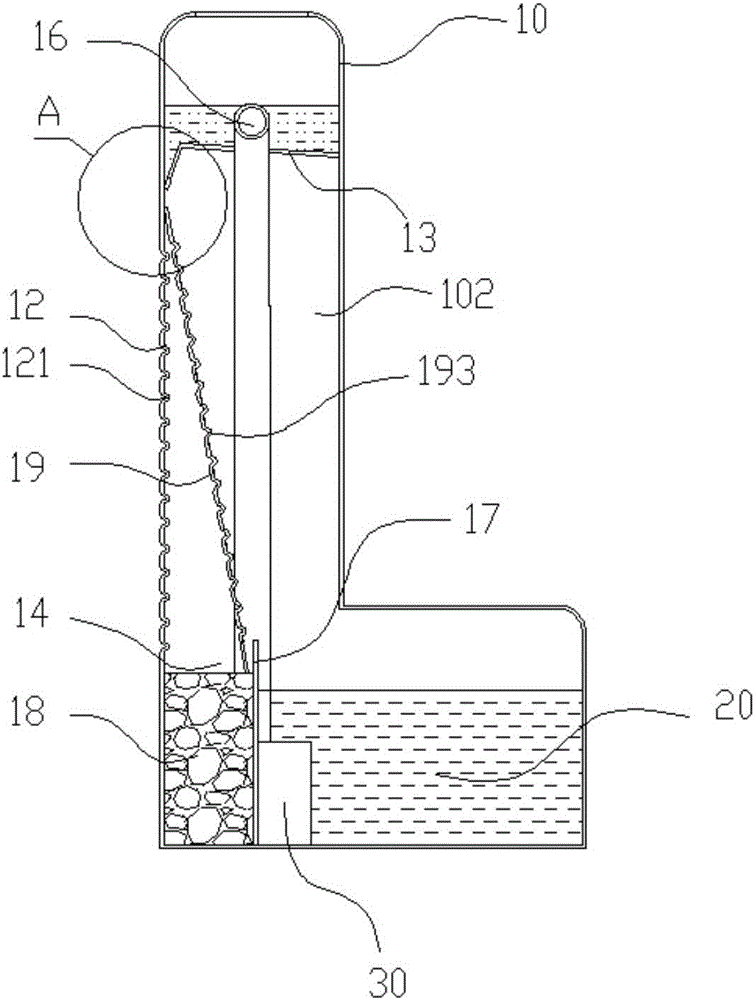

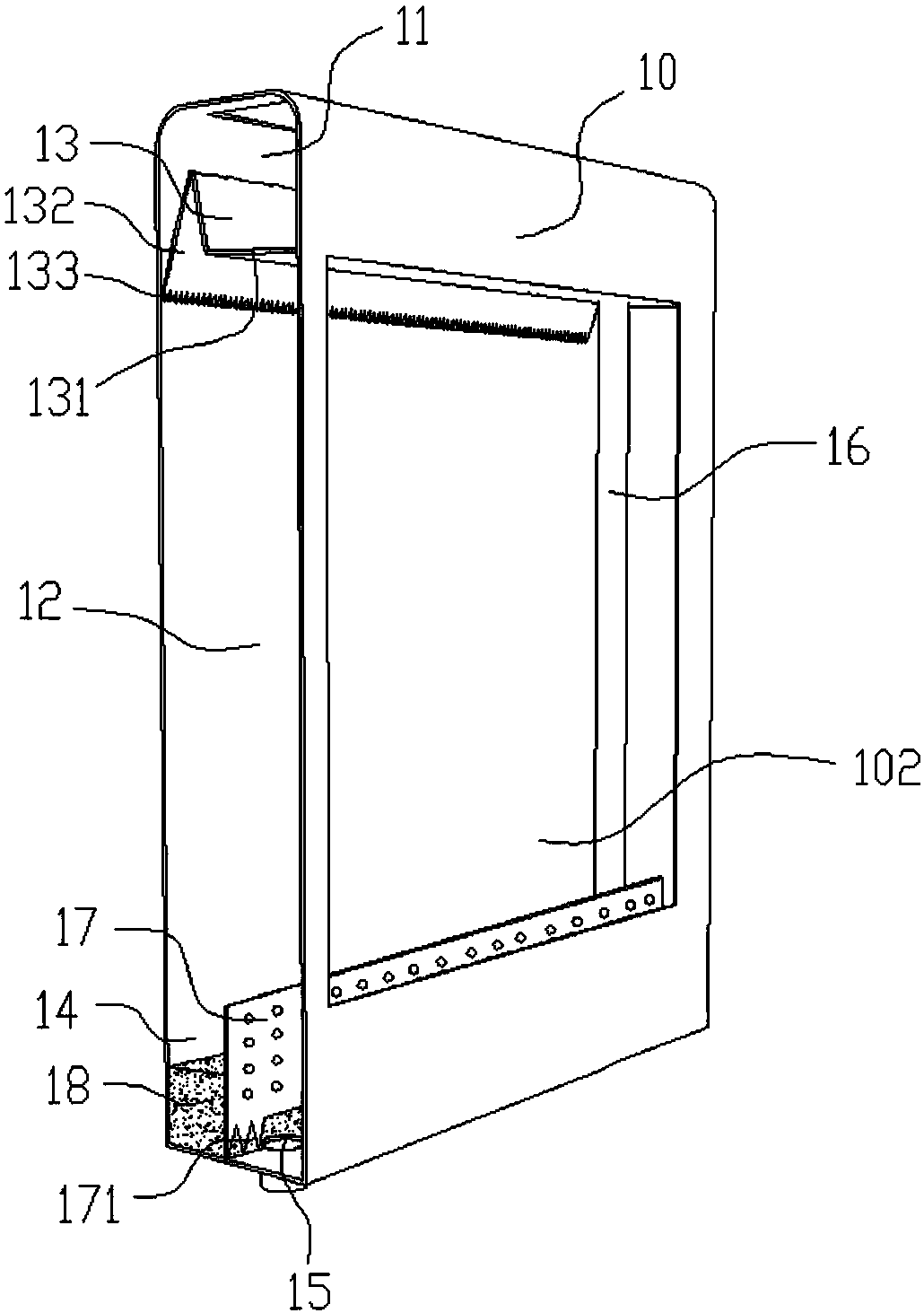

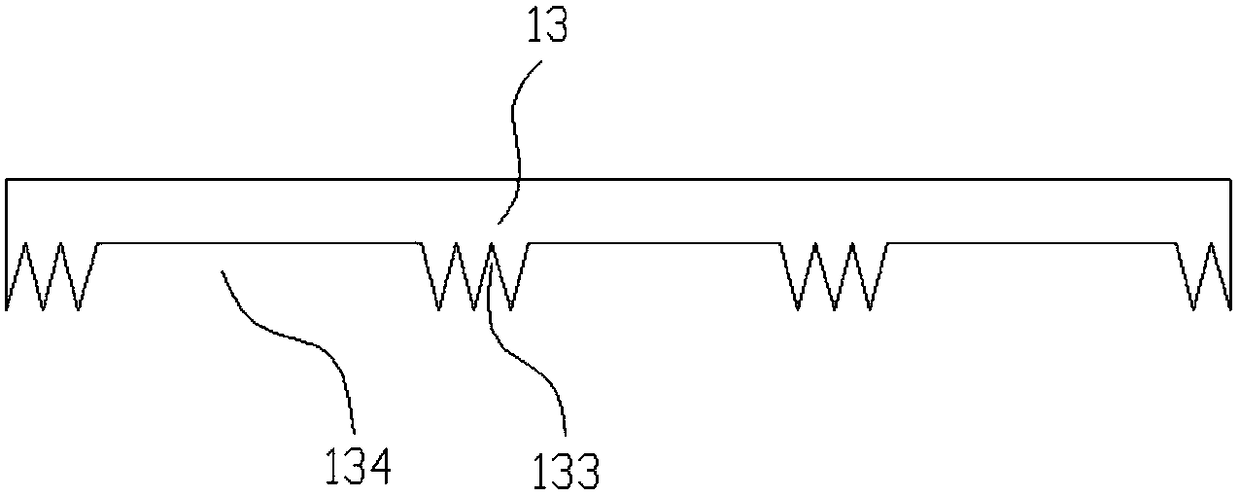

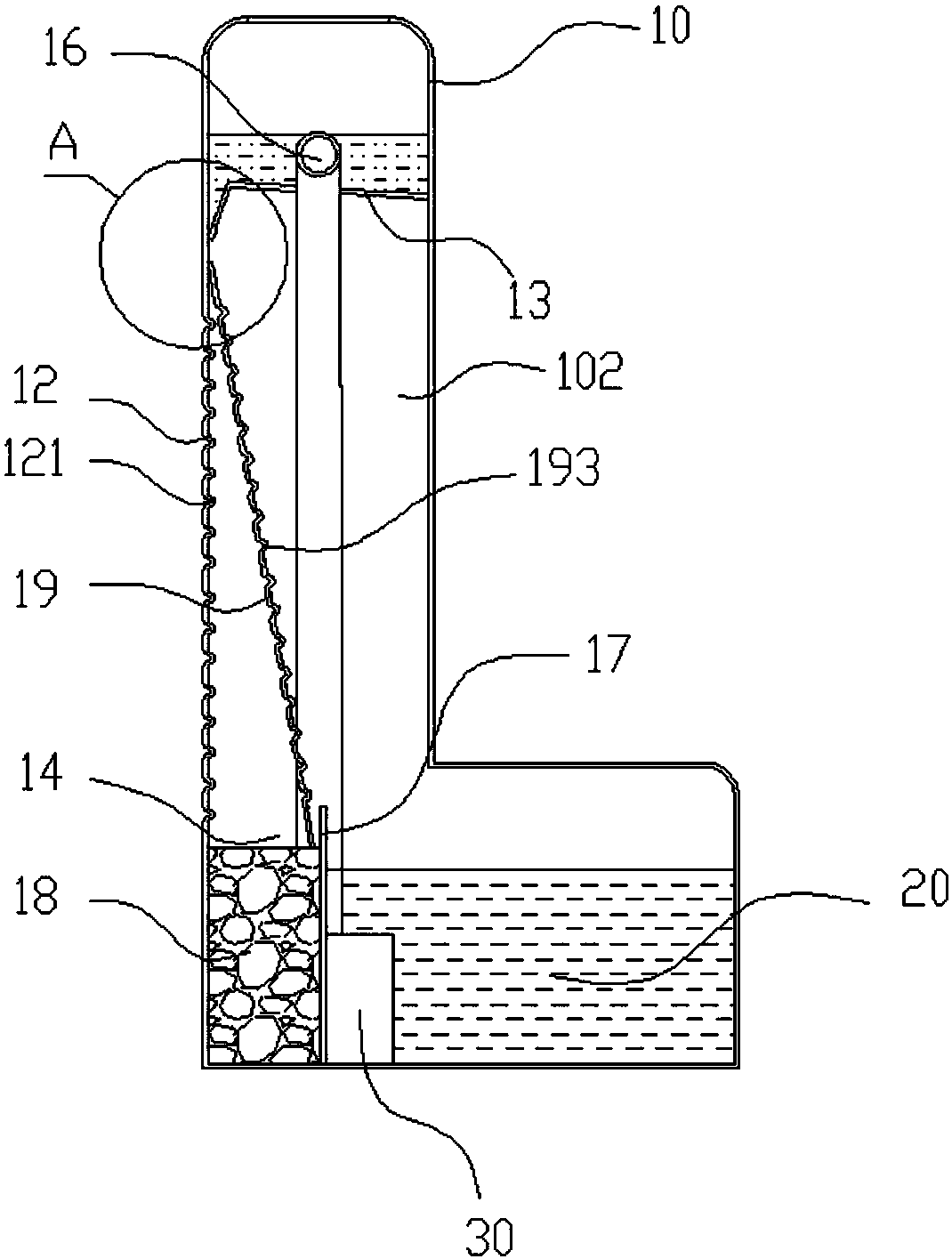

Water circulating humidifier mounted on heating plate

ActiveCN105890093AIncrease humidityComfortable lifeLighting and heating apparatusSpace heating and ventilation detailsWater dischargeWater vapor

The invention provides a water circulating humidifier mounted on a heating plate. The water circulating humidifier comprises a machine shell, a water storage tank and a water pump; a water dispersion groove and a water flowing wall are arranged on the machine shell; the machine shell is provided with an air outlet which faces to the water flowing wall; the water flowing wall is arranged in the vertical direction of the water dispersion groove; the water pump is mounted inside the water storage tank and is used for conveying water into the water dispersion groove; a water discharging gap is formed between the water flowing wall and the water dispersion groove; water flows to the water flowing wall along the water discharging gap and is capable of absorbing heat; a part of the water is evaporated into water steam and is exhausted via the air outlet; the other part of the water reflows to the water storage tank along the water flowing wall. The water circulating humidifier has the advantages of remarkable humidification effect and low cost.

