Cylindrical optical fiber water cooling device

A water-cooling device, cylindrical technology, applied in heat exchange equipment, lighting and heating equipment, indirect heat exchangers, etc., can solve the problems of unsatisfactory heat dissipation, uneven layout of water channels, and large space occupation, so as to save space , Good cooling effect, uniform water flow distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

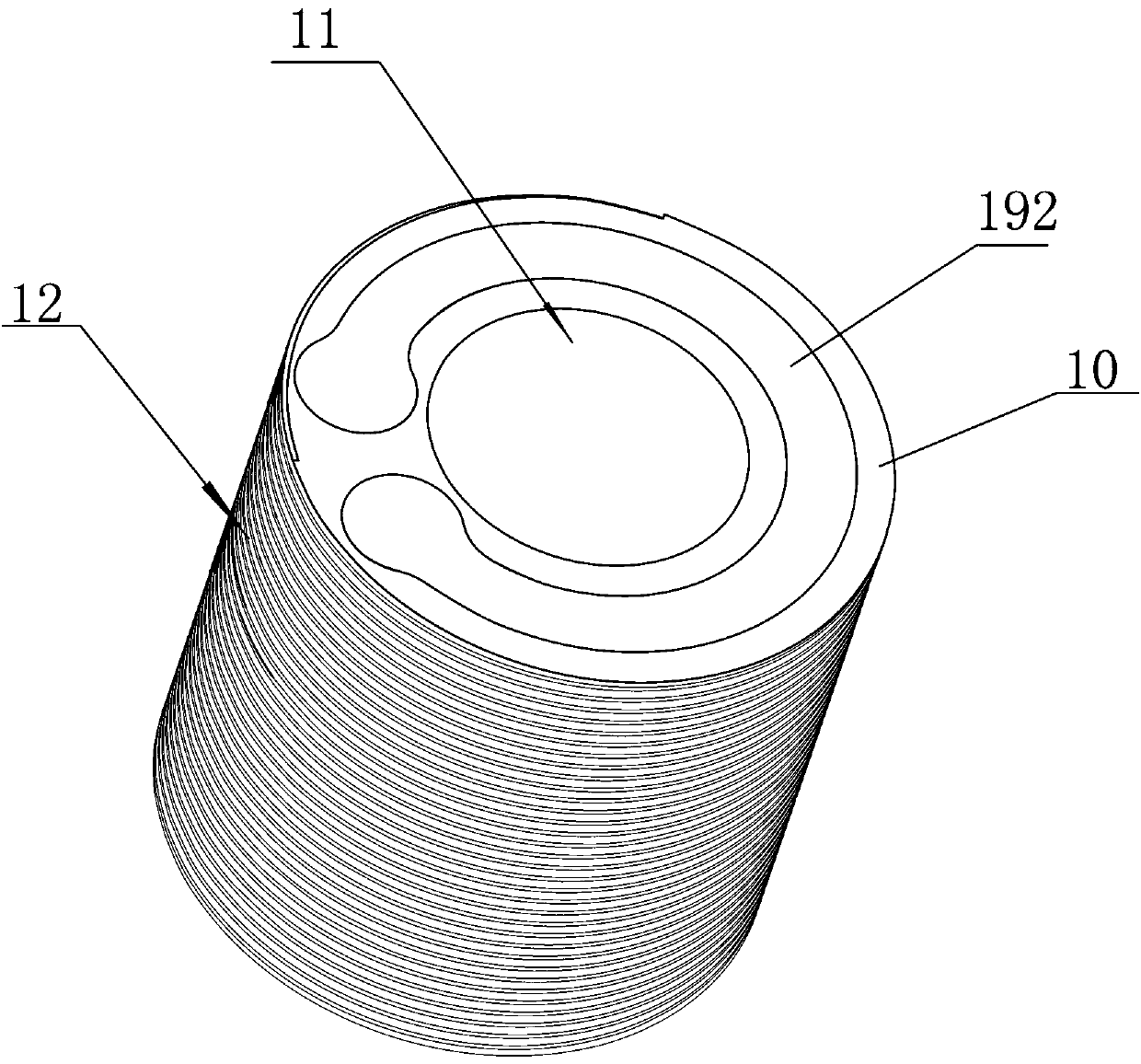

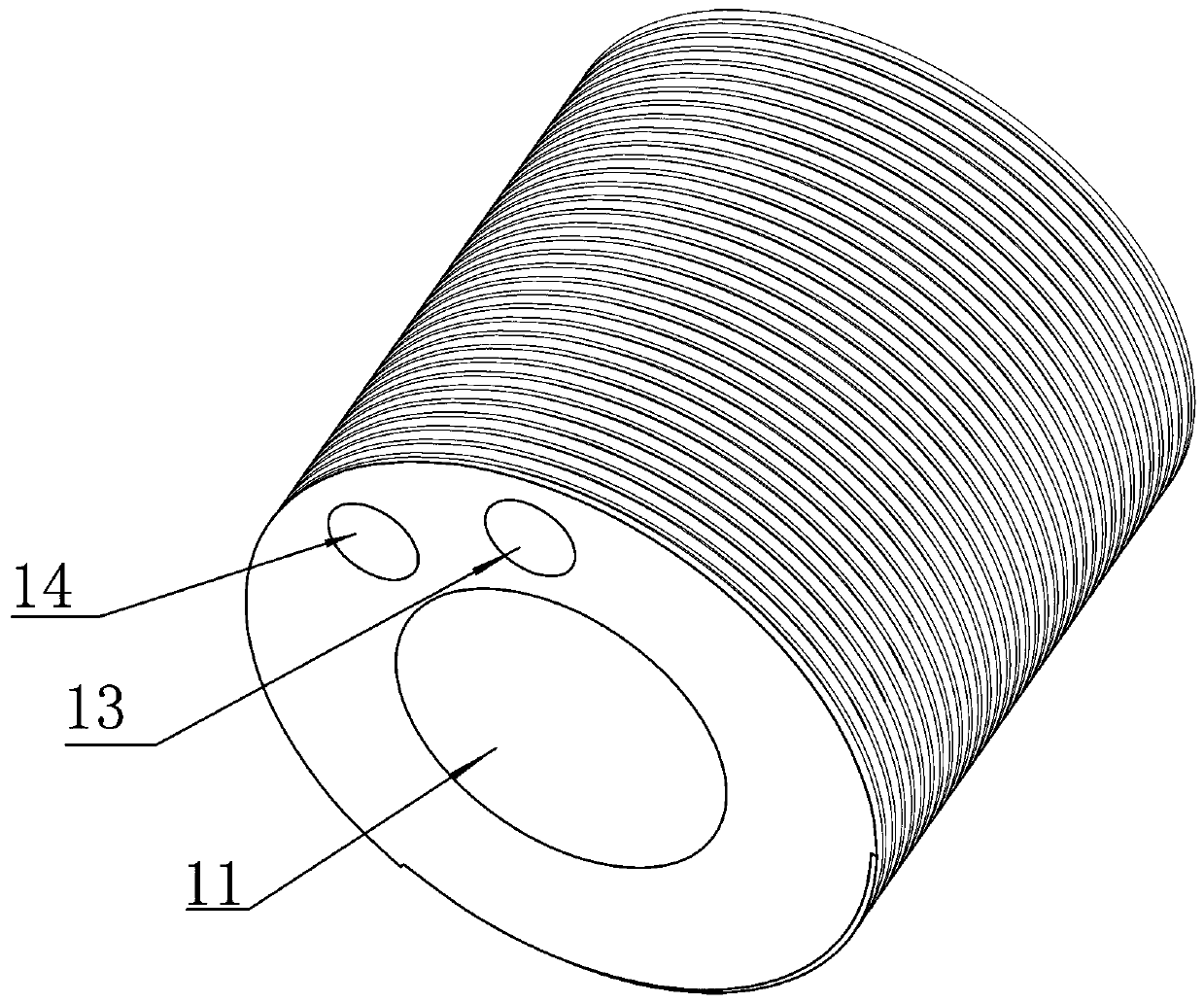