Owner:李铁超

Autotrophic denitrification artificial pond, construction method and method for denitrifying sewage by utilizing artificial pond

InactiveCN111717995AHigh deep denitrification efficiencyConducive to deep denitrificationWater contaminantsTreatment with aerobic and anaerobic processesWater qualityTotal nitrogen

The invention discloses an artificial pond, a construction method and a method for deep denitrification of sewage by using the artificial pond, and belongs to the field of innovation of environmentalengineering water treatment processes and theories. An artificial pond bed body is excavated in a sewage land to be treated, and filler blocks comprising sulfur, limestone, zeolite and volcanic rock are laid in a sulfur filler area at the bottom; an ecological floating island floating in water is arranged in the water body of the artificial pond, plants are planted on the part above the water surface, and a biological carrier filler is suspended on the part below the water surface. To-be-treated sewage is introduced into the artificial pond, and a bio-film culturing treatment is performed until the effluent quality is stable and the total nitrogen removal rate reaches 75% or above. A nitrification and de-nitrification treatment is carried out on ammonia nitrogen in the sewage by the artificial pond to realize deep nitrogen removal; the filler in the artificial pond is detachable, the artificial pond is convenient to construct and disassemble; the turbidity of the effluent treated by the method is obviously reduced, the manufacturing cost is low, the nitrogen removal efficiency is high, and the removal rates of ammonia nitrogen, total nitrogen and nitrate nitrogen all reach 80% or above.

Owner:BEIJING FORESTRY UNIVERSITY

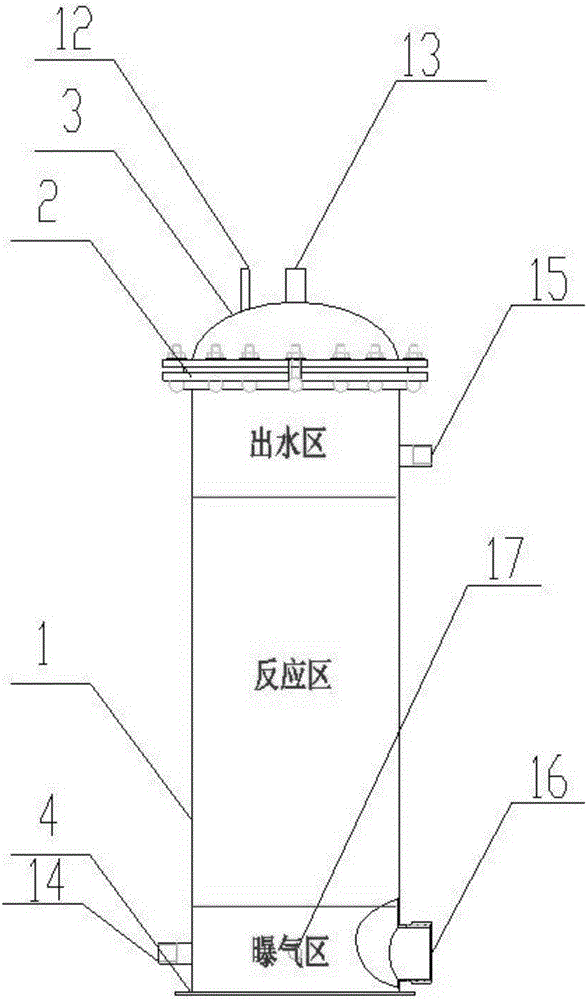

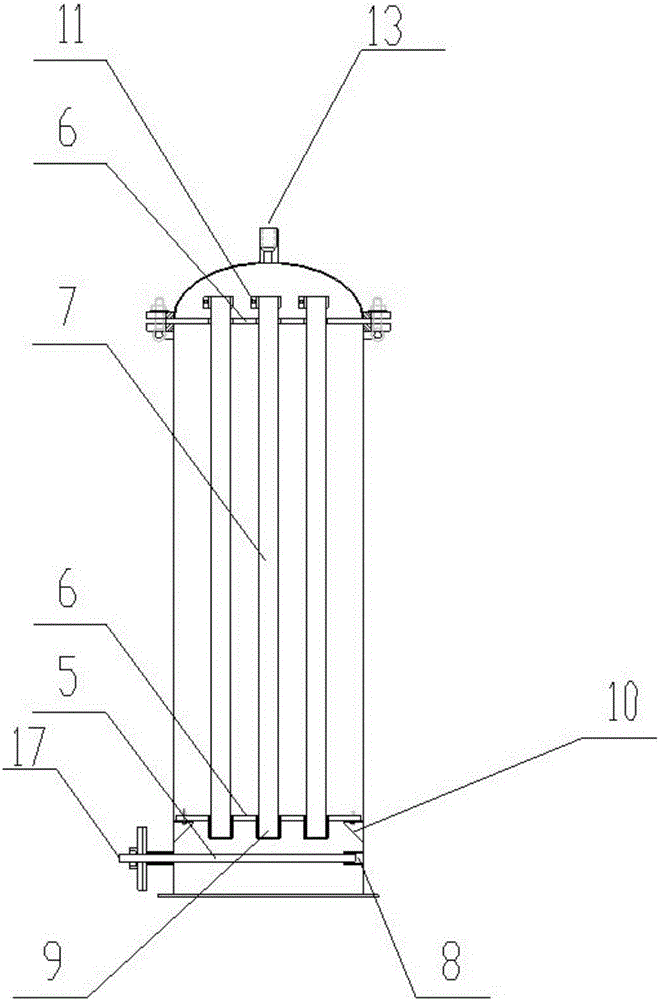

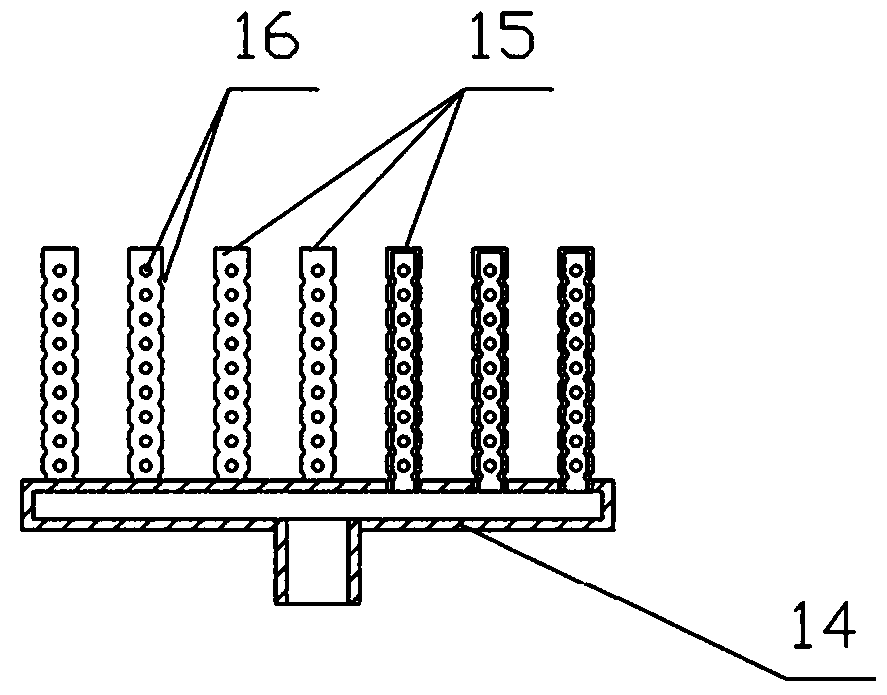

Electro-catalysis treatment device for seawater circulation culture system

ActiveCN105236525AEfficient removalClean environmentWater contaminantsWater/sewage treatment using germicide/oligodynamic-processElectricitySmall footprint

The invention discloses an electro-catalysis treatment device for seawater circulation culture system. The electro-catalysis treatment device comprises a barrel, a water inlet, an air inlet, a water outlet and an exhaust opening, wherein the water inlet and the air inlet are located in the bottom of the barrel, and the water outlet and the exhaust port are located in the top of the barrel. Multiple carbon rods are arranged in the barrel and parallel to a barrel body, and the carbon rods extend above the water outlet from the water inlet. The parts between the carbon rods are filled with catalyst particles. According to the device, ammonia nitrogen and COD in seawater culture waste water can be effectively removed, the trouble caused by the high salinity of seawater is converted into advantages, the seawater circulation culture system is made to stably run, and the electro-catalysis treatment device is efficient, convenient to use, small in occupied space, economical and environmentally friendly.

Owner:无锡市艾坦姆环保科技有限公司

Dust-collecting pole plate fixing structure, anode system and flexible wet electrostatic dust remover

ActiveCN107297279AGuaranteed clearanceEasy to assembleElectrode carrying meansExternal electric electrostatic seperatorEngineeringMechanical engineering

The invention discloses a dust-collecting pole plate fixing structure, an anode system and a flexible wet electrostatic dust remover. The dust-collecting pole plate fixing structure comprises a limiting device matched with a vertical column or / and a fixing device on a dust-collecting pole plate, wherein a plurality of longitudinal grooves are uniformly formed in the side surface of the vertical column so as to insert flexible pole plates; the limiting device comprises a connector; a convex column body capable of being inserted into the cavity of the vertical column is arranged at the upper end of the connector and a plurality of clamping slots are formed in the lower end of the connector so as to achieve flexible insertion; the fixing device comprises parallel clamping plates arranged on the two sides of the flexible pole plates, and a plurality of tightening components which are distributed along the clamping plates at intervals and clamp the flexible pole plates and flexible components on the inner side of the dust-collecting pole plate, so that close fit between the clamping plates and the flexible pole plates is achieved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

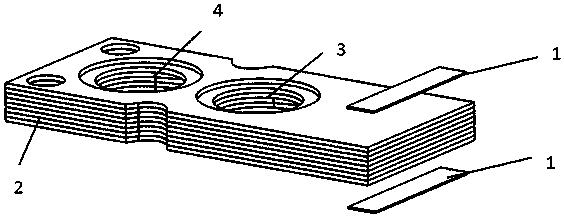

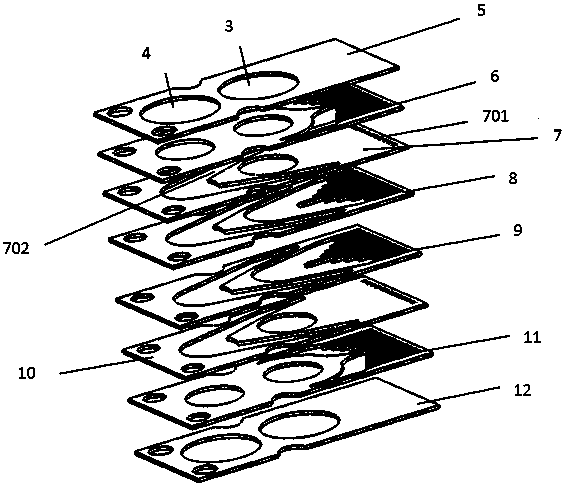

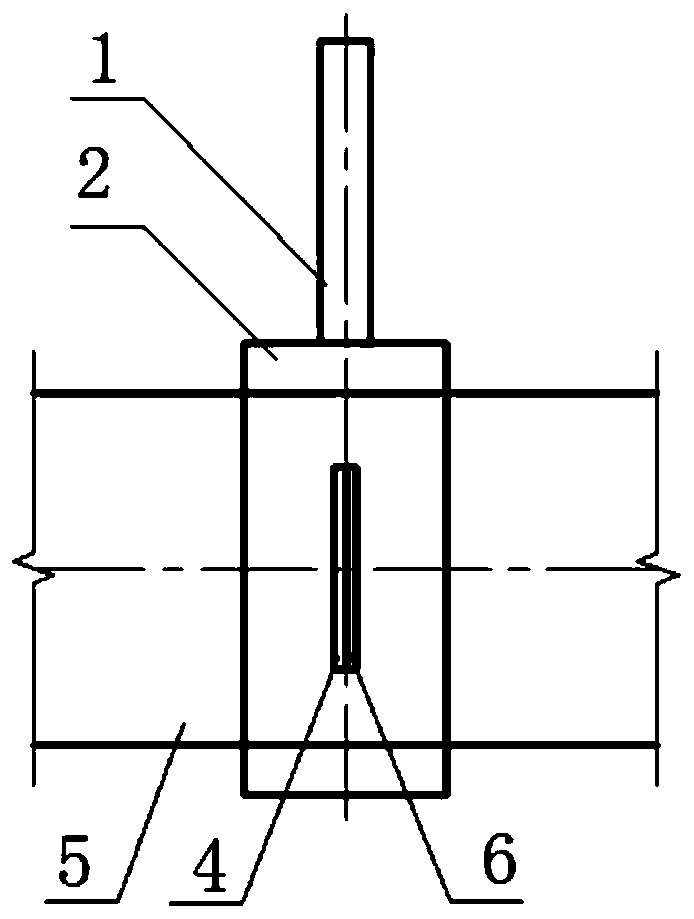

Double-side heat dissipation refrigerator and semiconductor device

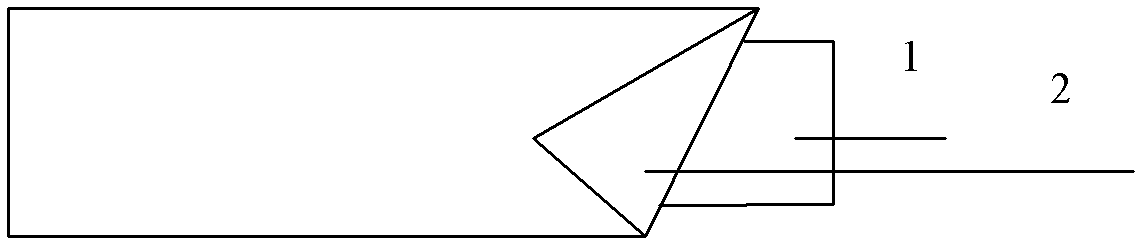

PendingCN107732652AEven distribution of water flowThere will be no local heat dissipationLaser detailsSemiconductor lasersWater flowEngineering

The invention proposes a double-side heat dissipation refrigerator. The double-side heat dissipation refrigerator is provided with a liquid inlet hole, a liquid outlet hole and a refrigeration water path, wherein the refrigeration water path communicates with the liquid inlet hole and the liquid outlet hole and comprises two water flow passages respectively along an upper end surface and a lower end surface of the double-side heat dissipation refrigerator, so that a refrigerating liquid flows through the liquid inlet hole, then respectively flows along the two water flow passages and is converged to and flows out of the liquid outlet hole, and heat dissipation of a bidirectional and parallel passage is achieved. Meanwhile, the invention also proposes a package structure of a semiconductordevice employing the double-side heat dissipation refrigerator, the application of a high-power density semiconductor device can be achieved and the reliability of the semiconductor device is ensured.

Owner:FOCUSLIGHT TECH

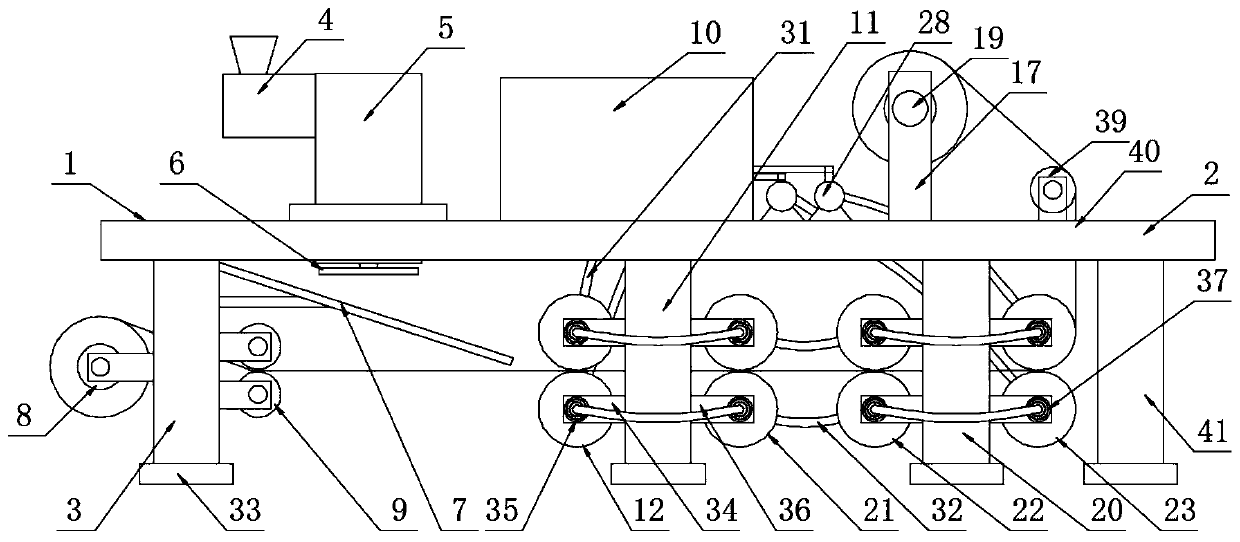

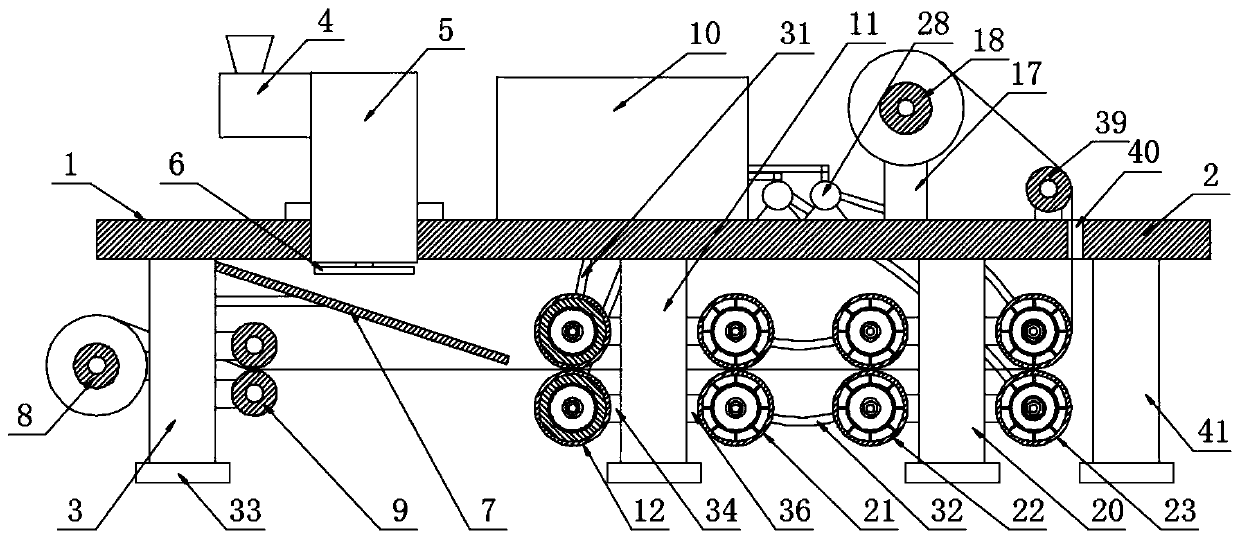

Equipment used for reinforcing composite knitted non-woven fabric

InactiveCN111501257AReduce production processReduce work costsLiquid/gas/vapor treatment of indefinite length materialsNon-woven fabricsWater storage tankWater flow

The invention discloses equipment used for reinforcing composite knitted non-woven fabric, and relates to the technical field of non-woven fabric equipment. The equipment comprises a supporting plate,a melting box, a high-pressure pushing mechanism, a spray head, a guide plate, a discharge roller, a first guide roller, a water storage tank, a hot pressure roller, a material receiving frame, a first cooling roller, a second cooling roller, a third cooling roller, a water pump, a first water conveying tube, a second water conveying tube and a third cavity. The equipment can perform three-time cooling treatment on semi-finished product cloth, gradually reduces a cooling temperature, can realize gradual type cooling treatment on the semi-finished product cloth, enables a knitted fabric layerto tightly paste to a non-woven fabric layer, is better in combination effect, directly conveys semi-finished products of non-woven fabric onto the knitted fabric, can effectively reduce production processes, saves working cost, and shortens processing time; and water flow inside a second cavity enters the third cavity, so that dual cooling treatment on the semi-finished product cloth can be realized, and therefore, semi-finished product cloth cooling is more uniform.

Owner:宁夏灵智科技有限公司

Electrodeionization module

InactiveCN103496765AReduce power consumptionBeautiful shapeSeawater treatmentDispersed particle separationFresh water organismAlloy

The invention discloses an electrodeionization module which comprises a compaction plate, a fixing screw, a freshwater partition plate, a membrane stack, an electrodeionization membrane, an electrode plate and a water channel, wherein the freshwater partition plate is positioned on the outer side of the membrane stack; the electrode plate and the electrodeionization membrane are arranged on the membrane stack; the compaction plate is positioned on the freshwater partition plate; the fixing screw is positioned on a housing; in terms of the material of the electrodeionization module, the freshwater partition plate is made of PE material; the compaction plate is formed by rolling casting of hard alloy aluminum.