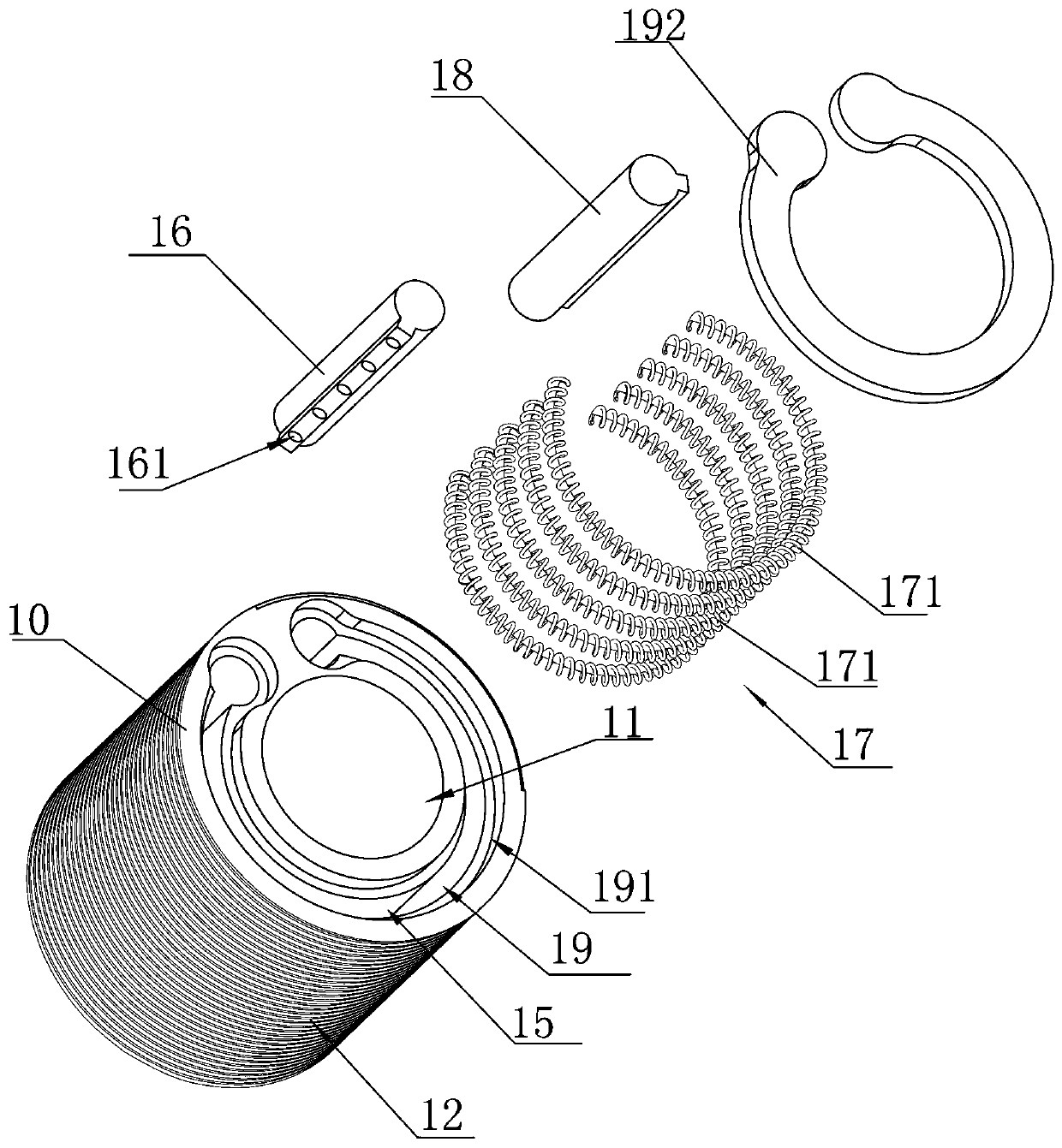

[0017] The preferred embodiments provided by the present invention will be specifically described according to the accompanying drawings.

[0018] Figure 1 to Figure 5 , is a preferred embodiment of a cylindrical optical fiber water cooling device provided by the present invention. Such as Figure 1 to Figure 5 As shown, the cylindrical optical fiber water-cooling device includes a cylindrical water-cooling body 10, the center of the cylindrical water-cooling body is provided with an installation through hole 11, and the outer surface of the cylindrical water-cooling body is provided with fiber grooves 12 for winding optical fibers. The water cooling body is provided with a water inlet 13 for water intake, a water outlet 14 for water outlet, and a water flow channel 15 communicating with the water inlet and the water outlet. One end of the water flow channel 15 is provided with a water inlet 13 for The inlet water distribution column 16 for diverting the water flow entering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com