Owner:山西永皓煤矸石发电有限公司

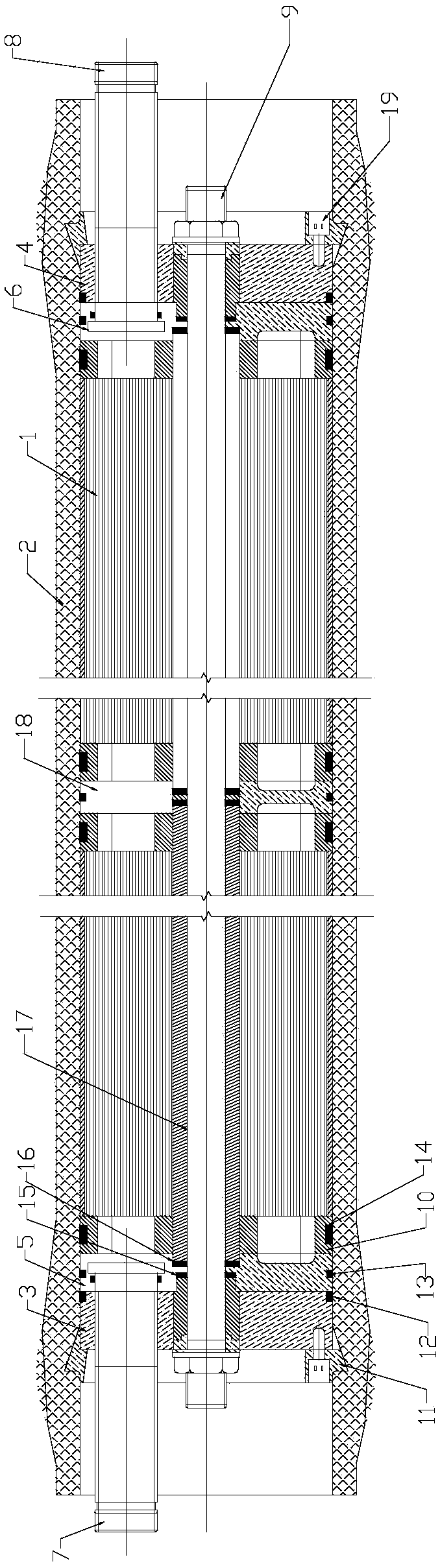

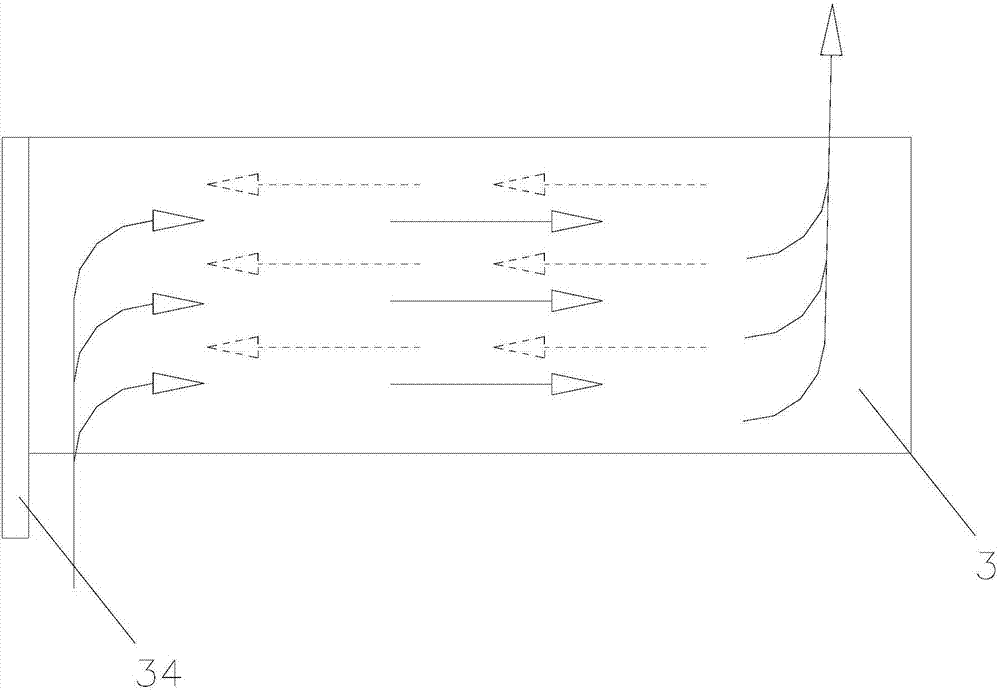

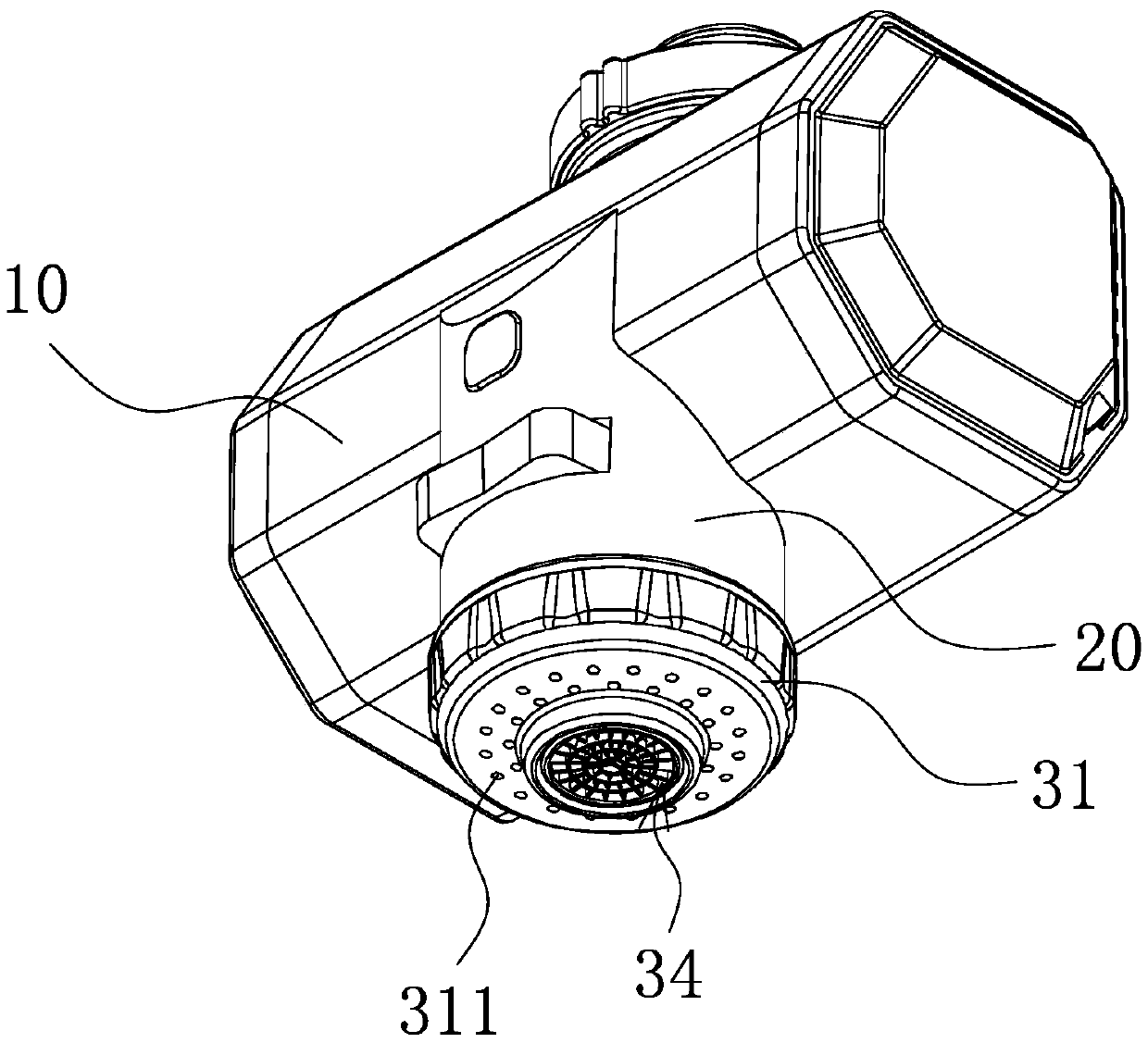

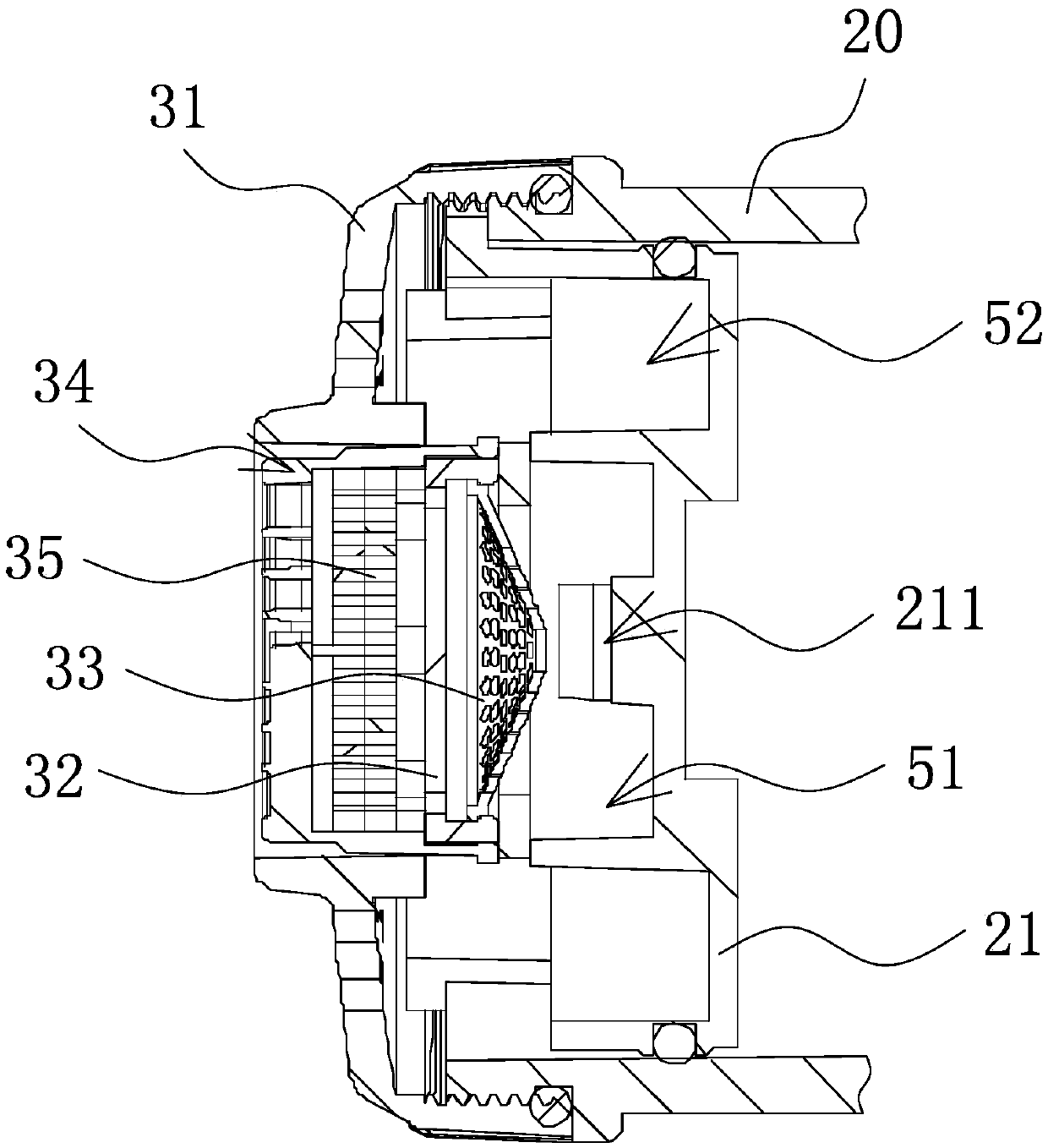

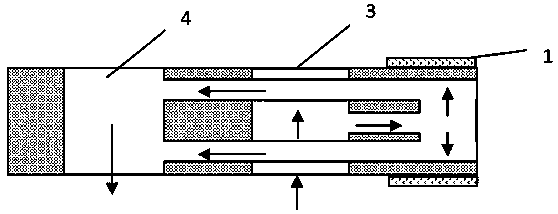

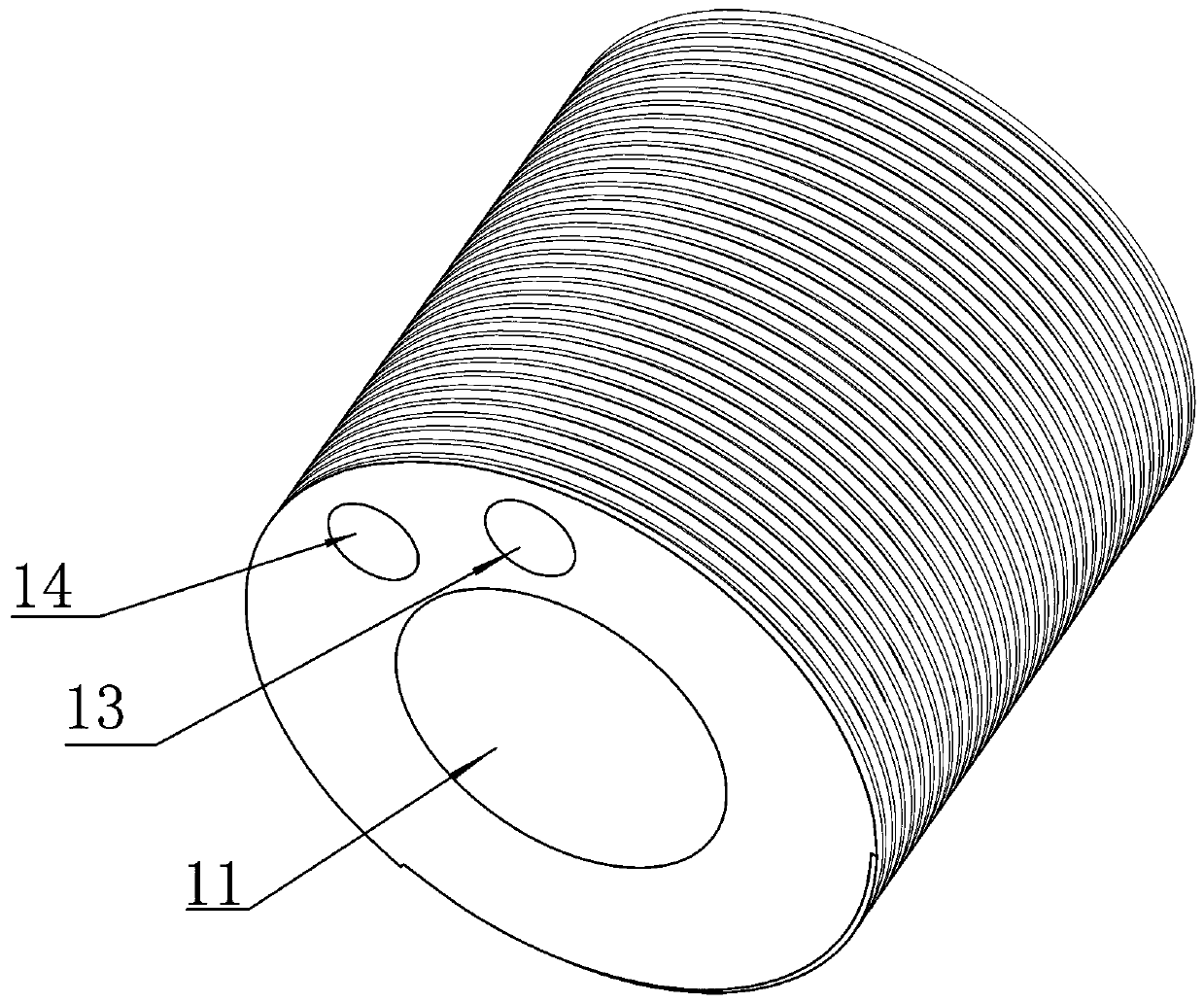

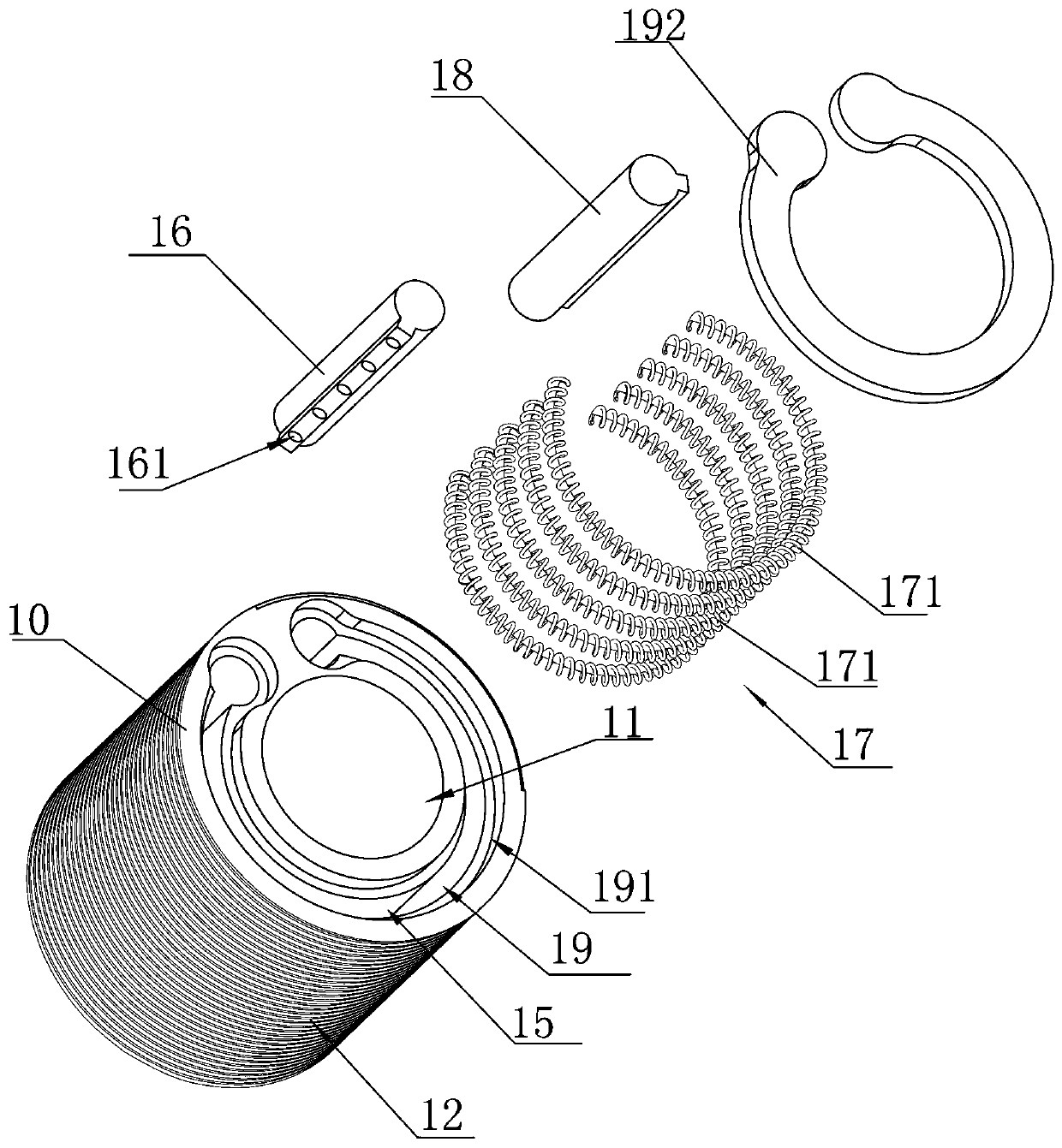

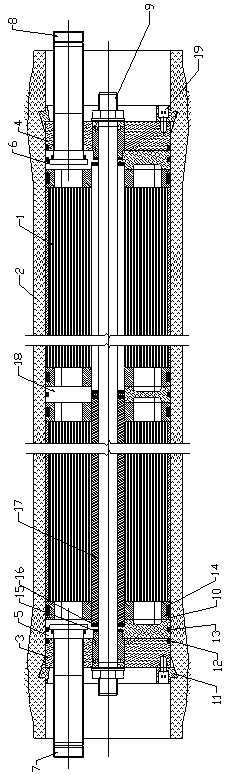

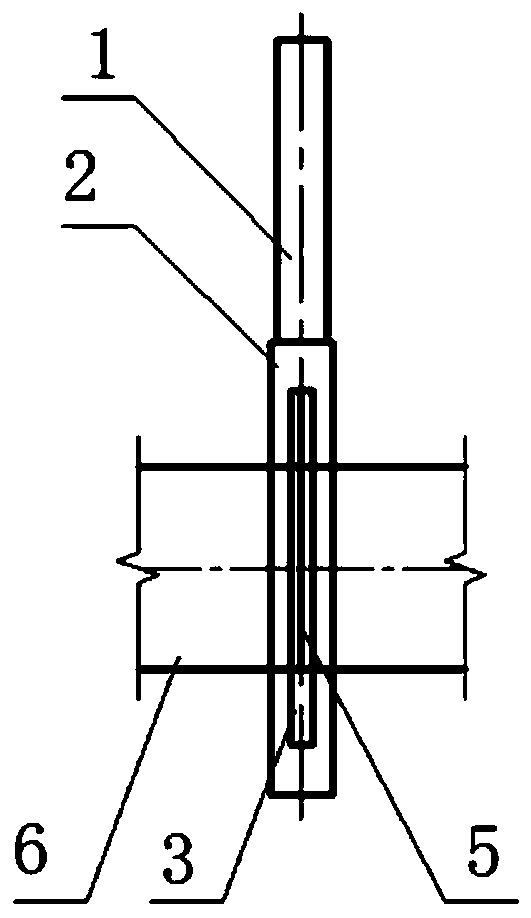

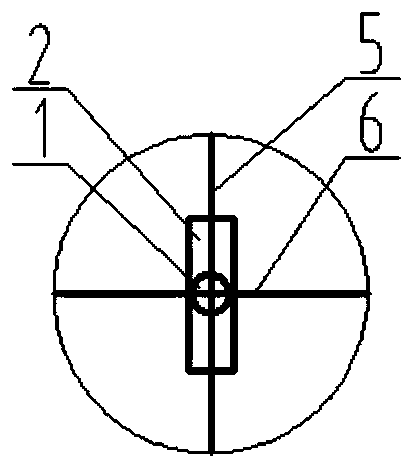

Cylindrical optical fiber water cooling device

PendingCN110068234AImprove cooling effectEven distribution of water flowIndirect heat exchangersHeat transfer modificationWater flowEngineering

The invention provides a cylindrical optical fiber water cooling device. The cylindrical optical fiber water cooling device comprises a cylindrical water cooling body, and a mounting through hole is formed in the cylindrical water cooling body. An optical fiber carving groove for allowing an optical fiber to be wound is formed in the outer surface of the cylindrical water cooling body. A water inlet for water input, a water outlet for water output and a water flow channel communicating with the water inlet and the water outlet are formed in the cylindrical water cooling body. An input water dividing column communicating with the water inlet for dividing water flow entering from the water inlet is arranged in one end of the water flow channel. At least two input water dividing holes communicating with the water flow channel are formed in the input water dividing column in a layered manner. Compared with the prior art, the cylindrical optical fiber water cooling device has the advantagesthat the water flow flows into the water flow channel in a layered manner through the input water dividing column, the water flow flows out in a layered manner through an output flow dividing column,the flowing direction of the water flow is disturbed by a flow disturbing part in the water flow channel, thus the water flow is evenly distributed in the water flow channel, optical fibers wound inthe cylindrical water cooling body are good in heat radiating effect, and meanwhile space is saved.

Owner:东莞市迈泰热传科技有限公司

Porous multi-hollow flexible composite nanofiber membrane material and preparation method thereof

ActiveCN113073426BImprove flexibilityHigh mechanical strengthHollow filament manufactureNon-woven fabricsHollow fibreFiber

The invention relates to a porous multi-hollow flexible composite nanofiber membrane material and a preparation method thereof. The method is to prepare a porous multi-hollow flexible composite nanofiber membrane through coaxial electrospinning; the outer layer solution of coaxial electrospinning is prepared by sacrificial Composed of high molecular polymer, retained high molecular polymer and solvent A; the inner layer solution of coaxial electrospinning is composed of sacrificial high molecular polymer, which can generate both semiconducting properties and low surface energy substances during the spinning process. material and solvent B; then remove the sacrificial polymer in the porous multi-hollow flexible composite nanofiber membrane to obtain a membrane material composed of porous multi-hollow nanofiber stacks, the porous multi-hollow nanofiber has multiple hollow The three-dimensional through-hole micro-nano structure from the pipe and the surface to the hollow; the membrane material of the present invention has good flexibility and mechanical strength, and solves the problems of brittleness and low mechanical strength of porous composite fiber materials and single hollow fiber materials.

Owner:DONGHUA UNIV

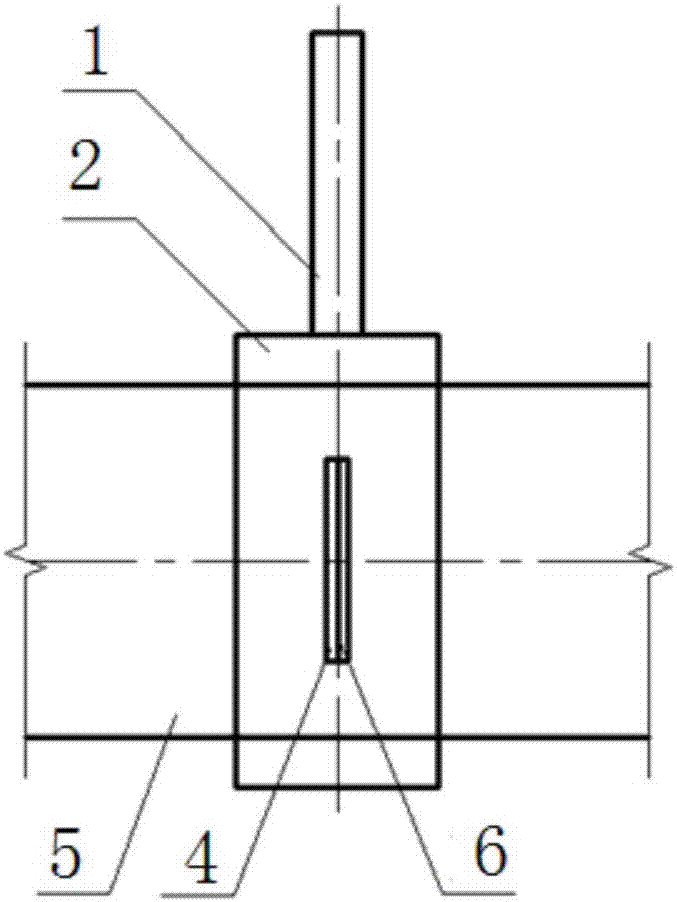

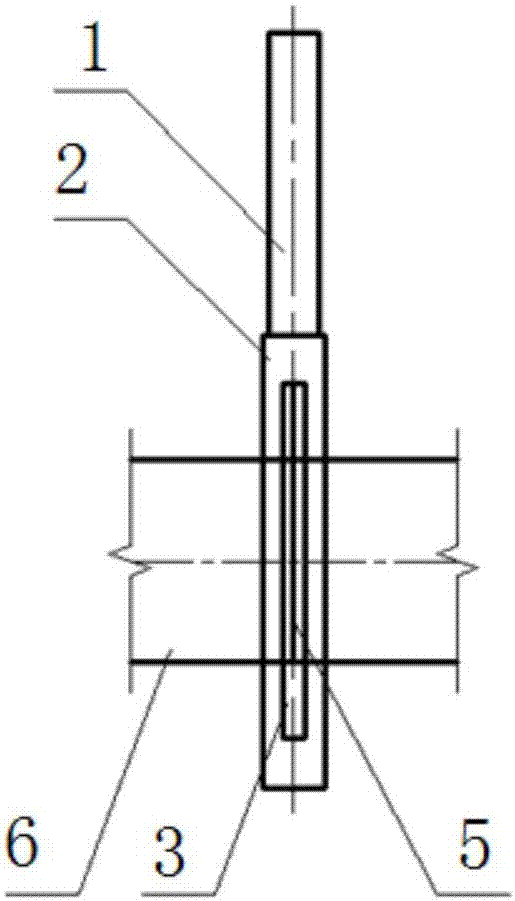

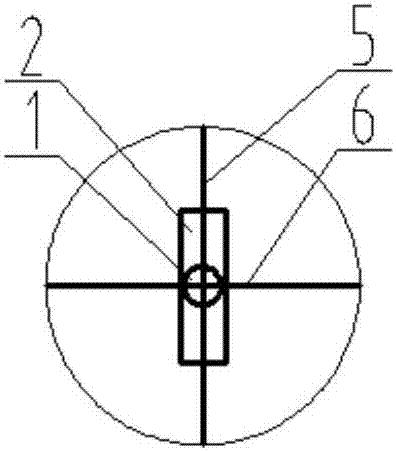

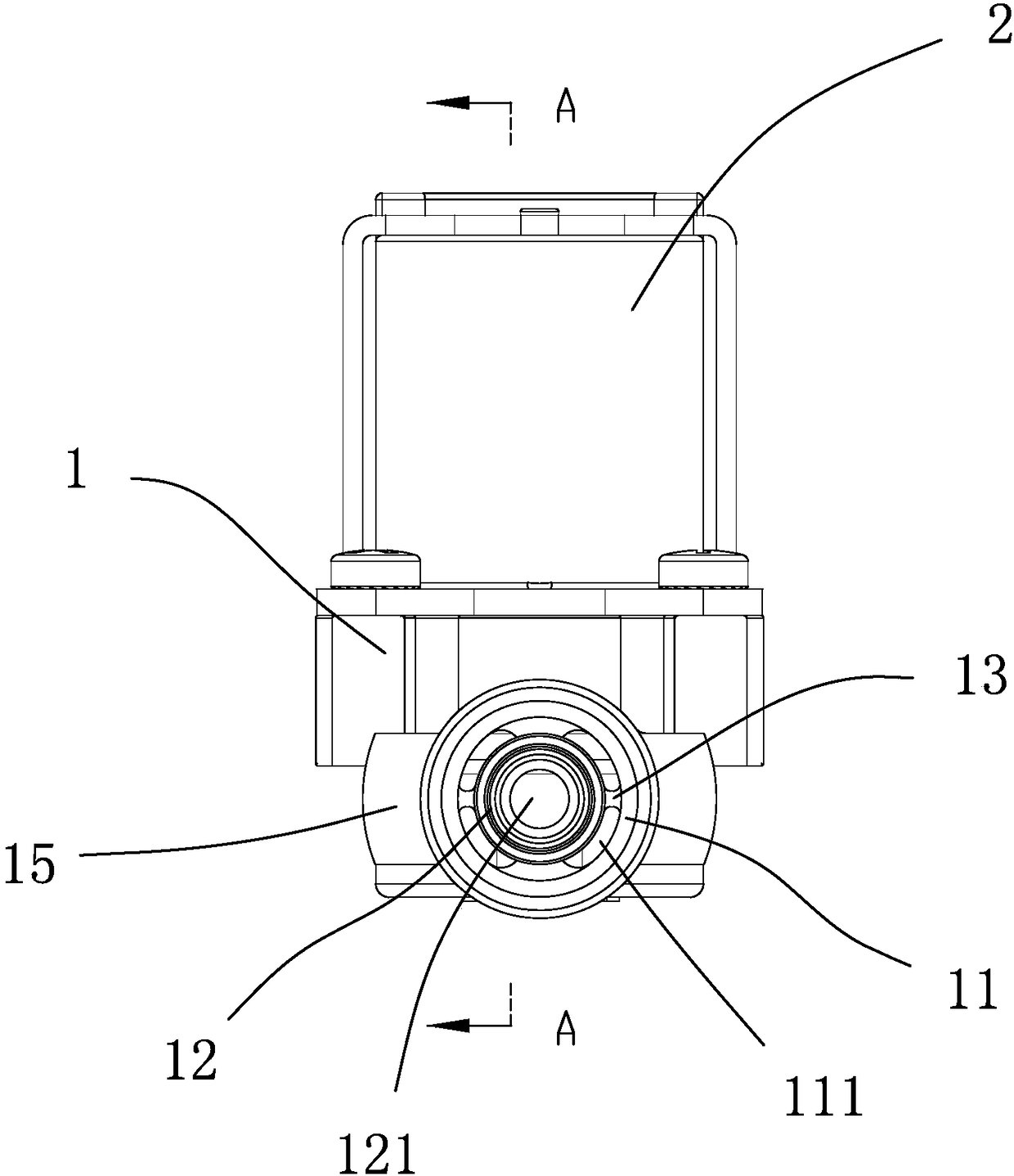

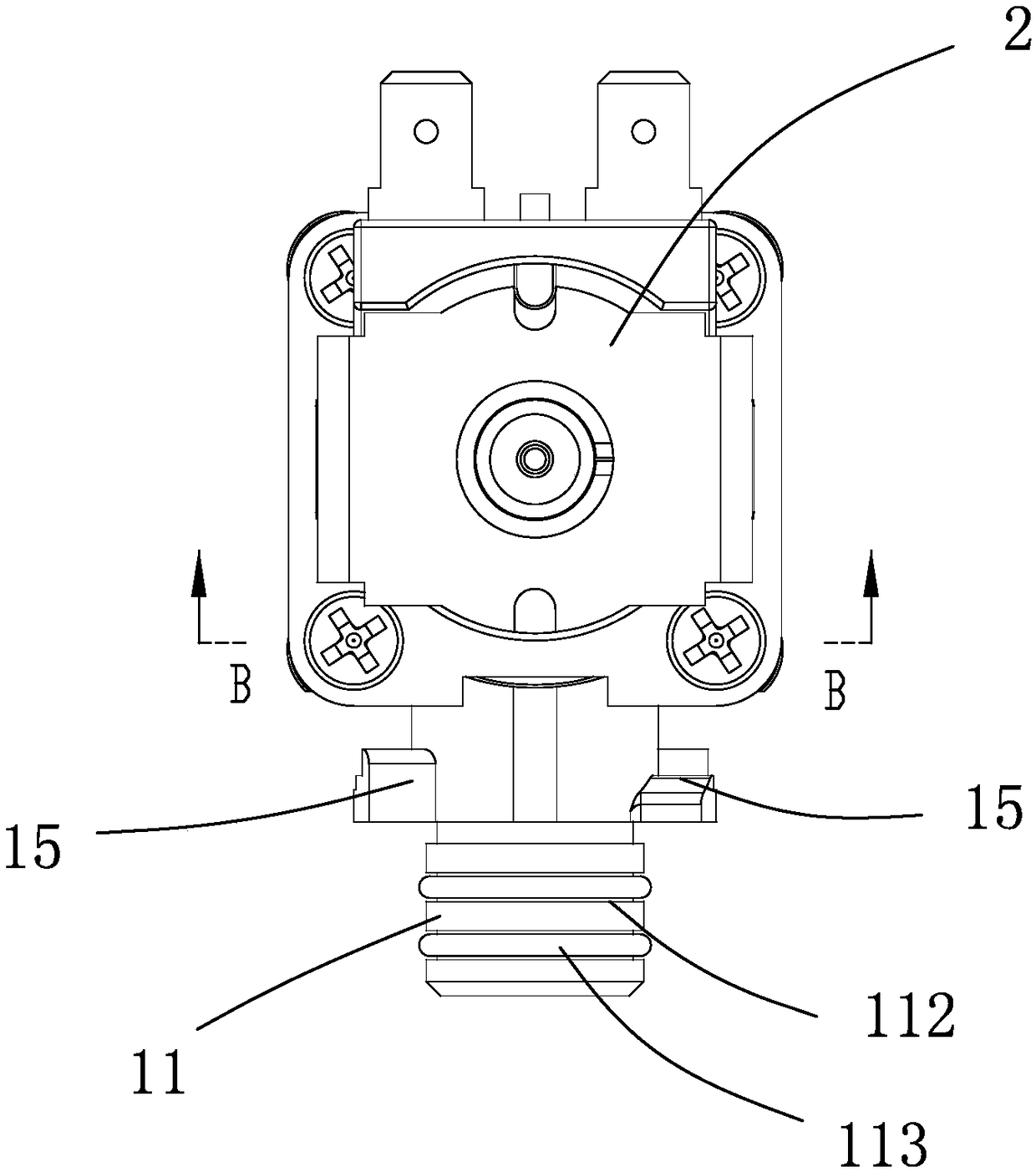

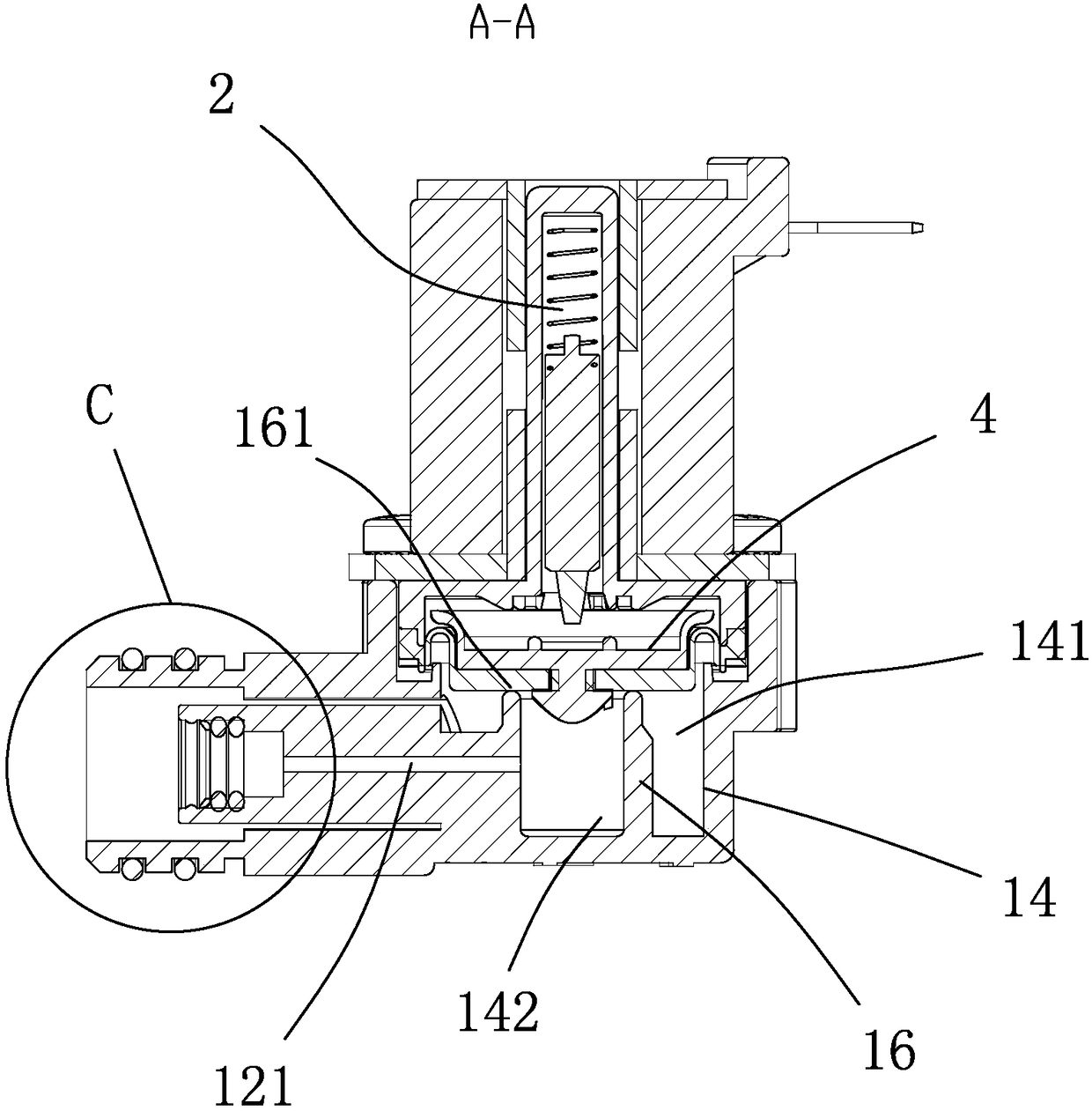

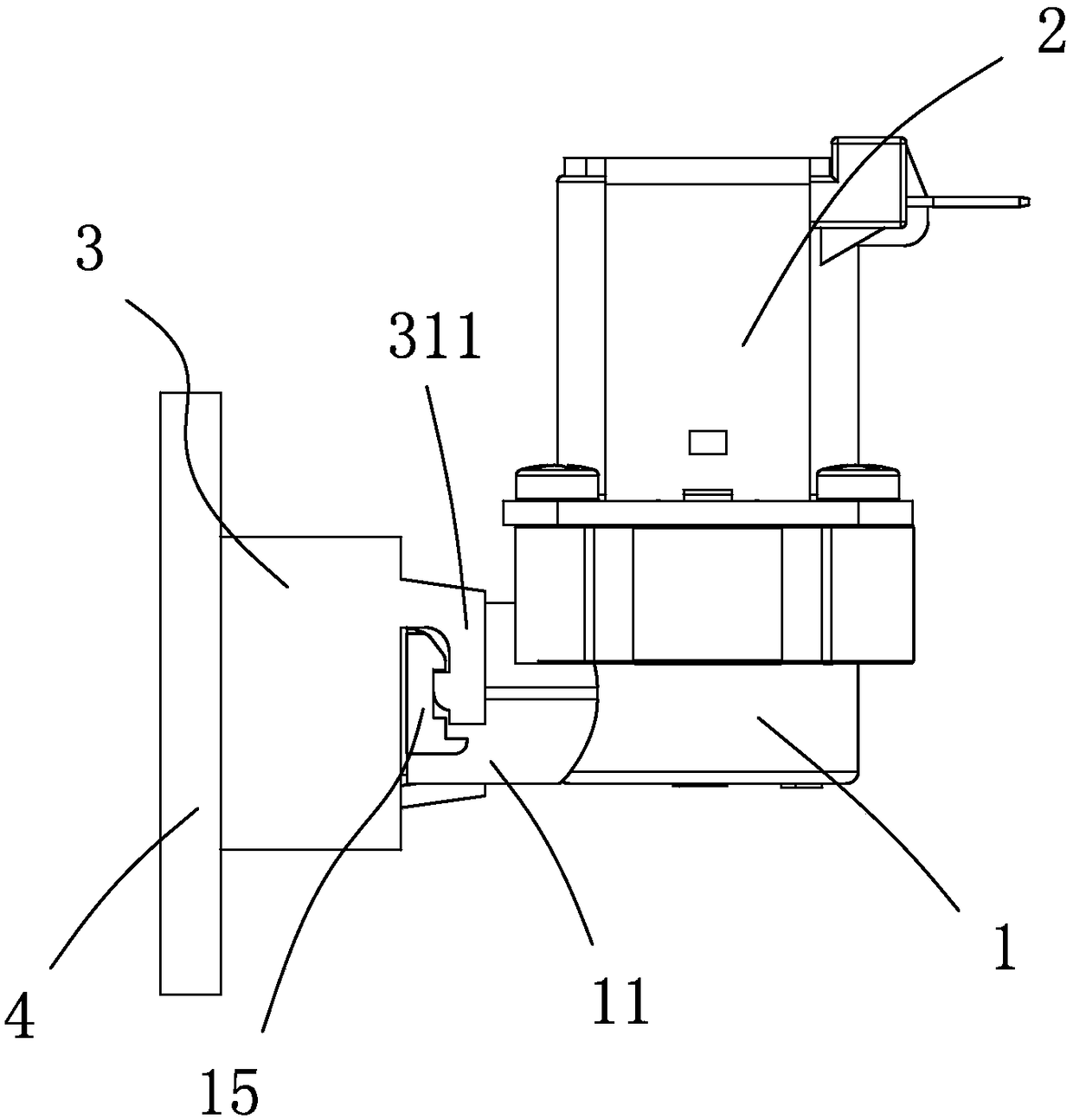

Solenoid valve with compact structure

The invention discloses a solenoid valve with the compact structure. The solenoid valve comprises a valve body and an electromagnetic driving mechanism connected with the valve body. The valve body comprises an inner cavity. An annular water separation wall is arranged in the inner cavity of the valve body to divide the inner cavity into a water inlet cavity and a water outlet cavity. One end of the water separation wall is provided with a valve port. The valve body is provided with a water inlet pipe and a water outlet pipe both extending outwards in the same direction. The water outlet pipeis arranged at an inner hole of the water inlet pipe. A water inlet channel communicating with the water inlet cavity is formed between the outer wall of the water outlet pipe and the inner wall of the water inlet pipe. The inner hole of the water outlet pipe forms a water outlet channel communicating with the water outlet cavity. The solenoid valve is simple in structure, small in size, small inoccupied space and capable of being in butting connection with a water inlet / outlet pipeline more conveniently and is not likely to be mounted reversely.

Owner:ZHEJIANG DAWEI ELECTRONICS

A water circulation humidifier installed on the radiator

ActiveCN105890093BIncrease humidityComfortable lifeLighting and heating apparatusSpace heating and ventilation detailsWater dischargeWater vapor

The invention provides a water circulating humidifier mounted on a heating plate. The water circulating humidifier comprises a machine shell, a water storage tank and a water pump; a water dispersion groove and a water flowing wall are arranged on the machine shell; the machine shell is provided with an air outlet which faces to the water flowing wall; the water flowing wall is arranged in the vertical direction of the water dispersion groove; the water pump is mounted inside the water storage tank and is used for conveying water into the water dispersion groove; a water discharging gap is formed between the water flowing wall and the water dispersion groove; water flows to the water flowing wall along the water discharging gap and is capable of absorbing heat; a part of the water is evaporated into water steam and is exhausted via the air outlet; the other part of the water reflows to the water storage tank along the water flowing wall. The water circulating humidifier has the advantages of remarkable humidification effect and low cost.

Owner:李铁超

Connecting structure of electromagnetic valve and water in-out pipeline

PendingCN108413093ACompact structureEasy to disassemble and replaceMultiple way valvesValve housingsEngineeringElectromagnetic valve

The invention discloses a connecting structure of an electromagnetic valve and a water in-out pipeline. The connecting structure comprises the electromagnetic valve and a switchover part, wherein theelectromagnetic valve comprises a valve body; the valve body comprises a cavity; a first water inlet pipe and a first water outlet pipe are arranged on the valve body; the first water outlet pipe is arranged at the inner hole of the first water inlet pipe; a first water inlet passage is formed between the outer wall of the first water outlet pipe and the inner wall of the first water inlet pipe; the inner hole of the first water outlet pipe forms a first water outlet passage; the switchover part comprises a base, a second water inlet pipe and a second water outlet pipe; the second water inletpipe and the second water outlet pipe are fixedly arranged on the base; a second water inlet passage is formed between the outer wall of the second water outlet pipe and the inner wall of the second water inlet pipe; and the inner hole of the second water outlet pipe forms a second water outlet passage. The connecting structure is simple, small and exquisite in size, small in occupied area, more convenient for butt joint with the water in-out pipeline and unlikely to be mounted reversely.

Owner:ZHEJIANG DAWEI ELECTRONICS

A method for wild bionic hatching salmon fertilized eggs

ActiveCN104304121BShen goodStable shape and structureClimate change adaptationPisciculture and aquariaWater flowSalmon roe

The invention discloses a field bionic hatching method of fertilized salmon eggs and belongs to the technical field of salmon breeding. A hatcher comprises a first side plate, a second side plate and nylon bolts. The first side plate and the second side plate can be symmetrically fastened to each other and are provided with nylon bolt plug holes which are symmetric; after symmetric fastening, the first side plate and the second side plate are fixed through nylon bolt plugs; the first side plate and the second side plate are both evenly provided with egg carrier cells in diamond shapes; the egg carrier cells of the first and second side plates are symmetrically fastened; the center of each egg carrier cell of the first side plate is provided with an escape hole; one corner of each egg carrier cell, on the same side, of the second side plate is provided with another escape hole. The hatcher can sink well in water, has stable shape and structure, allows smooth passage of water and allows water flow to be evenly distributed; the hatcher has the advantages that the size is small, materials are easy to obtain and assembly is simple; egg survival rate is up to greater than 70%.

Owner:HEILONGJIANG RIVER FISHERY RES INST CHINESE ACADEMY OF FISHERIES SCI

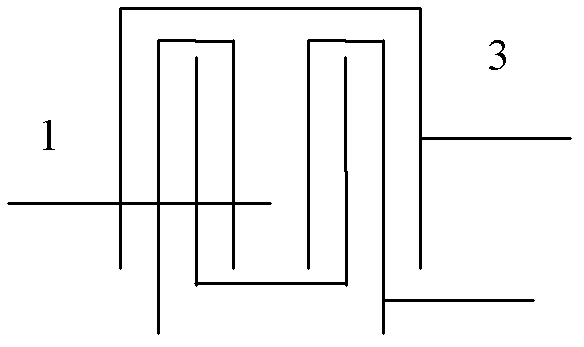

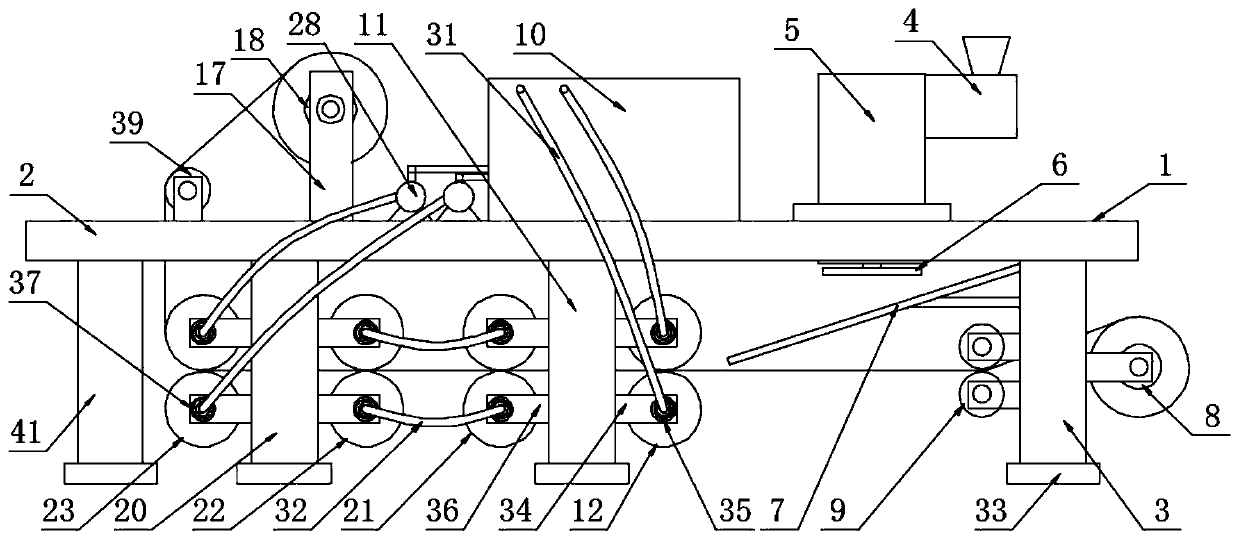

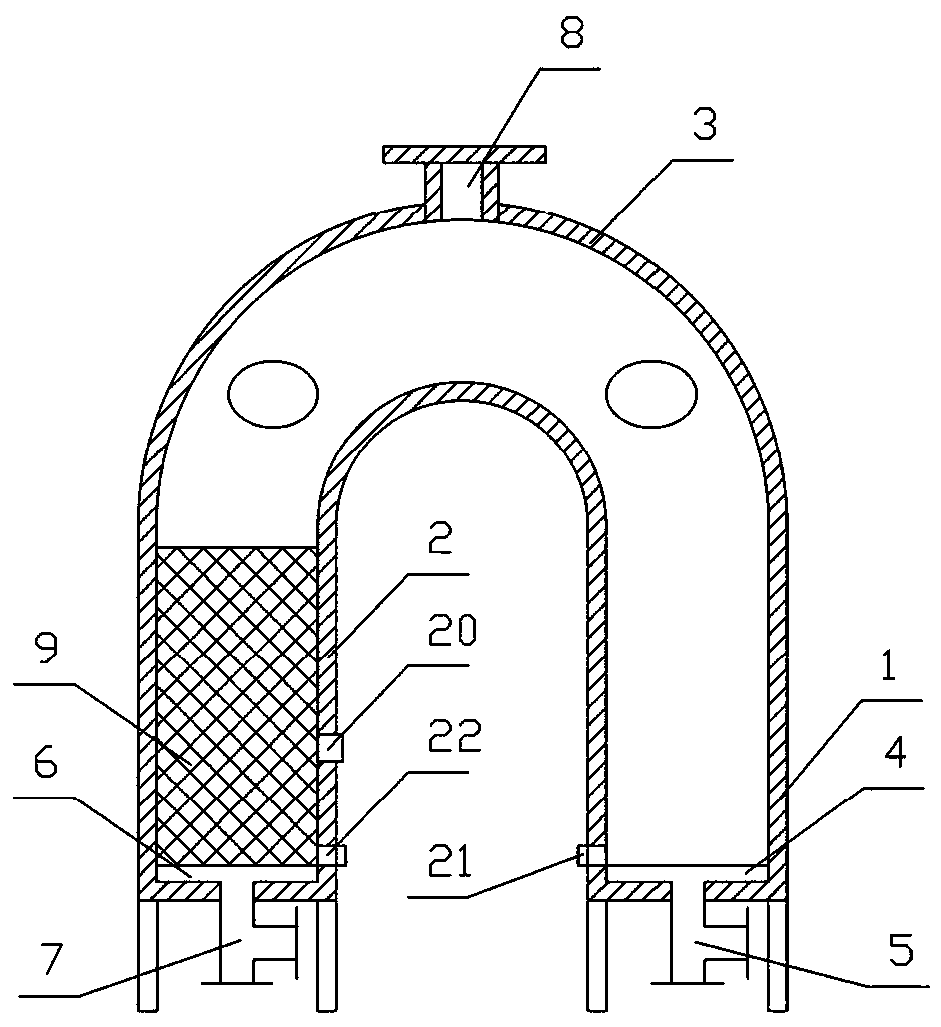

Tank body of water treatment device

InactiveCN109110875AReasonable structureEasy to useTreatment involving filtrationWater/sewage treatment by ion-exchangeWater flowCaking

The invention relates to the technical field of water treatment equipment, in particular to a tank body of a water treatment device. The tank body comprises a first chamber, a second chamber and a communicating chamber, wherein the communicating chamber is connected with the first chamber and the second chamber; the first chamber and the second chamber are respectively arranged in parallel; waterdistributors are respectively arranged in inner cavities of the first chamber and the second chamber; the communication chamber is arranged at the upper ends of the first chamber and the second chamber; both ends of the communication chamber are respectively communicated with the upper ends of the first chamber and the second chamber. The tank body of the water treatment device has the advantagesthat the structure is reasonable, the convenience in use is realized, and the use efficiency of filtrate and resin is high; the tank body can be applied to the filtering procedure or resin exchange procedure in the water treatment technology; the distribution of water flow at each part in the tank body is uniform, the easiness in caking of the filtrate is avoided, and the resin exchange efficiencyis high.

Owner:李存良 +1

a water collecting element

ActiveCN105084460BImprove maintainabilityExtended service lifeWater/sewage treatment by ion-exchangeMaintainabilityAgricultural engineering

A water collecting element, comprising a water collection tank, an outlet pipe and a shuttle-shaped flange connected to the water collection tank, the water collection tank includes a concave grid installation seat, and several grid units arranged side by side are arranged on the upper end of the grid installation seat, A baffle is provided between adjacent grid units, and the grid unit is formed by stacking several grids with several bumps, and the two ends of the grid mounting base are provided with water collection tank connecting blocks . It can effectively intercept the resin, and at the same time make the water flow evenly distributed. The interception layer in the water collection element adopts a movable compression grid, which has better maintainability than welding or other connection methods. It has the characteristics of simple structure, convenient installation, use and maintenance. .

Owner:中国船舶集团有限公司第七零七研究所九江分部

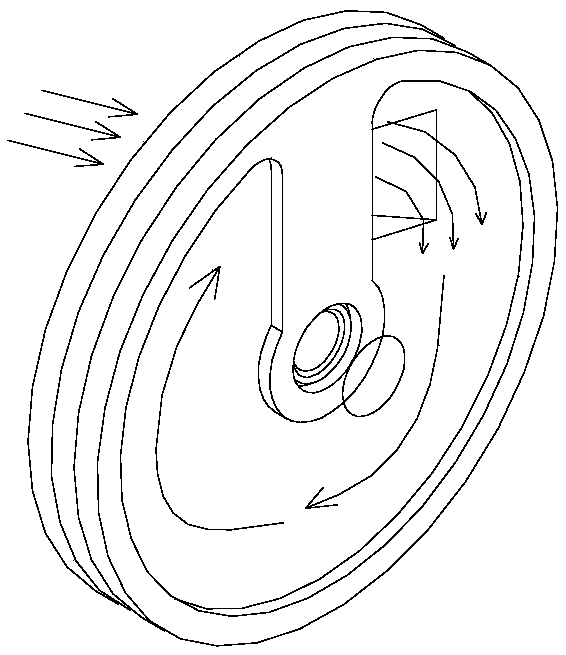

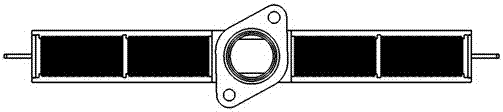

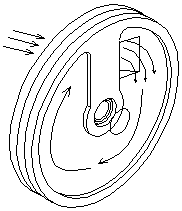

High-efficiency open network pipe channel reverse osmosis membrane module

ActiveCN106422783BPrevent scalingReduce exposureWater/sewage treatmentReverse osmosisWater flowReverse osmosis

The invention relates to a high-efficiency open network pipe flow channel reverse osmosis membrane module, including a membrane shell, a central water production pipe arranged in the membrane shell, and several membrane elements arranged around the central water production pipe. The membrane element has an open network pipe flow channel, and the membrane shell One end of the water inlet is provided with a water inlet flange end cover, and the inner side of the water inlet flange end cover is provided with a water inlet swirling flow guide plate; one end of the membrane shell outlet is provided with a water outlet flange end cover, and the inner side of the water outlet flange end cover is installed There is a water outlet swirling diversion plate; the ends of the central water production pipe are respectively provided with water production joints; the inner peripheral wall of the membrane shell is provided with a circular card groove, and a retaining ring is arranged in the card groove, and the retaining ring is tightly pressed against the end cover; Along the water inlet direction, it includes at least two sets of membrane elements connected in series before and after, and the two membrane elements connected in series in the axial direction are communicated through a diversion tube connector. The application can simultaneously take into account the advantages of resistance to pollution and blockage, small pressure loss, uniform water flow distribution, larger effective area of the membrane, simple structure, convenient maintenance, and long service life.

Owner:JIANGSU KUNYI ENVIRONMENTAL ENG CO LTD

Vegetation Restoration System and Method for Vegetation Restoration Using the System

The invention provides a vegetation recovery system which comprises an exposed hillside with a certain slope or level sandy land, a water cellar arranged in a high position of the hillside or a level position higher than the sandy land, vegetation planting units laid along a sloping surface of the hillside or the sandy land lower than the water cellar, a main flow pipe and branch pipes; the vegetation planting units comprise square plastic frames, crossed four-way pipes located in the centers of the plastic frames and provided with openings on the top surfaces, and cotton yarns located at the openings of the top surfaces of the four-way pipes and extending to the side edges of the plastic frames; the four-way pipes in the centers of the adjacent vegetation planting units are mutually connected via the branch pipes; one end of the main flow pipe is connected with a water outlet at the bottom of the water cellar; and the other end of the main flow pipe is connected with the branch pipe in any vegetation planting unit.The vegetation recovery system employs the vegetation planting units in special structures, is convenient to construct and low in maintenance cost, and does not require manual sprinkling and watering, a plant survival rate is high, and after plants grow, roots of the plants can penetrate into rock or the earth surface and can exert a good water holding and soil fixation effect.The invention further provides a method for vegetation recovery of the hillside or the sandy land exposing the rock with the vegetation recovery system.

Owner:王承辉

Fixed structure of dust collecting plate, anode system and flexible wet electrostatic precipitator

ActiveCN107297279BGuaranteed clearanceEasy to assembleElectrode carrying meansExternal electric electrostatic seperatorEngineeringDust collector

The invention discloses a dust-collecting pole plate fixing structure, an anode system and a flexible wet electrostatic dust remover. The dust-collecting pole plate fixing structure comprises a limiting device matched with a vertical column or / and a fixing device on a dust-collecting pole plate, wherein a plurality of longitudinal grooves are uniformly formed in the side surface of the vertical column so as to insert flexible pole plates; the limiting device comprises a connector; a convex column body capable of being inserted into the cavity of the vertical column is arranged at the upper end of the connector and a plurality of clamping slots are formed in the lower end of the connector so as to achieve flexible insertion; the fixing device comprises parallel clamping plates arranged on the two sides of the flexible pole plates, and a plurality of tightening components which are distributed along the clamping plates at intervals and clamp the flexible pole plates and flexible components on the inner side of the dust-collecting pole plate, so that close fit between the clamping plates and the flexible pole plates is achieved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com